Note

PROCEDURE 1

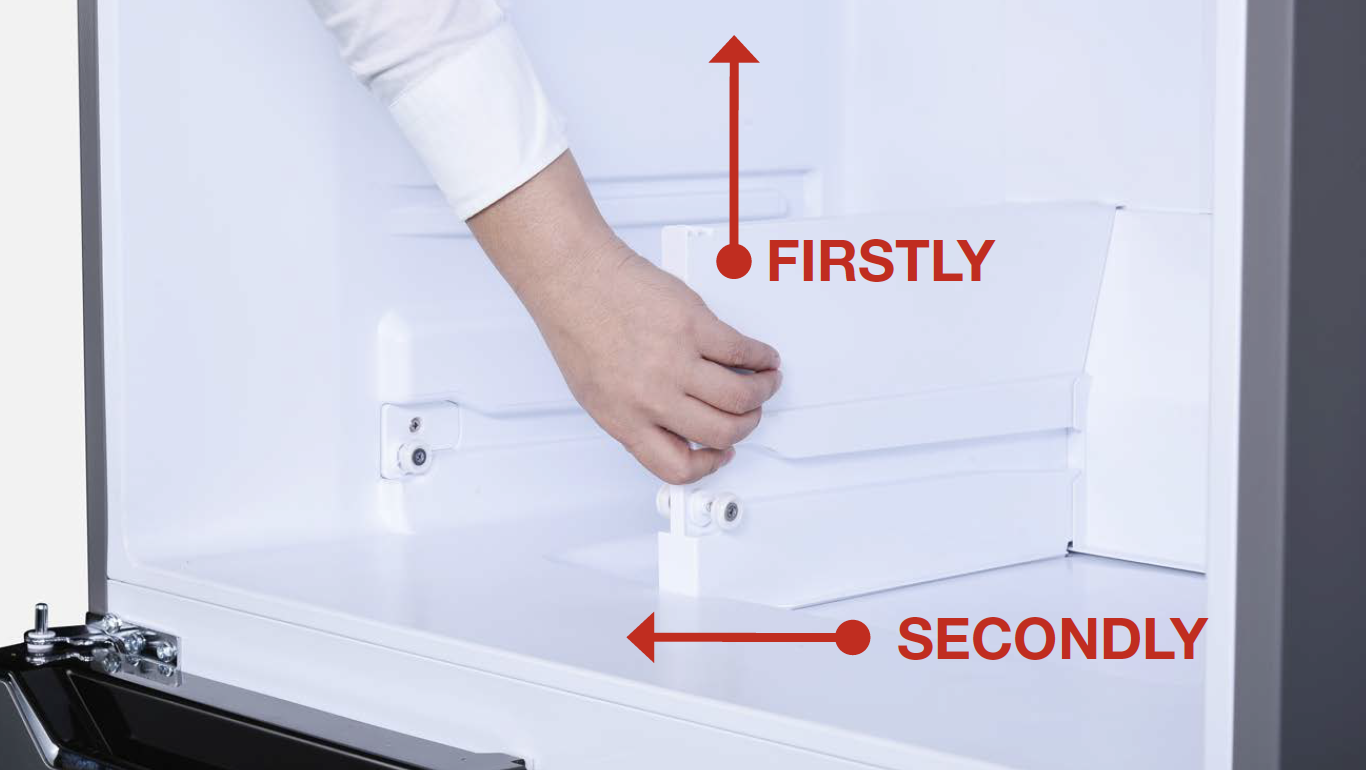

Step 1

Remove shelves.

Step 2

Remove crispers.

Step 3

Remove shelf cover.

Step 4

Remove partition plate.

Step 5

Hold the cover and turn

in counter-clockwise

direction to loosen cover.

Then, remove cover.

Step 6

Use 6mm cross-head screwdriver to loosen the screw in counter clockwise direction.

Step 7

Hold the edge of air duct to pull it out.

Step 8

Disconnect the terminal for fridge temp. sensor.

CHECK AND TEST 1

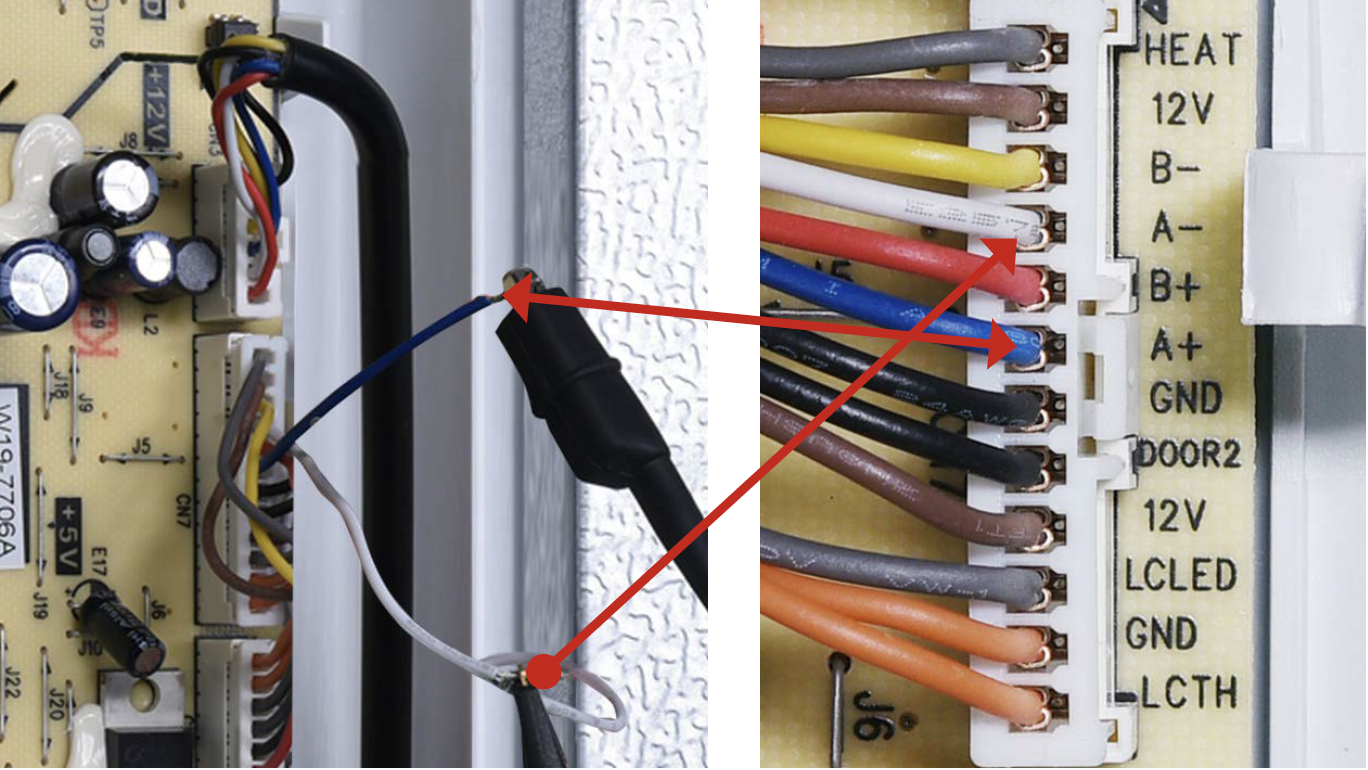

Step 1

Connect damper terminal to terminals inside fridge.

Step 2

Unscrew cover of mainboard with a cross- head screwdriver.

Step 3

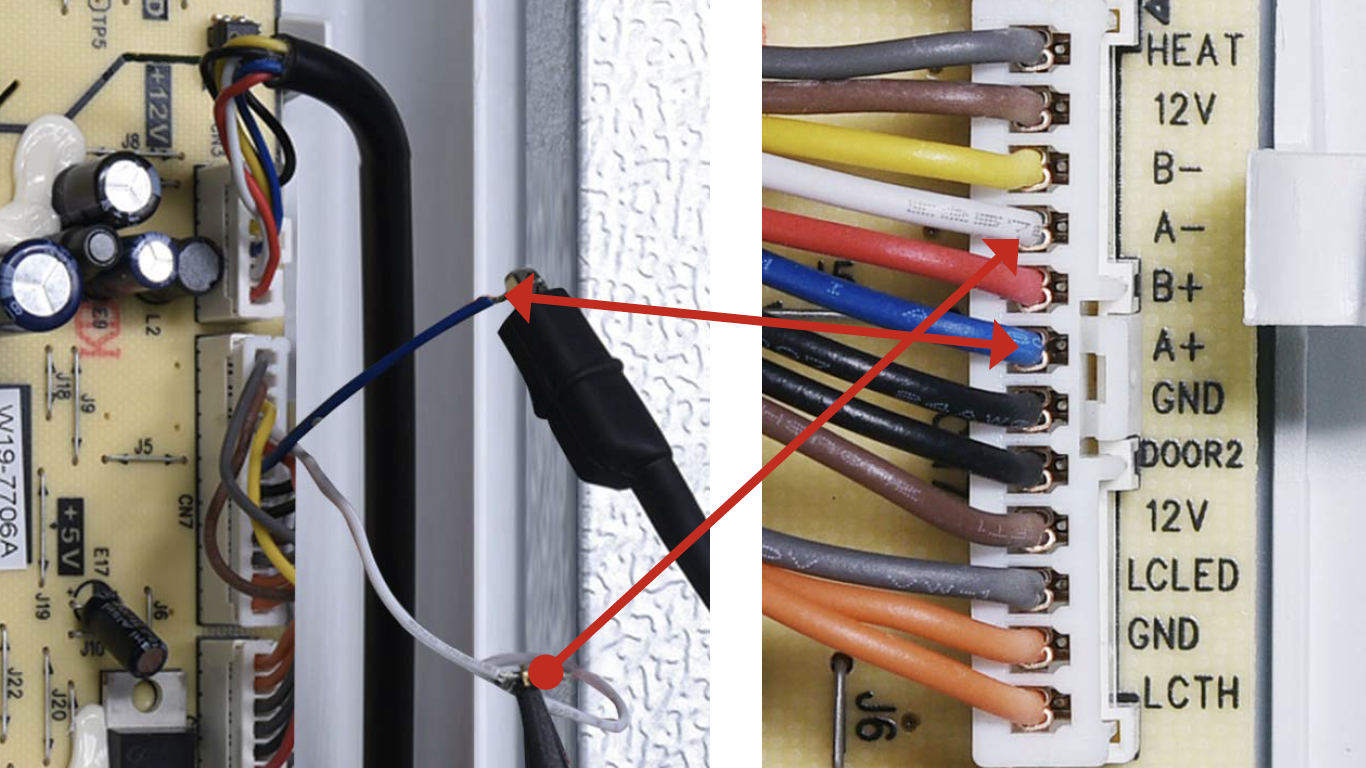

Strip off sleeves of wires in PCB area, and supply signal to damper from terminal in PCB area.

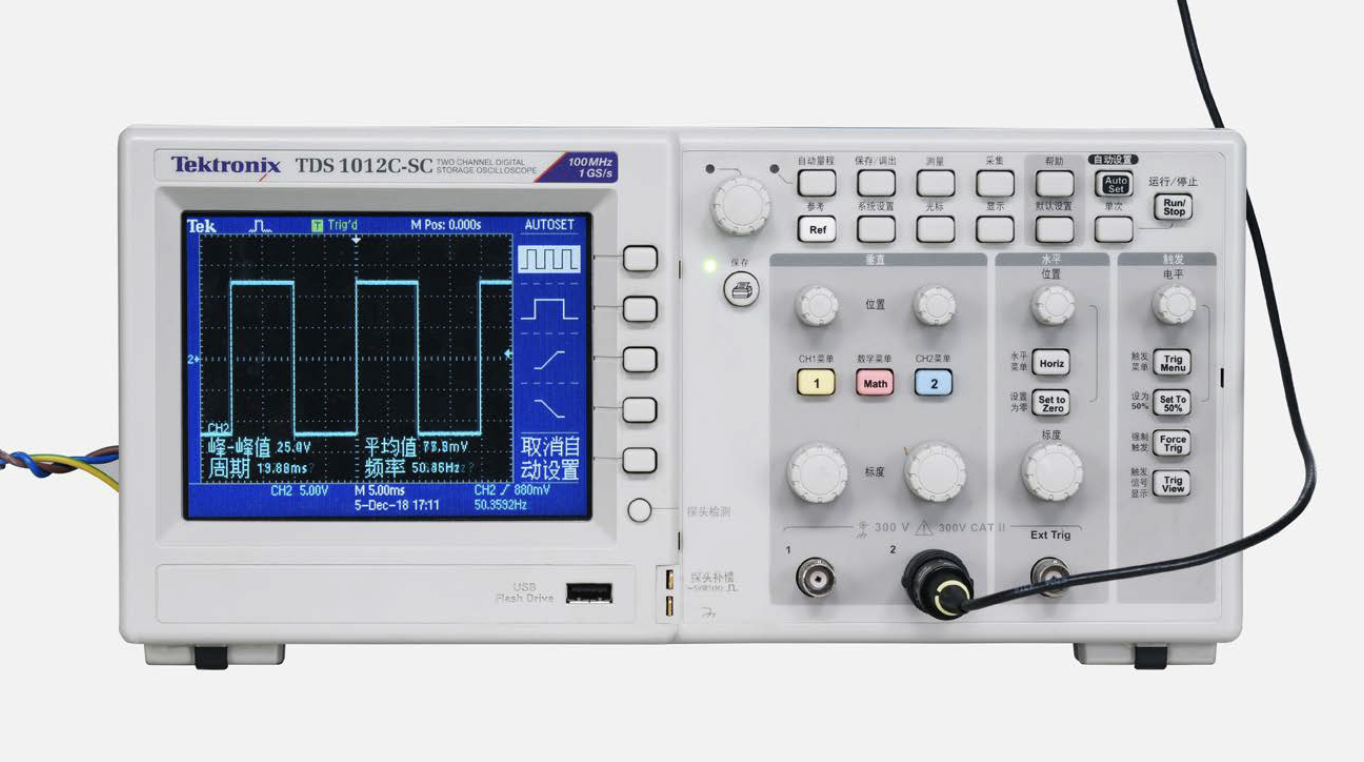

Step 4

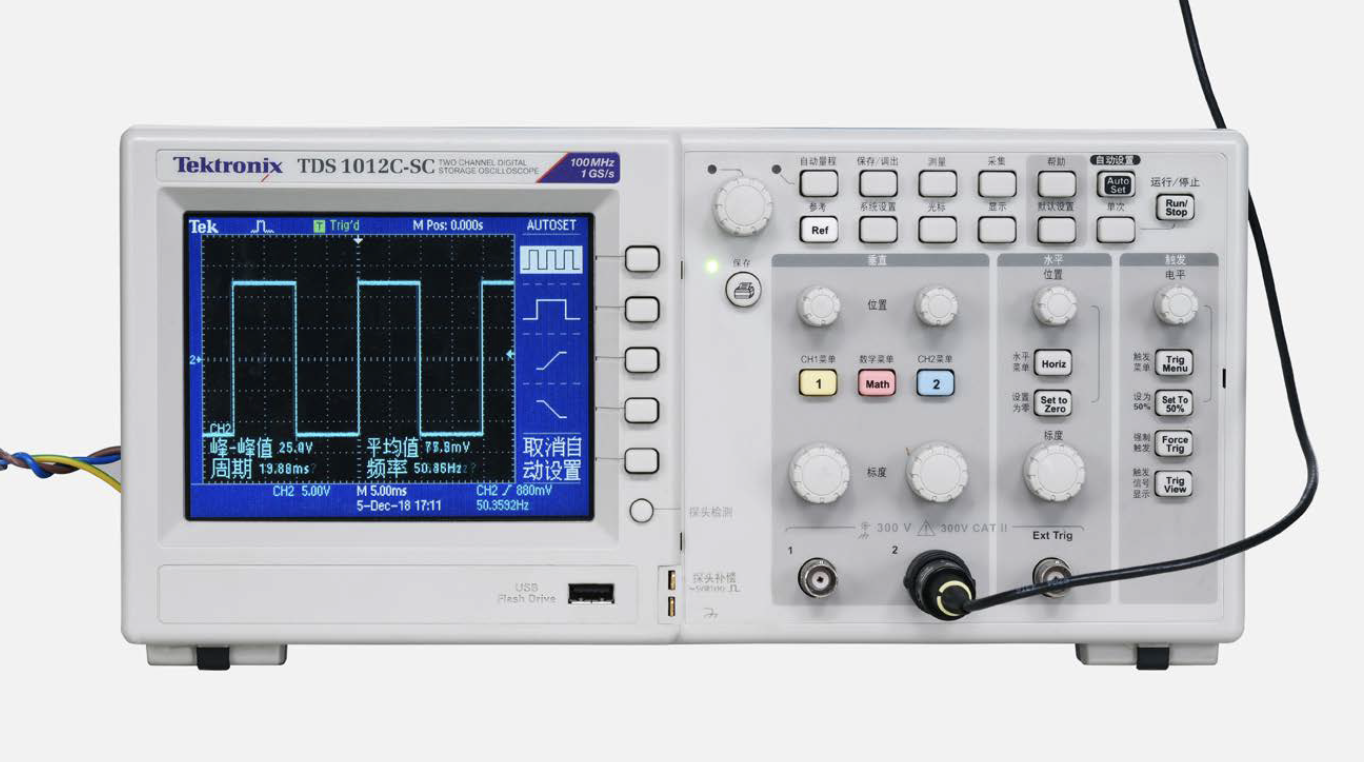

An oscilloscope should display a square wave signal.

Step 5

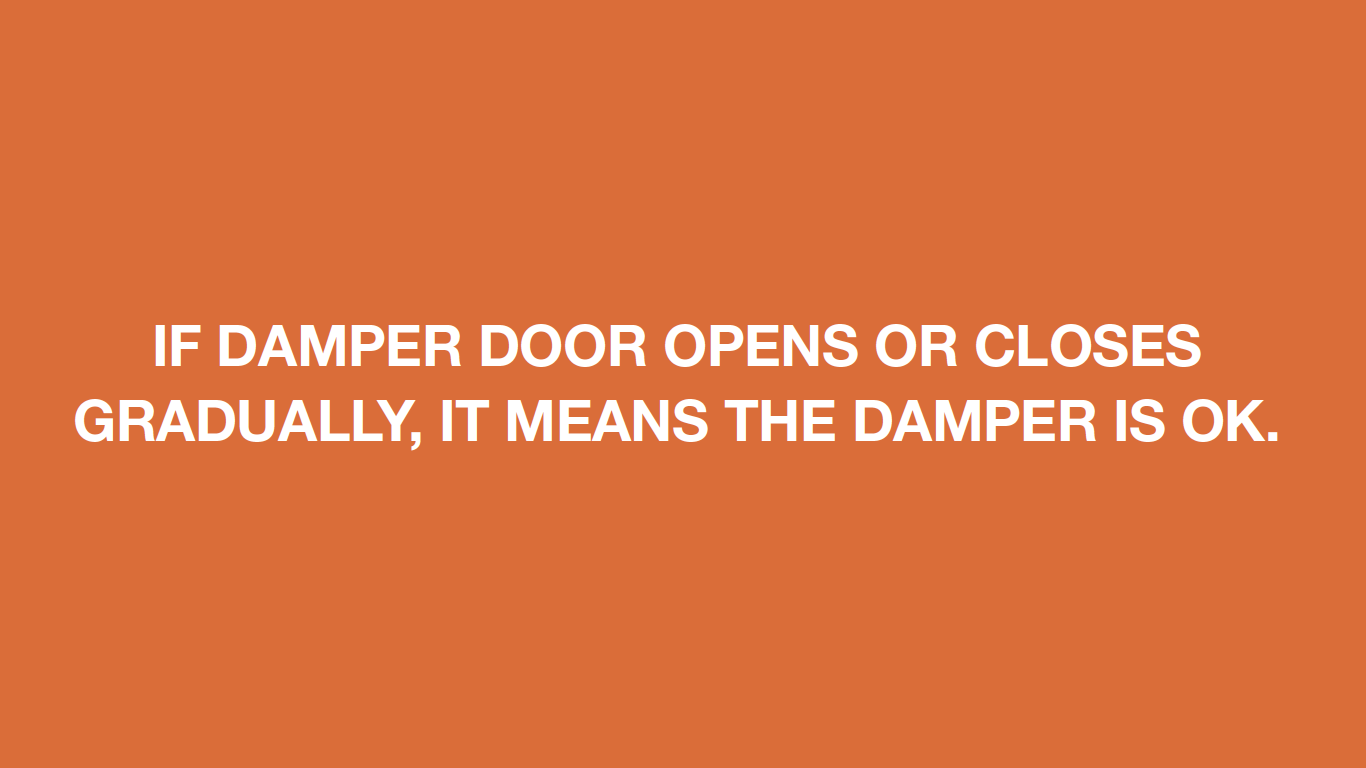

See if damper door opens gradually.

DIAGNOSIS 1

PROCEDURE 2

Step 1

Unscrew with 6mm cross-head screwdriver.

Step 2

Disconnect the terminal

Step 3

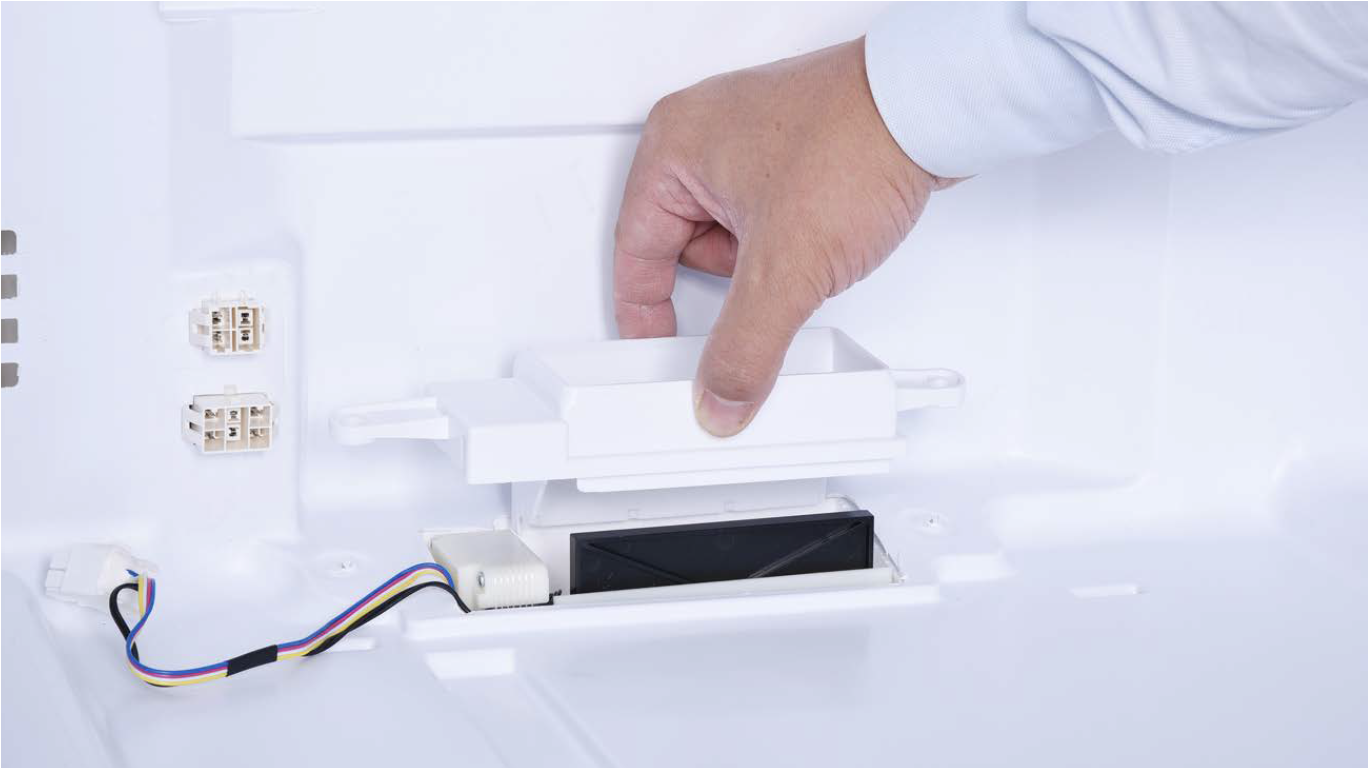

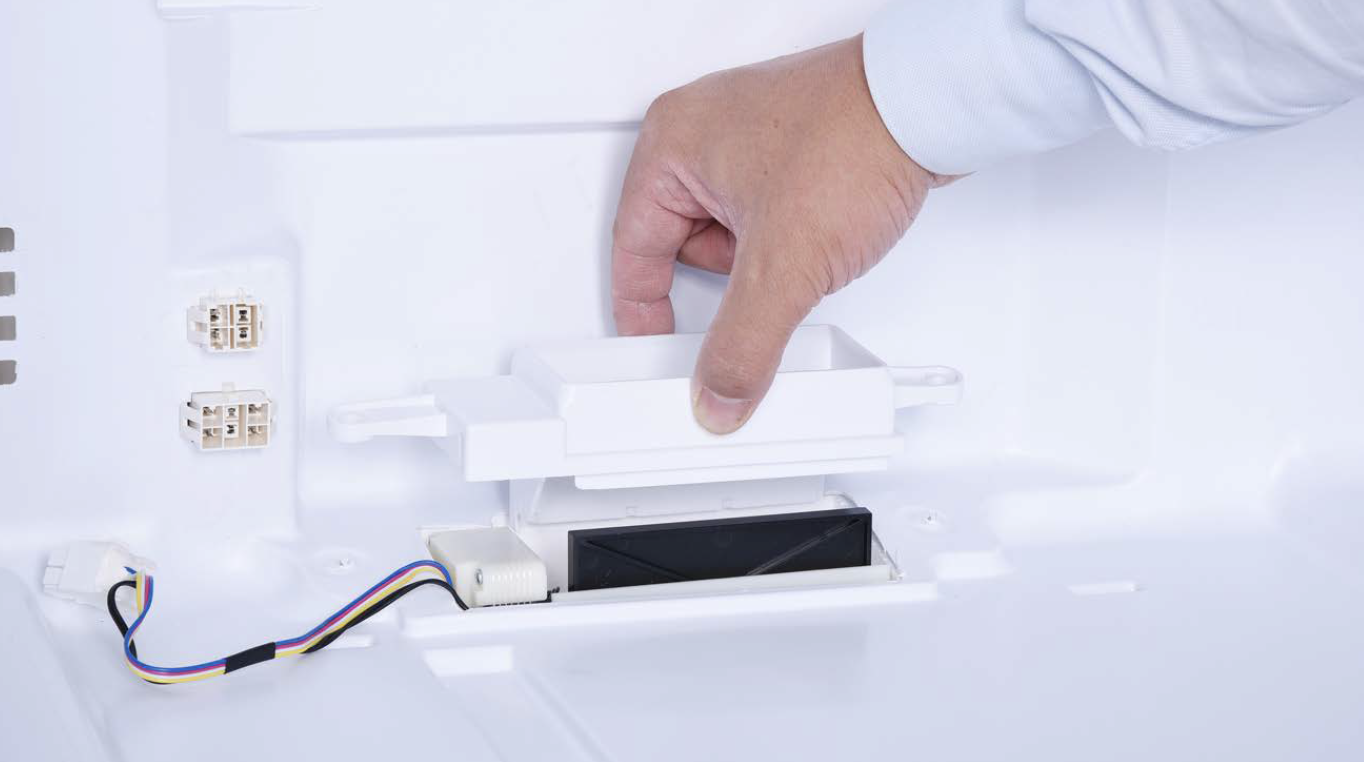

Lift the plastic cover off of the damper.

Step 4

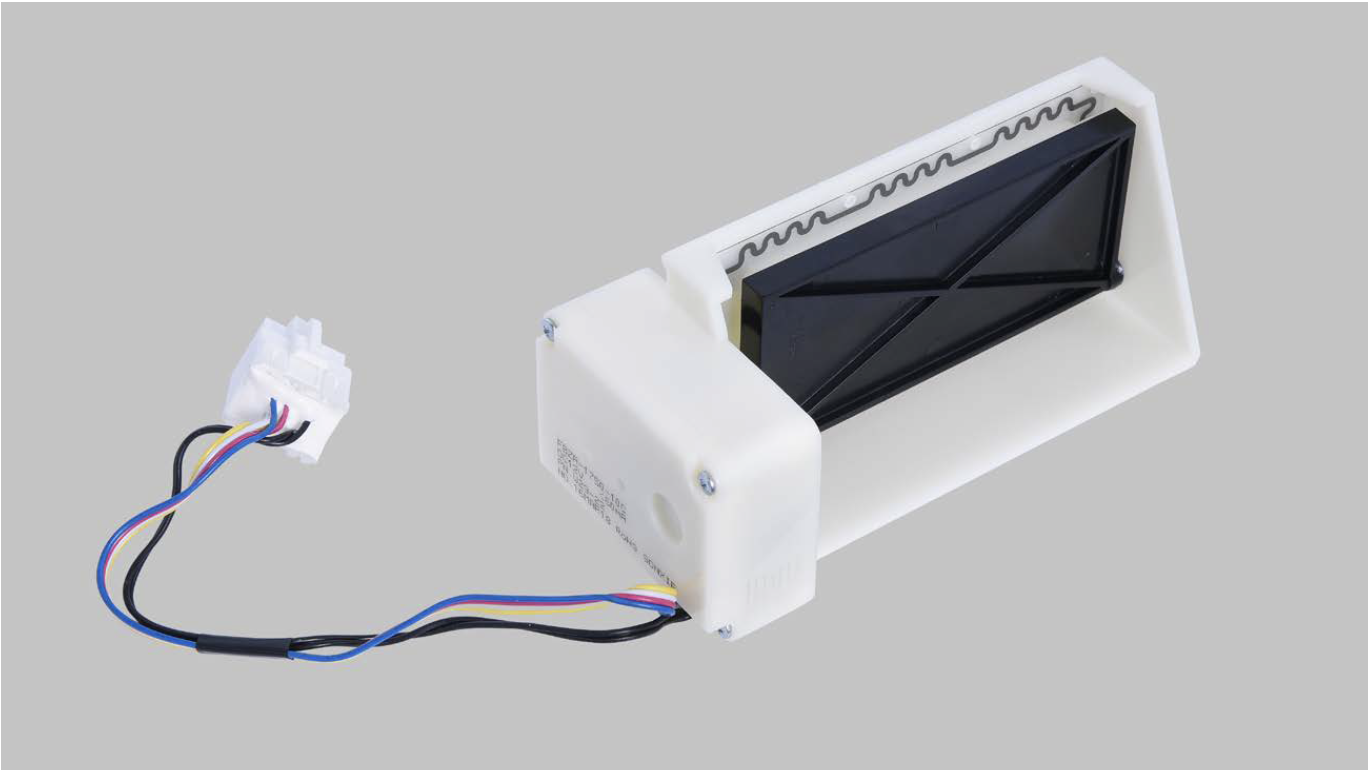

Take damper out of air duct in foam.

CHECK AND TEST 2

Step 1

Use a standard signal producer to supply square wave to damper from terminal in fridge area.

DIAGNOSIS 2

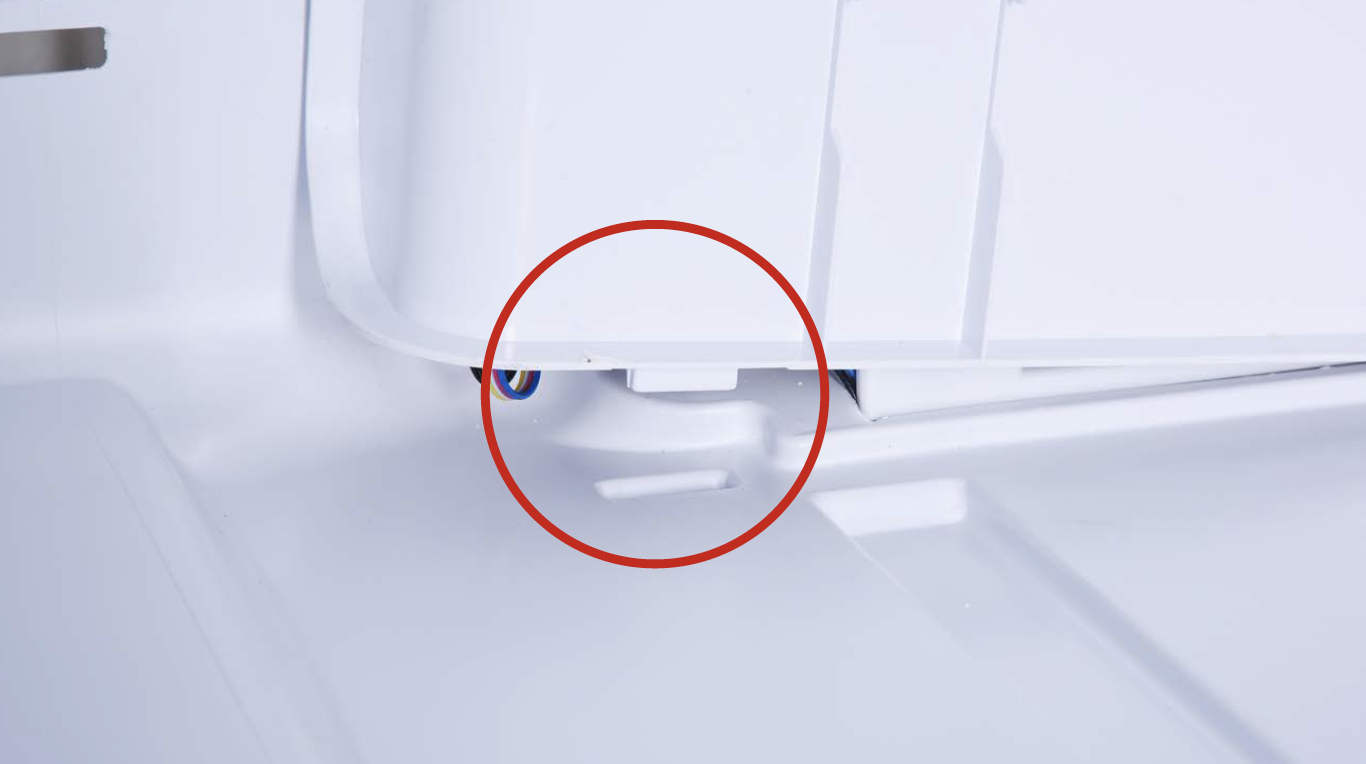

CHECK AND TEST 3

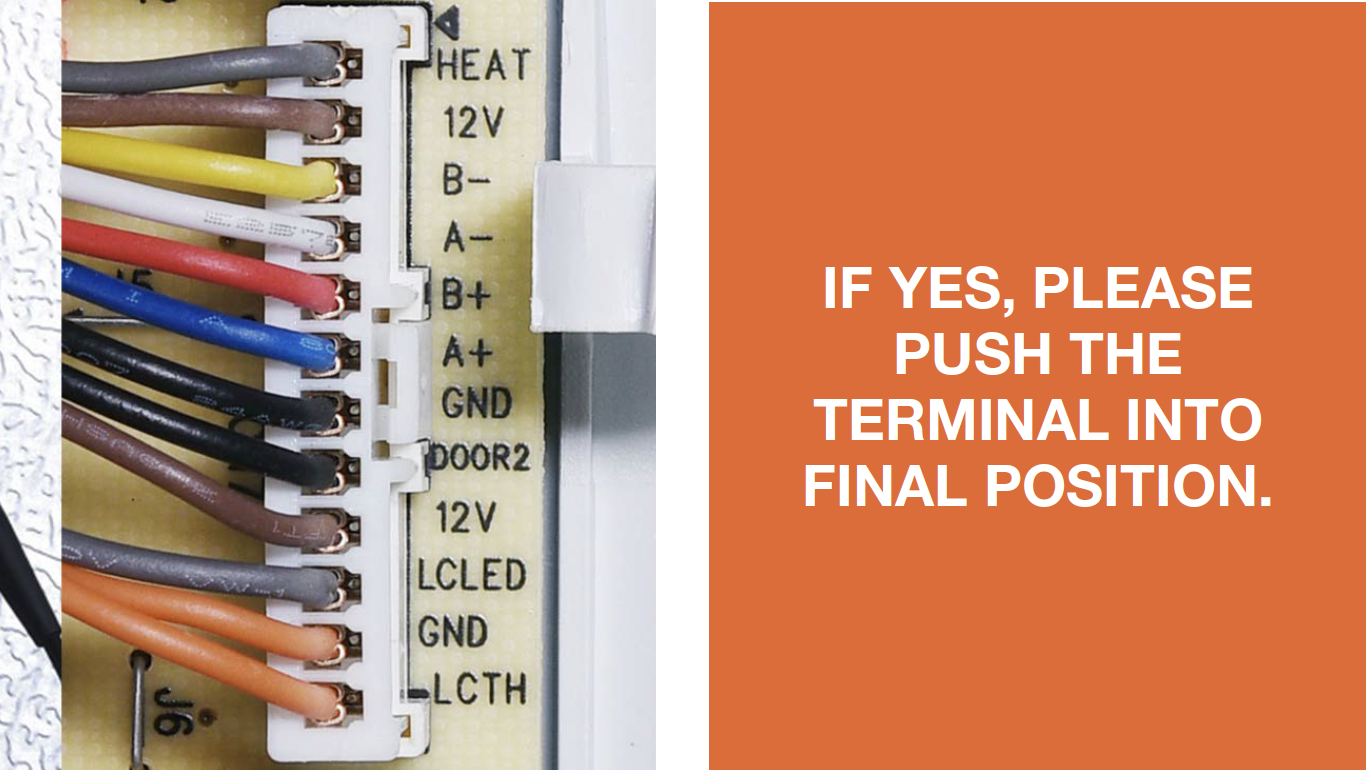

Step 1

In duct area, check if terminal is pushed into final position.

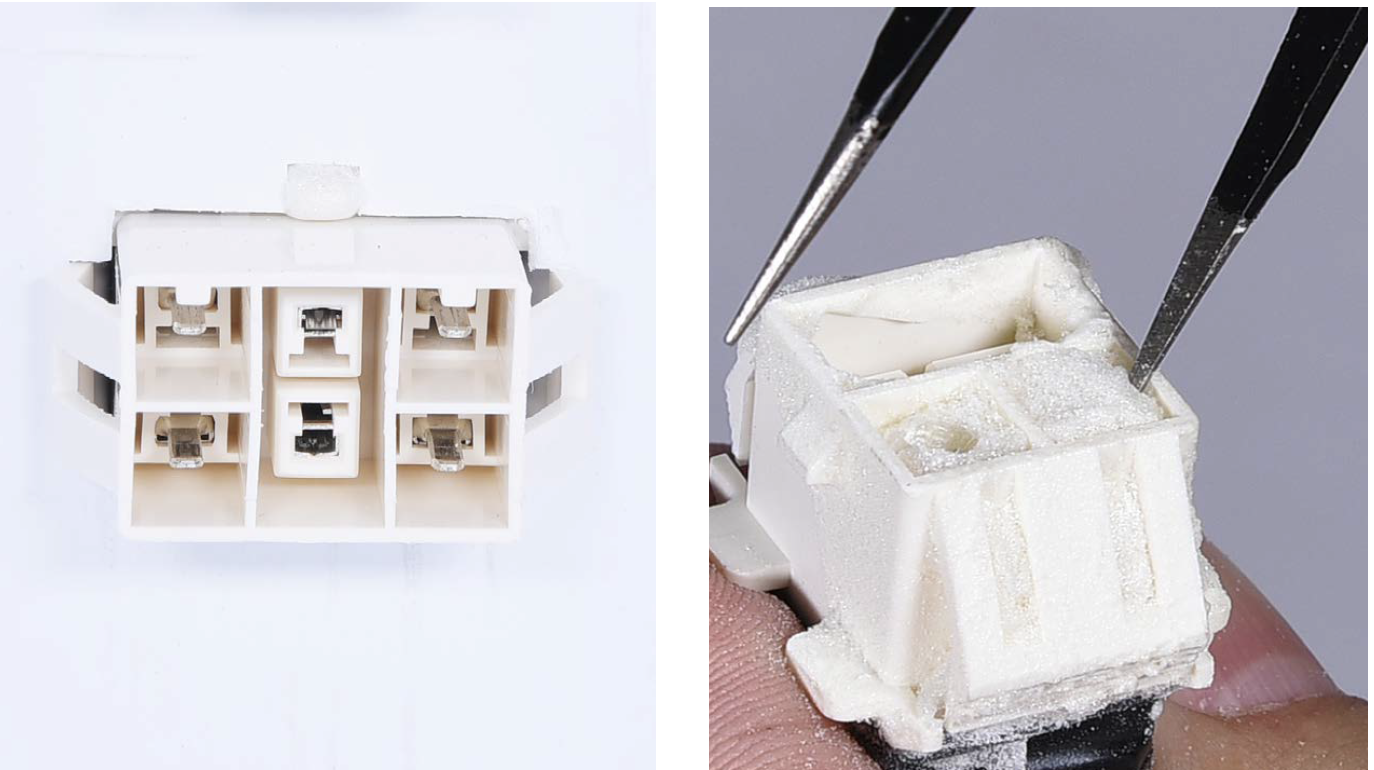

Step 2

Check if terminal is filled

with foam or not.

IF YES, please use

tweezers to clean and

remove the foam.

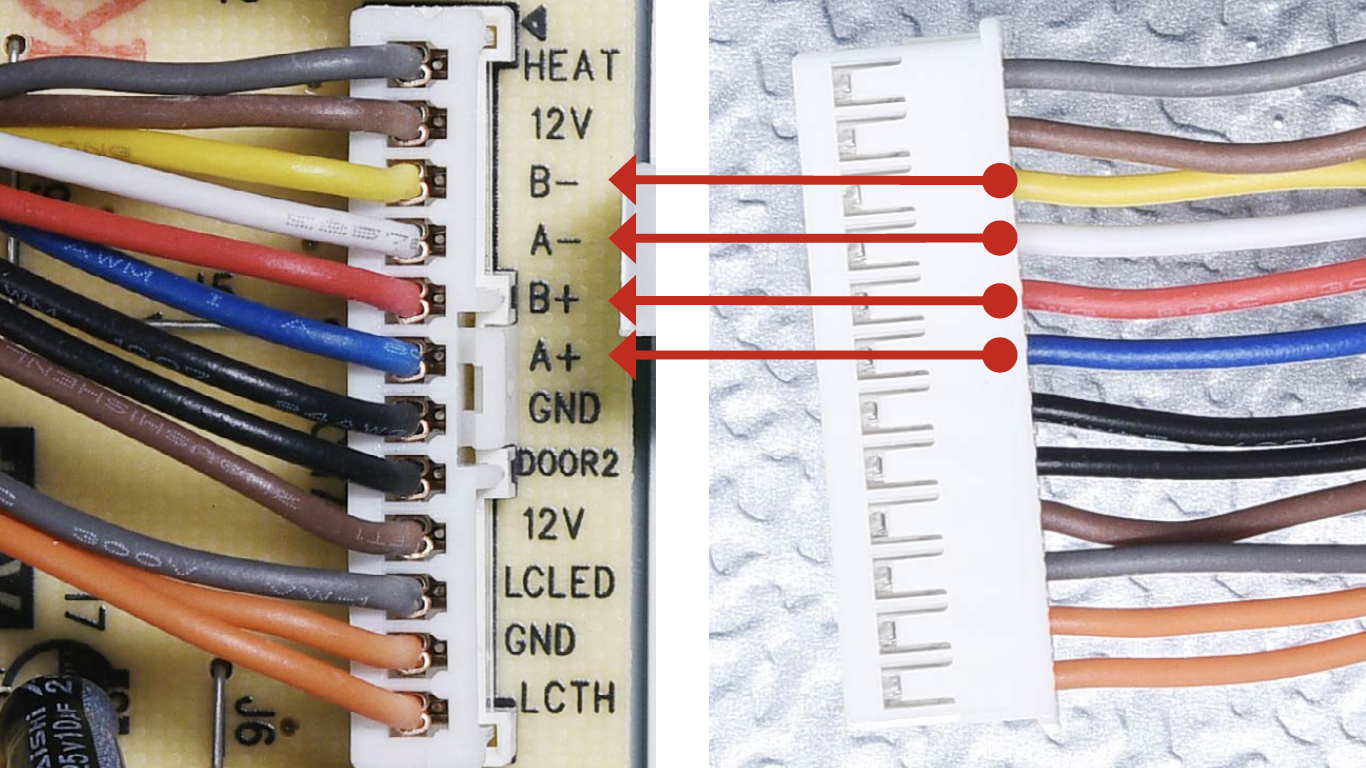

Step 3

Check to ensure that wires are in proper order.

IF WIRE ORDER IS WRONG, PLEASE FOLLOW PROCEDURE 3 TO CORRECT THEM.

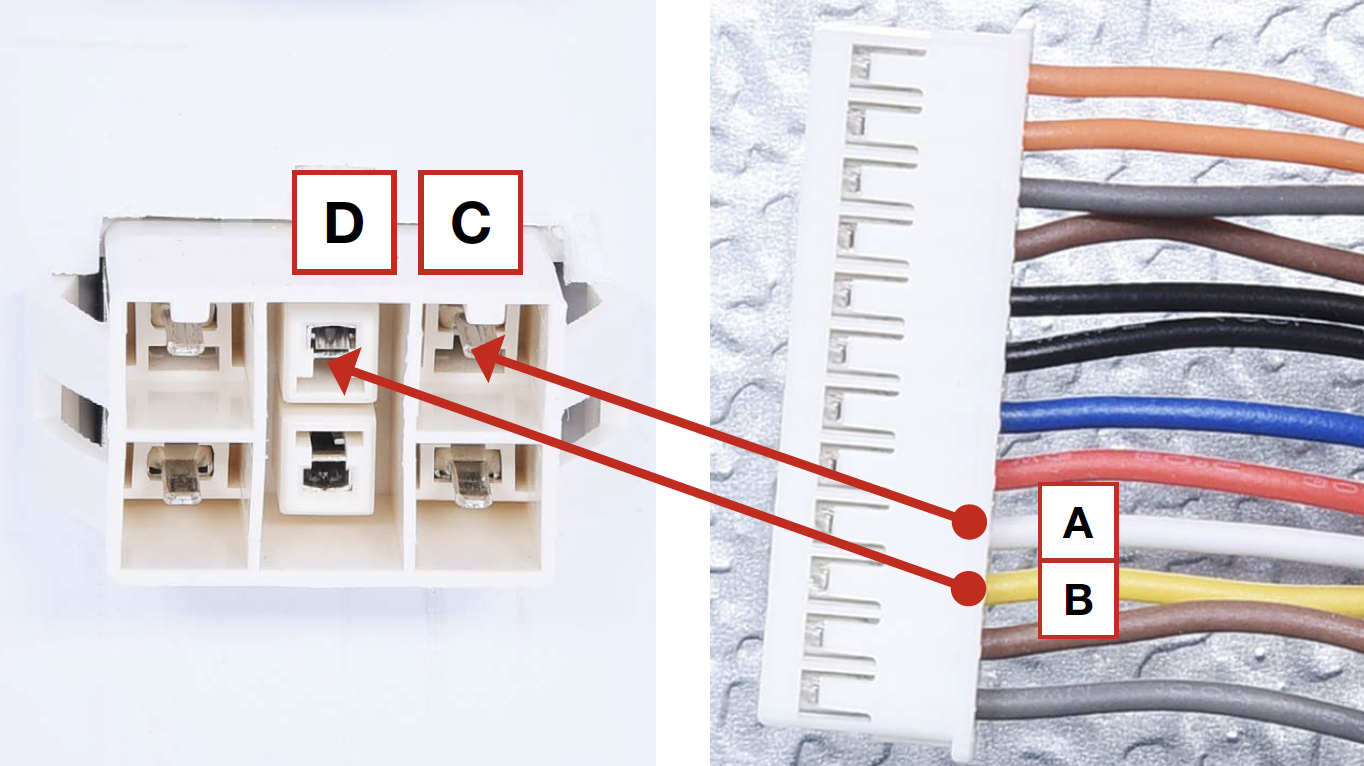

Step 4

Check to make sure wire

order in the foam is right

and/or see if it’s been cut H

off.

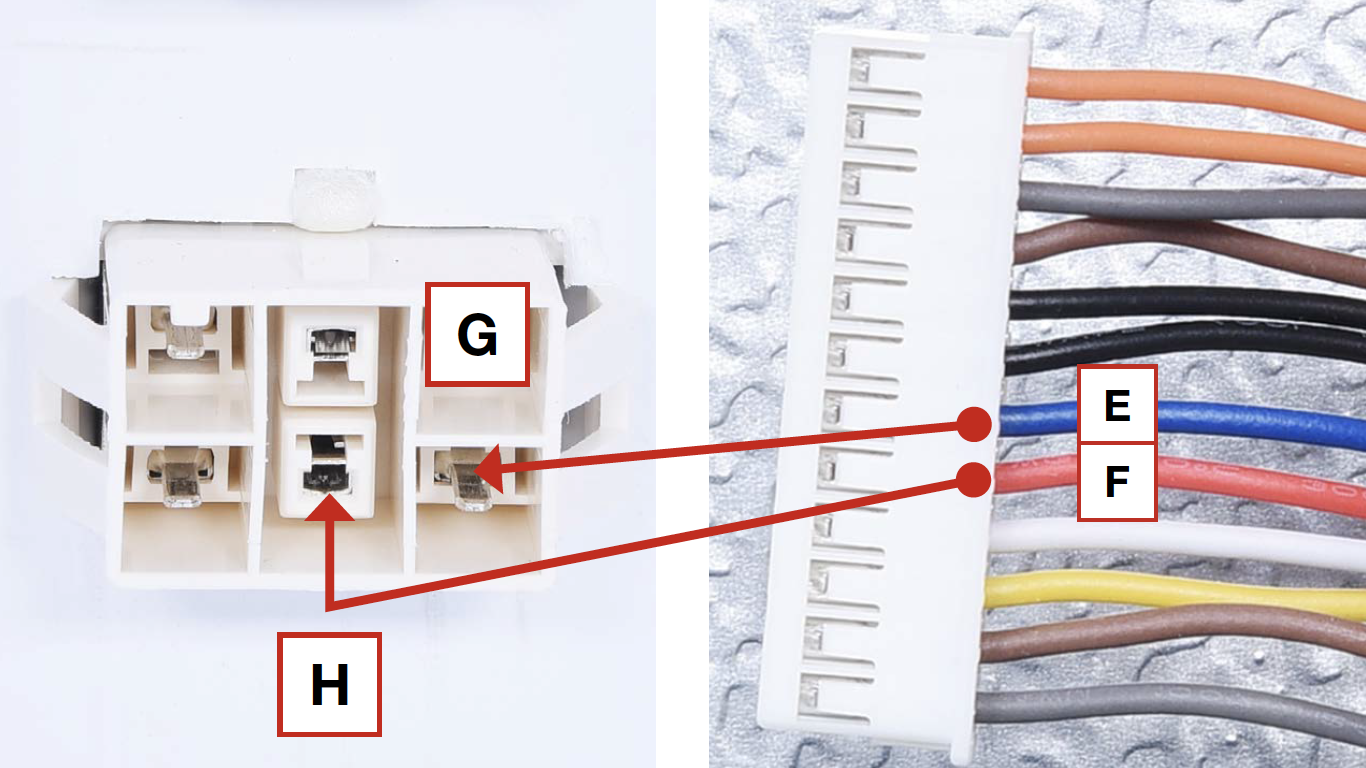

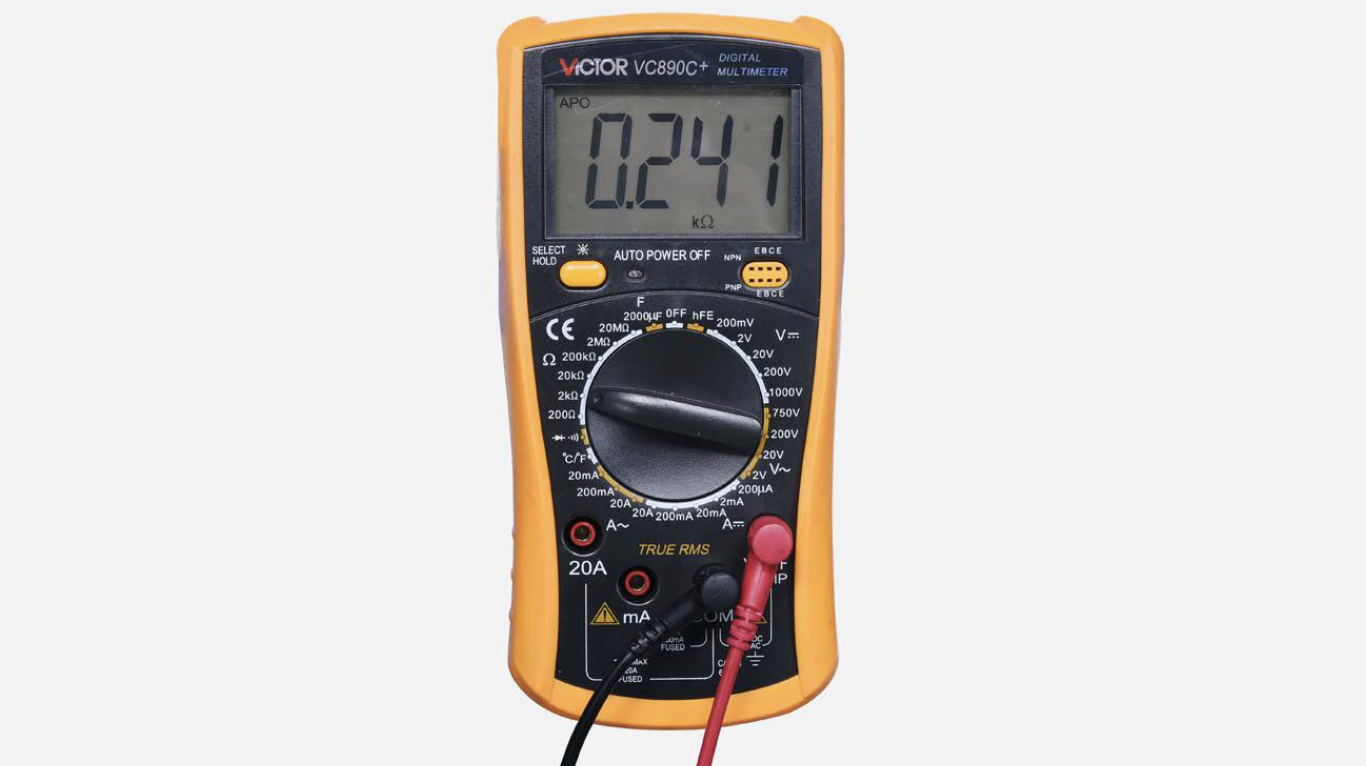

Step 5

Use multimeter to test

connections.

a. Put detector into one

end of wires in PCB

area;

b. Put another detector

into end of wires

behind air duct.

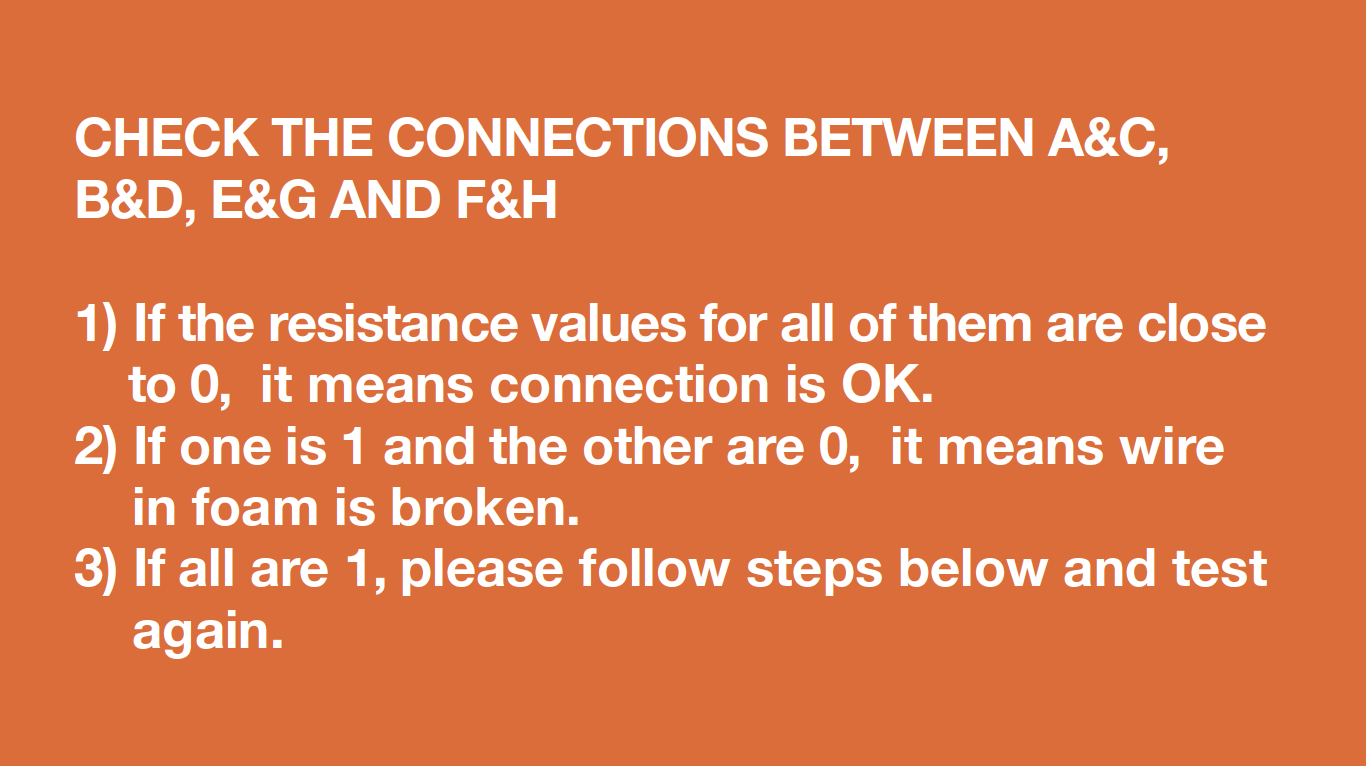

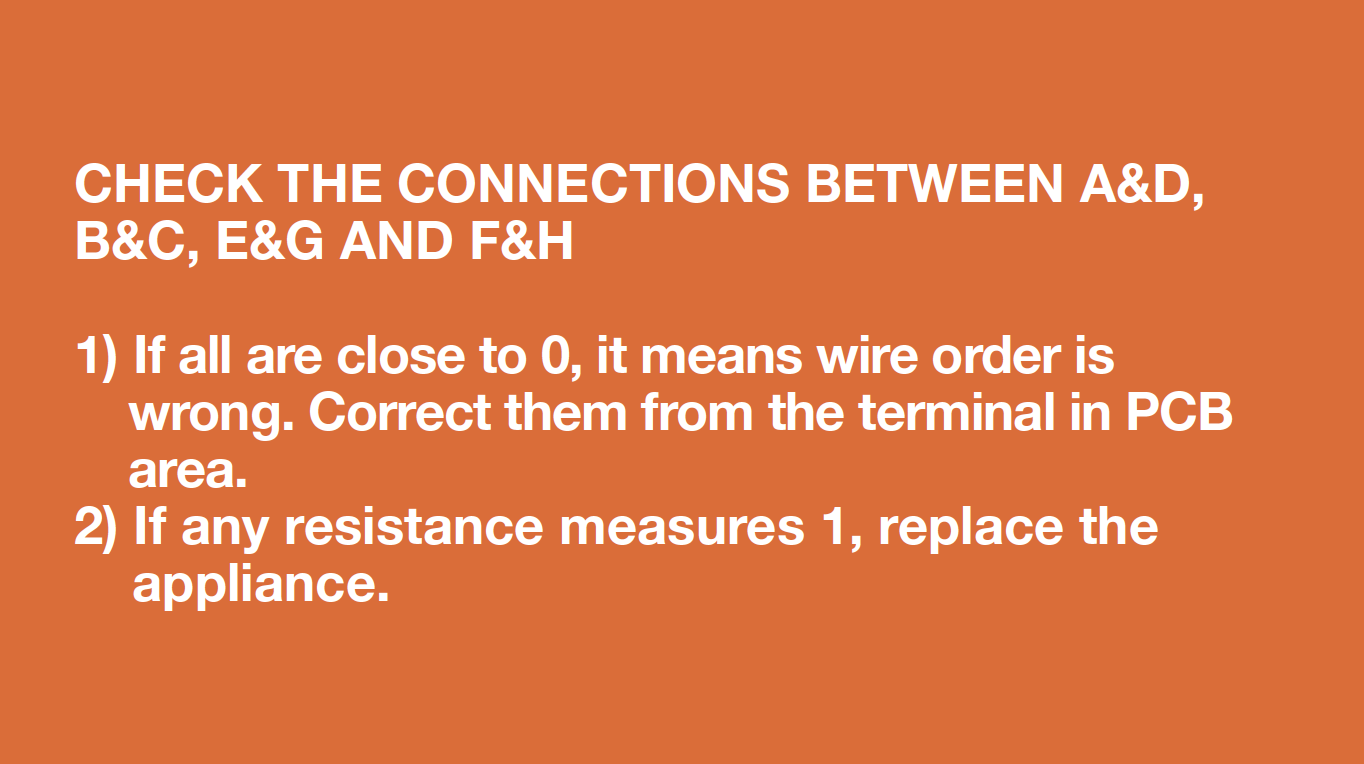

DIAGNOSIS 3

DIAGNOSIS 4

Note

PROCEDURE 3

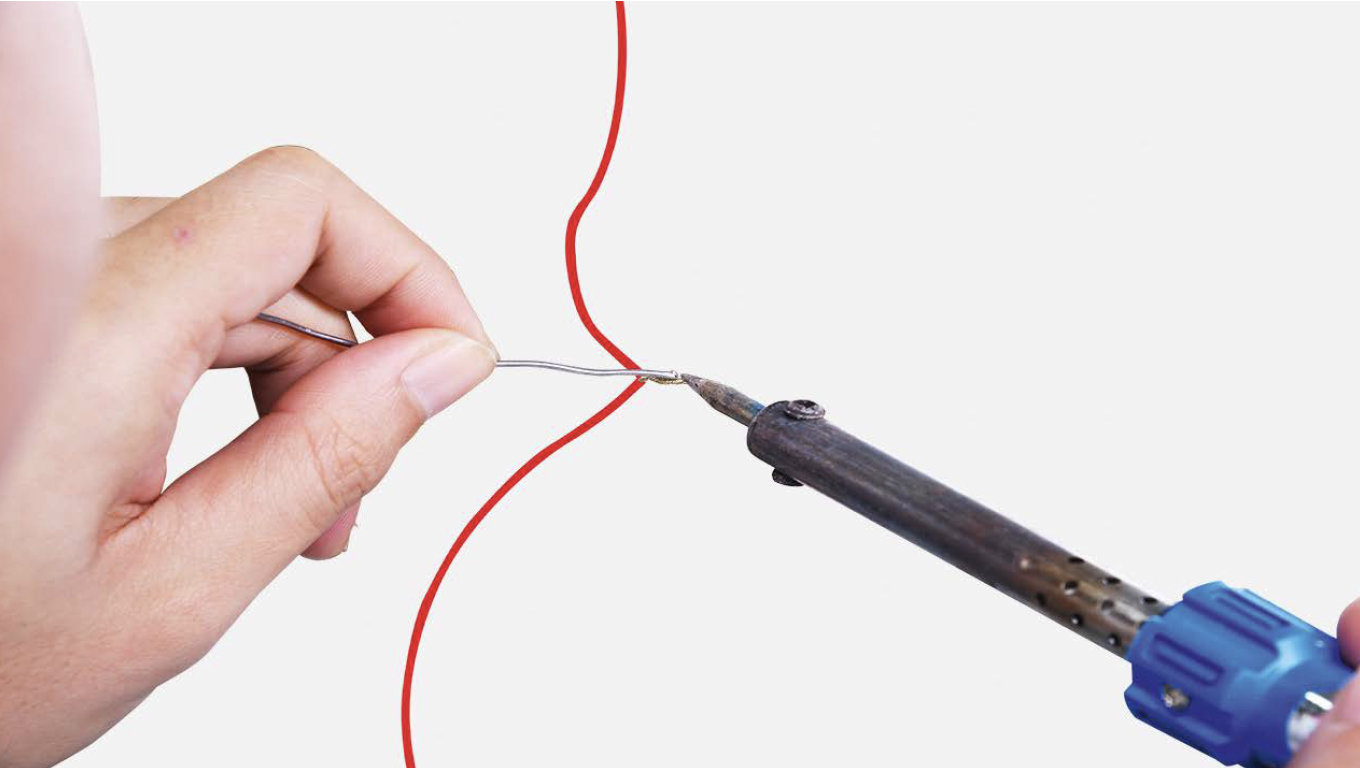

Step 1

Cut the wire

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and reconnect them.

Step 4

Tin soldering.

Step 5

Cover connecting point with electrical tape.

CHECK AND TEST 4

Step 1

Connect damper terminal to terminals inside fridge.

Step 2

Strip off sleeves of wires in PCB area, and supply signal to damper from terminal in PCB area.

Step 3

An oscilloscope should display a square wave signal.

Step 4

See if damper door opens gradually.

DIAGNOSIS 5

PROCEDURE 4

Step 1

Put damper into air duct in foam.

Step 2

Put the plastic cover on top of damper.

Step 3

Connect the terminal.

Step 4

Screw with 6mm cross-head screwdriver.

PROCEDURE 5

Step 1

Re-connect the terminals.

Step 2

Hold air duct by edges to put it back in place.

Step 3

Use a 6 mm cross-head screwdriver to tighten the screw clockwise.

Step 4

Hold the cover and turn it clockwise to tighten the lid, then move it backwards.

Step 5

Insert partition plate.

Step 6

Insert shelf cover.

Step 7

Insert crispers.

Step 8

Insert shelves.

TIPS DURING INSTALLATION PROCEDURES FOR FRIDGE AIR DUCT.

Tip 1

Connect the terminals.

Tip 2

Push terminals into place, then move wires to prevent crushing of wires with edge of air duct.

Tip 3

When reinstalling the air duct, first insert positive shaft into the negative hole.

Tip 4

Then, fasten the clasp on top using the same method.

DIAGNOSIS 6

Step 1

Power on the appliance, then open the doors on the same side to the same degree, wait 5 seconds, and put your hand in front of fridge air duct outlet to verify.