CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

Power off the appliance, and turn the power output of transformer to DC 12V.

Step 3

Supply power from terminal in PCB area.

Step 4

Open fridge and freezer doors on same side to same degree. After 5 seconds, the LED is off, put your hand in freezer compartment to feel if fan is blowing or not.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove all drawers.

Step 2

Remove all shelves.

Step 3

Remove the vertical

partition plate:

a. Insert 2mm slotted

screwdriver into

the gap;

b. Lever up the cover

plate from bottom;

c. Insert 2mm slotted

screwdriver into the

side gap;

d. Lever up the cover

plate from bottom;

e. Pull the bottom end of

cover out;

f. Pull the top of the

cover out;

g. Pull pipes down to a

horizontal position;

h. Push the latch down

and pull top out of the

cavity;

i. Push the latch up and

pull bottom out of the

cavity;

j. Pull the partition

outward and remove

the partition;

k. View inside once partition has been removed.

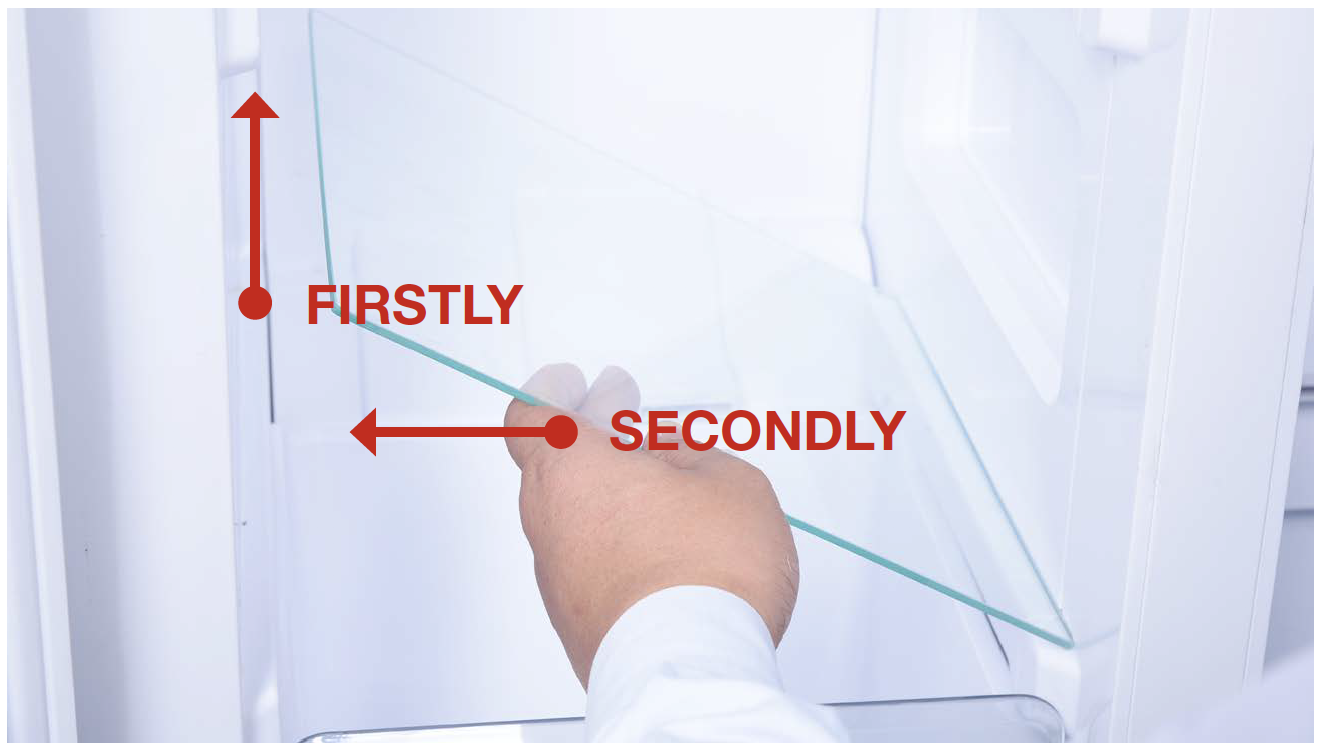

Step 4

Dismantle the air duct.

a. Hold the bottom of

air duct;

b. Pull air duct out from

below;

c. Disconnect the

terminal for fan motor;

d. Disconnect the

terminal of freezer temp. sensor;

e. Move air duct away.

CHECK AND TEST 2

Step 1

In duct area, check if terminal is pushed into final position.

Note

A & C are not OK; B is OK..

Step 2

Check if terminal is filled with foam or not.

IF YES, please use

tweezers to clean and

remove the foam.

Later, reconnect the

terminals

Step 3

Power off the appliance and turn the power output of transformer to DC 12V.

Step 4

Supply power from terminal in PCB area.

Step 5

Open fridge and freezer doors on same side to same degree to feel if fan is blowing or not.

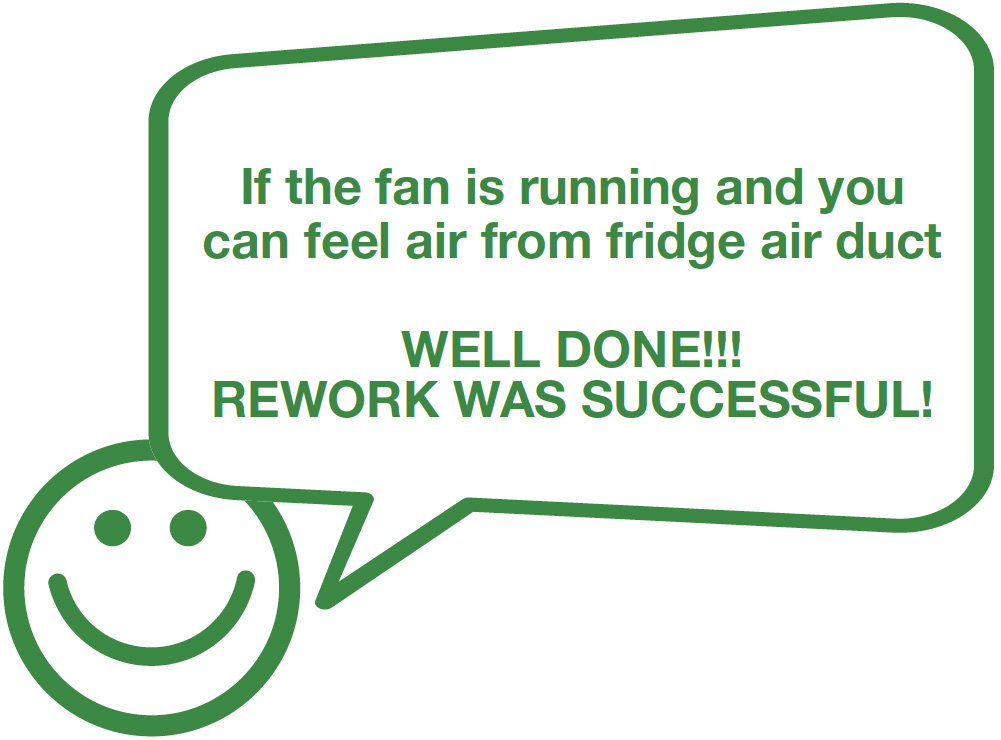

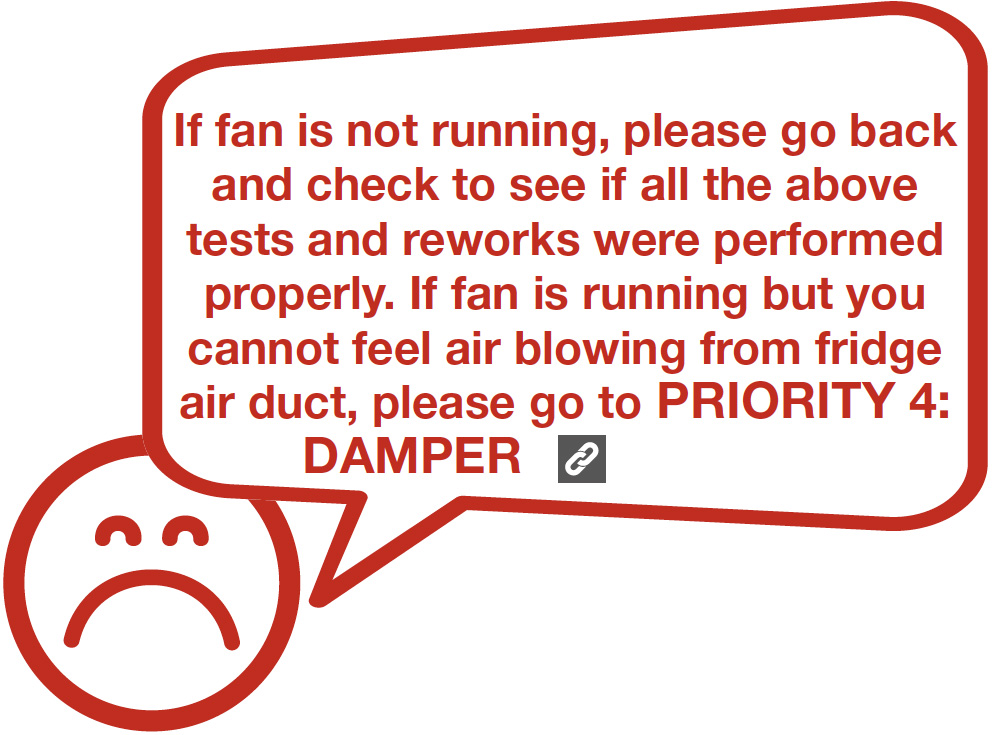

DIAGNOSIS 2

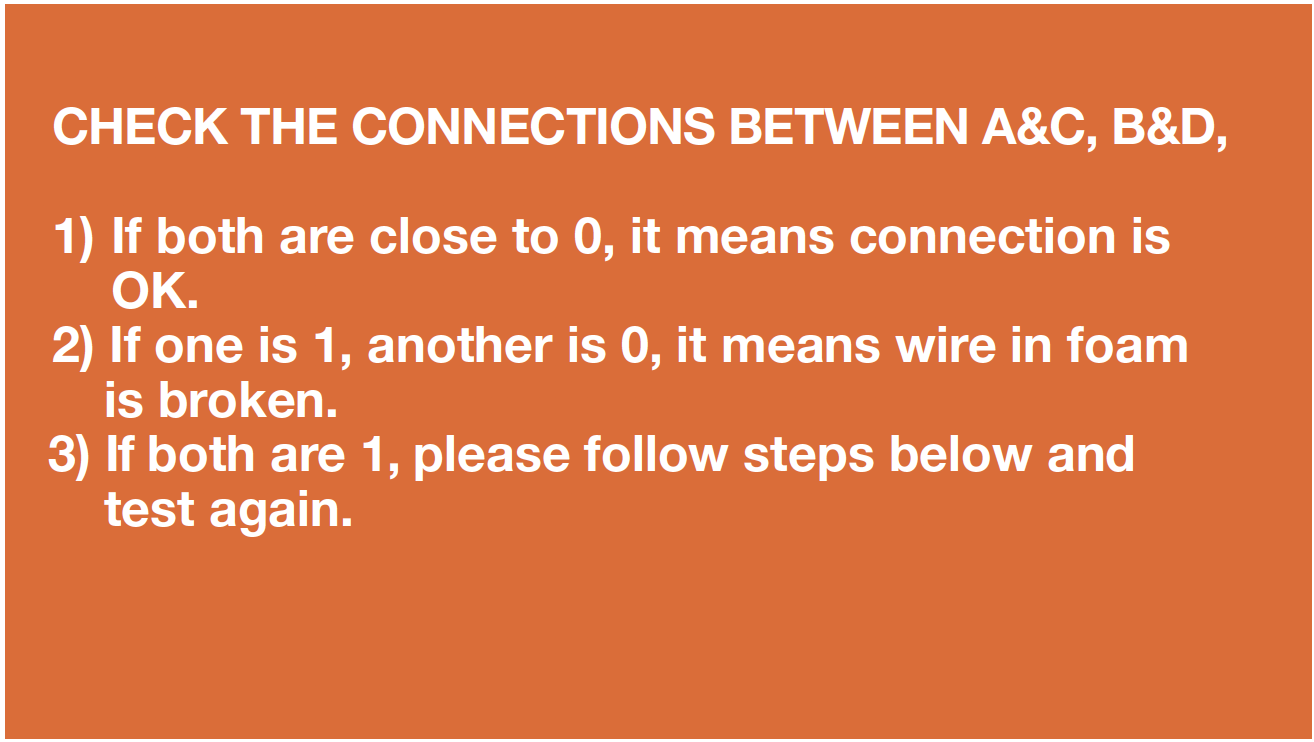

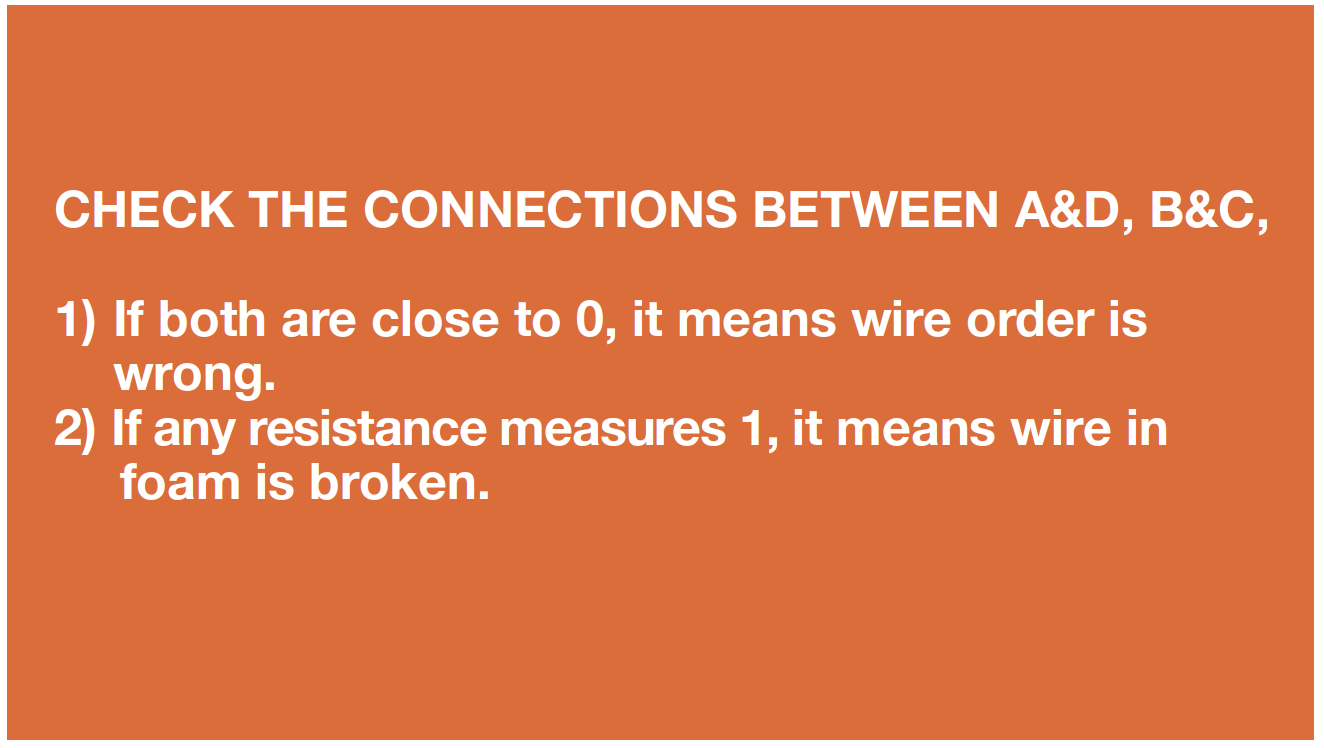

Step 2

Check to see if the wires

are in the correct order

and their connections in

the foam are correct:

1. Set multimeter to

resistance gear;

2. Put detector into one end of wires in PCB area;

3. Put another detector into end of wires behind air duct.

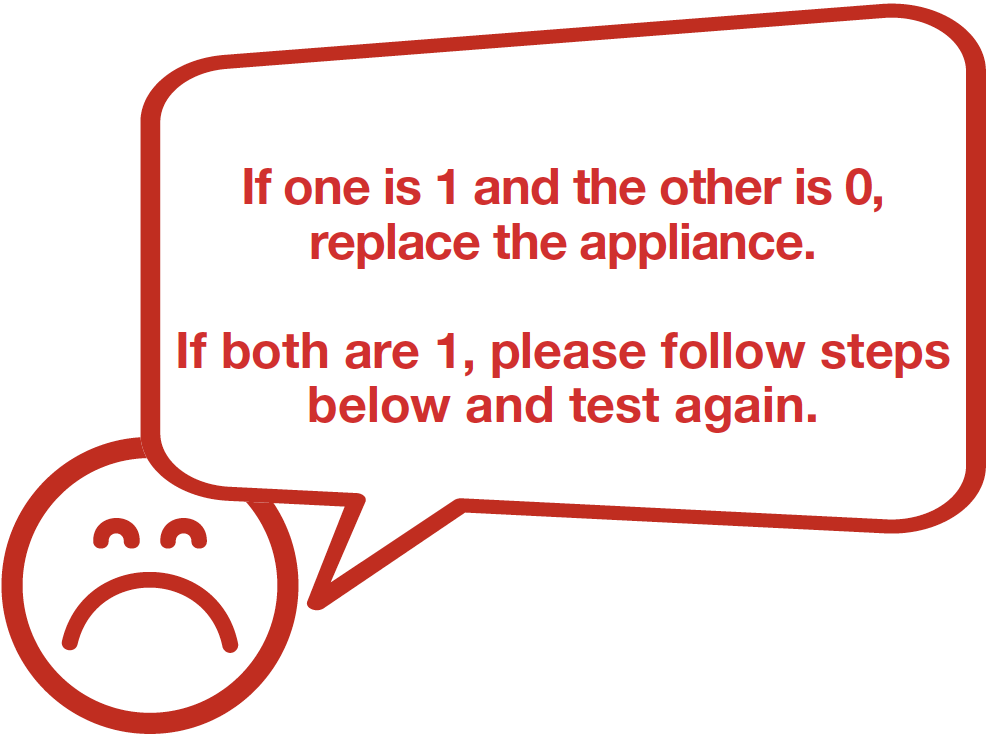

DIAGNOSIS 3

DIAGNOSIS 4

PROCEDURE 2

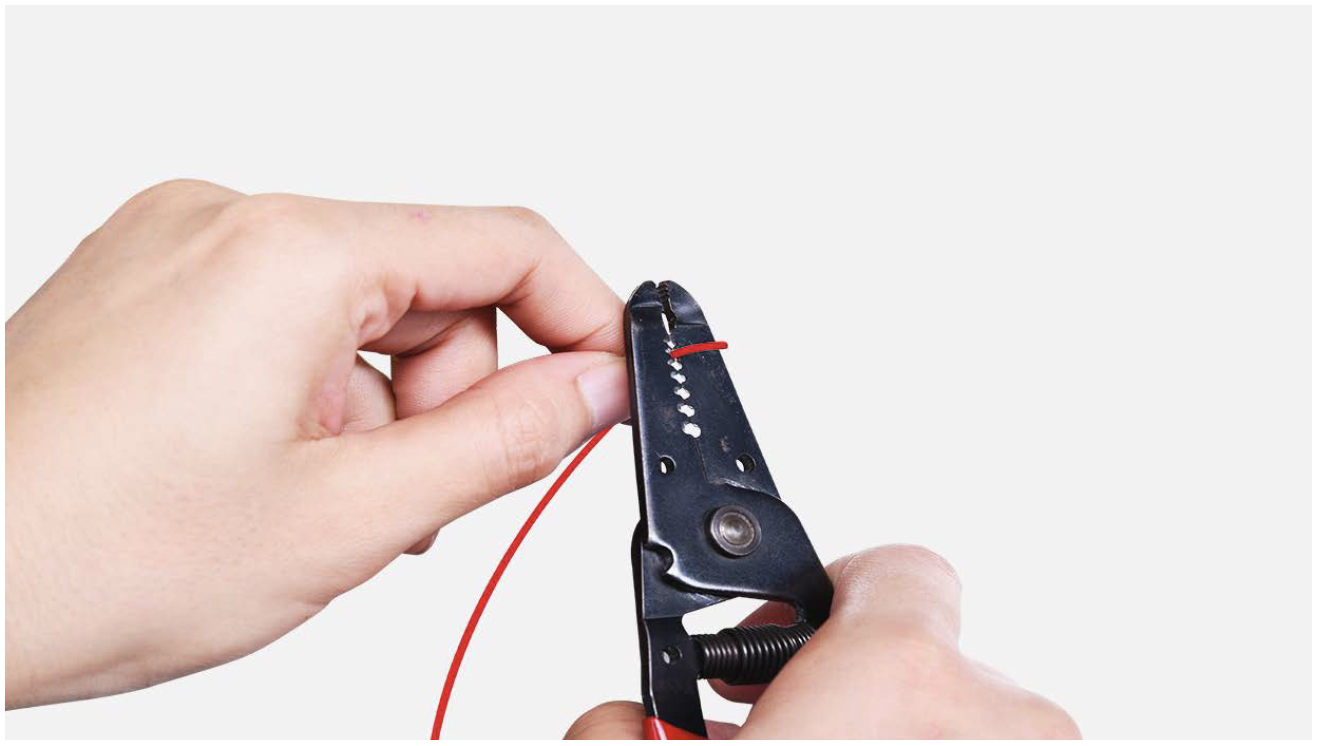

Step 1

Cut wire off from broken area.

Step 2

Peel off the sleeves.

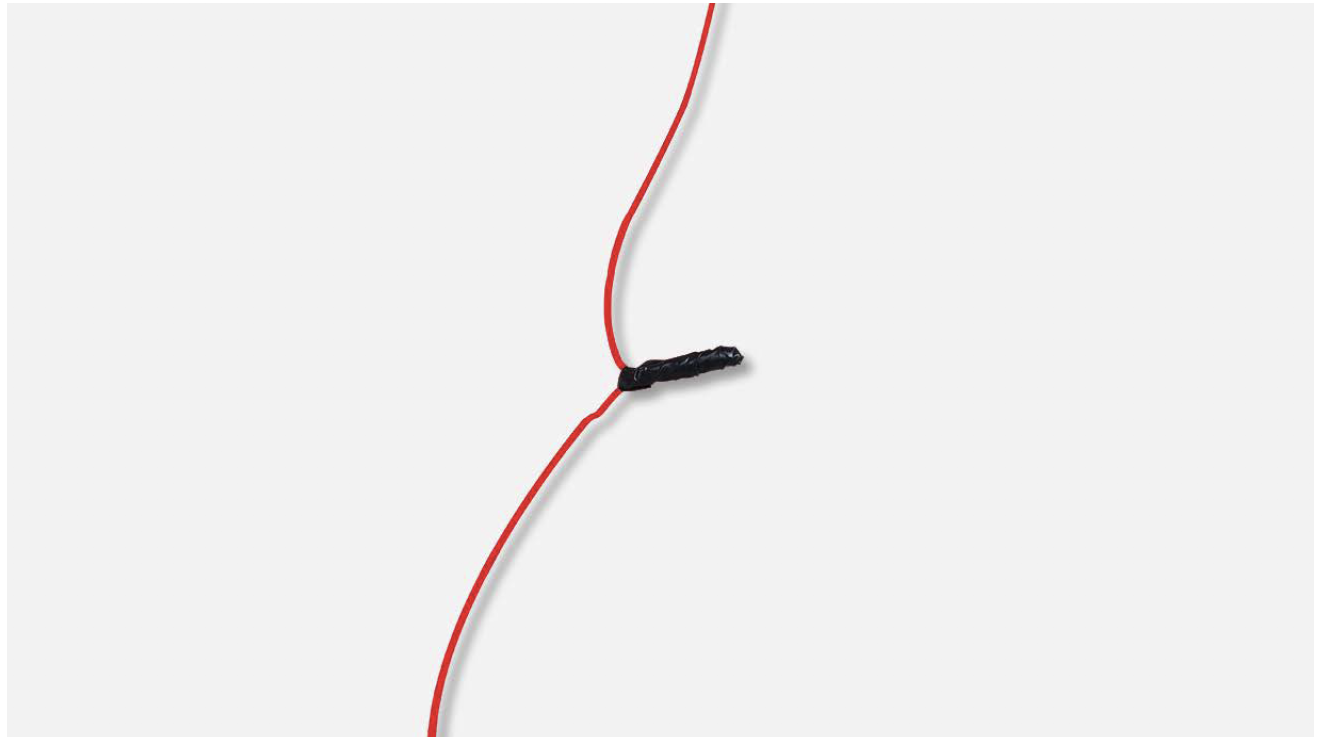

Step 3

Check to ensure proper wire order and connect them.

Step 4

Tin soldering.

Step 5

Cover connection with electrical tape.

CHECK AND TEST 4

Step 1

Set output of transformer to DC 12V to test fan from the terminal behind the air duct.

DIAGNOSIS 5

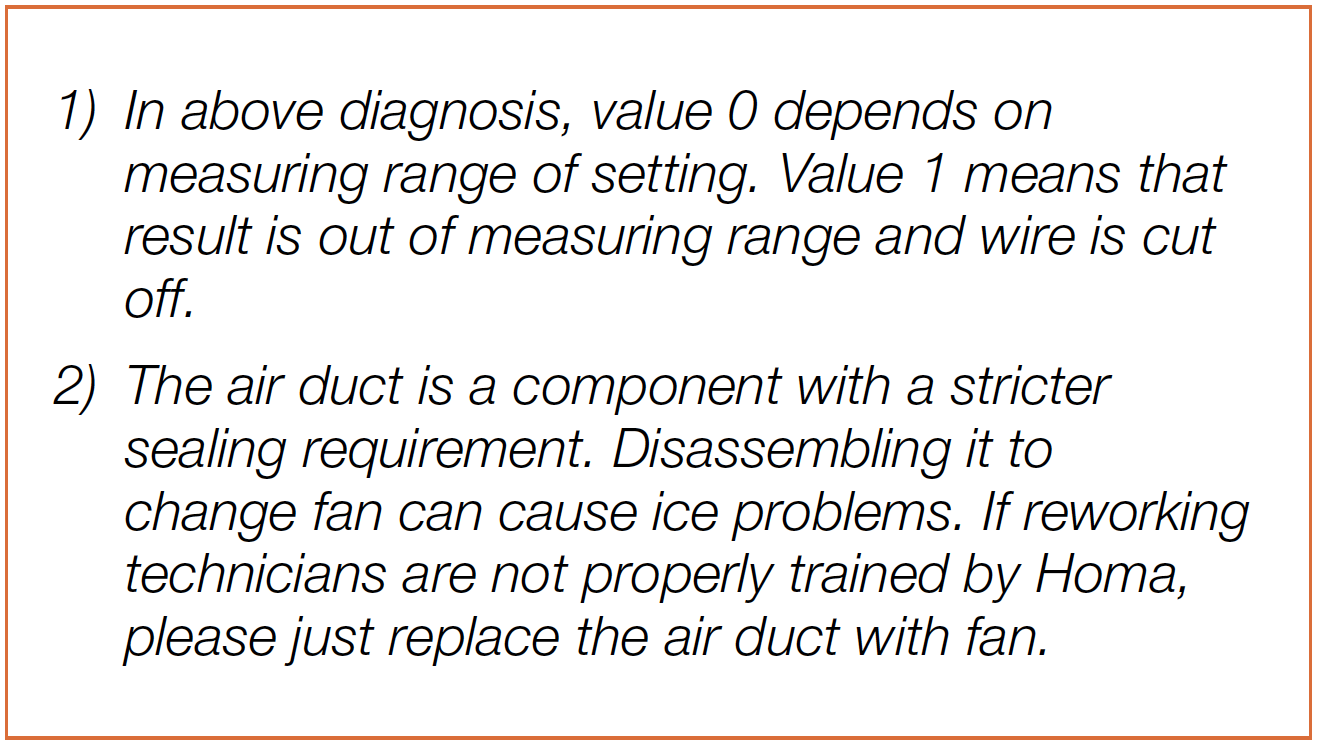

Note

Tip 1

When re-installing the air duct, move the wires out of the way so that they won’t be crushed by air duct.

Tip 2

After pushing air duct

into position, it should

make a click sound.

If no click is heard, do it again.

Tip 3

Check to see if there is a wide gap between air duct and cabinet.

IF SO, install air duct again.

Tip 4

Check to ensure that the latch is properly inserted into the cavity.

Tip 5

First, insert top of the cover plate into the gap, then bend the plate to insert the bottom. Finally, push the middle into the slot.

CHECK AND TEST 5

Step 1

Open fridge and freezer doors on same side to same degree.

DIAGNOSIS 6