CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a cross-head screwdriver.

Step 2

Test resistance of sensor from terminal in PCB area.

Step 3

Take note of value.

Step 4

Measure the temperature of sensor.

DIAGNOSIS 1

PROCEDURE 1

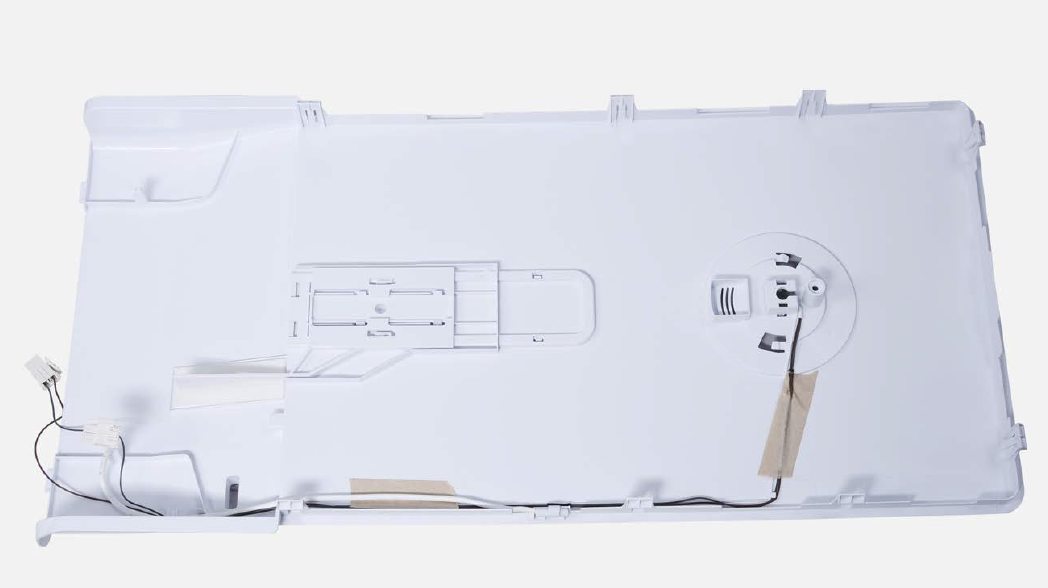

Step 1

Remove shelves.

Step 2

Remove crispers.

Step 3

Remove shelf cover.

Step 4

Remove partition plate.

Step 5

Hold the cover and turn

in counter-clockwise

direction to loosen cover.

Then, remove cover.

Step 6

Use 6mm cross-head screwdriver to loosen the screw in counter clockwise direction.

Step 7

Hold the edge of air duct to pull it out.

Step 8

testo testo

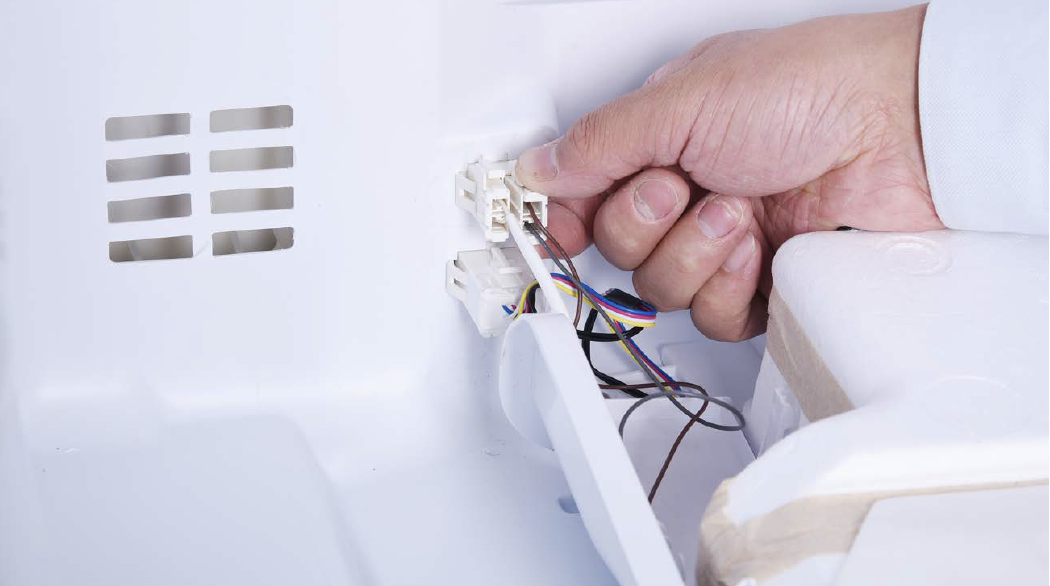

CHECK AND TEST 2

Step 1

Test resistance of sensor from terminal in duct cover.

Step 2

Measure temperature of fridge temp. sensor.

DIAGNOSIS 2

Note

PROCEDURE 2

Step 1

Release the clasp.

Step 2

Remove the foam air duct.

Step 3

Remove tape.

Step 4

Remove the broken

sensor.

Note

Reverse the procedures to install new sensor.

CHECK AND TEST 3

Step 1

Check to see if terminal is full of foam.

Step 2

Use tweezers or tools with sharp tip to remove foam in terminal

Step 3

Check to ensure that wires are connected properly.

Step 4

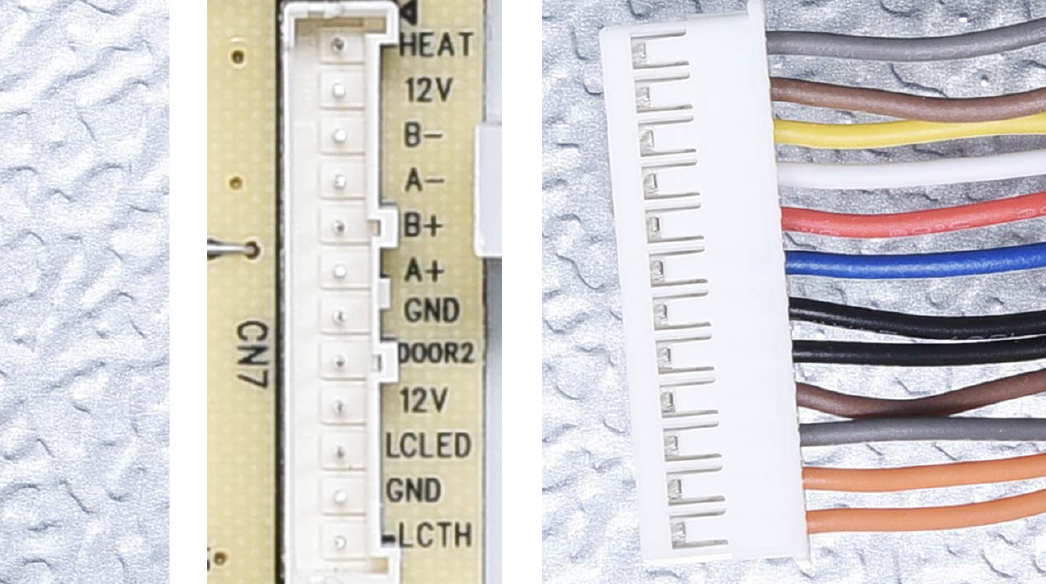

Use multimeter to test

connections.

1. Put detector into one

end of wires in PCB

area;

2. Put another detector

into end of wires

behind air duct.

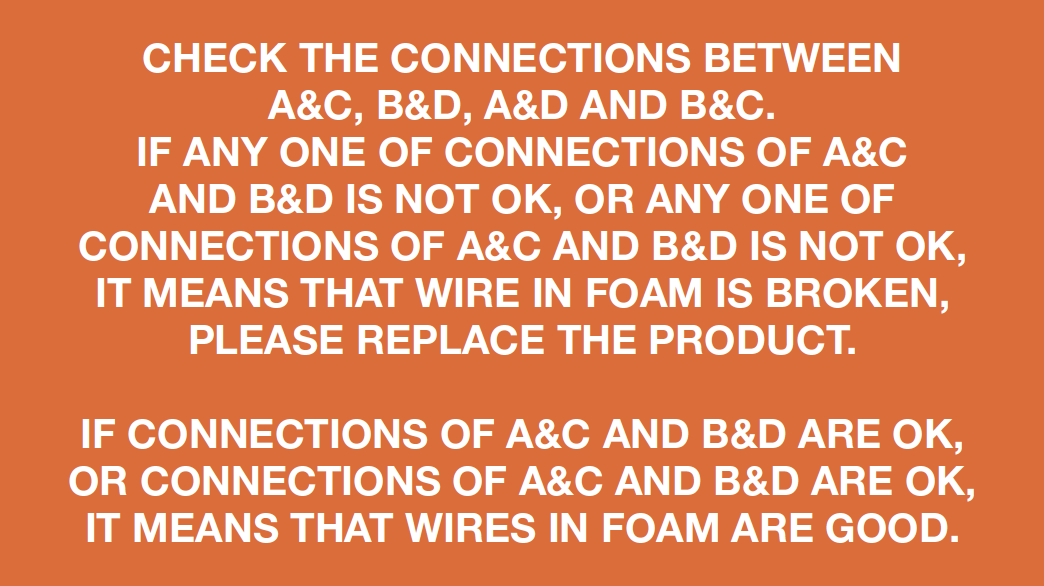

DIAGNOSIS 3

PROCEDURE 3

Step 1

Reinsert the terminals

for sensor.

Make sure that the

terminal is pushed into

final position

Step 2

Screw on the cover of mainboard with a cross-head screwdriver.

Step 3

Re-connect the terminals.

Step 4

Hold air duct by edges to put it back in place.

Step 5

Use a 6 mm cross-head screwdriver to tighten the screw clockwise.

Step 6

Hold the cover and turn it clockwise to tighten the lid, then move it backwards.

Step 7

Insert partition plate.

Step 8

Insert shelf cover.

Step 9

Insert crispers.

Step 10

Insert shelves.

TIPS DURING INSTALLATION PROCEDURES FOR FRIDGE AIR DUCT.

Tip 1

Connect the terminals.

Tip 2

Push terminals into place, then move wires to prevent crushing of wires with edge of air duct.

Tip 3

When reinstalling the air duct, first insert positive shaft into the negative hole.

Tip 4

Then, fasten the clasp on top using the same method.

DIAGNOSIS 4