CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a cross-head screwdriver.

Step 2

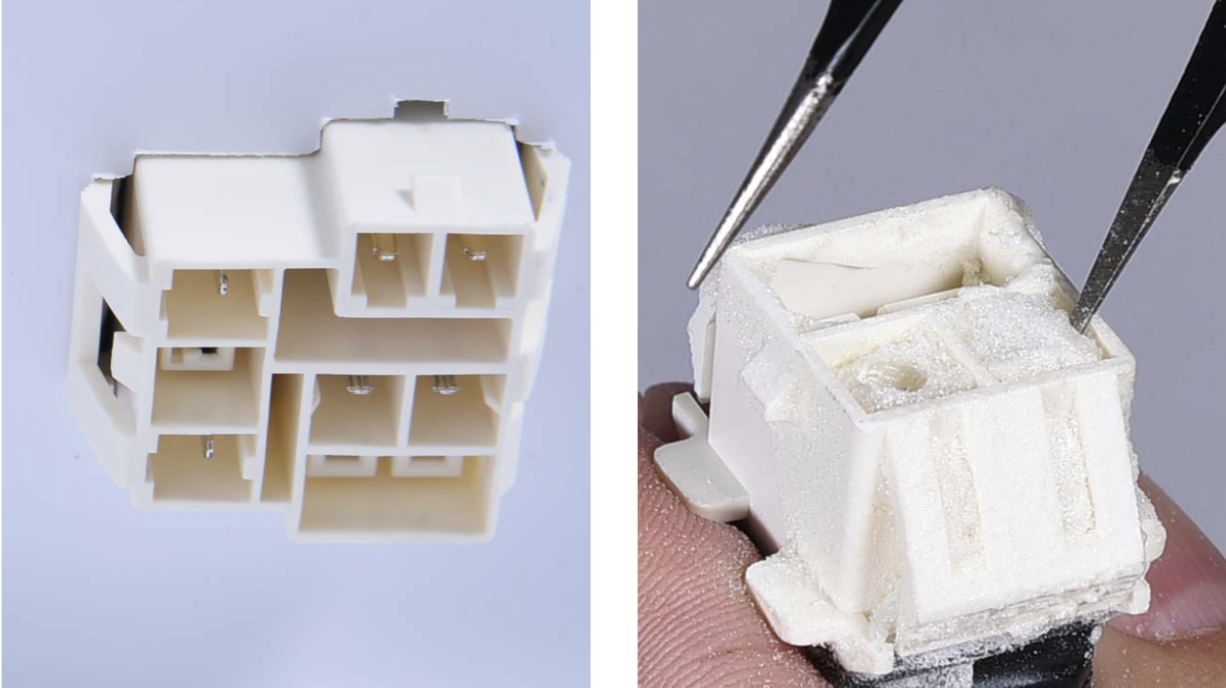

In PCB area, check if terminal is pushed into final position.

IF NOT, PUSH IT INTO FINAL POSITION.

Step 3

In PCB, check to see if terminal is full of foam.

IF SO, USE TWEEZERS TO REMOVE FOAM.

Step 4

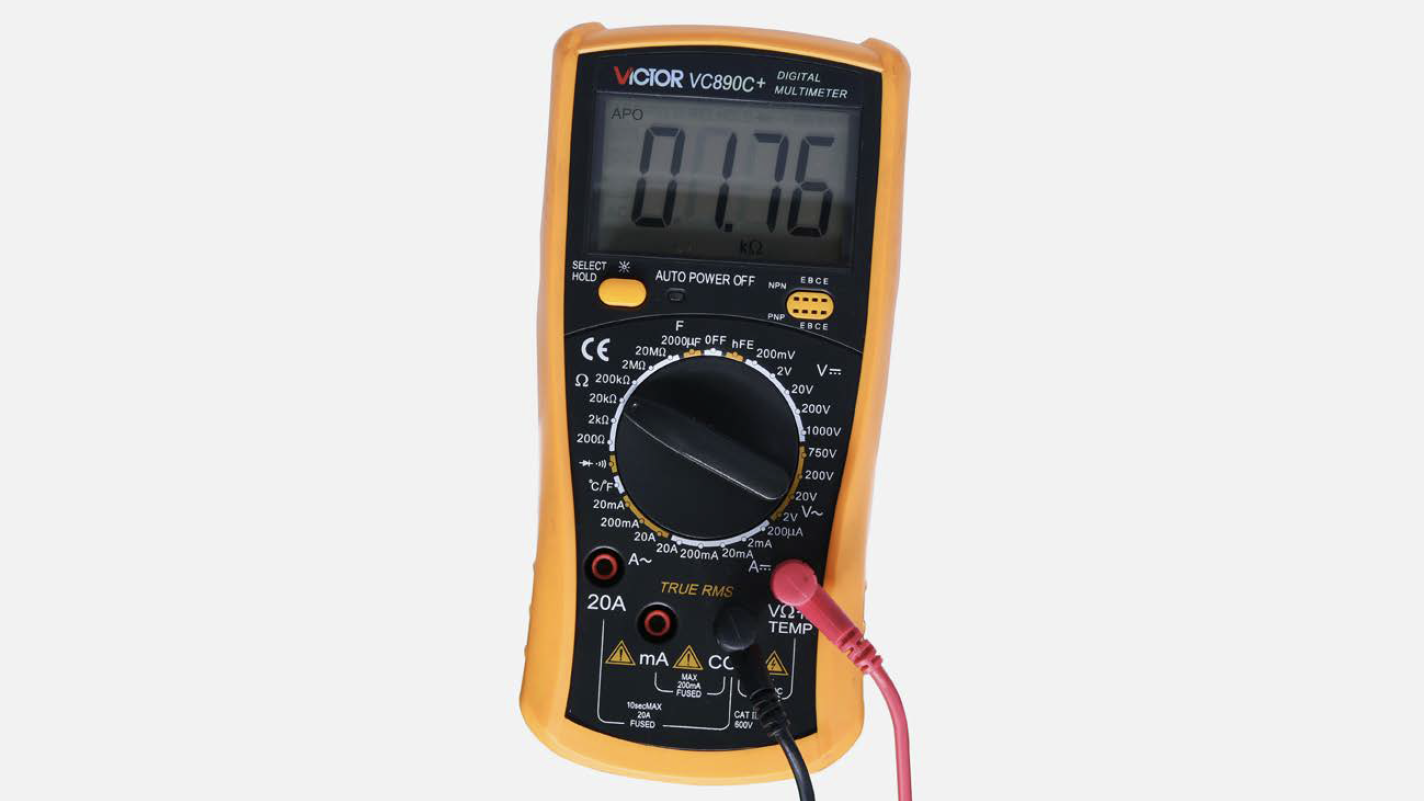

In PCB area, use multimeter to measure resistance value.

Step 5

Take note of the test result

Step 6

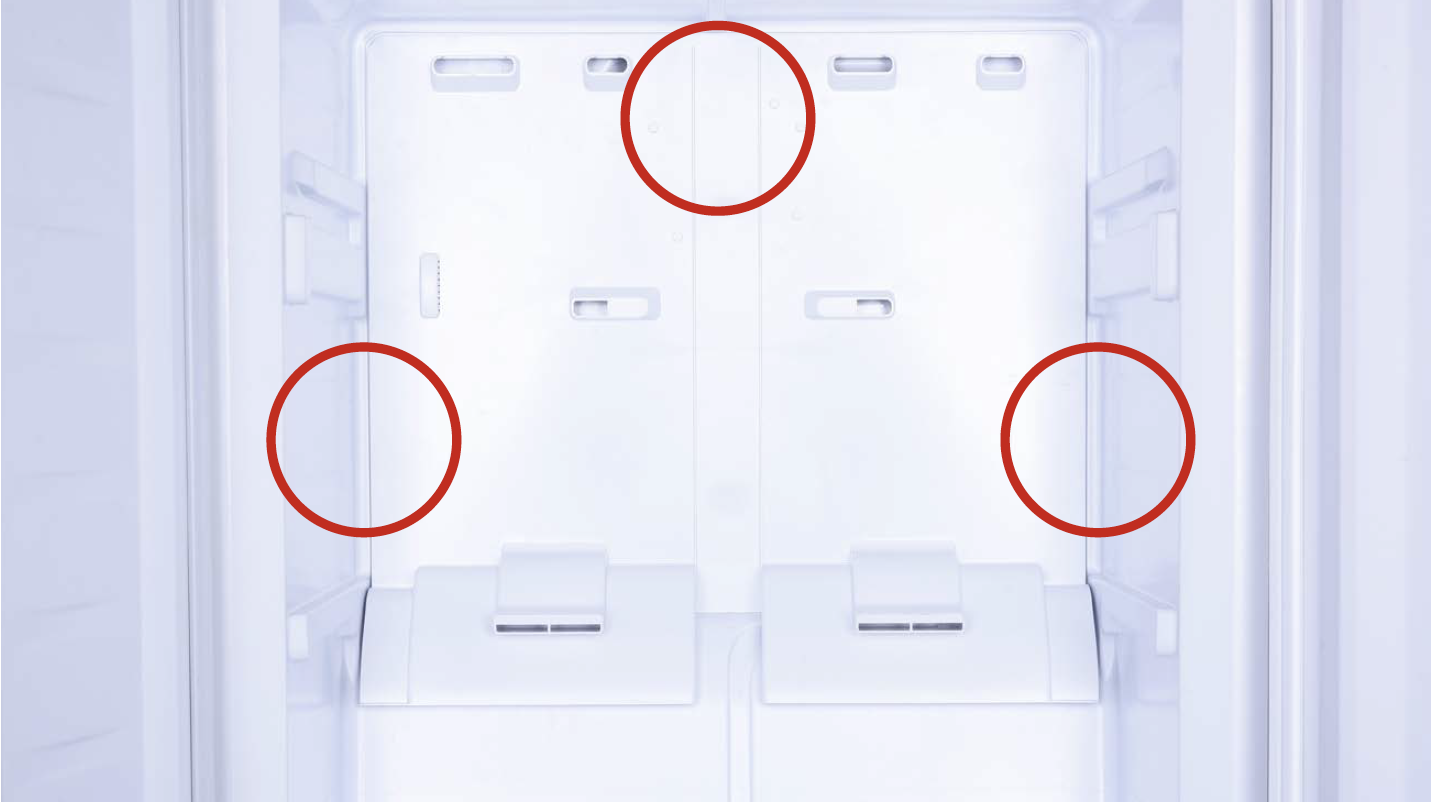

Use infrared detector to measure the temperature of freezer air duct (see red square in picture) for reference temperature for defrost temp. sensor.

Note

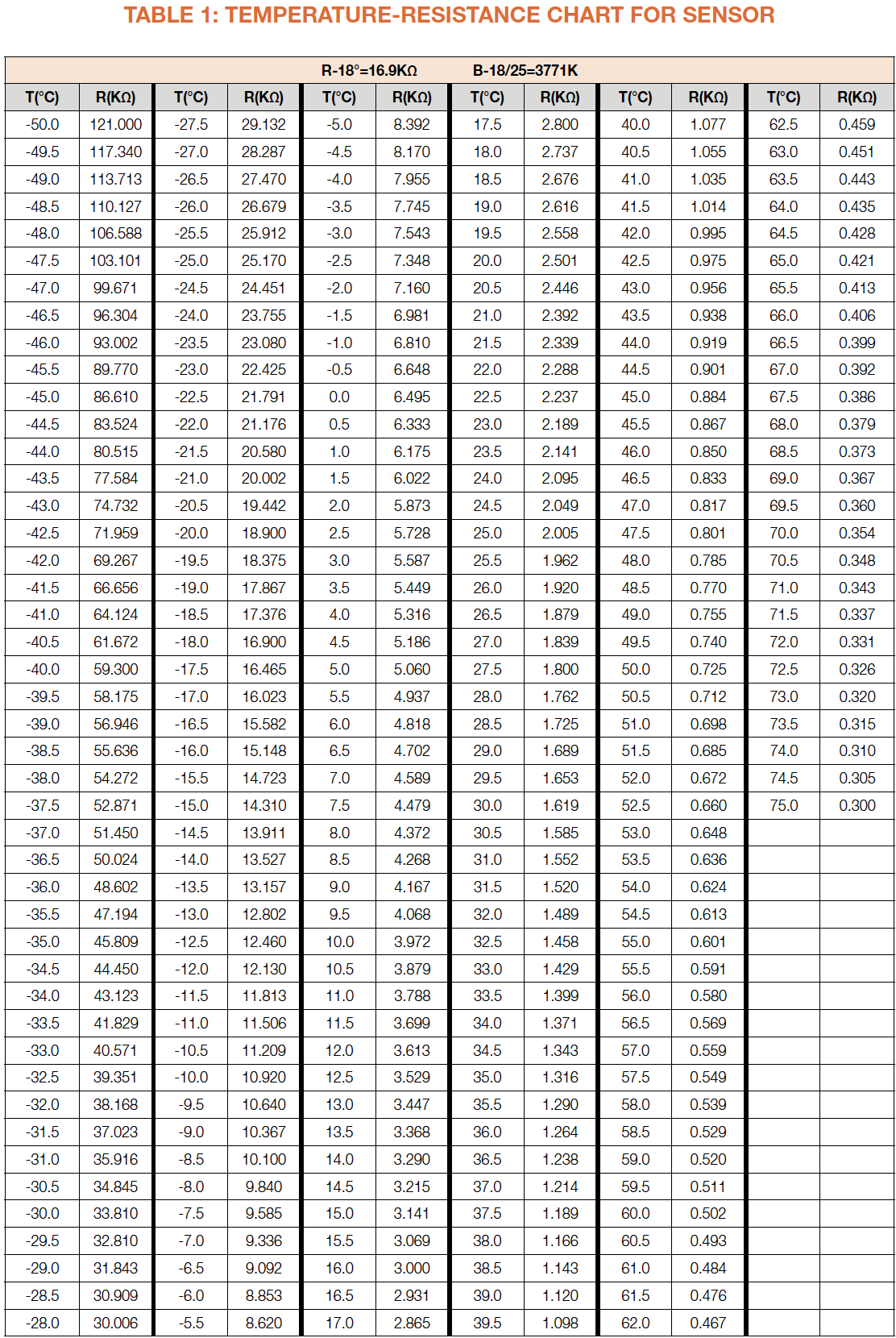

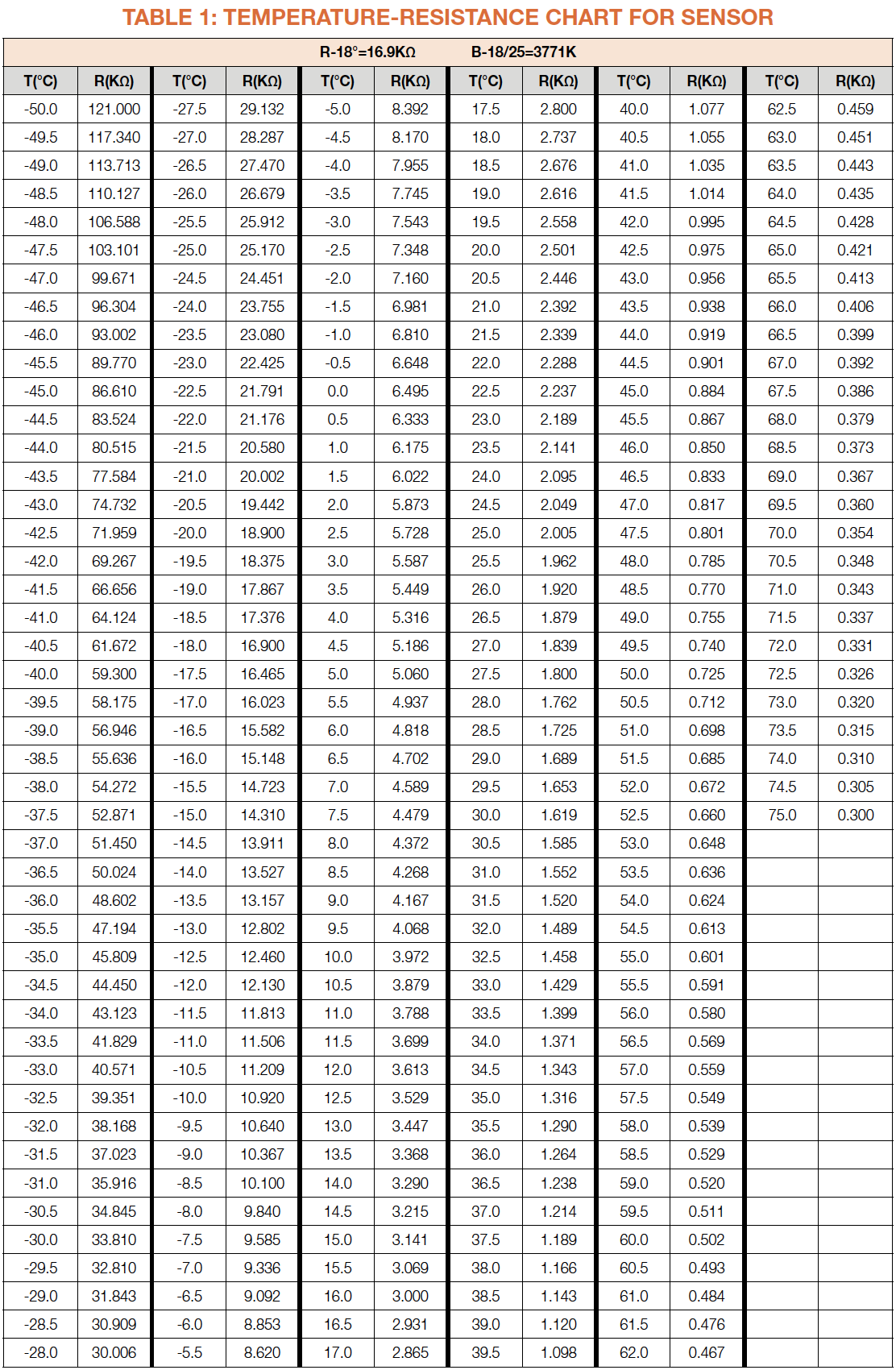

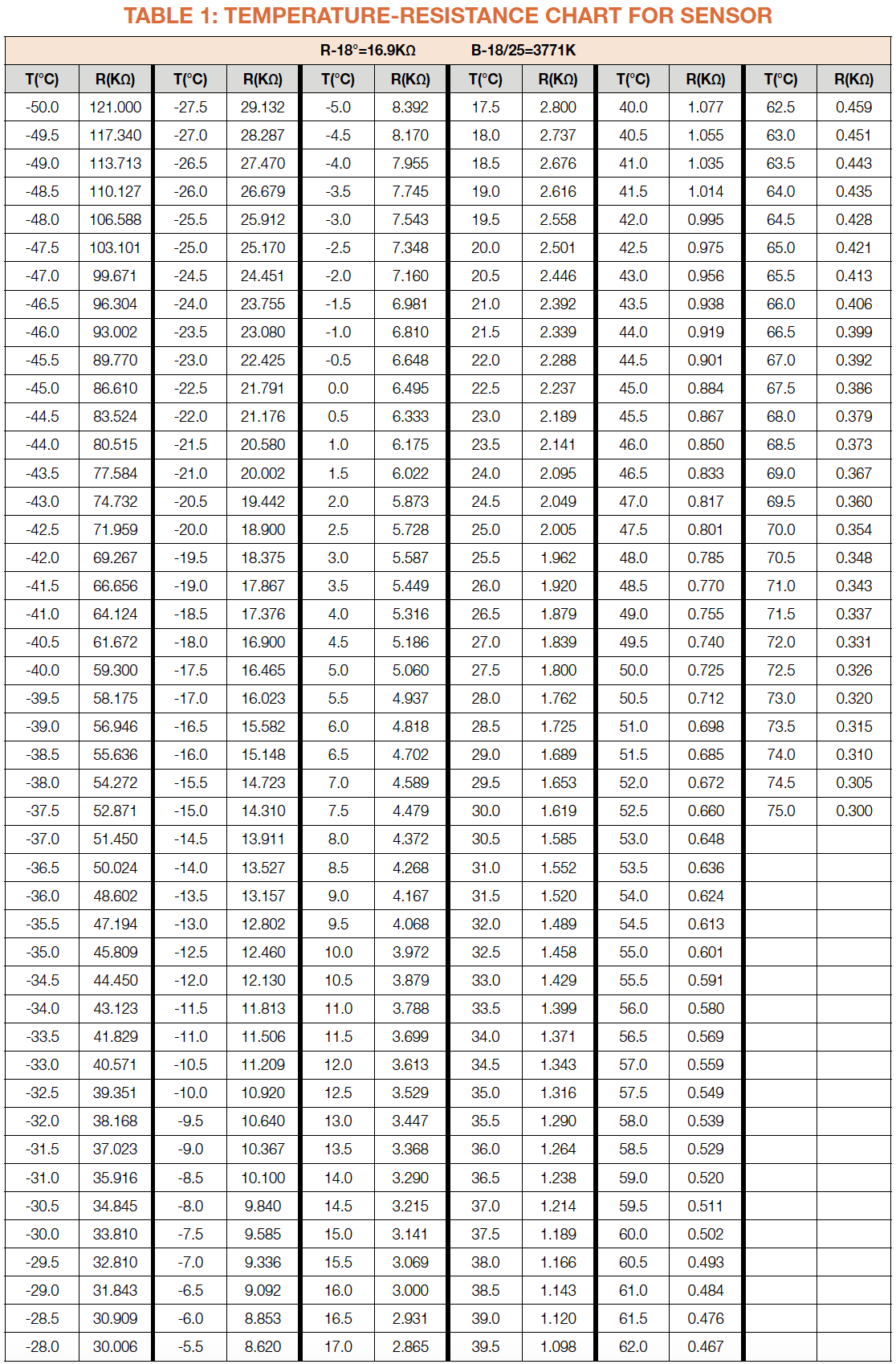

Use tested reference temperature to find out standard resistance value in table 1 below.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove all the drawers.

Step 2

Remove all shelves.

Step 3

Remove the vertical

partition plate:

a. Insert 2mm slotted

screwdriver into

the gap;

b. Lever up the cover

plate from bottom;

c. Insert 2mm slotted

screwdriver into the

side gap;

d. Lever up the cover

plate from bottom;

e. Pull the bottom end of

cover out;

f. Pull the top of the

cover out;

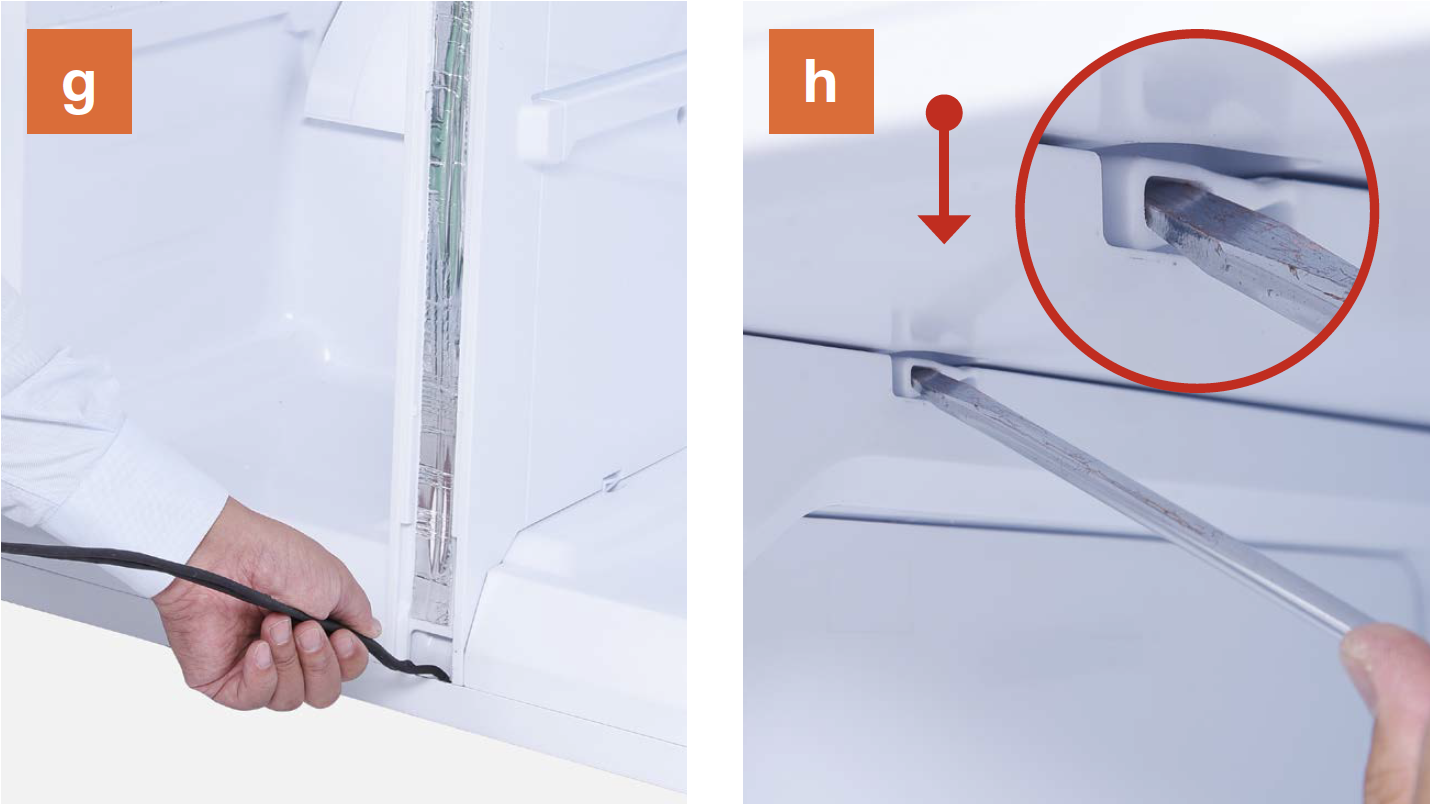

g. Take pipes out and

place in horizontal

position;

h. Push latch down and

lift top out of cavity;

i. Push latch up and

pull bottom out of the

cavity;

j. Pull partition outward

and remove partition.

k. Internal view after partition has been removed.

Step 4

Dismantle the air duct.

a. Hold the bottom of

air duct;

b. Pull air duct out from

below;

c. Disconnect the terminal for fan motor;

d. Disconnect the terminal of freezer temp. sensor;

e. Remove air duct.

CHECK AND TEST 2

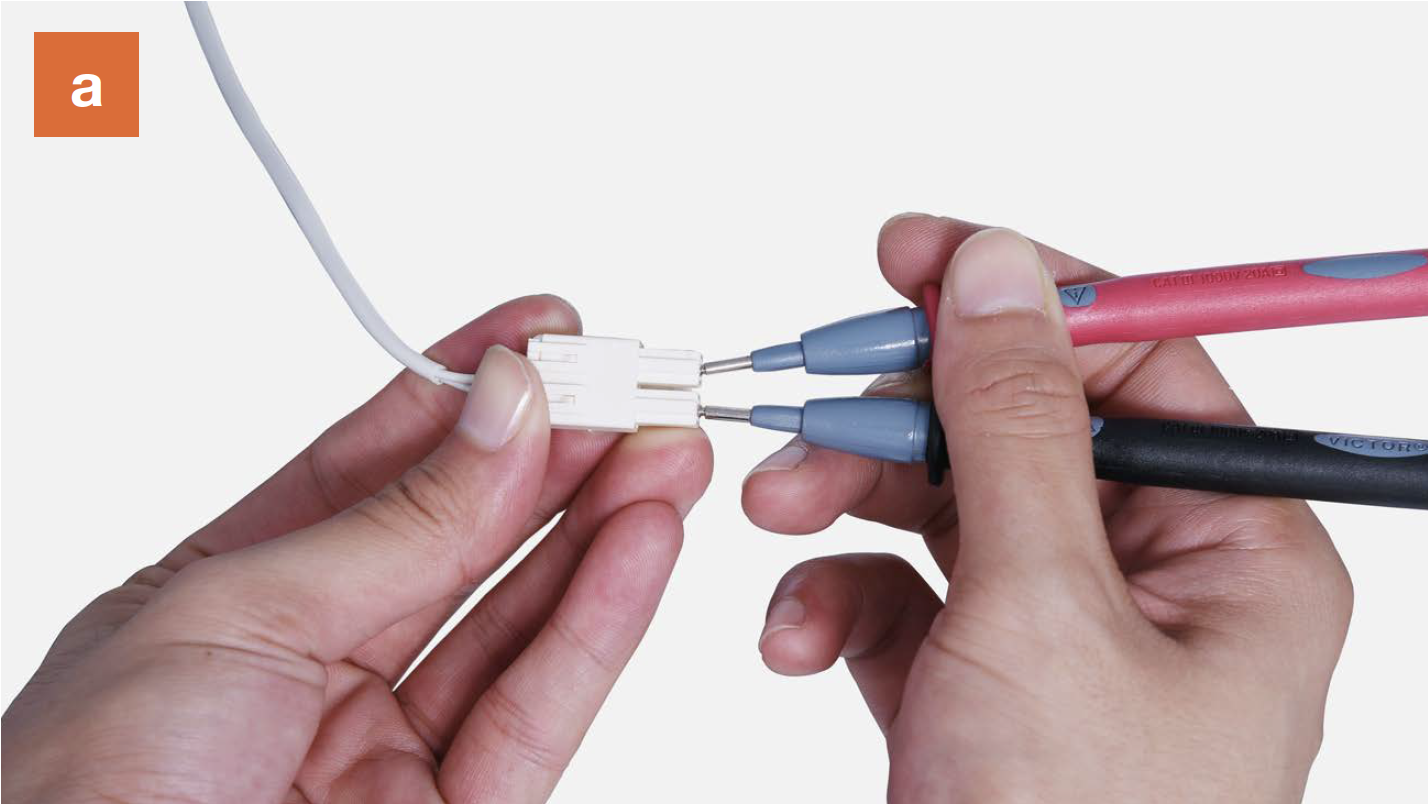

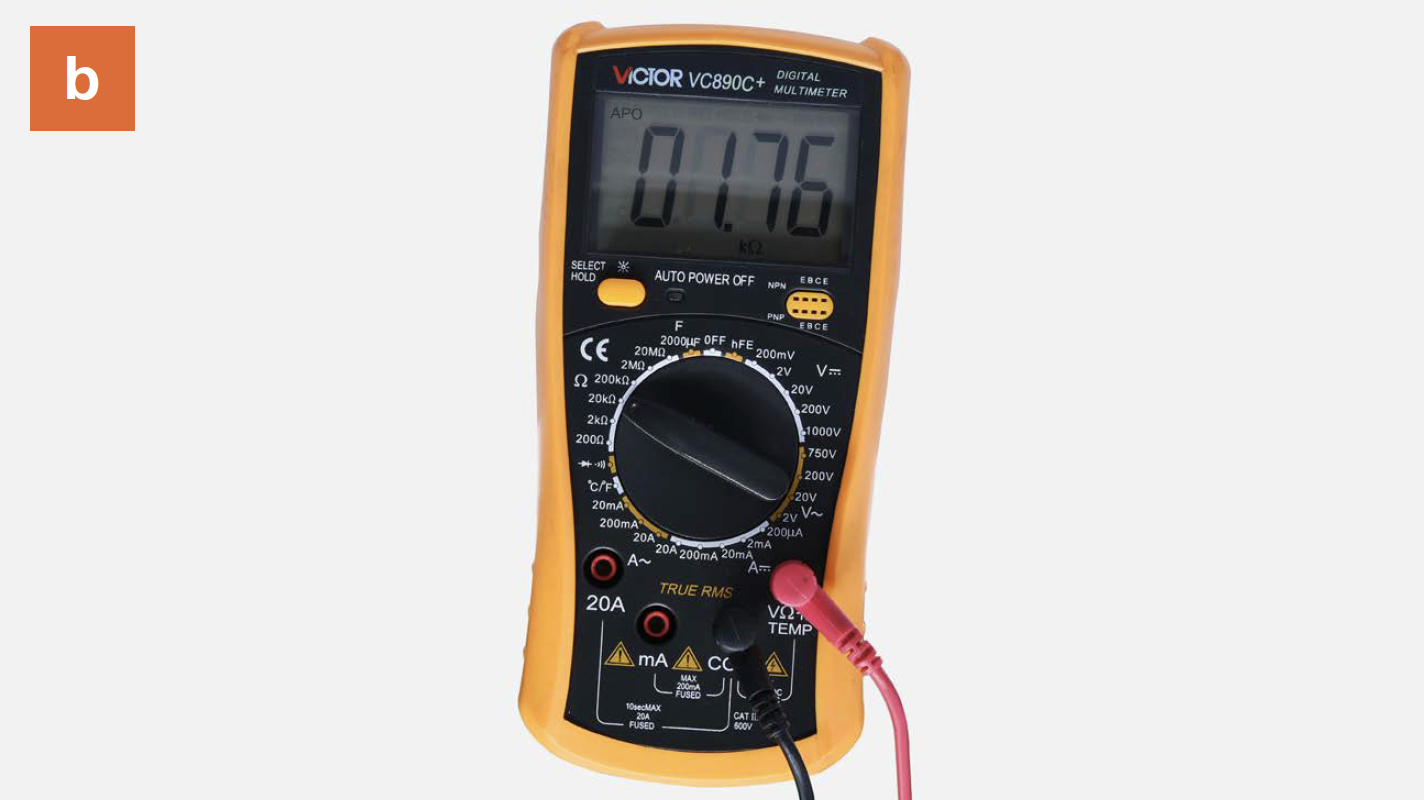

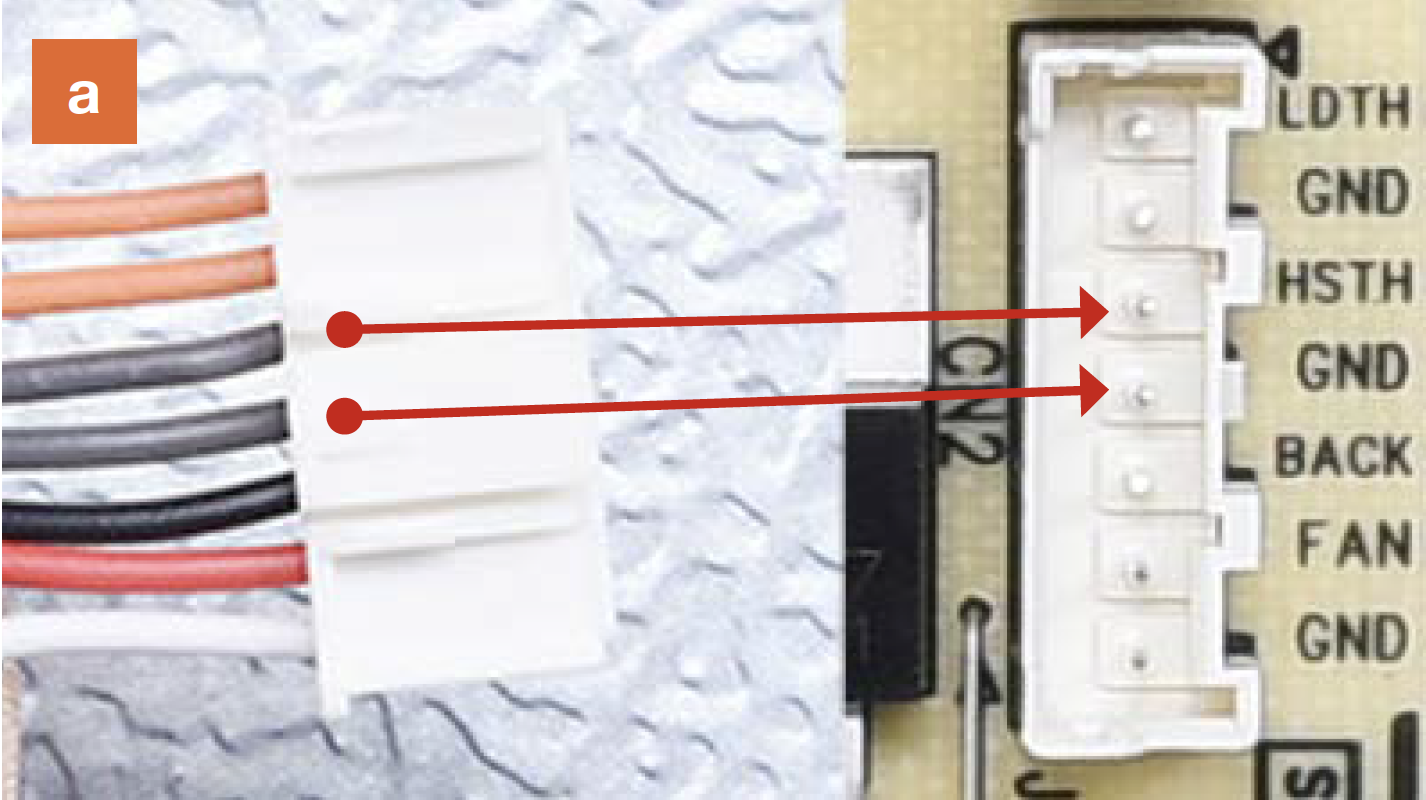

Step 1

Use a multimeter to measure the resistance value of defrost temp. sensor from terminal located in freezer.

a. Insert the detectors

into terminal and

make sure connection

is good;

b. Read the value;

Step 2

Measure the temperature of defrost temp. sensor.

Note

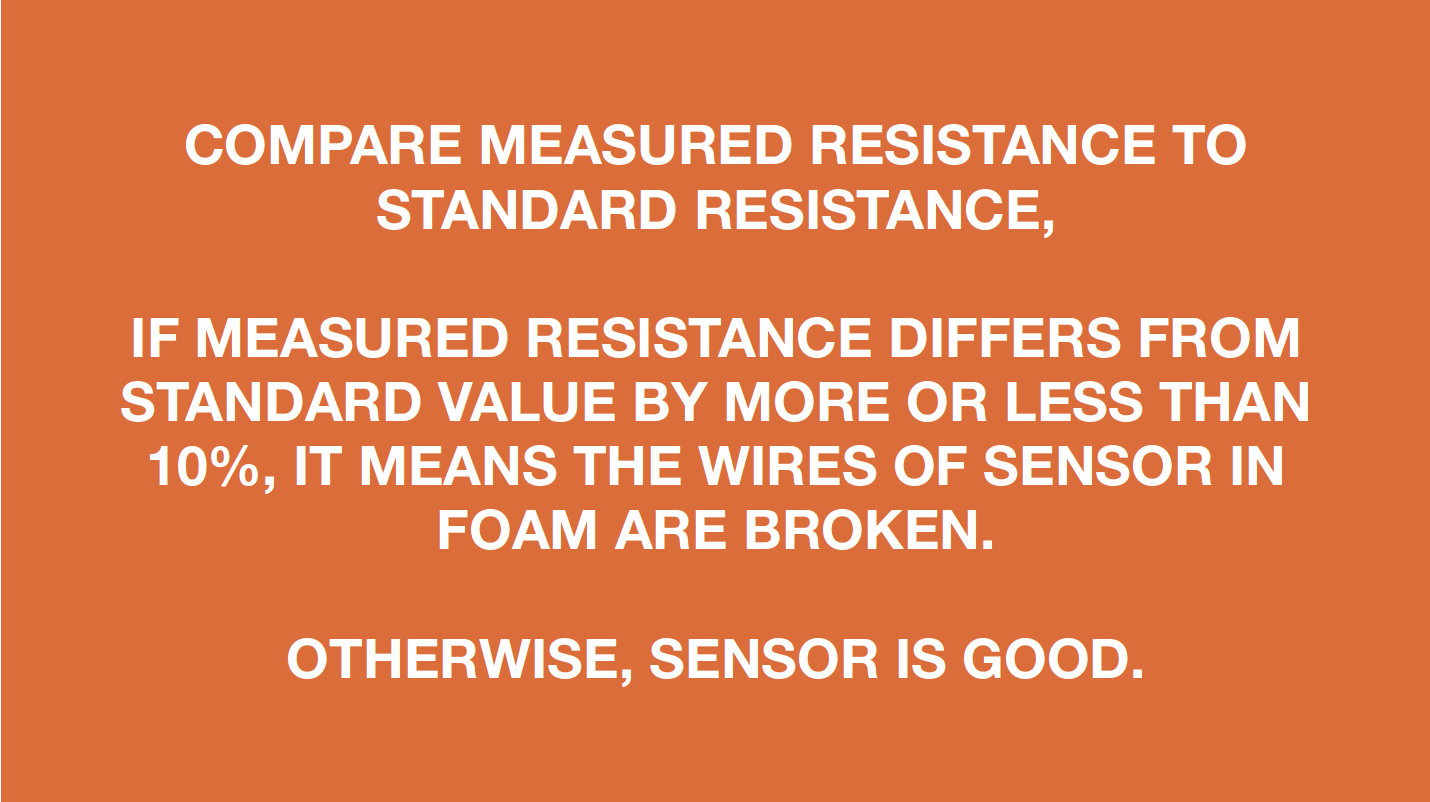

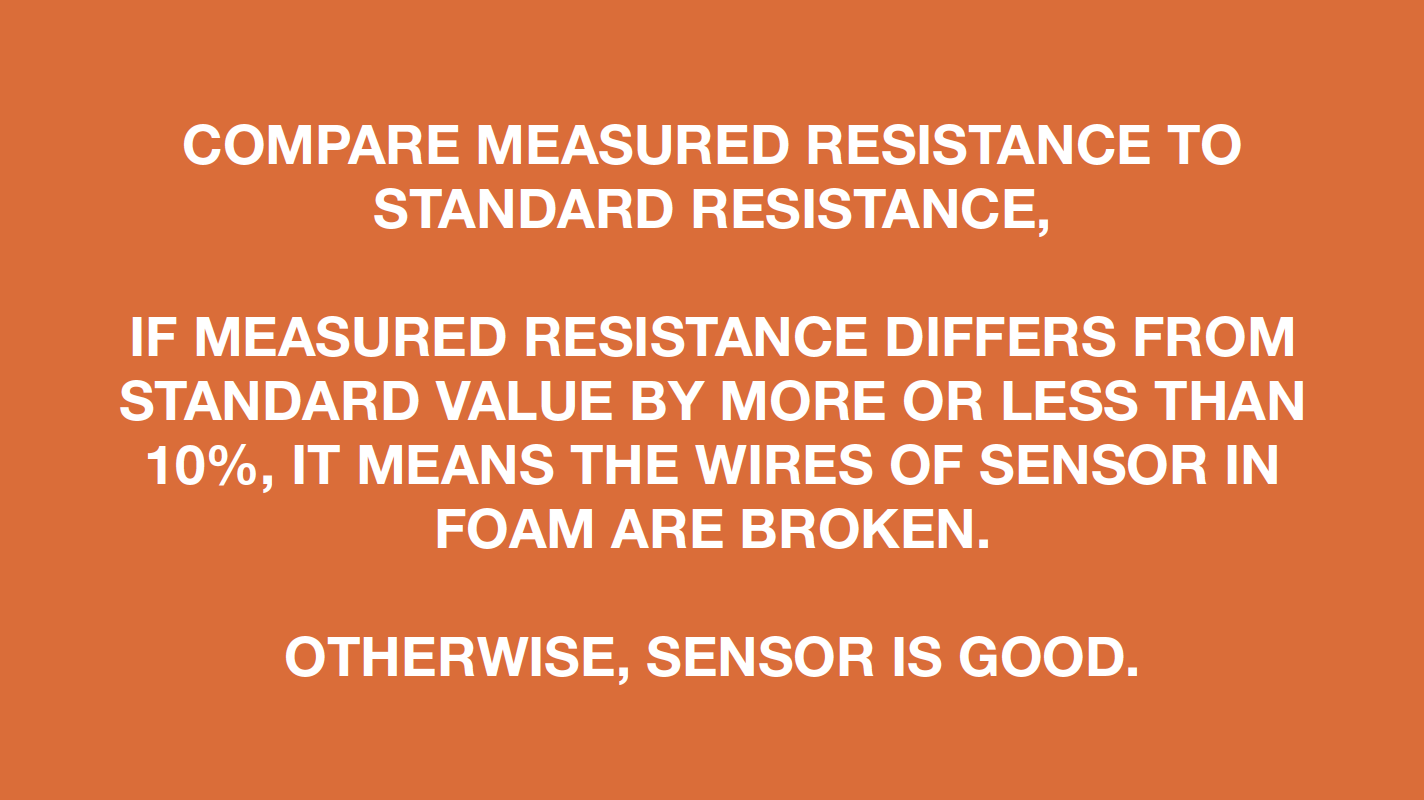

DIAGNOSIS 2

PROCEDURE 2

Step 1

Disconnect the terminal.

Step 2

Cut off plastic tie.

Step 3

Take sensor out of the

plastic buckle.

REVERSE STEPS

ABOVE TO INSTALL

DEFROST SENSOR.

CHECK AND TEST 3

Step 1

Check to see if the

terminal is full of foam.

IF SO, USE TWEEZERS

TO CRUSH AND

REMOVE FOAM.

Step 2

Make sure sensor is

properly located by

comparing with photo

on right.

IF SENSOR IS NOT IN

SAME POSITION AS

PHOTO, FIX IT.

Step 3

Check to see if sensor wires have been cut off; if so, follow procedures below to rework.

DIAGNOSIS 3

PROCEDURE 3

Step 1

Cut off the wire.

Step 2

Peel off the sleeves

Step 3

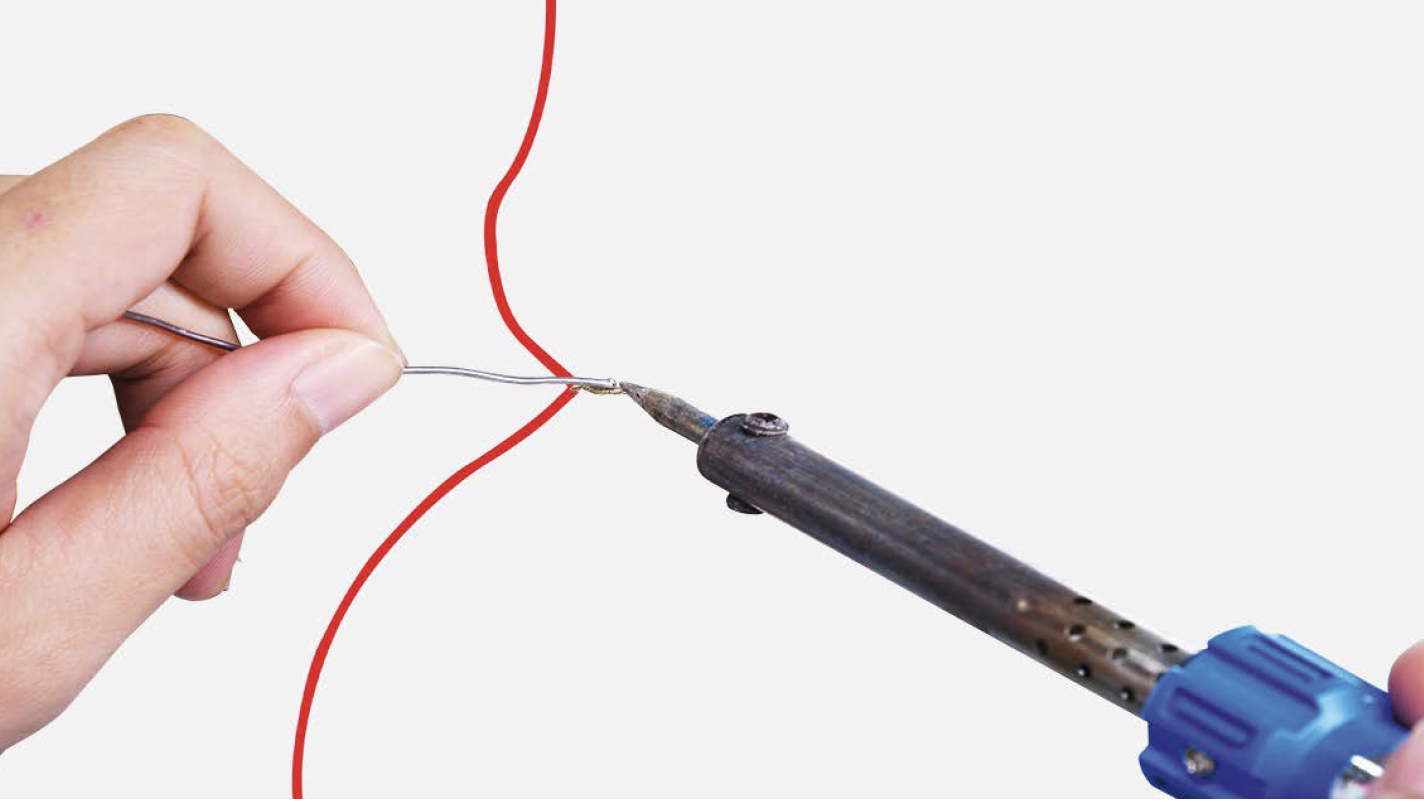

Check for proper wire order, then connect them.

Step 4

Tin soldering.

Step 5

Cover point of connection with electrical tape.

CHECK AND TEST 4

Step 1

After confirming the sensor and terminals are OK, or replace the sensor, reconnect the terminal.

Step 2

Use a multimeter to measure the resistance value of defrost temp. sensor from terminal located in mainboard area.

a. Insert the detectors

into terminal and

make sure connection

is good;

b. Read the value;

Step 3

Measure the temperature of defrost temp. sensor.

Note

DIAGNOSIS 4

Tip 1

When installing the air duct, make sure to move wires out of the way to prevent crushing by air duct.

Tip 2

After pushing air duct back into position, you should hear a clicking sound. If not, repeat again.

Tip 3

Check to see whether there is a wide gap between air duct and cabinet. If so, reinstall air duct again.

Tip 4

Check to ensure latches are properly inserted into cavities.

Tip 5

First, insert top of cover plate into the gap, then bend plate to insert the bottom. Lastly, snap middle into slot.