CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a cross-head screwdriver.

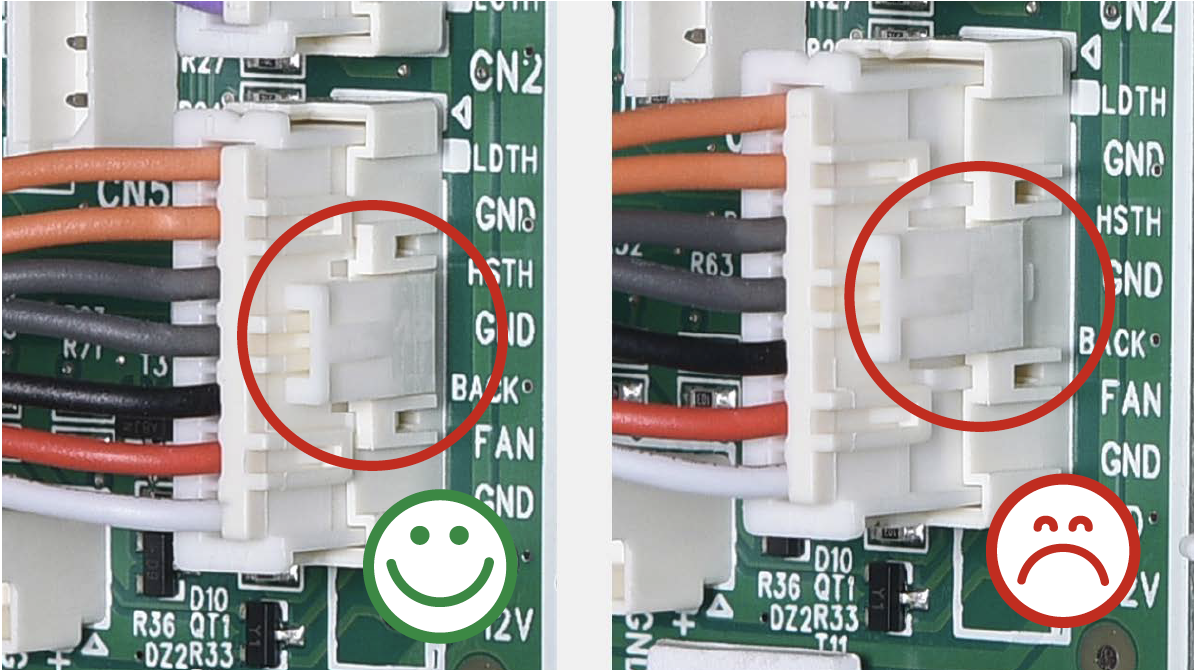

Step 2

In mainboard area, check if terminal is inserted to proper final position.

If not, reinsert it to final position.

Step 3

Power on the appliance, open the freezer door (fridge door can be opened or closed), heat freezer temp. sensor and put your hand near outlet of freezer air duct to feel if fan is blowing or not.

DIAGNOSIS 1

CHECK AND TEST 2

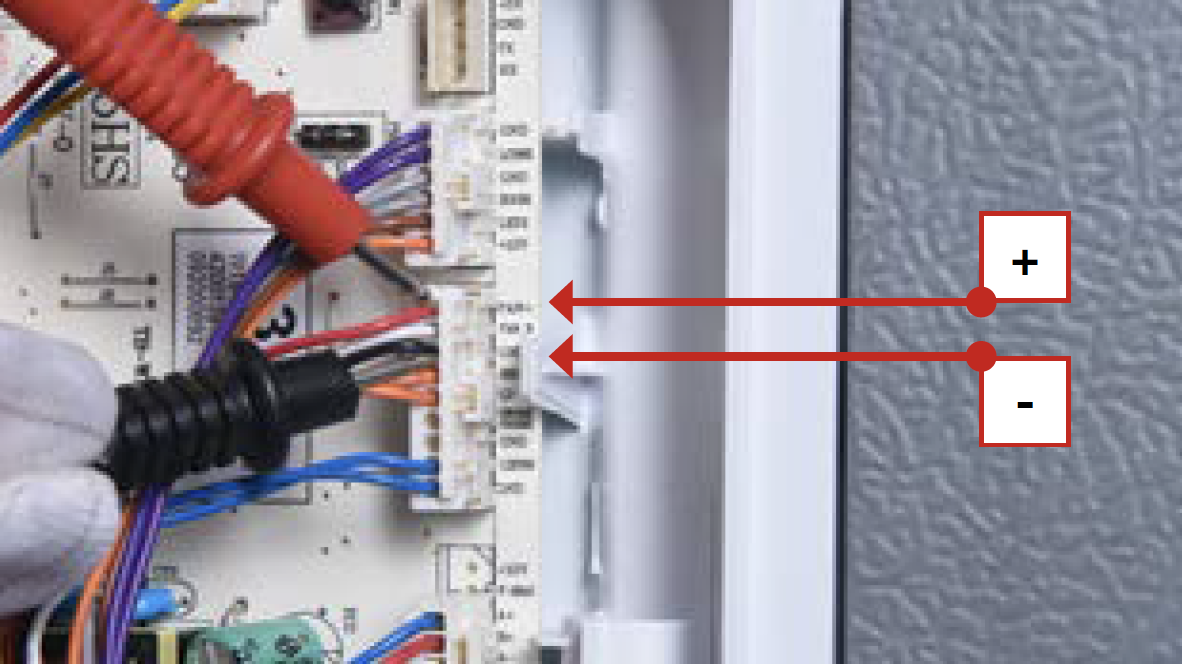

Step 1

Turn power output of transformer to DC 12V.

Step 2

Supply power from terminal in PCB area (FAN & GND).

Step 3

Put your hand near outlet of freezer air duct to feel if fan is blowing or not.

DIAGNOSIS 2

PROCEDURE 1

Step 1

Remove all freezer drawers.

Step 2

Remove all glass shelves.

Step 3

Unscrew the screws on

air duct.

a. Check the freezer air

duct to find the three

screw covers.

b. Remove the screw covers (total of three) on the air duct with slotted screw driver.

c. Unscrew the screws (total three) with Cross-head screw driver.

Step 4

Dismantle the air duct.

a. Catch the bottom of

air duct and pull down

the air duct.

b. Pay attention to the connectors when pulling out the air duct.

c. Disconnect the

terminal for fan motor.

Disconnect the

terminal for freezer

temp. sensor.

d. Move the air duct out of the freezer compartment.

CHECK AND TEST 3

Step 1

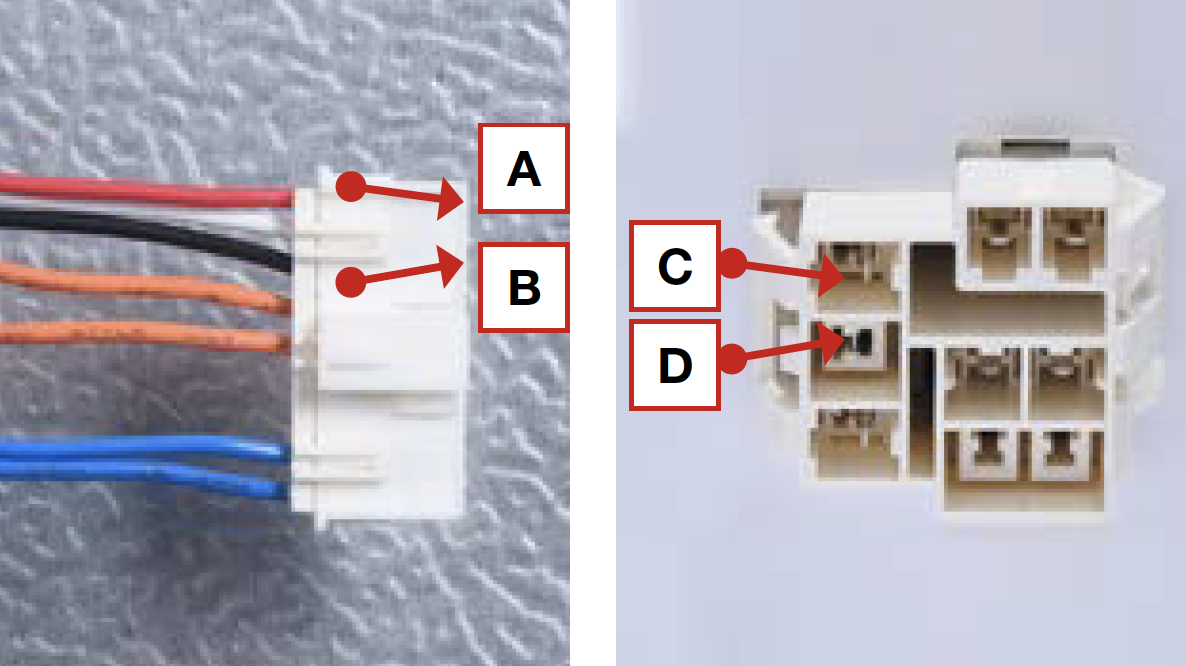

In duct area, check if terminal is pushed into final position. If not, reconnect it.

Step 2

Check whether terminal

is filled with foam.

If yes, please use

tweezers to clean and

remove the foam, and

reconnect it again.

DIAGNOSIS 3

CHECK AND TEST 4

Step 1

Check if wires of fan motor are damaged or not.

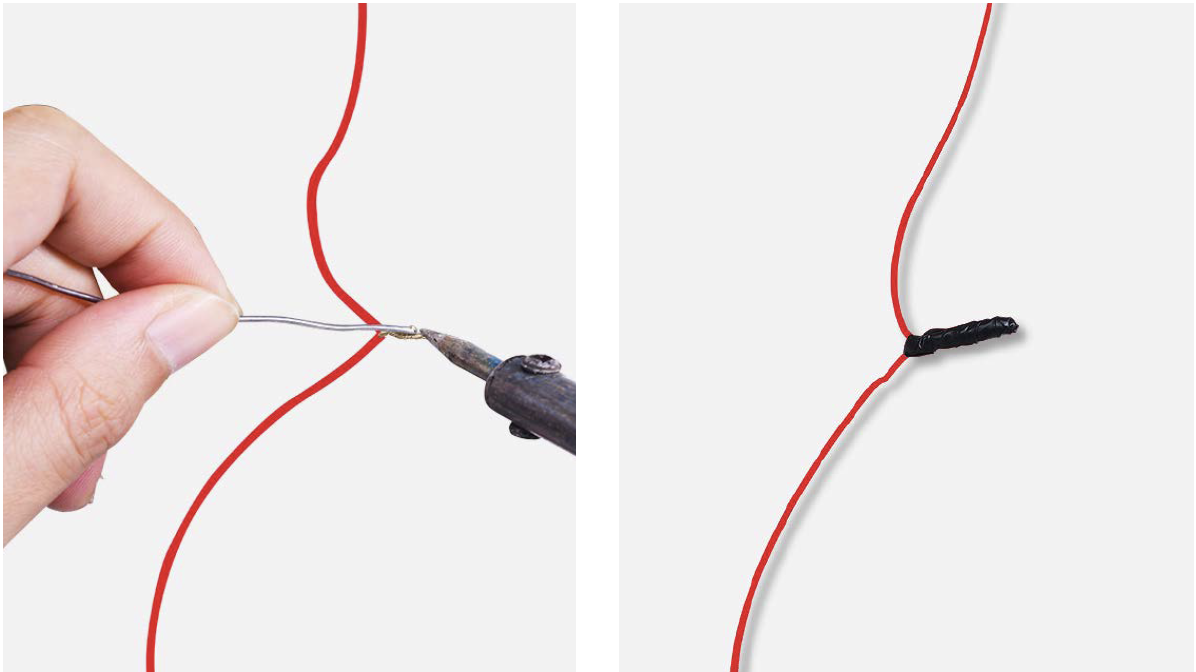

PROCEDURE 2

Step 1

Cut wire off.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and connect them.

Step 4

Tin soldering.

Step 5

Cover connection with electrical tape.

CHECK AND TEST 5

Step 1

Set output of transformer to DC 12V to test fan from the terminal behind the air duct.

Step 2

Use power source to test fan from terminal in the back of air duct.

DIAGNOSIS 1

Note

CHECK AND TEST 5

Step 1

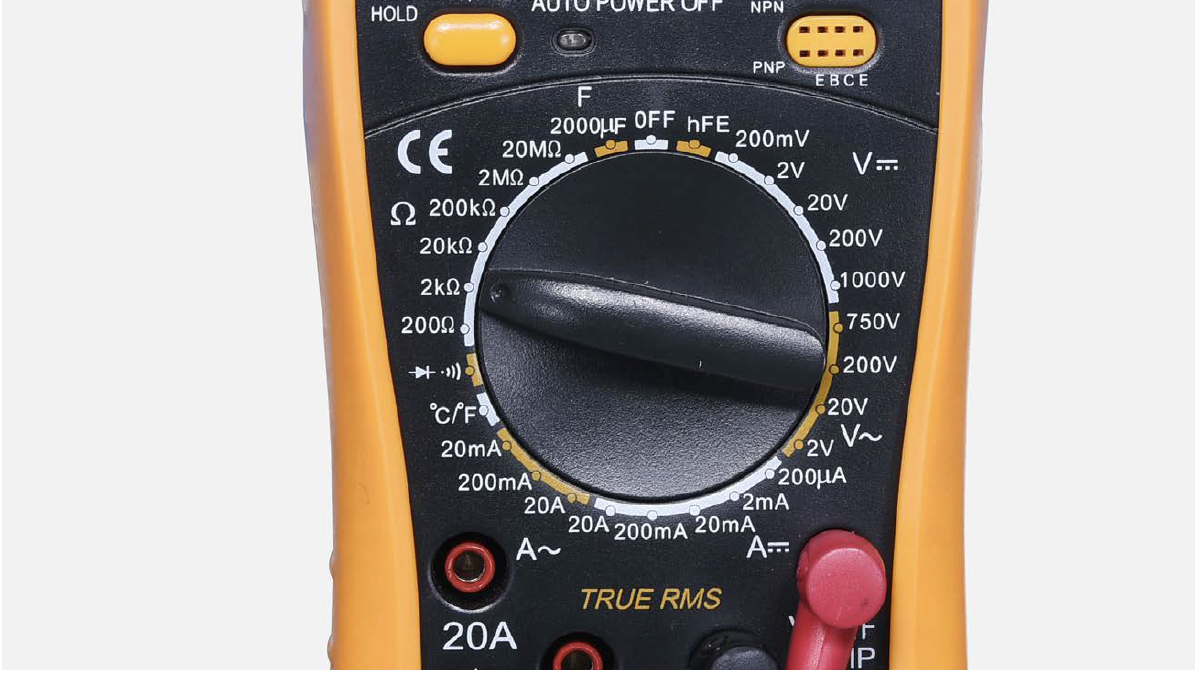

Set multimeter to resistance gear.

Step 2

Put one detector into end of wires in PCB area, and another detector into end of wires behind air duct.

Note

Tip 1

Make sure the sealing sponges are in good condition.

Tip 2

When reinstalling the air duct, fasten the wires to avoid crushing with air duct.

Tip 3

Install the top side first when installing the air duct.

Tip 4

After pushing air duct into place, you should hear a clicking sound. If not, repeat again.

Tip 5

Check to see if there is

a wide gap between air

duct and cabinet. If there

is, reinstall air duct.