CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

In PCB area, check if terminal is inserted to final position.

If not, reinsert it to final position.

Step

Measure resistance of heater from terminal in PCB area.

Step 4

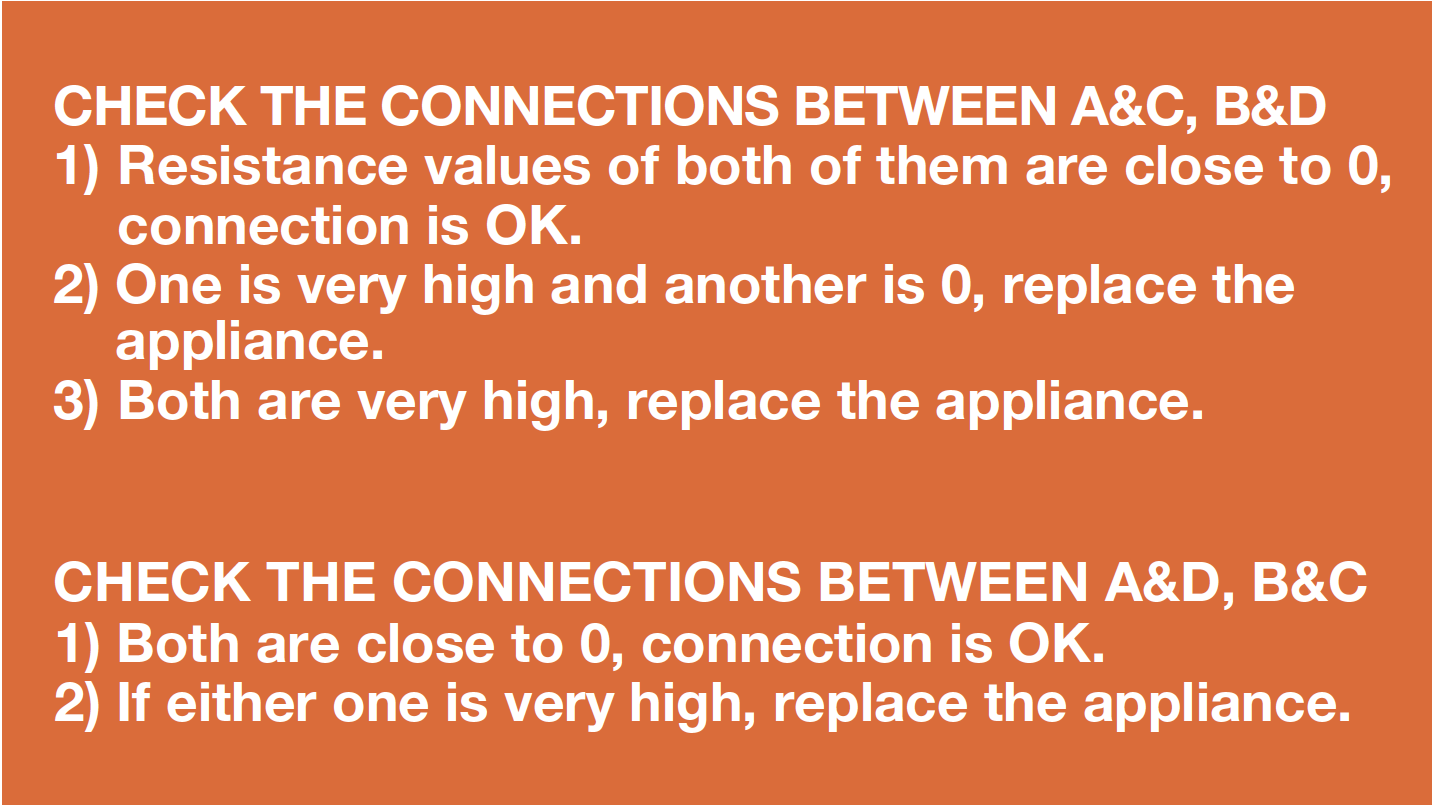

Check the result.

DIAGNOSIS 1

PROCEDURE 1

GENERAL DISASSEMBLY PROCEDURES FOR FREEZER AIR DUCT.

Step 1

Remove all freezer drawers.

Step 2

Remove all glass shelves.

Step 3

Unscrew the screws on air duct.

a. Check the freezer air duct to find the three screw covers.

b. Remove the screw covers (total of three) on the air duct with slotted screw driver.

c. Unscrew the screws (total three) with Cross-head screw driver.

Step 4

Dismantle the air duct.

a. Catch the bottom of air duct and pull down the air duct.

b. Pay attention to the connectors when pulling out the air duct.

c. Disconnect the

terminal for fan motor.

Disconnect the

terminal for freezer

temp. sensor.

d. Move the air duct out of the freezer compartment.

CHECK AND TEST 2

Step 1

Check if terminal is pushed properly into final position.

Step 2

Check if the terminal is stuffed with foam.

Step 3

Check if wires of defrost

heater are broken.

If yes, follow procedures

to

replace the heater.

Step 4

Measure resistance of heater from terminal in freezer.

DIAGNOSIS 2

PROCEDURE 2

Step 1

Disconnect terminal of heater.

Step 2

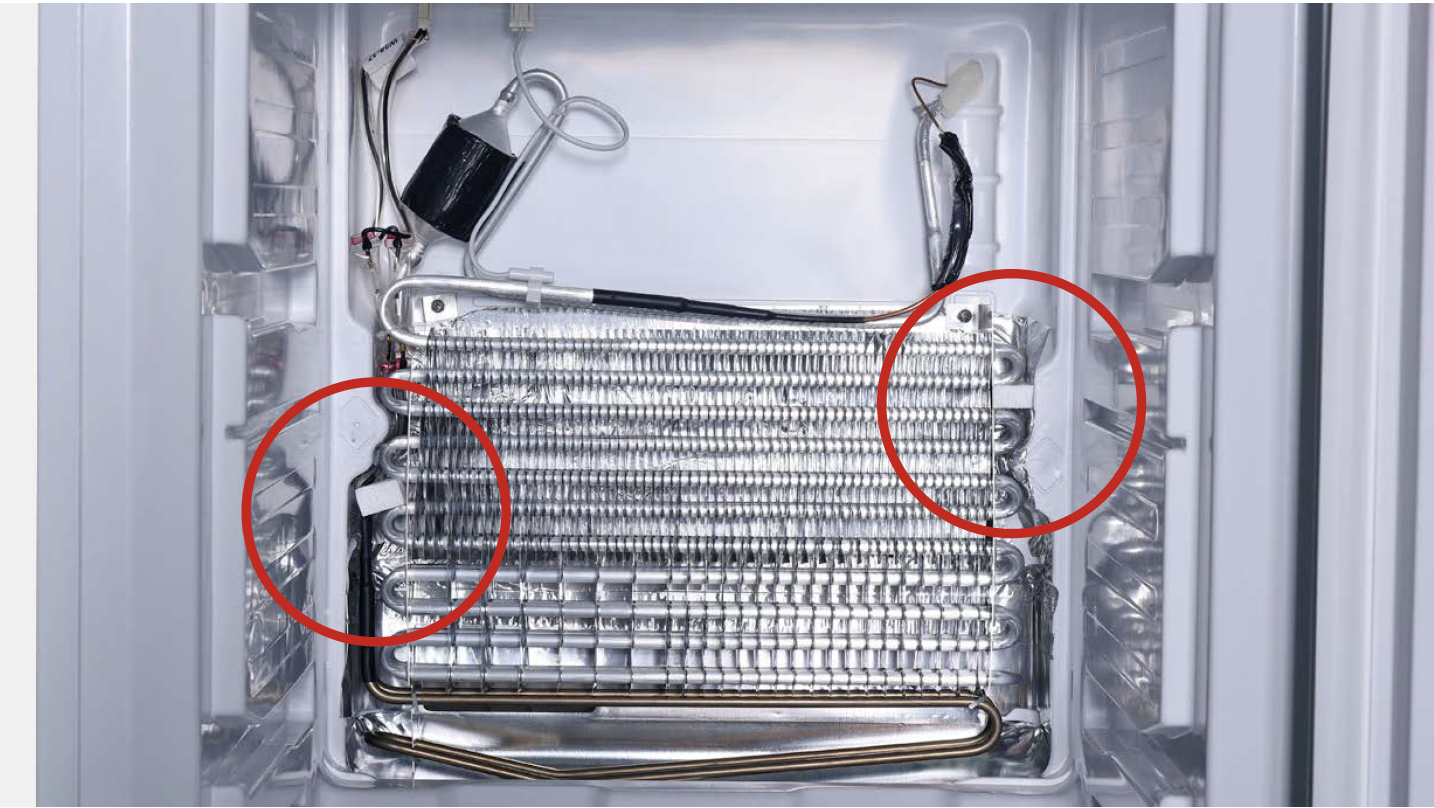

Unscrew the two screws with 6mm Philips driver.

Step 3

Cut off the fastening strap.

Step 4

Take out the holding foam.

Step 5

Loosen heater fastening clips.

Step 6

Lift evaporator with heater up 20mm. Bottom of evaporator must be higher than the edge of water trough.

Step 7

Remove the heater.

WARNING:

Make sure not to deform pipes in red square during steps 5 to step 7.

Reverse steps above to reinstall the heater and pay attention to the key points below

Tip 1

Do not damage the wires of the heater while installing the new heater.

CHECK AND TEST 3

Step 1

Set multimeter to resistance gear.

Step 2

Put detector into one end of wires in PCB area.

Put another detector into end of wires behind air duct.

DIAGNOSIS 3

CHECK AND TEST 4

Step 1

Power on the appliance, and start manual defrost.

Case 1:

OUTSIDE DISPLAY

a) Press FREEZER button together with MODE button and hold for 5 seconds. Alarm will sound, freezer temperature shows 0 and flashes.

b) Then touch FREEZER

button continuously,

freezer temperature

will display 0, 1 and 3 in

a loop.

c) When freezer temperature displays 3, stop touching and manual defrost is selected.

Case 2:

INTERNAL TOP CONTROLLERa) Press TEMP button together with MODE button and hold for 5 seconds. Alarm will sound, freezer temperature shows 0 and flashes.

b) Then press Temp button continuously, temperature will display 0, 1 and 3 in a loop;

c) When temperature displays 3, stop pressing and manual defrost is selected.

Note

Step 2

Put your hand close to

defrost heater.

WARNING !!!

DO NOT TOUCH DEFROST HEATER

DIAGNOSIS 4

Tip 1

Make sure the sealing sponges are in good condition.

Tip 2

When reinstalling the air duct, fasten the wires to avoid crushing with air duct.

Tip 3

Install the top side first when installing the air duct.

Tip 4

After pushing air duct into place, you should hear a clicking sound. If not, repeat again.

Tip 5

Check to see if there is

a wide gap between air

duct and cabinet. If there

is, reinstall air duct.