CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

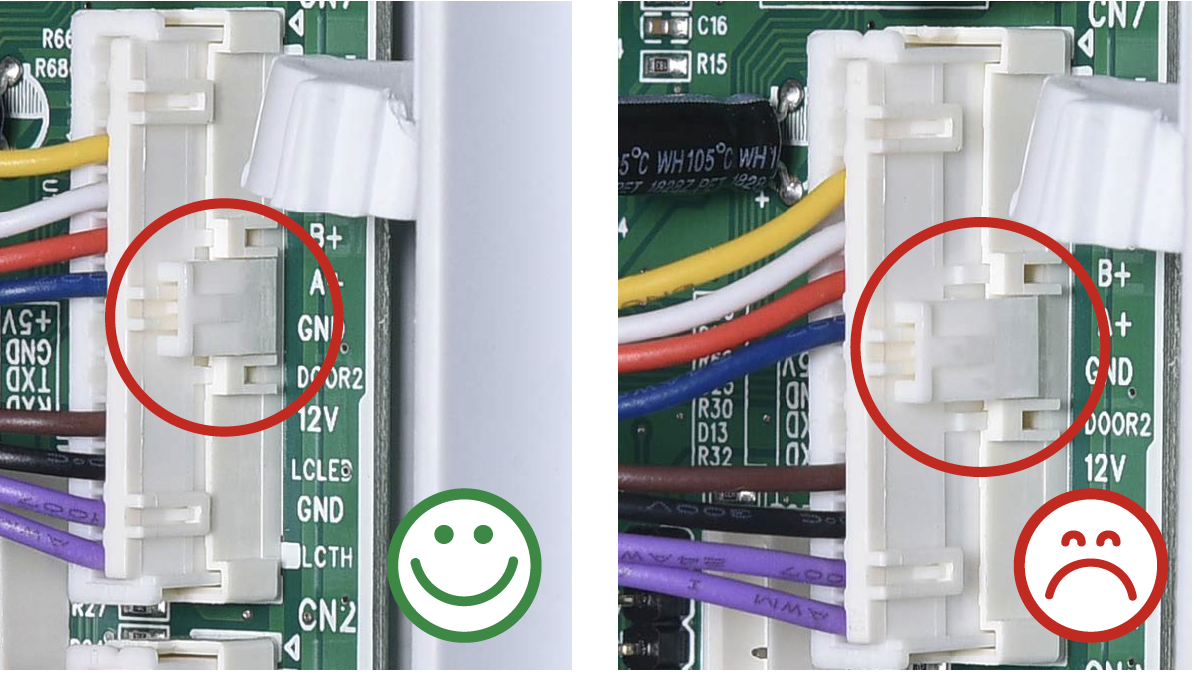

In mainboard area, check if terminal is pushed into proper final position.

Step 3

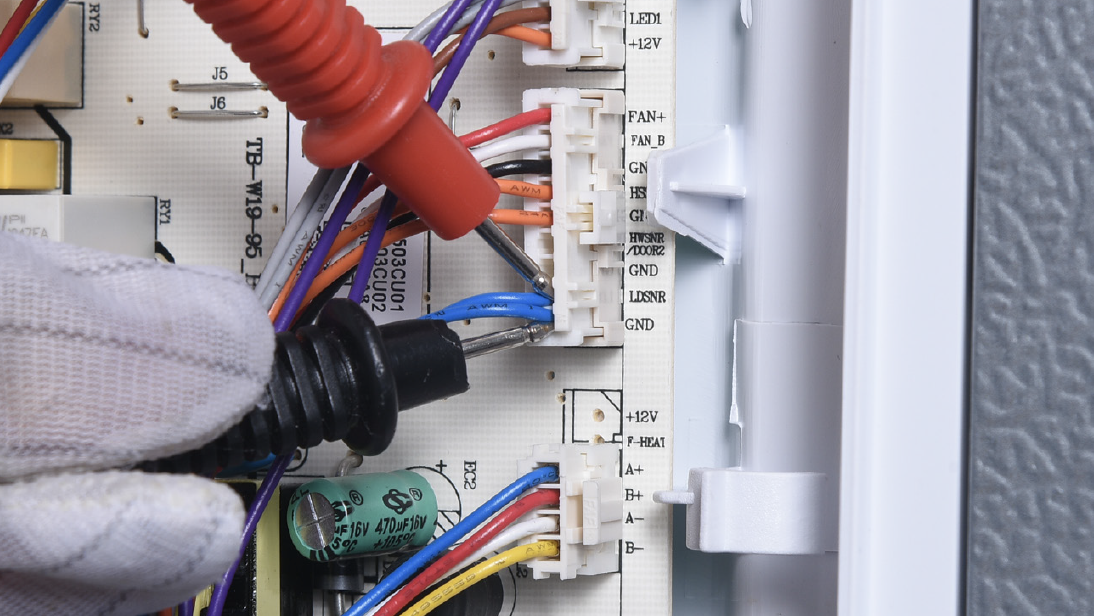

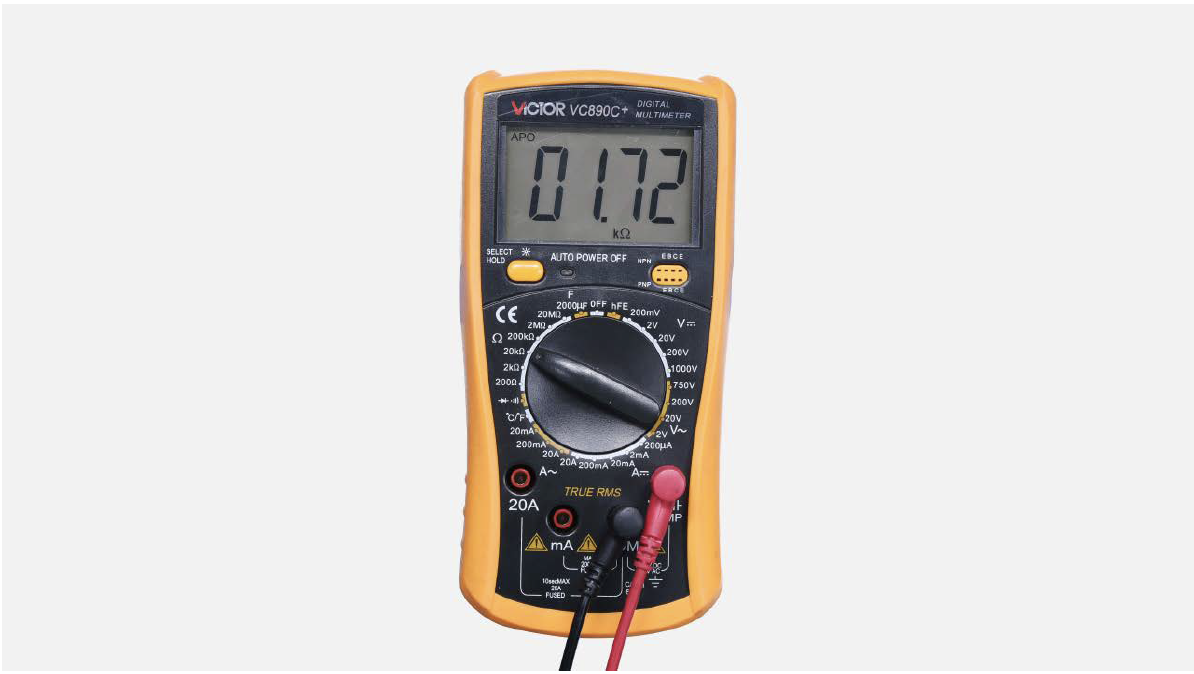

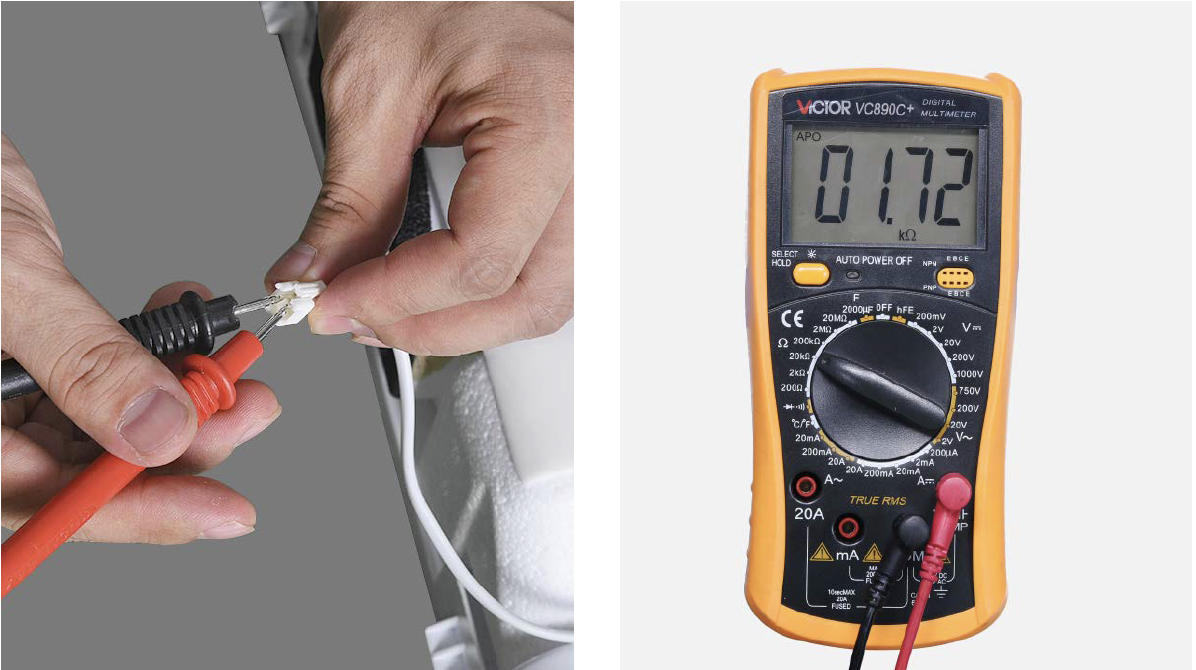

Set multimeter to resistance gear.

Step 4

Measure resistance of fridge temp. sensor from terminal in PCB area.

Step 5

Take note of value.

Step 6

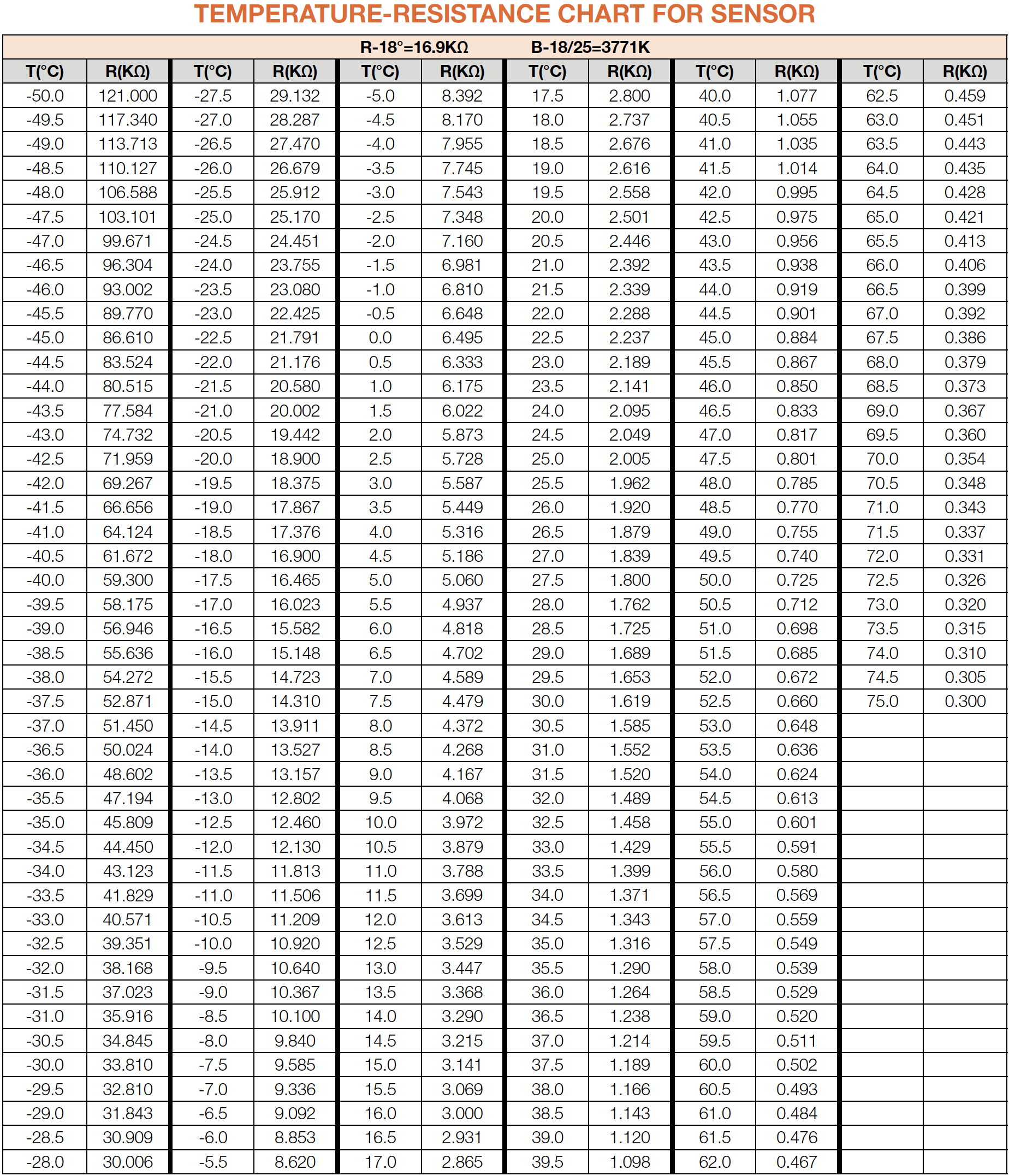

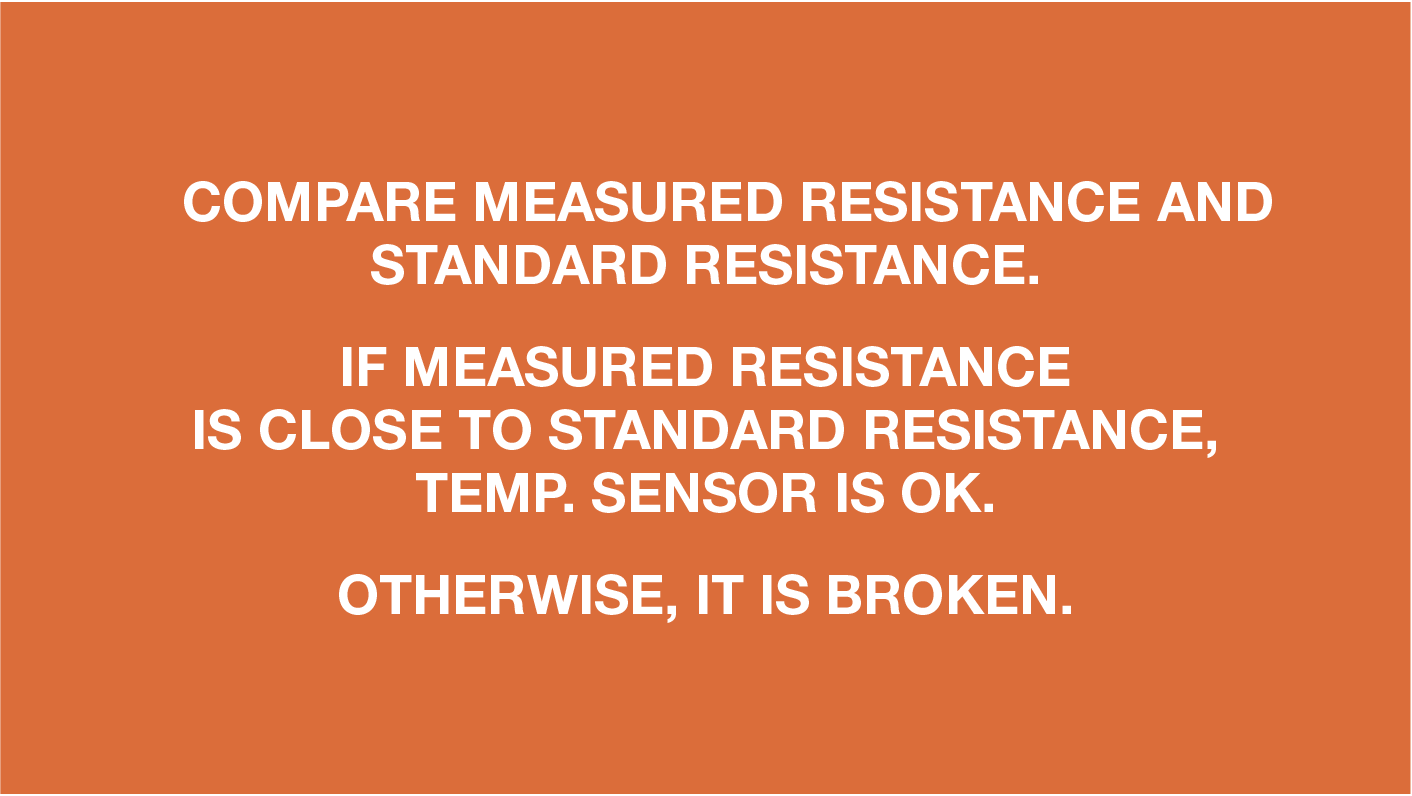

Measure the temperature of fridge temp. sensor. Use the measured temperature to find the standard resistance value in Temperature- Resistance Chart for Sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove crispers.

Step 2

Remove shelves.

Step 3

Loosen the decorative plate and remove.

Step 4

Remove the screw covers on the air duct with slotted screw driver.

Step 5

Unscrew the screws (total of three) with Cross-head screw driver.

Step 6

Lift the air duct up slightly and pull it out.

CHECK AND TEST 2

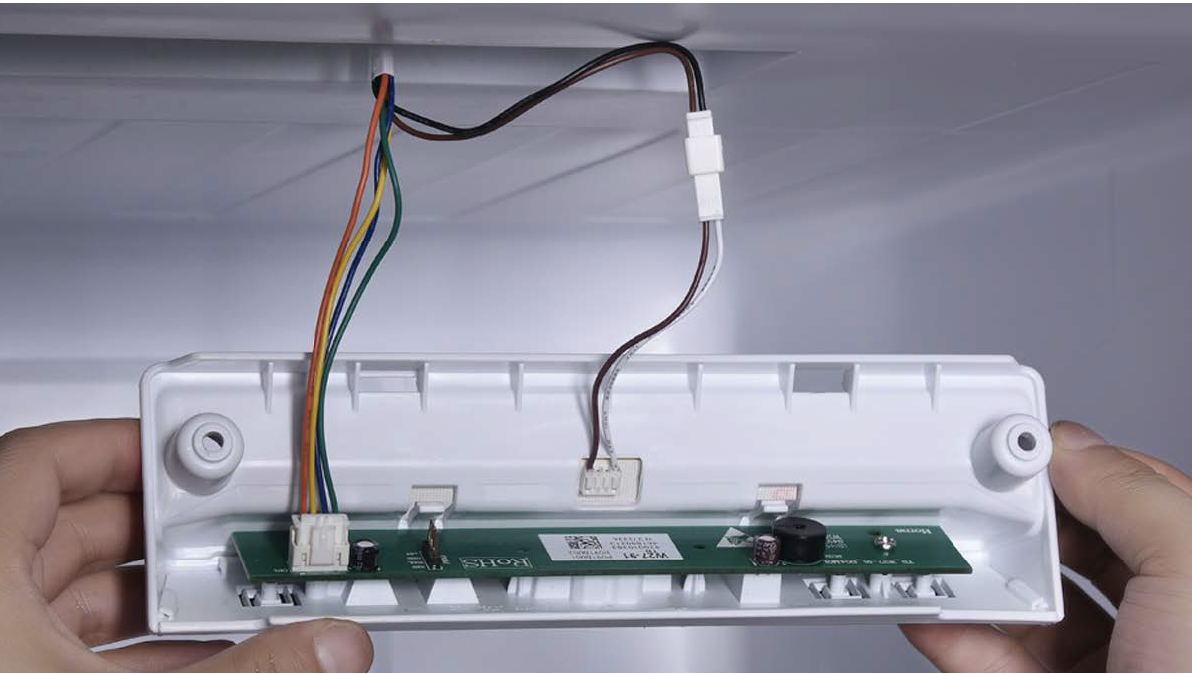

Step 1

Check if terminal is properly inserted to final position.

If not, reinsert it.

Step 2

Check if wires of fridge temp. sensor are damaged or not.

PROCEDURE 2

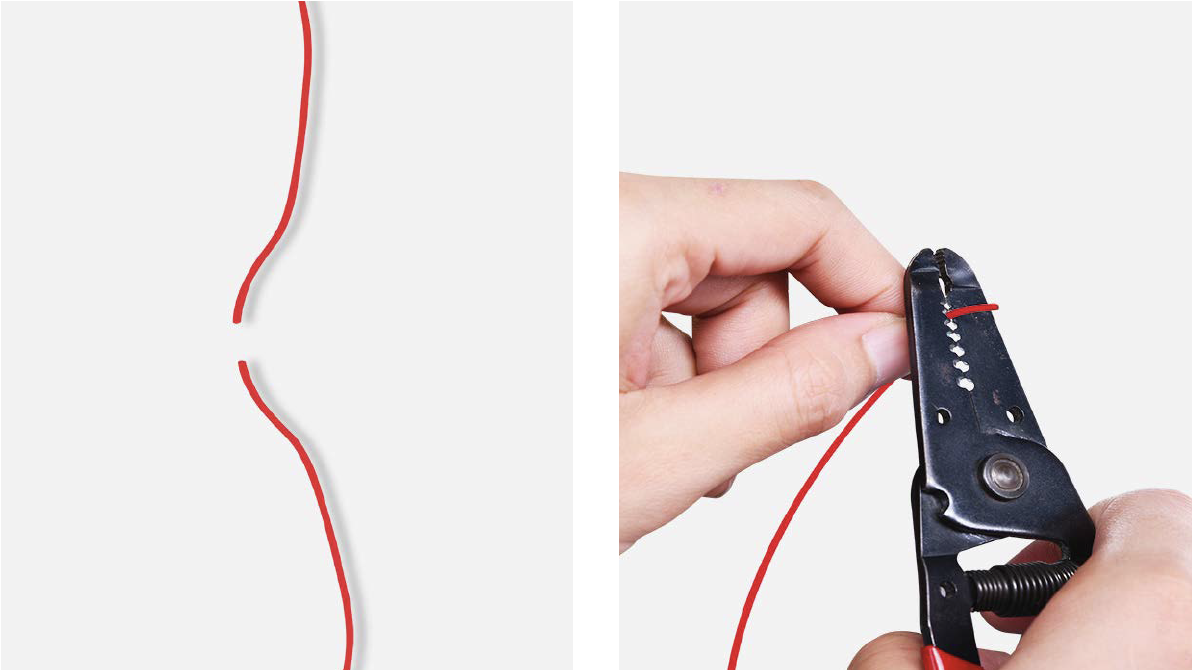

Step 1

Cut wire off.

Step 2

Peel off the sleeves.

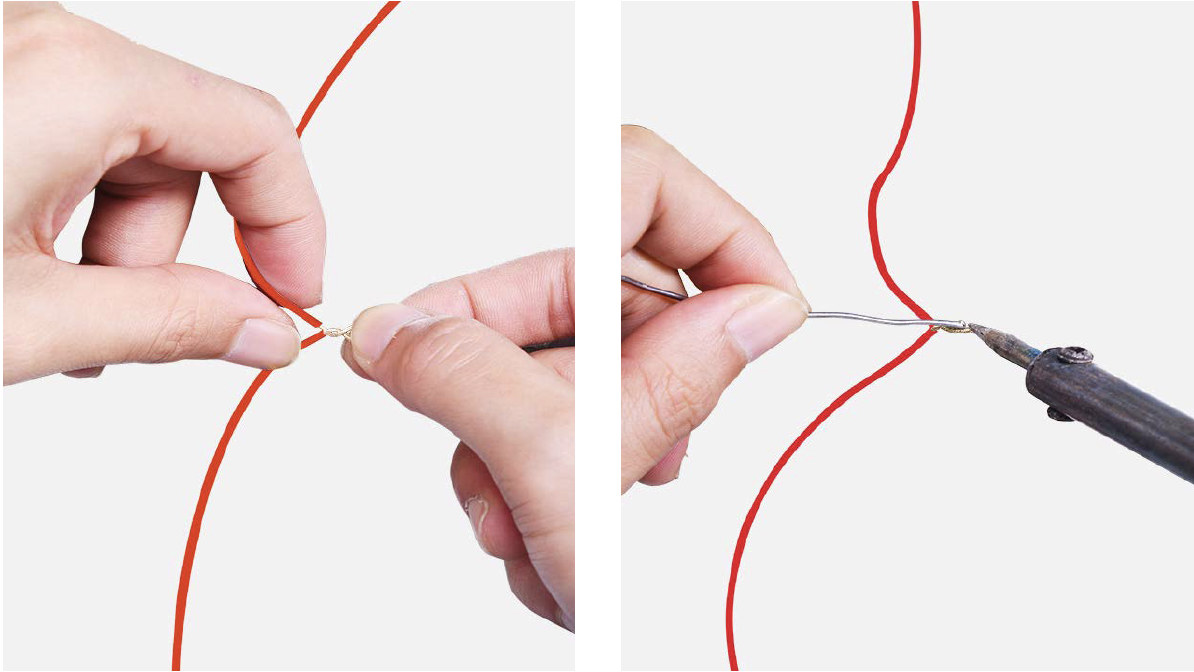

Step 3

Check to ensure proper wire order and reconnect them.

Step 4

Tin soldering.

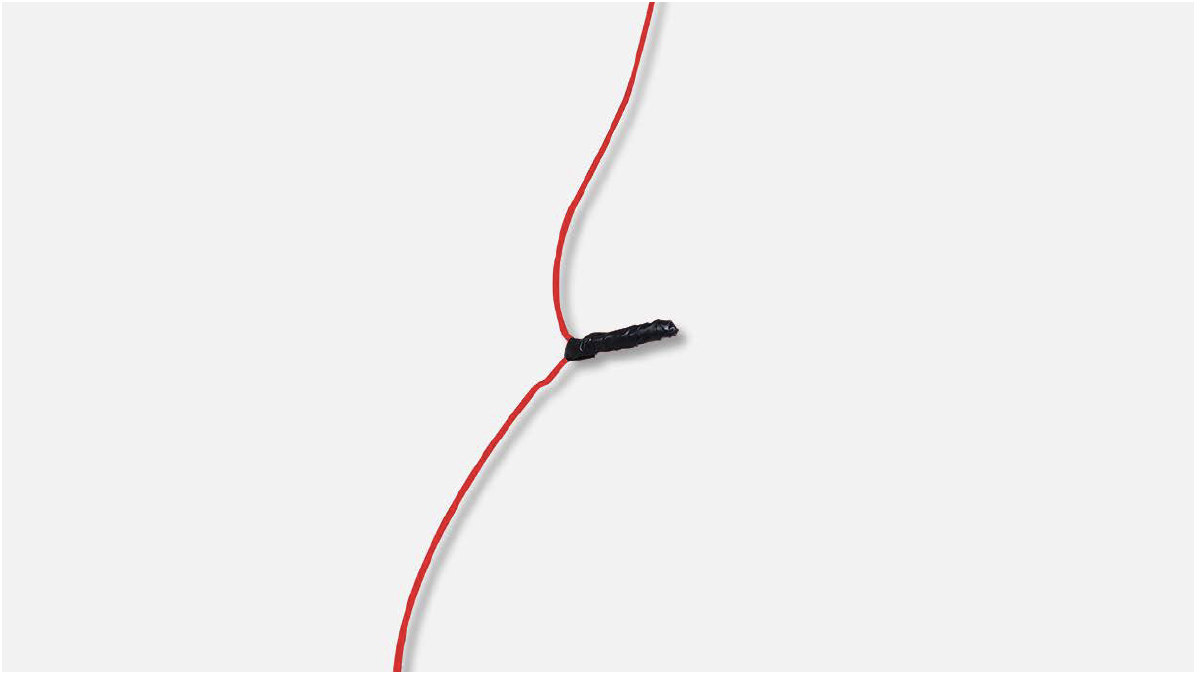

Step 5

Cover connecting point with electrical tape.

CHECK AND TEST 3

Step 1

Disconnect terminal of fridge temp. sensor.

Step 2

Measure resistance of fridge sensor from terminal in fridge air duct cover.

Step 3

Measure the temperature of fridge temp. sensor. Use the measured temperature to find the standard resistance value in Temperature- Resistance Chart for Sensor.

DIAGNOSIS 3

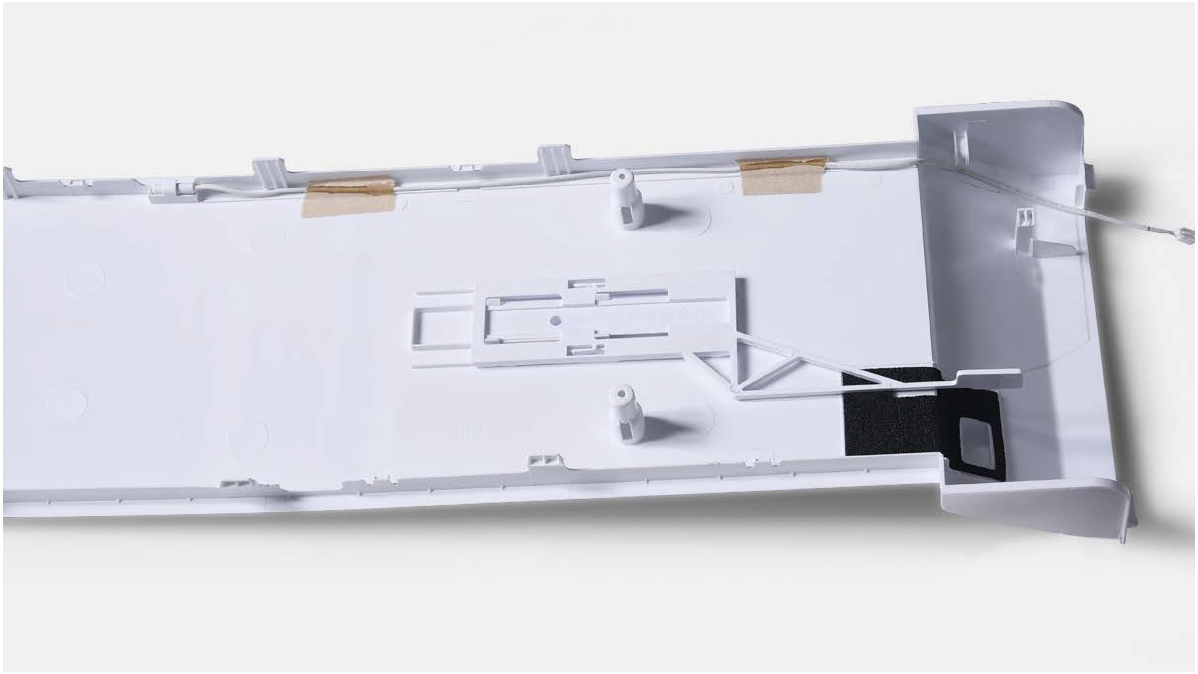

PROCEDURE 2

Step 1

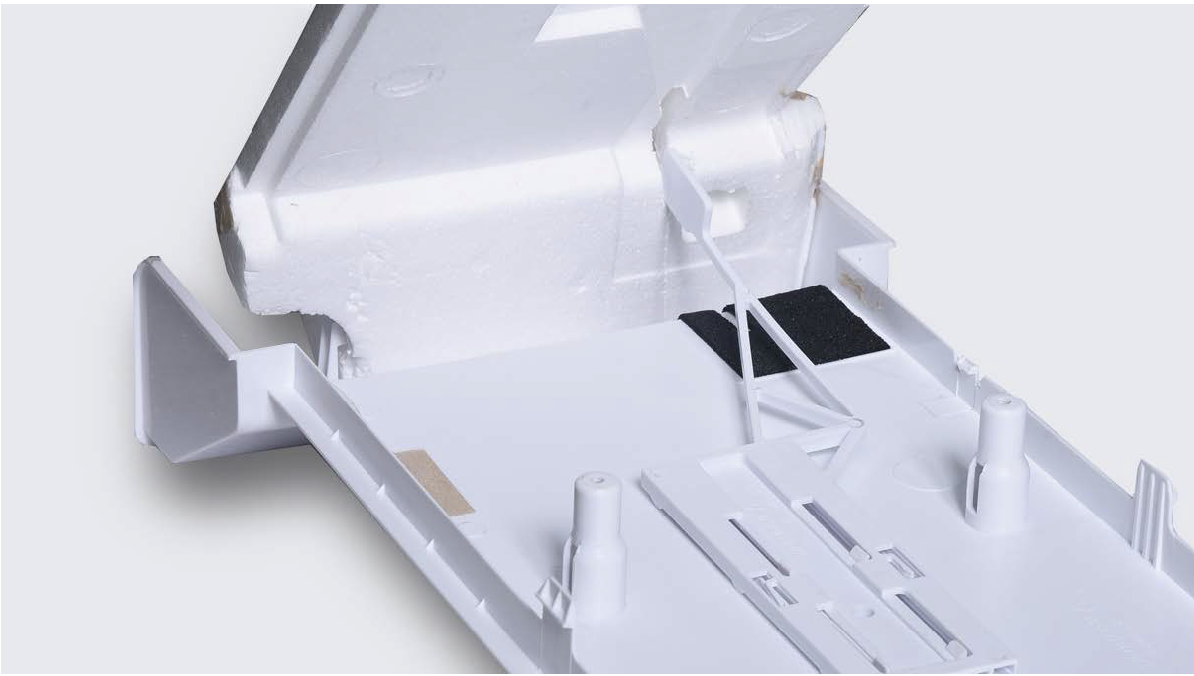

Release the clasp.

Step 2

Remove the foam air duct.

Step 3

Remove tape.

Step 4

Remove the broken

sensor, and replace it

with a new one.

Reverse steps above to reinstall the air duct.

Please pay attention to bellow key points.

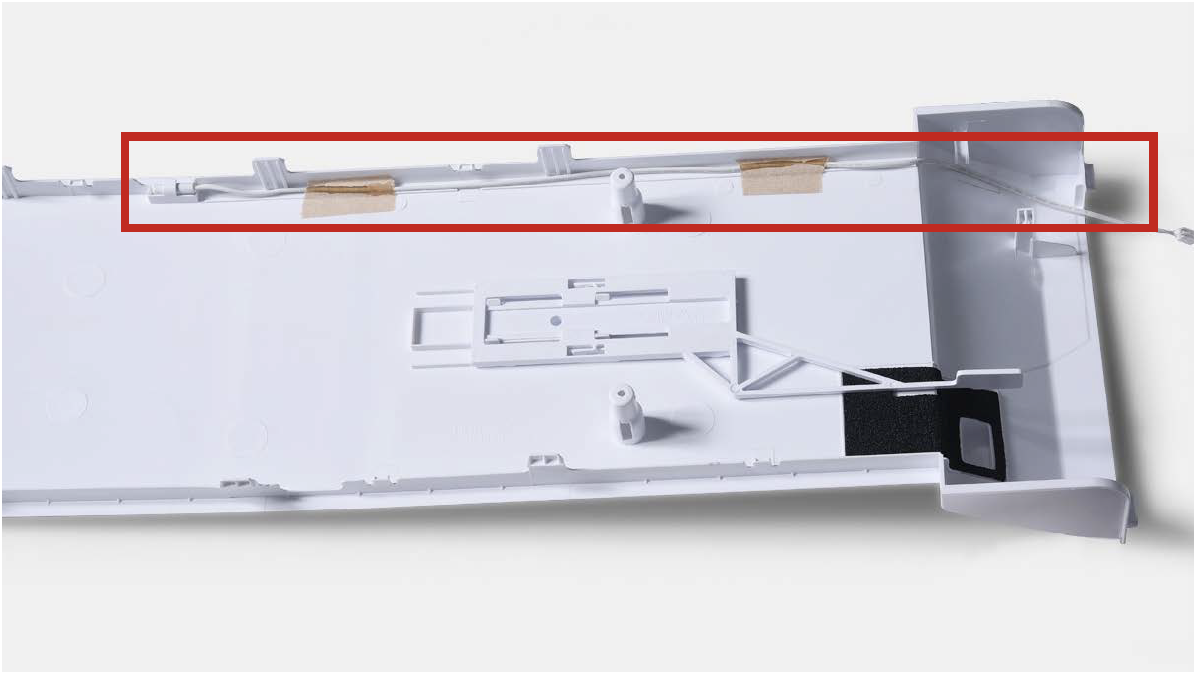

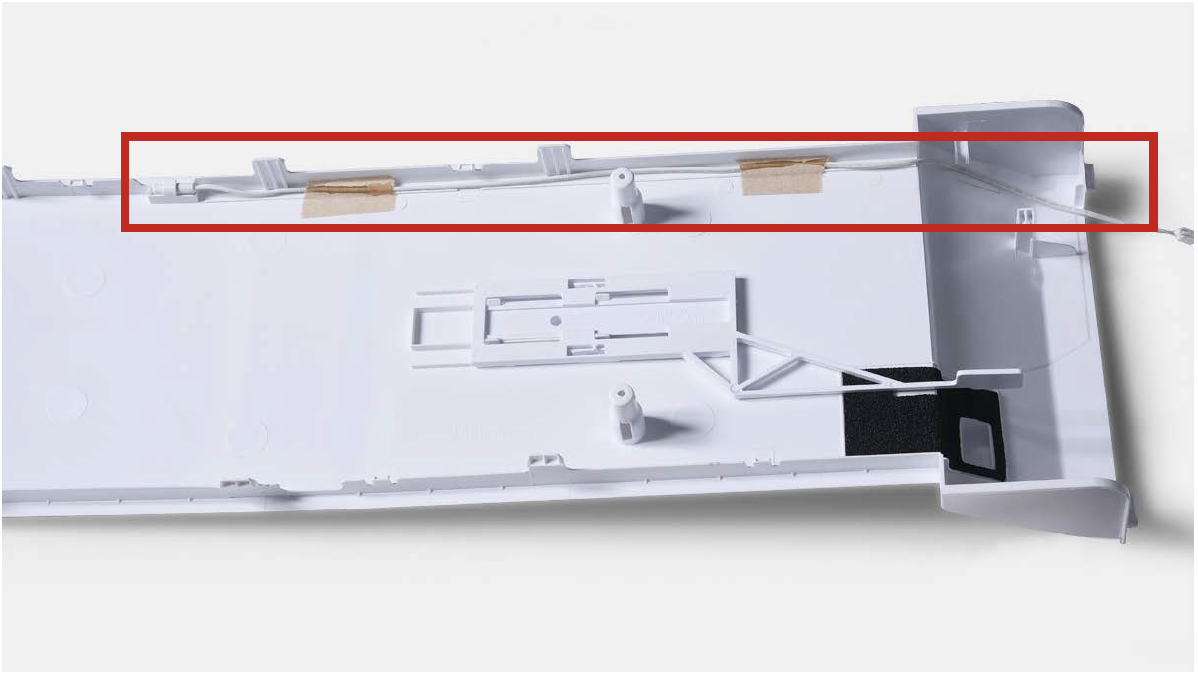

Tip 1

Attach the sensor properly onto air duct cover, as picture in right.

Tip 2

Make sure the sealing sponge is in good condition.

Tip 3

Make sure back cover of the air duct is not broken.

Tip 4

Make sure chiller temperature controller is installed to correct position.

CHECK AND TEST 4

Step 1

Set multimeter to resistance gear.

Step 2

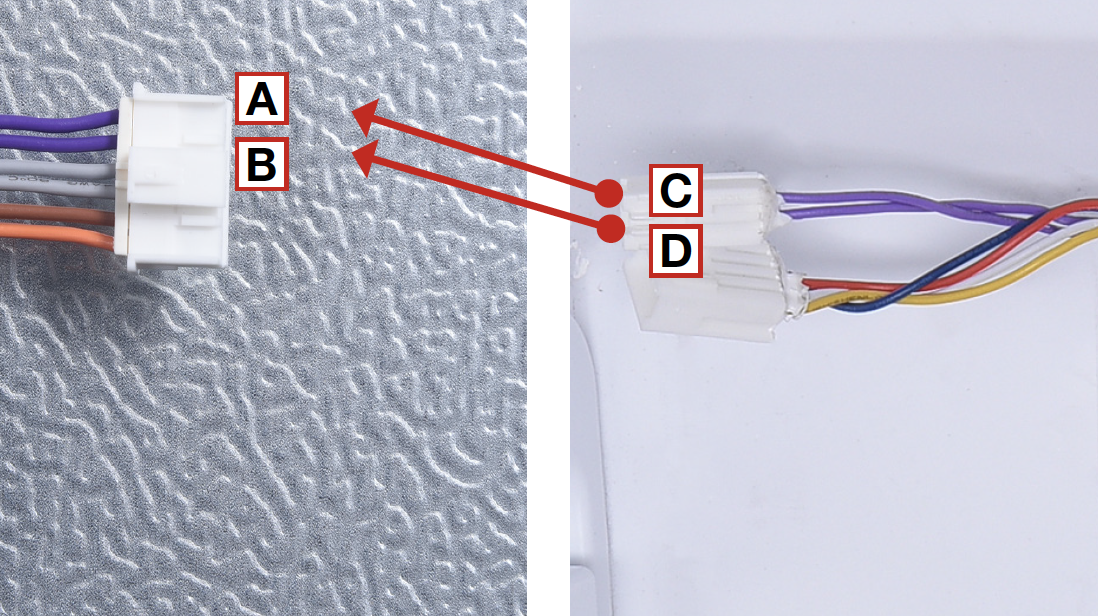

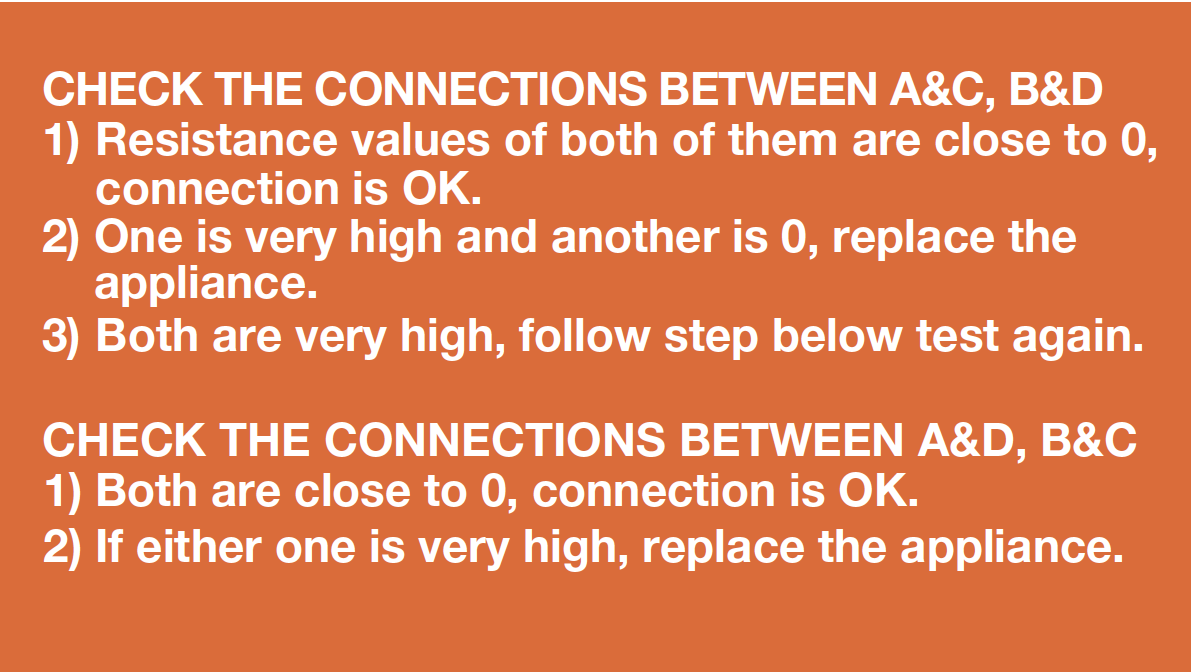

Put one detector into one end of wires in PCB area, and another detector into one end of wires in fridge air duct cover.

DIAGNOSIS 4

Tip 1

Push terminals into final position, and then move wires onto cavity to avoid crushing wires with edge of air duct.

Tip 2

When reinstalling the air duct, first put the positive end of buckle (on the bottom) into the negative end.

Tip 3

Later, fasten the buckles on the top with same method.

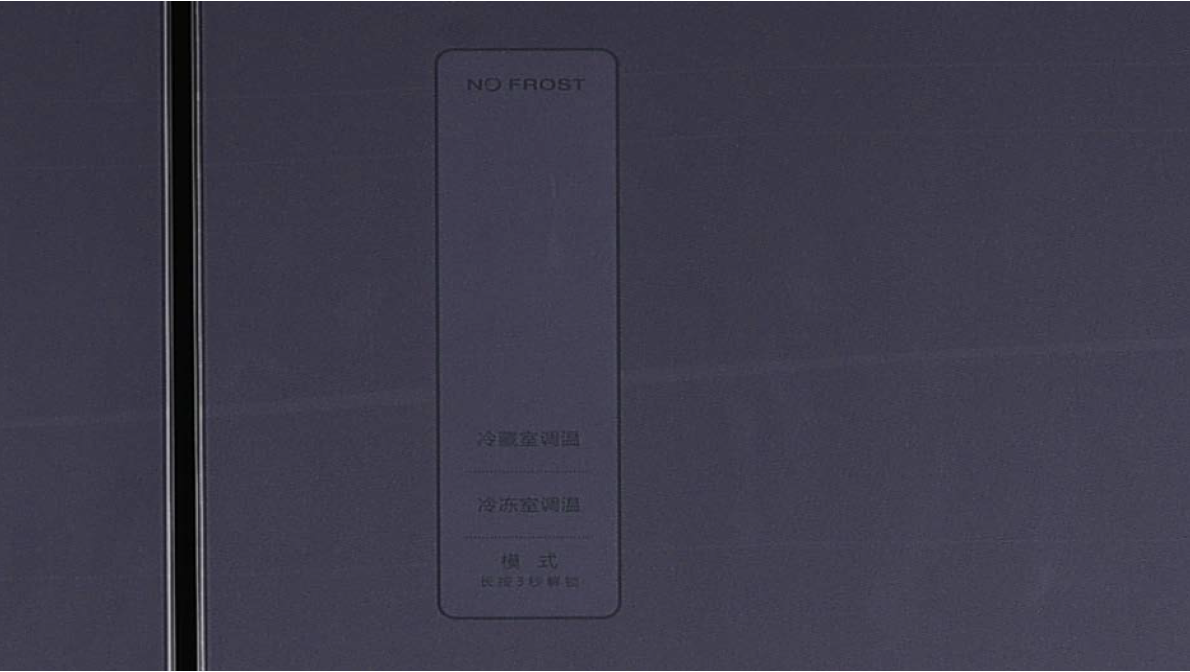

CHECK AND TEST 5

DIAGNOSIS 5

PROCEDURE 4

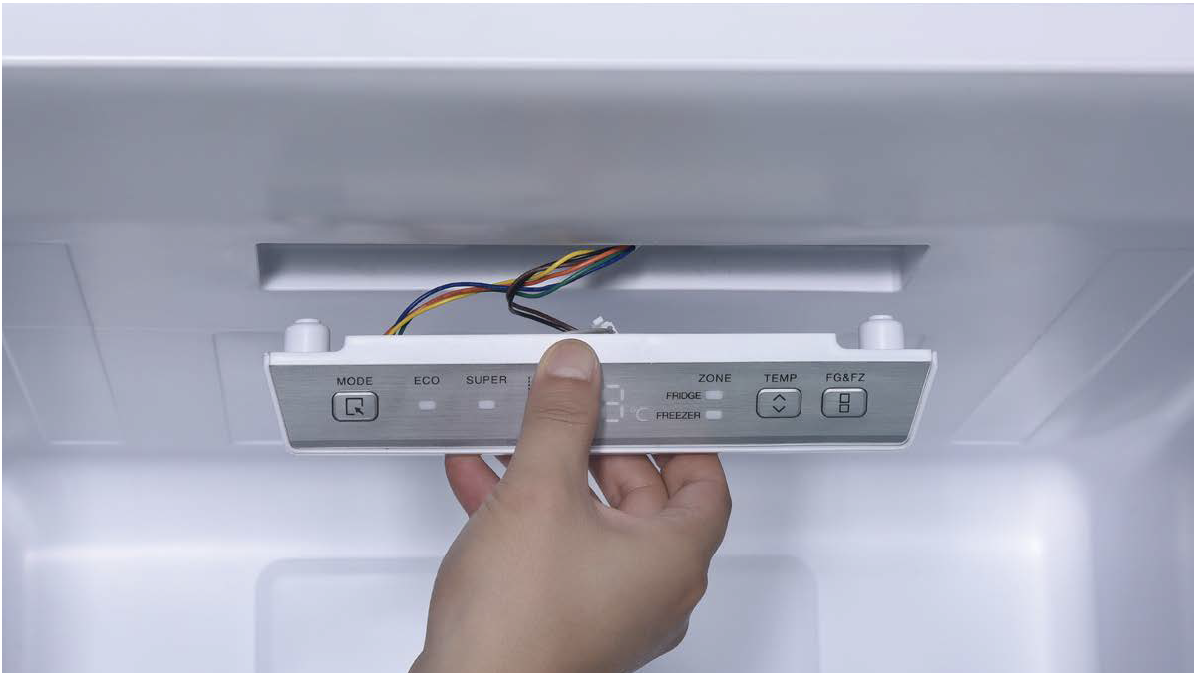

Step 1

Push a 6mm sucker onto display and turn the knob to strengthen suction force.

Step 2

Wrap a belt around knob to make it easier to pull out of display board.

Tips for installing display.

Tip 1

After connecting terminal, please use tape to fasten wires to avoid crushing with cover.

Tip 2

After putting display

into cavity, press edge

until you hear a clicking

sound, this means the

board is pushed into final

position.

Tip 3

Please press all buttons on display board to make sure it works well.

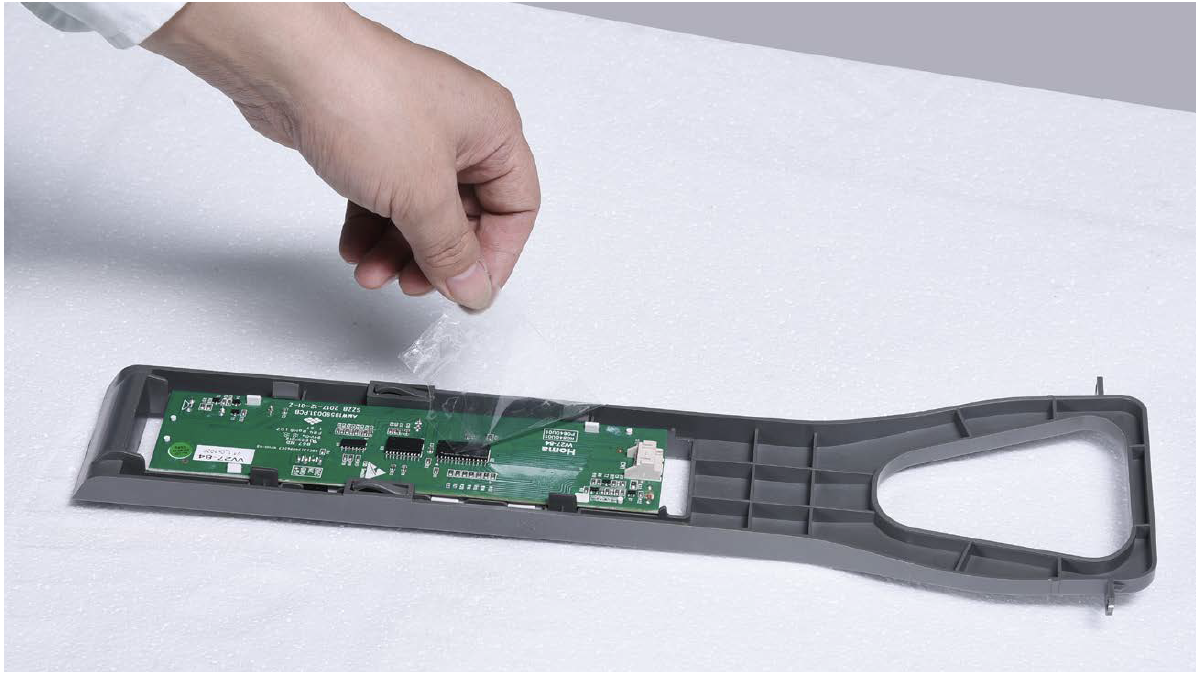

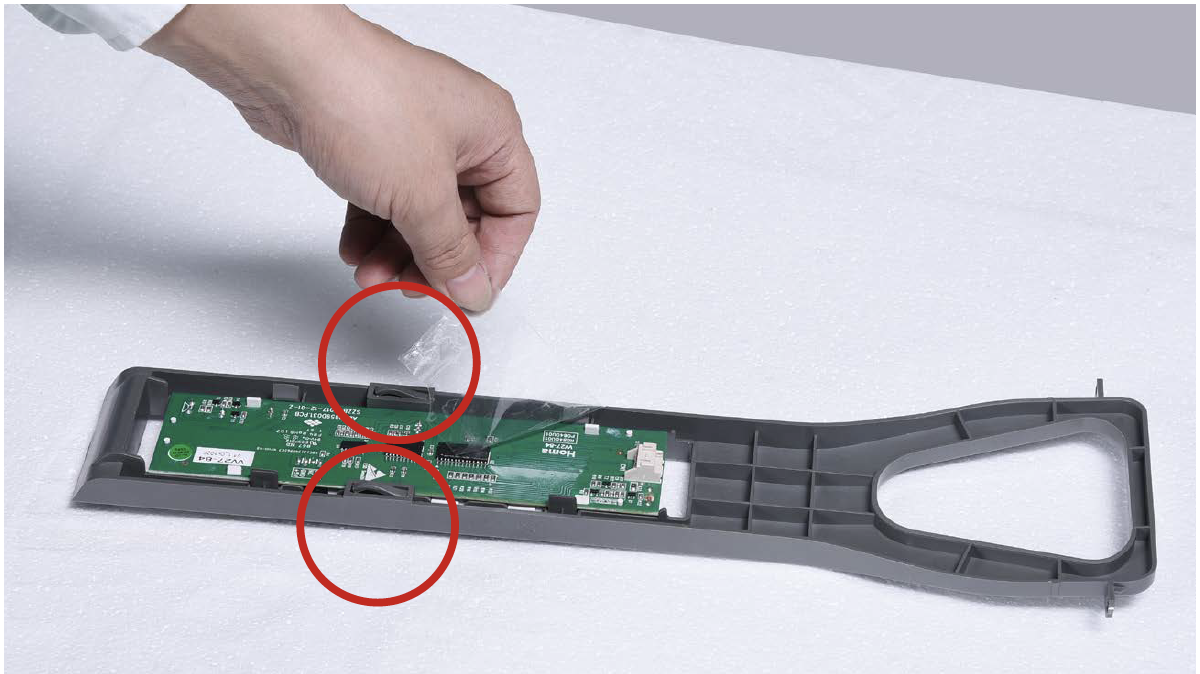

PROCEDURE 5

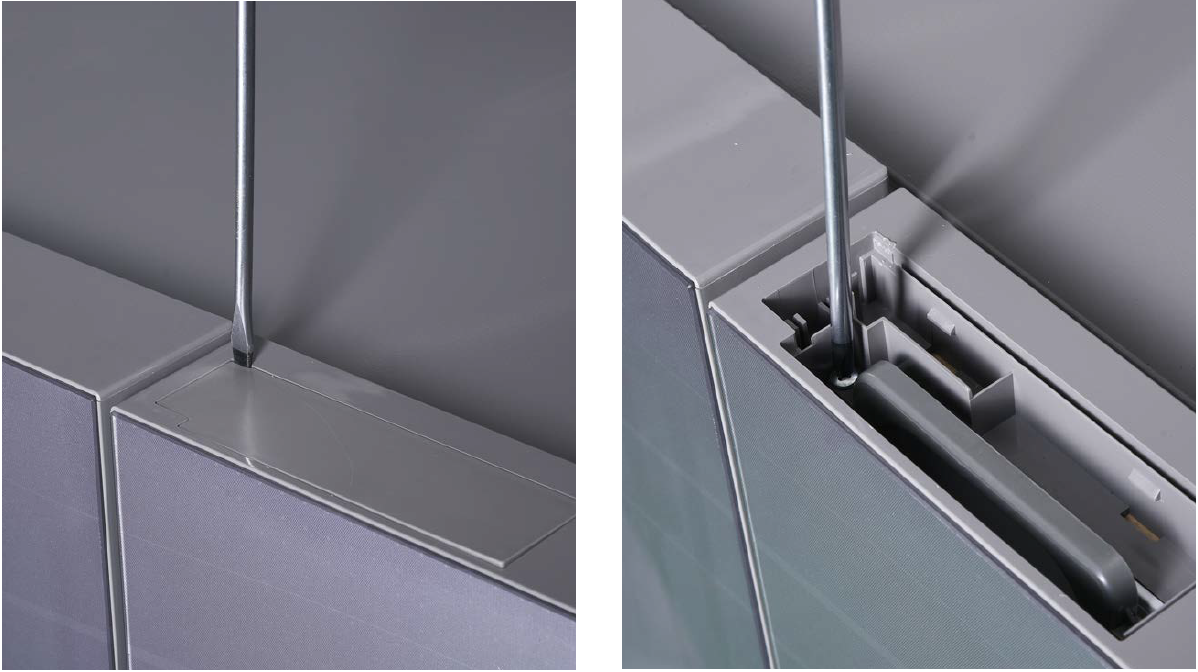

Step 1

Prize off the cover on door cap.

Step 2

Remove the screws (in total 2).

Step 3

Pull out the plastic.

Step 4

Disconnect the terminal for display panel.

Step 5

Remove tape.

Step 6

Push the display away from the corner.

Reverse steps above

to install display

board.

Follow tips carefully:

Tip 1

Please press all buttons on display board to check if it works well or not. Make sure words and icons are clear.

Tip 2

If not, disassemble it and put tape onto the point indicated by red circle.

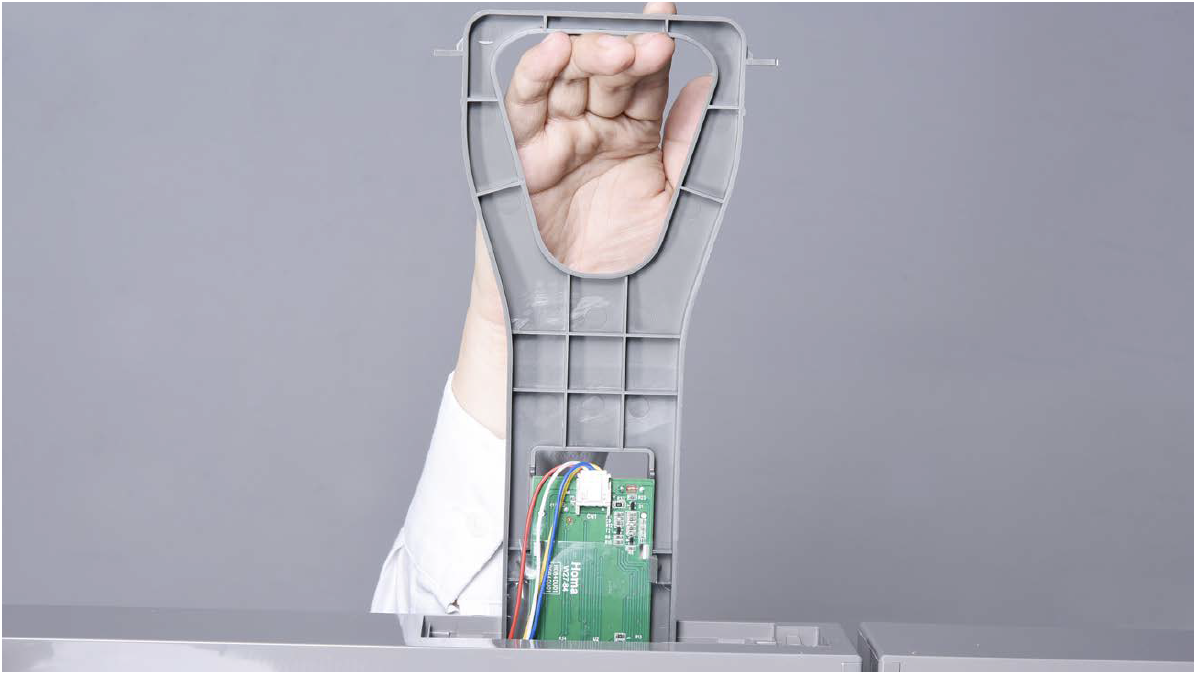

PROCEDURE 6

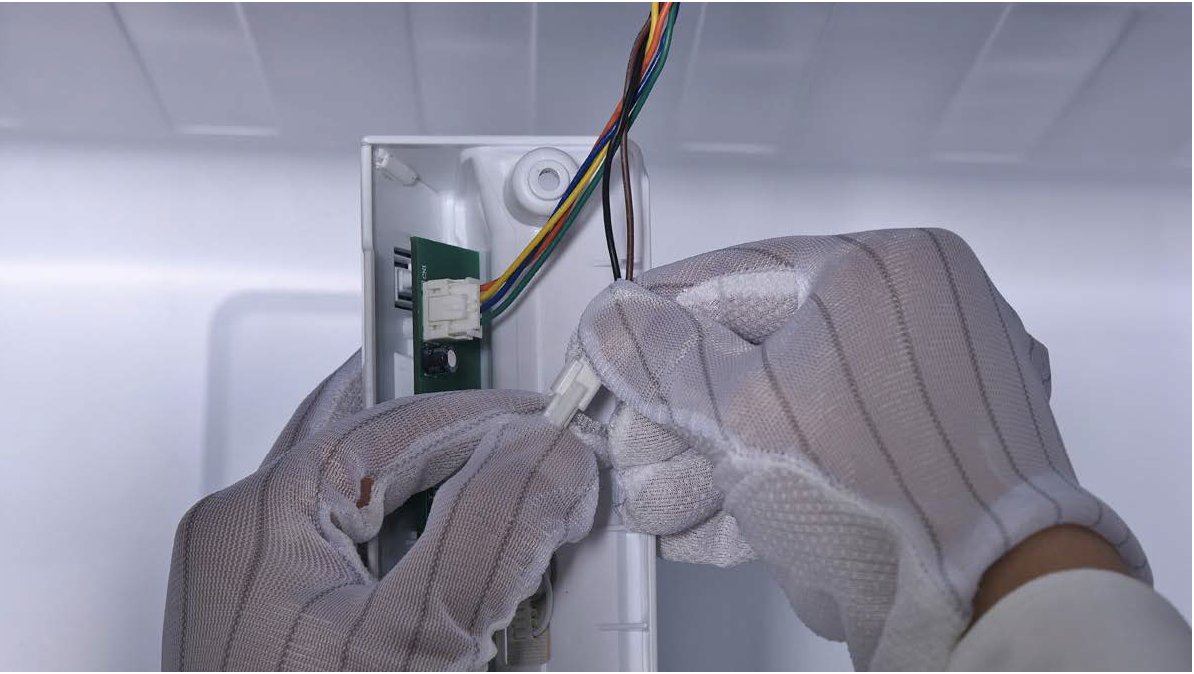

Step 1

Prize off the cover with slotted driver from back of cover.

Step 2

Unscrew with 6mm Cross-head screwdriver.

Step 3

Pull down the lamp box.

Step 4

Disconnect the terminals for LED and for control board.

Step 5

Loosen the clips and take off the control panel.

Step 6

Unscrew with 6mm Philips screwdriver and move away the control board.

Reverse steps above to install the controll board. Please note below point:

Tip 1

Pay attention to wires while installing the internal display, to avoid damaging with screw.

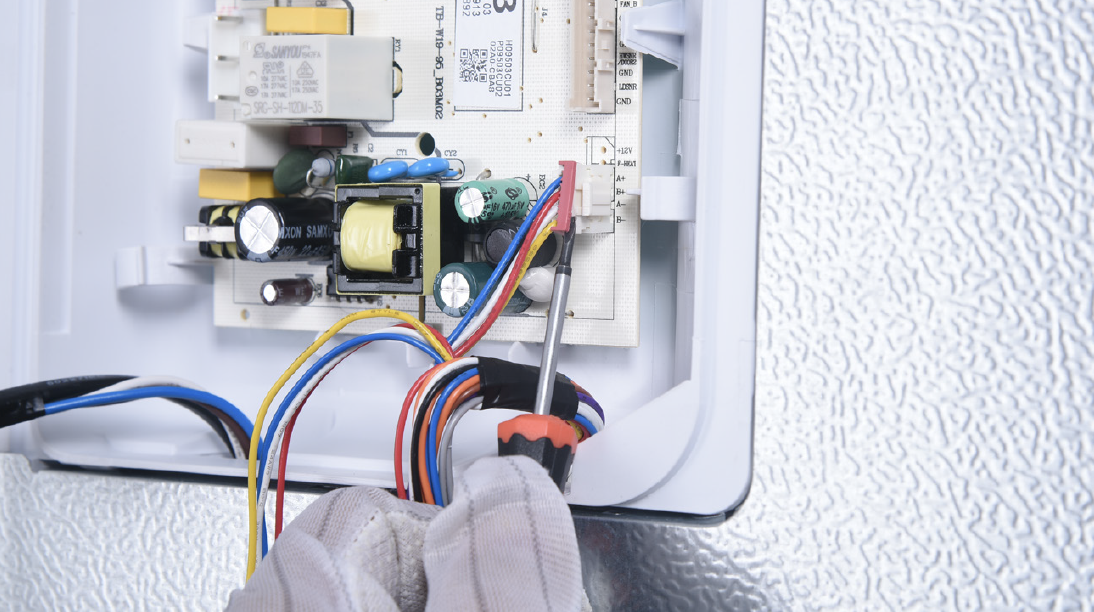

PROCEDURE 7

GENERAL PROCEDURES FOR DISASSEMBLY AND INSTALLATION OF MAINBOARD

Step 1

Prize up the terminal

clicks (if any).

Step 2

Disconnect the terminals.

Step 3

Unscrew the mainboard.

Step 4

Prize off the buckle to remove mainboard.

Reverse steps above to install a new mainboard.

DIAGNOSIS 6