CHECK AND TEST 1

Step 1

Unscrew cover of

mainboard with a

cross-head screwdriver.

Step 2

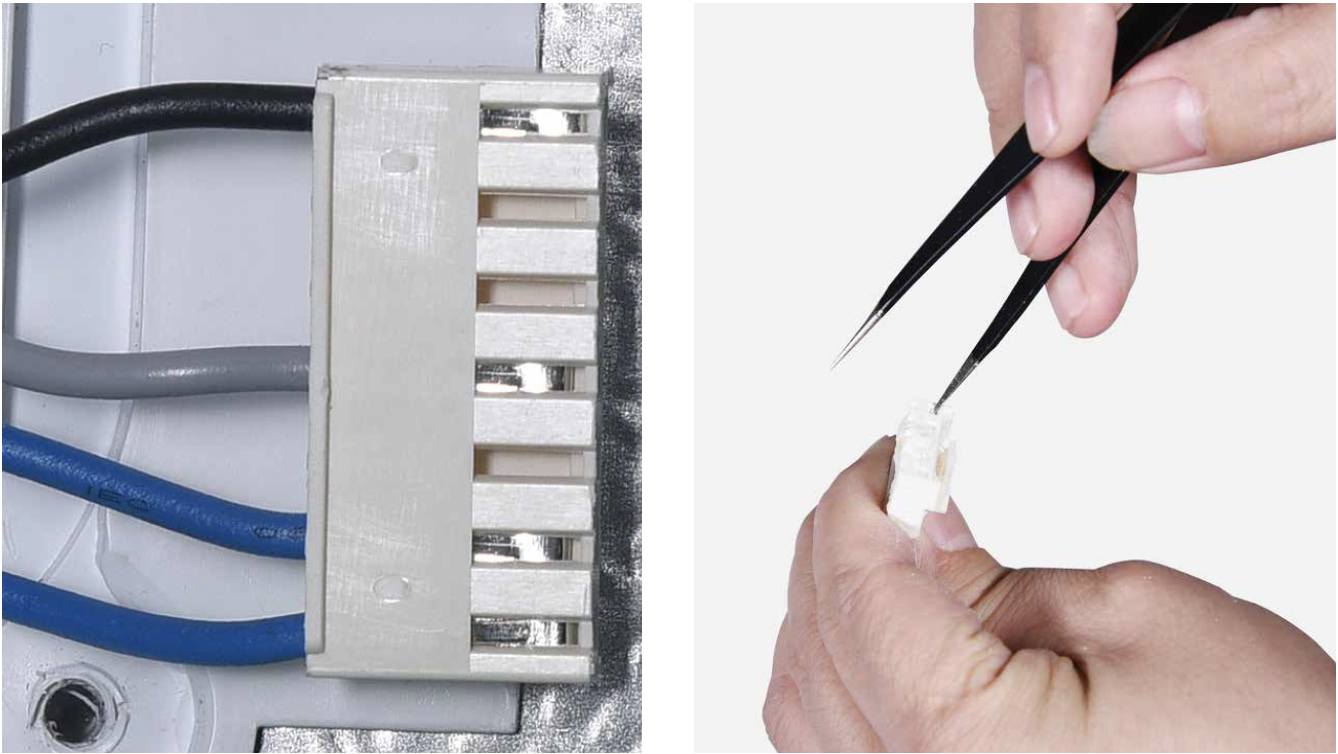

Check if terminal is not insert final position.

Step 3

In mainboard area, check if terminal is stuffed with foam.

Step 4

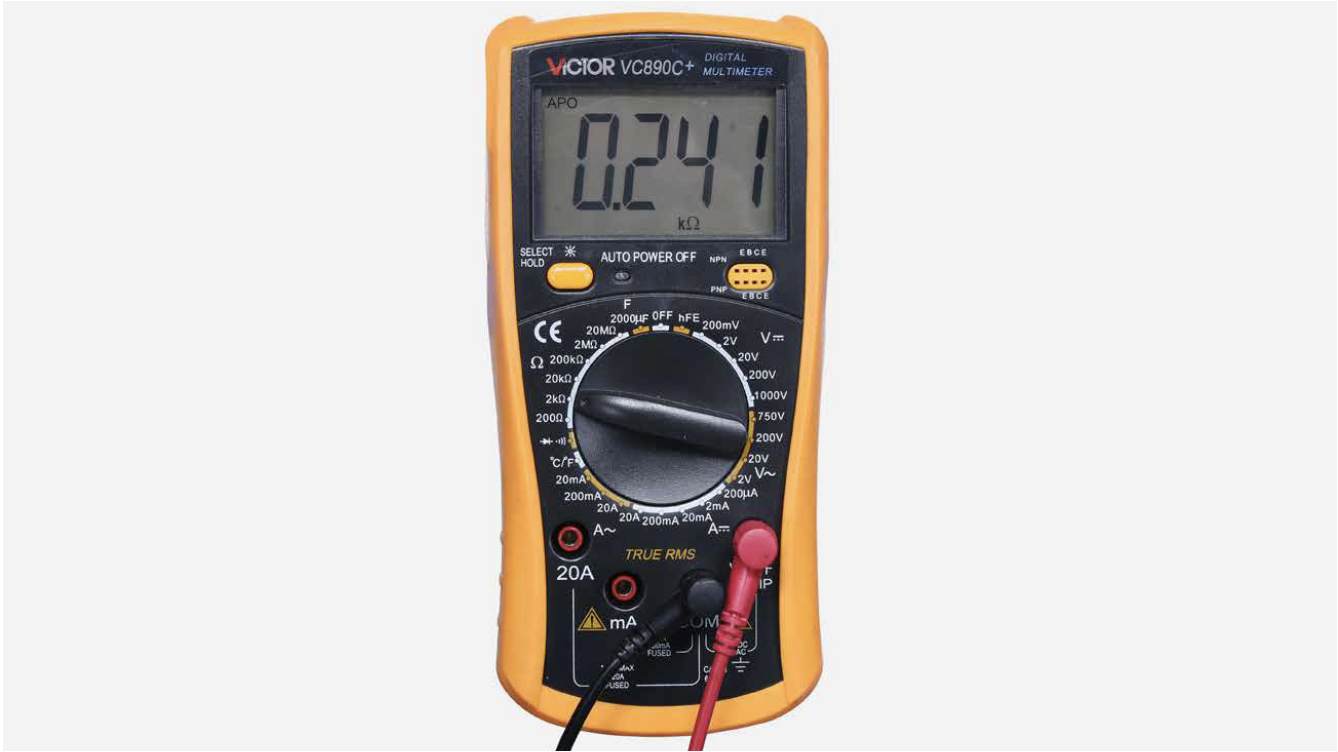

Measure resistance of heater from terminal in PCB area.

Step 5

Check the result.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove the drawers

Step 2

Remove the glass partition.

Step 3

Remove the 3 screw covers.

Step 4

Remove the 3 screws.

Step 5

Pull air duct out.

Step 6

Disconnect the terminal of fan motor.

Step 7

Remove the air duct.

CHECK AND TEST 2

Step 1

Check to see if terminal is full of foam.

If yes, use tweezers to remove foam.

Step 2

Ensure terminals behind freezer air duct are properly inserted.

Step 3

Please press the button SW1 on mainboard (within 1 minute after powering on the appliance) to start manual defrost.

DIAGNOSIS 2

CHECK AND TEST 3

Step 1

Connect 2 ends on terminal in PCB area.

Step 2

Check the connection of wires in foam with multimeter.

DIAGNOSIS 3

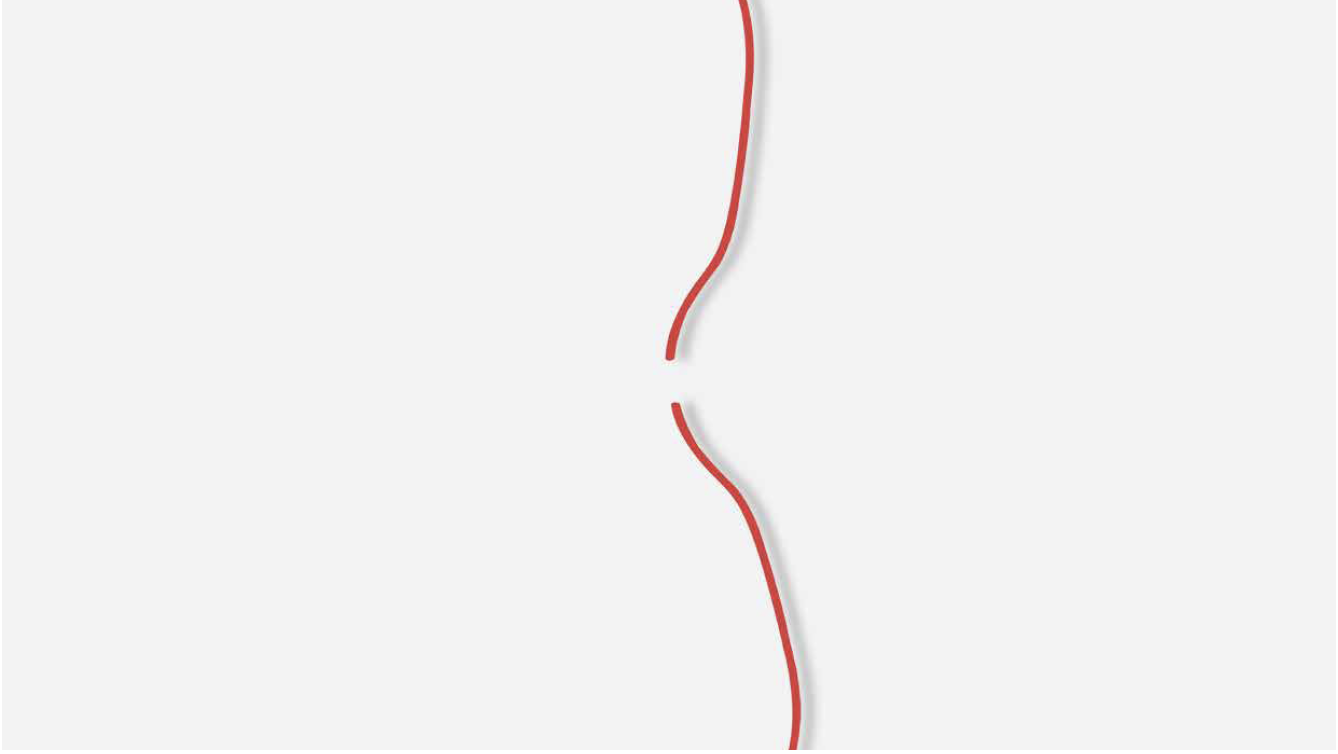

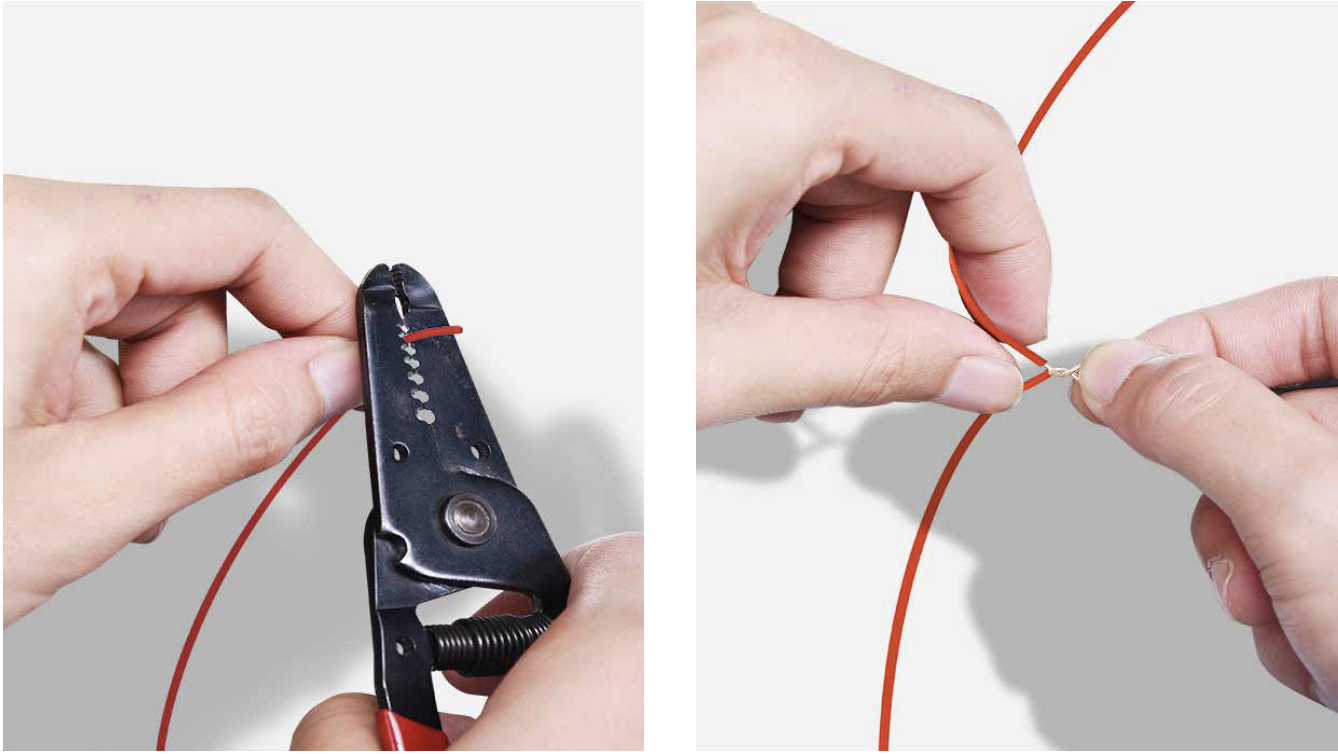

CHECK AND TEST 4

Step 1

Check if wires for defrost heater are broken or not.

DIAGNOSIS 4

PROCEDURE 2

Step 1

Cut off the wire.

Step 2

Peel off the sleeves.Step 3

Ensure proper wire order and connect.

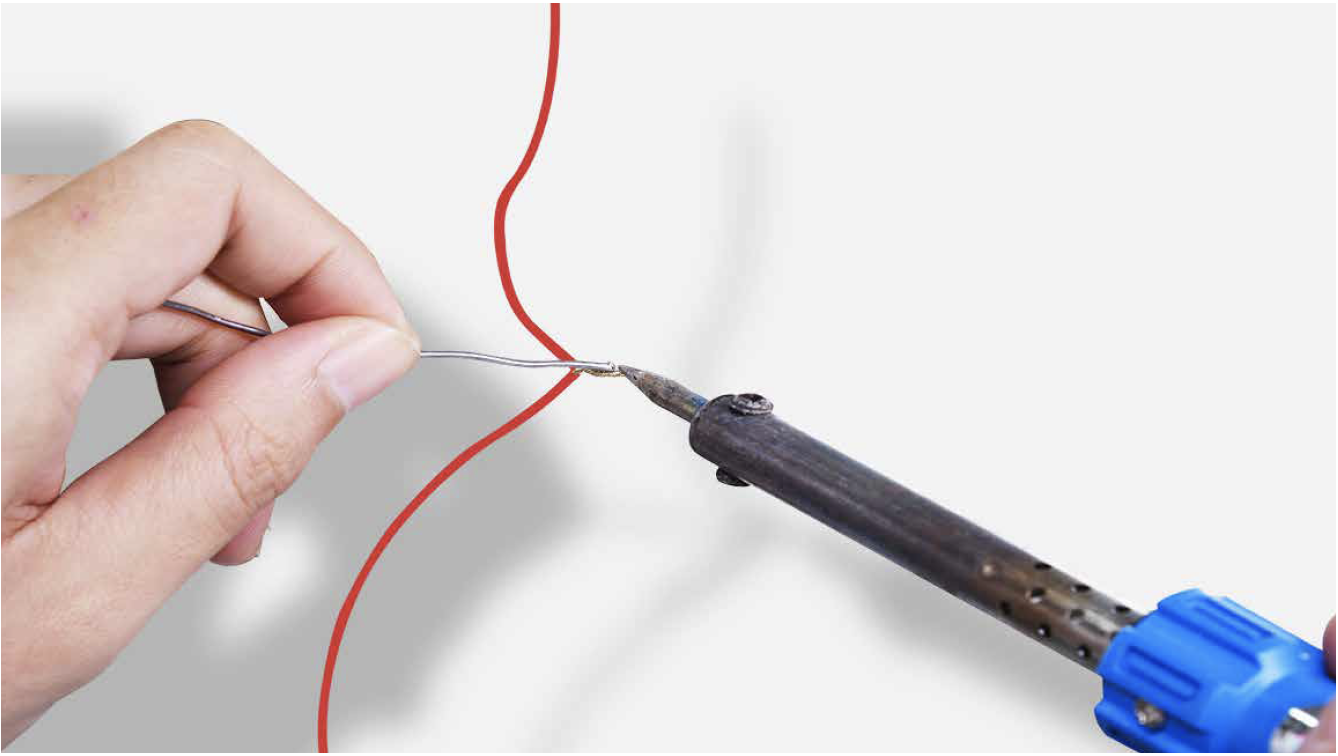

Step 4

Tin soldering.

Step 5

Cover point of connection with electrical tape.

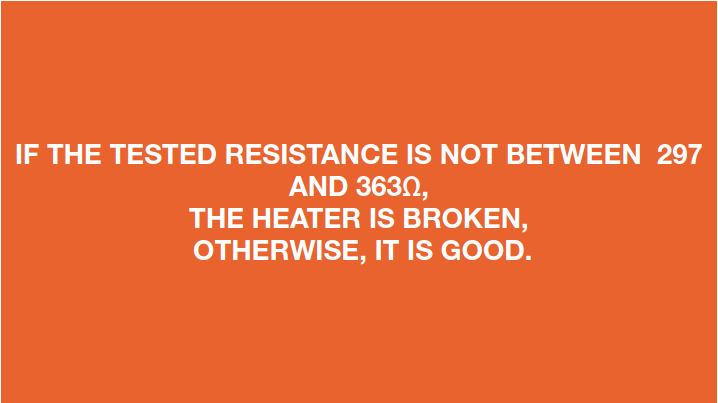

CHECK AND TEST 5

Step 1

Measure the resistance of heater from terminal in freezer.

DIAGNOSIS 5

PROCEDURE 3

Step 1

Disconnect the terminal of heater.

Step 2

Use screwdriver to remove the heat conductor (if any).

Step 3

Use 6mm cross-head driver to unscrew on left and right.

Step 4

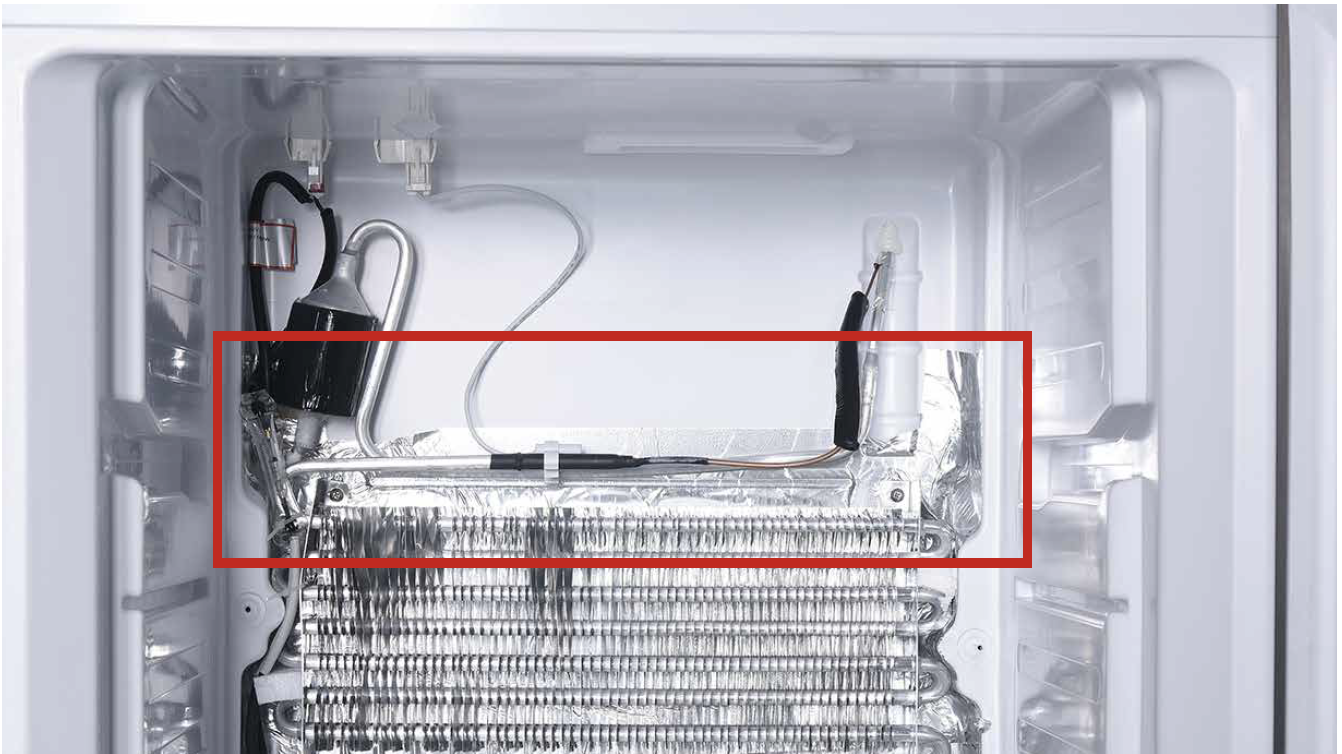

Lift evaporator and heater 20mm, the bottom must be higher than the edge of the trough.

WARNING:

Be careful not to deform pipes in red square during steps 4.

Step 5

Loosen the clips for fastening heater. There are 8 clips in total.

Step 6

Remove the heater.Reverse above procedures to reinstall the heater.

CHECK AND TEST 6

Step 1

Ensure terminals behind freezer air duct are properly inserted.

Step 2

Power on and press the button SW1 on mainboard (within 1 minute after powering on the appliance) to start manual defrost.

DIAGNOSIS 6

Tip 1

When reassembling the

air duct, move wires to

prevent crushing with

edge of air duct.

Tip 2

After pushing air duct into position, it should make a click sound. If no click is heard, do it again.

Tip 3

Check to see if there is a large gap between air duct and cabinet.

If there is, re-install air duct again.