CHECK AND TEST 1

Step 1

Unscrew cover of

mainboard with a

cross-head screwdriver.

Step 2

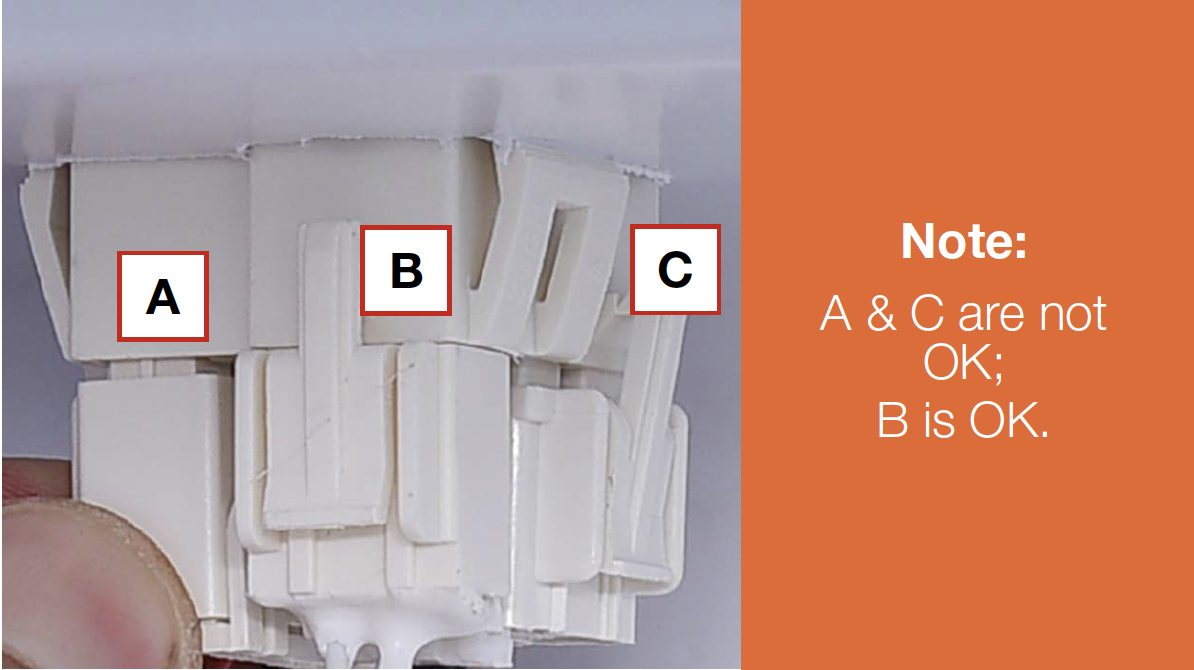

In mainboard area, check

if terminal is pushed into

final position.

IF NOT, reconnect

it to make sure that

connections are good.

Step 3

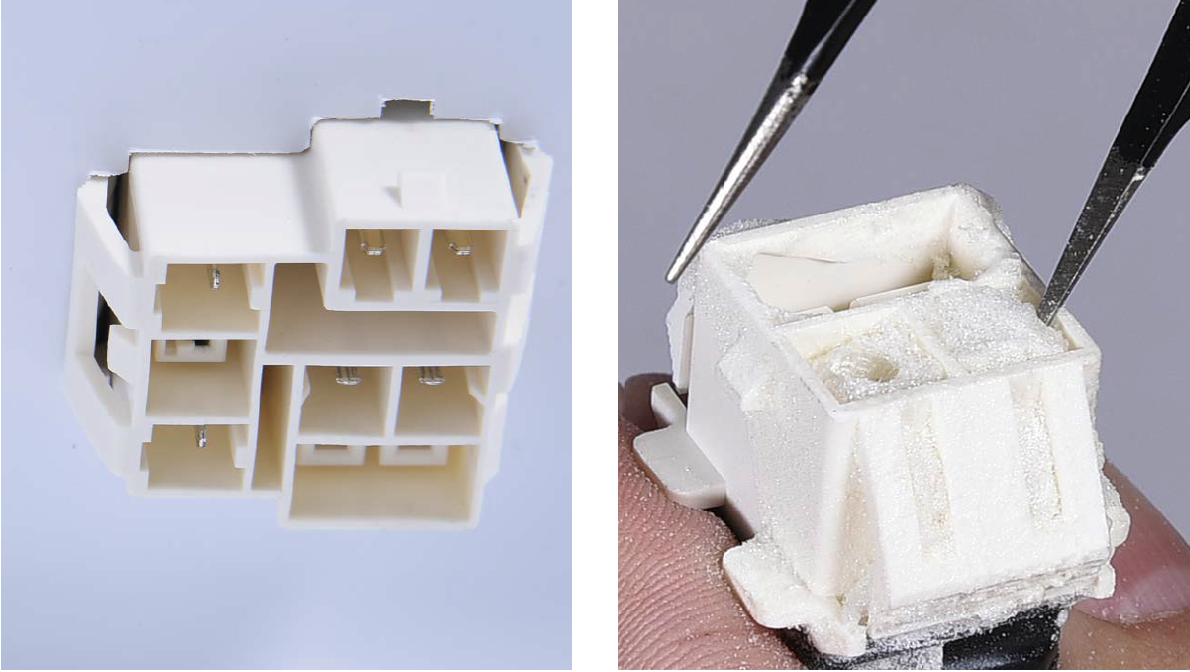

Check if wire order is right, or if terminal is filled with foam.

Step 4

If terminal is filled with foam: use tweezers to pick foam out and insert the terminal into position again.

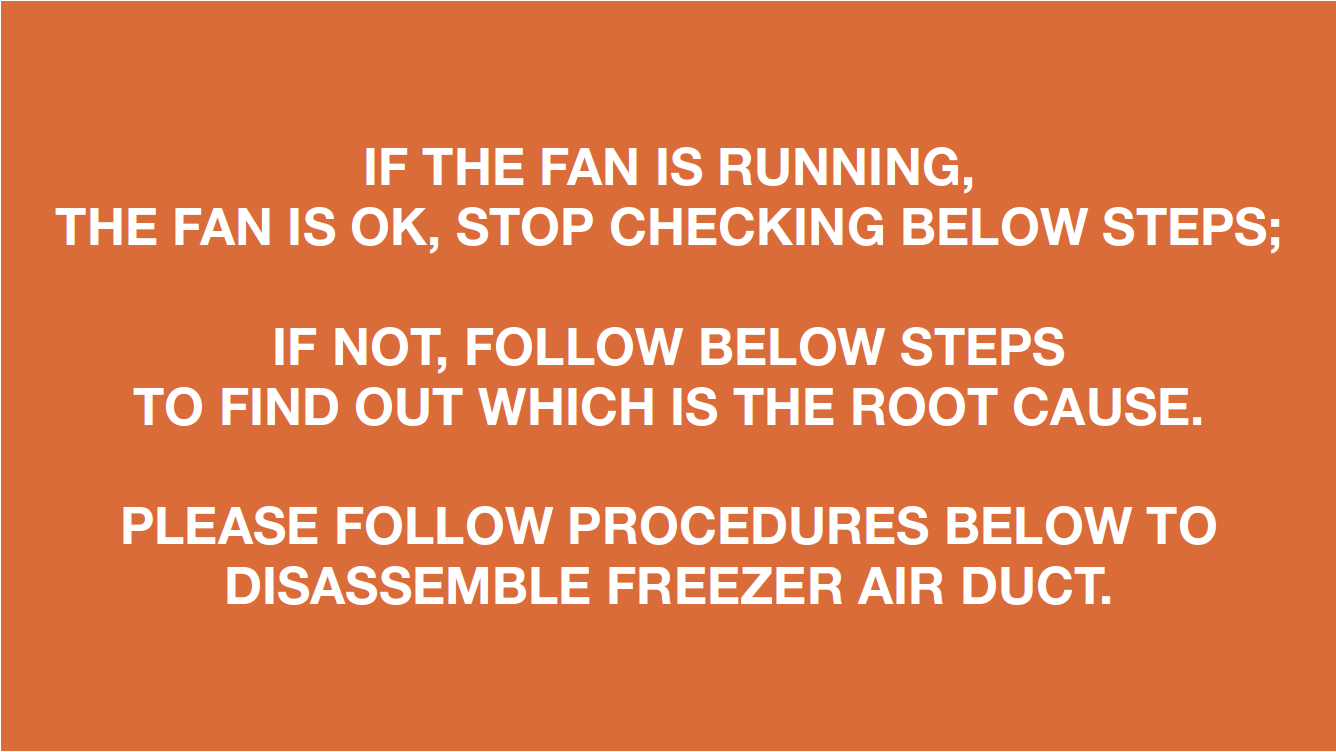

DIAGNOSIS 1

CHECK AND TEST 2

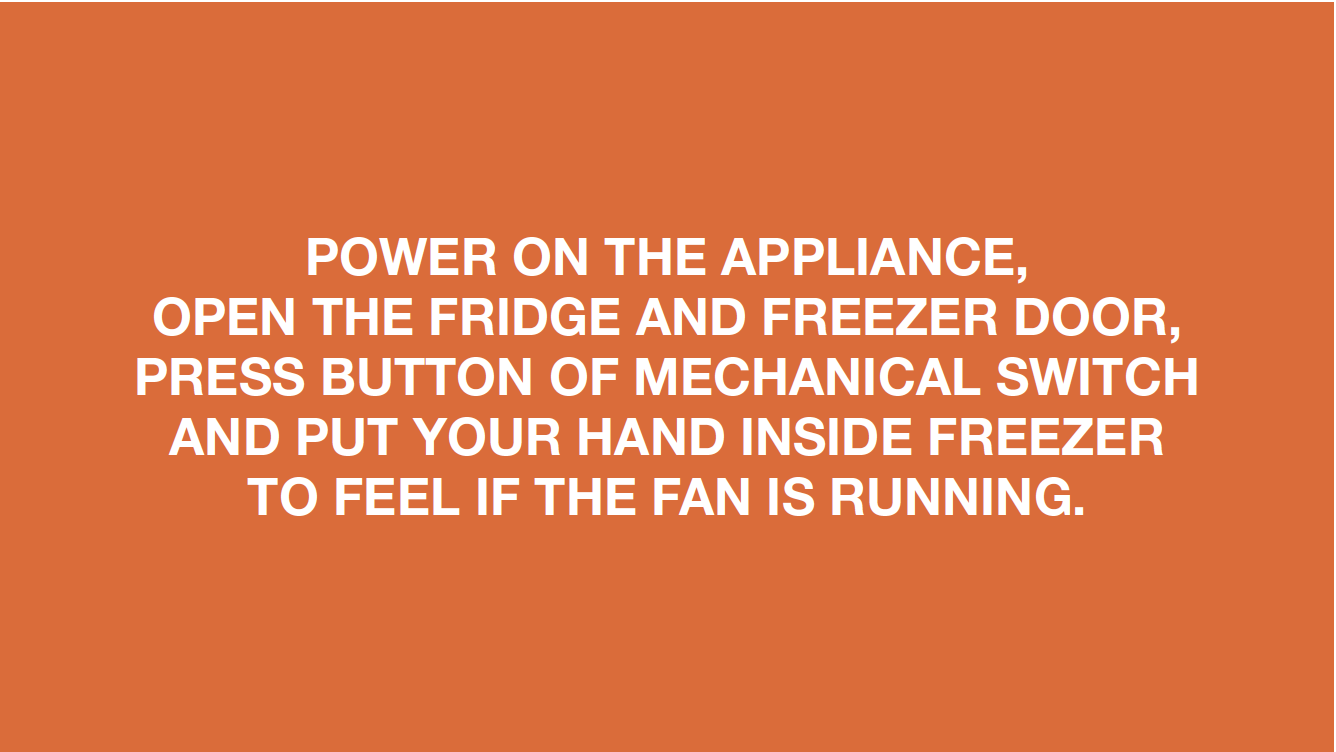

Step 1

Turn power output of transformer to DC 12V.

Step 2

Supply power from

terminal in PCB area.

Step 3

Put your hand near outlet

of freezer air duct to feel

if fan is blowing or not.

DIAGNOSIS 2

PROCEDURE 1

Step 1

Remove the drawers

Step 2

Remove the glass

partition.

Step 3

Remove the 3 screw

covers.

Step 4

Remove the 3 screws.

Step 5

Pull air duct out.

Step 6

Disconnect the terminal of fan motor.

Step 7

Remove the air duct.

CHECK AND TEST 3

Step 1

In duct area, check if terminal is pushed into final position. If not, reconnect it.

Step 2

Check whether terminal

is filled with foam.

If yes, please use tweezers to clean and remove the foam, and reconnect it again.

DIAGNOSIS 3

CHECK AND TEST 4

Step 1

Check if wires of fan motor are damaged or not.

PROCEDURE 2

Step 1

Cut wire off from broken area.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and connect them.

Step 4

Tin soldering.

Step 5

Cover connection with electrical tape.

CHECK AND TEST 5

Step 1

Set output of transformer to DC 12V to test fan from the terminal behind the air duct.

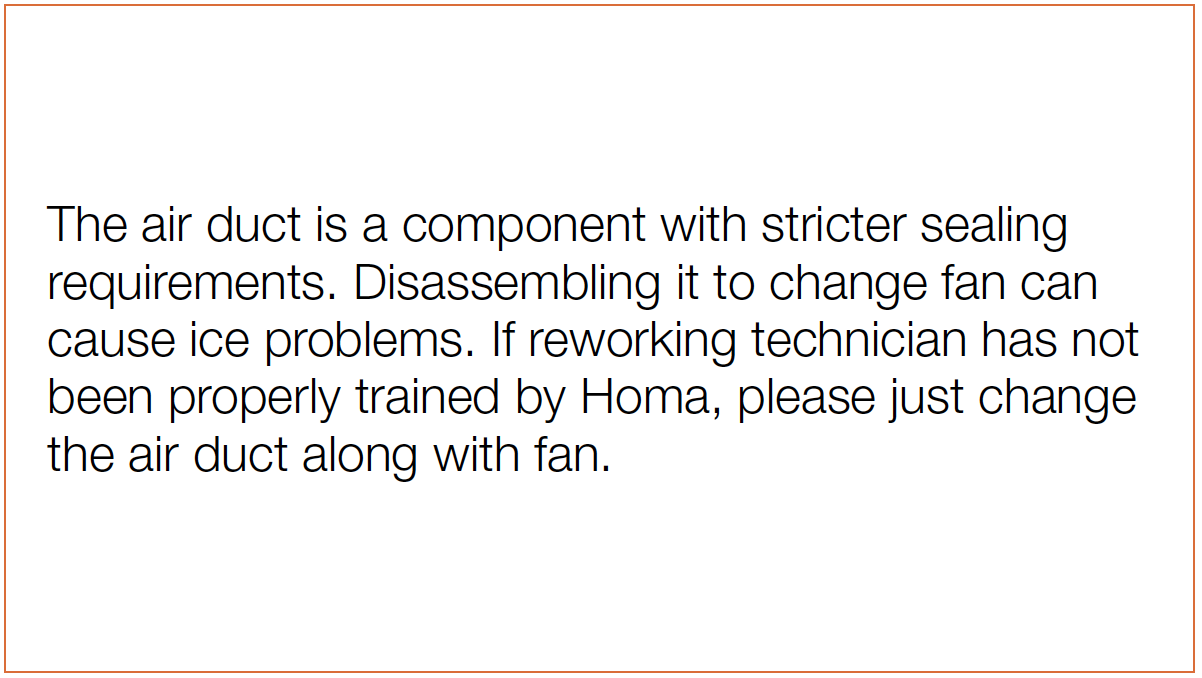

DIAGNOSIS 4

Note

CHECK AND TEST 6

Step 1

Set multimeter to resistance gear.

Step 2

Put one detector into end of wires in PCB area, and another detector into end of wires behind air duct.

Note

Tip 1

When reassembling the

air duct, move wires to

prevent crushing with

edge of air duct.

Tip 2

After pushing air duct

into position, it should

make a click sound. If no

click is heard, do it again.

Tip 3

Check to see if there is

a large gap between air

duct and cabinet.

If there is, re-install air duct again.