CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

In PCB area, check if terminal is pushed into final position.

Step 3

In PCB, check to see if terminal is filled with foam.

Step 4

If so, use tweezers to remove it.

Step 5

In PCB area, use multimeter to measure resistance value.

Step 6

Take note of the result.

Step 7

Measure the temperature

of freezer air duct, close to

sensor.

DIAGNOSIS 1

PROCEDURE 1

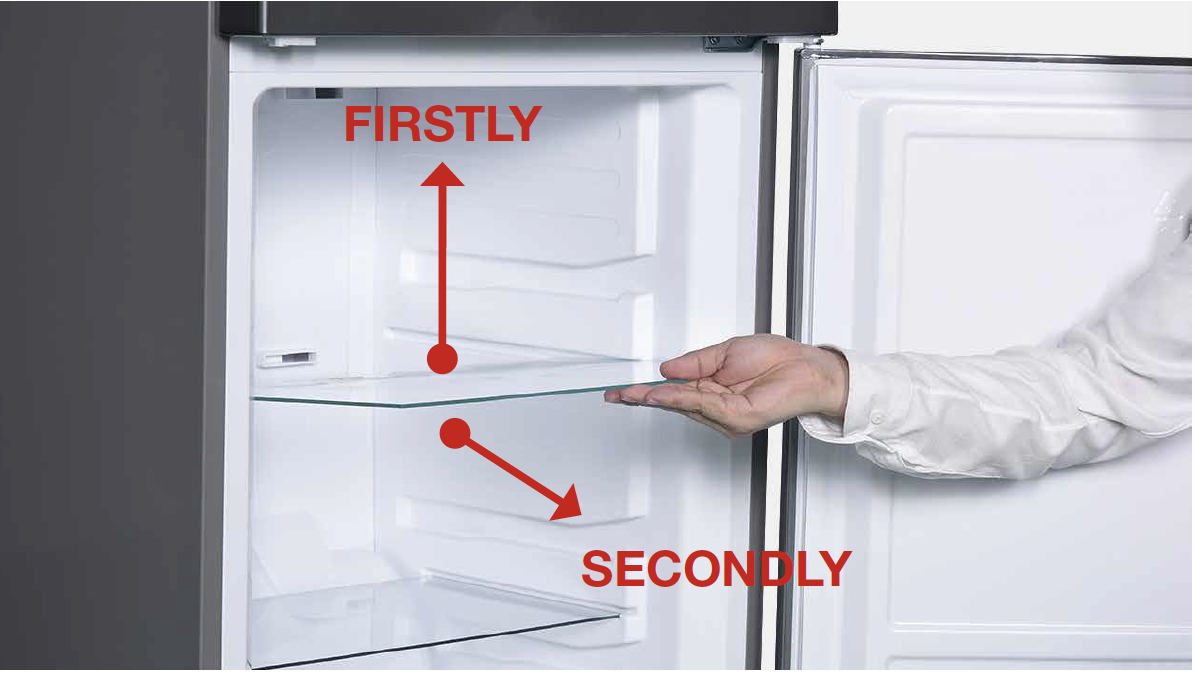

Step 1

Remove the drawers

Step 2

Remove the glass partition.

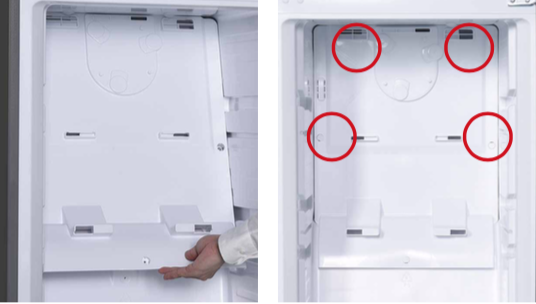

Step 3

Remove the 3 screw covers.

Step 4

Remove the 3 screws.

Step 5

Pull air duct out.

Step 6

Disconnect the terminal

of fan motor.

Step 7

Remove the air duct.

CHECK AND TEST 2

Step 1

Check if terminal is

inserted to final position.

If not, please re-insert it

to final position.

Step 2

Check if sensor is attached in proper position, as

showing in picture.

If not, correct it.

Step 3

Check if wire of defrost

sensor is broken.

IF YES, REPLACE IT

WITH A NEW ONE.

Step 4

Disconnect terminal of defrost temp. sensor.

Step 5

Check if the terminal is

stuffed with foam.

If so, use tweezers to

smash it and remove.

Step 6

Measure resistance of defrost temp. sensor from terminal in freezer, and take note of it.

Step 7

Measure the temperature of defrost temp. sensor.

DIAGNOSIS 2

Tip 1

When reassembling the air duct, move wires to prevent crushing with edge of air duct.

Tip 2

After pushing air duct into position, it should make a click sound. If no click is heard, do it again.Tip 3

Check to see if there is

a large gap between air

duct and cabinet.

If there is, re-install air duct again.

DIAGNOSIS 3

CHECK AND TEST 3

Step 1

Set multimeter to resistance gear.

Step 2

Use a wire to connect the terminals in PCB area and measure the resistance in foam side (as shown in photo).

DIAGNOSIS 4