CHECK AND TEST 1

Step 1

Unscrew cover ofmainboard with a

Cross-head screwdriver.

Step 2

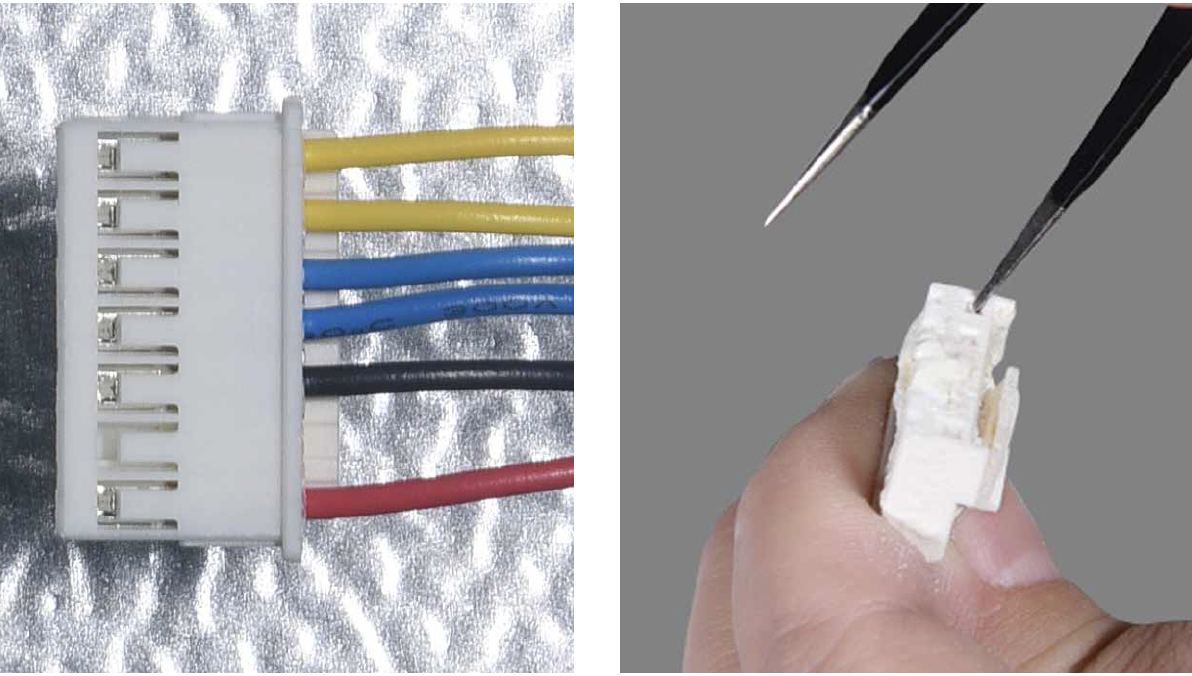

In PCB area, check if

terminal is pushed into

final position.

Step 3

In PCB, check to see ifterminal is filled with foam.

Step 4

If so, use tweezers toremove it.

Step 5

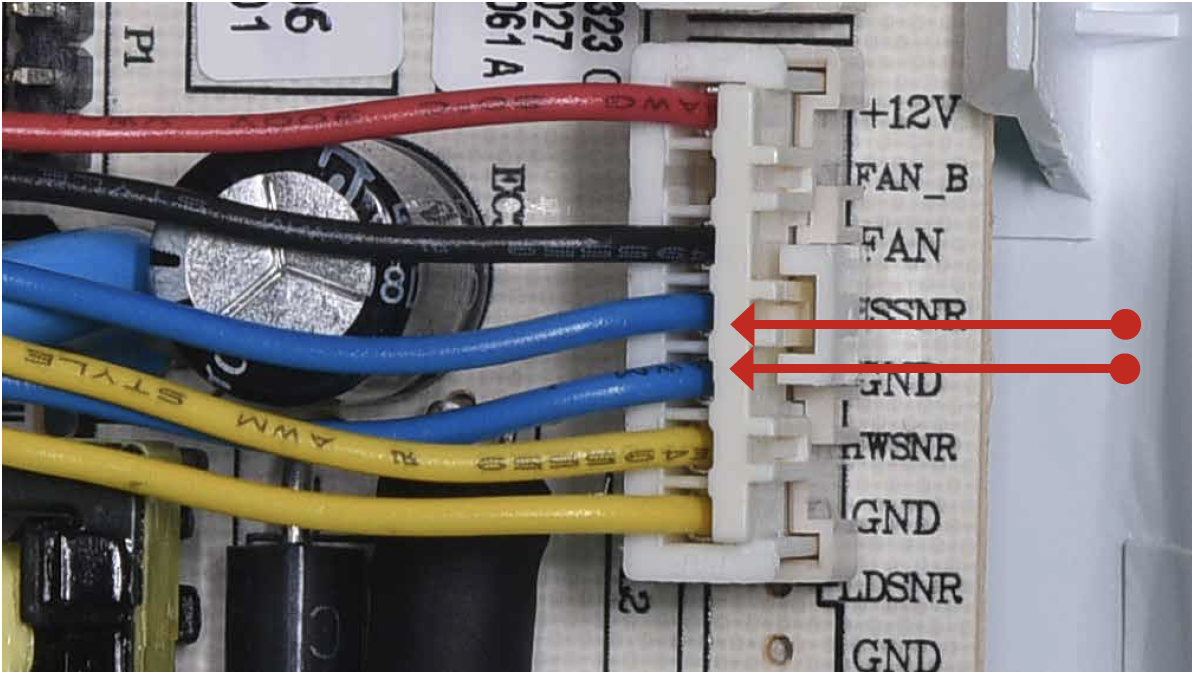

In PCB area, use multimeter

to measure resistance value.

Step 6

Take note of the result.

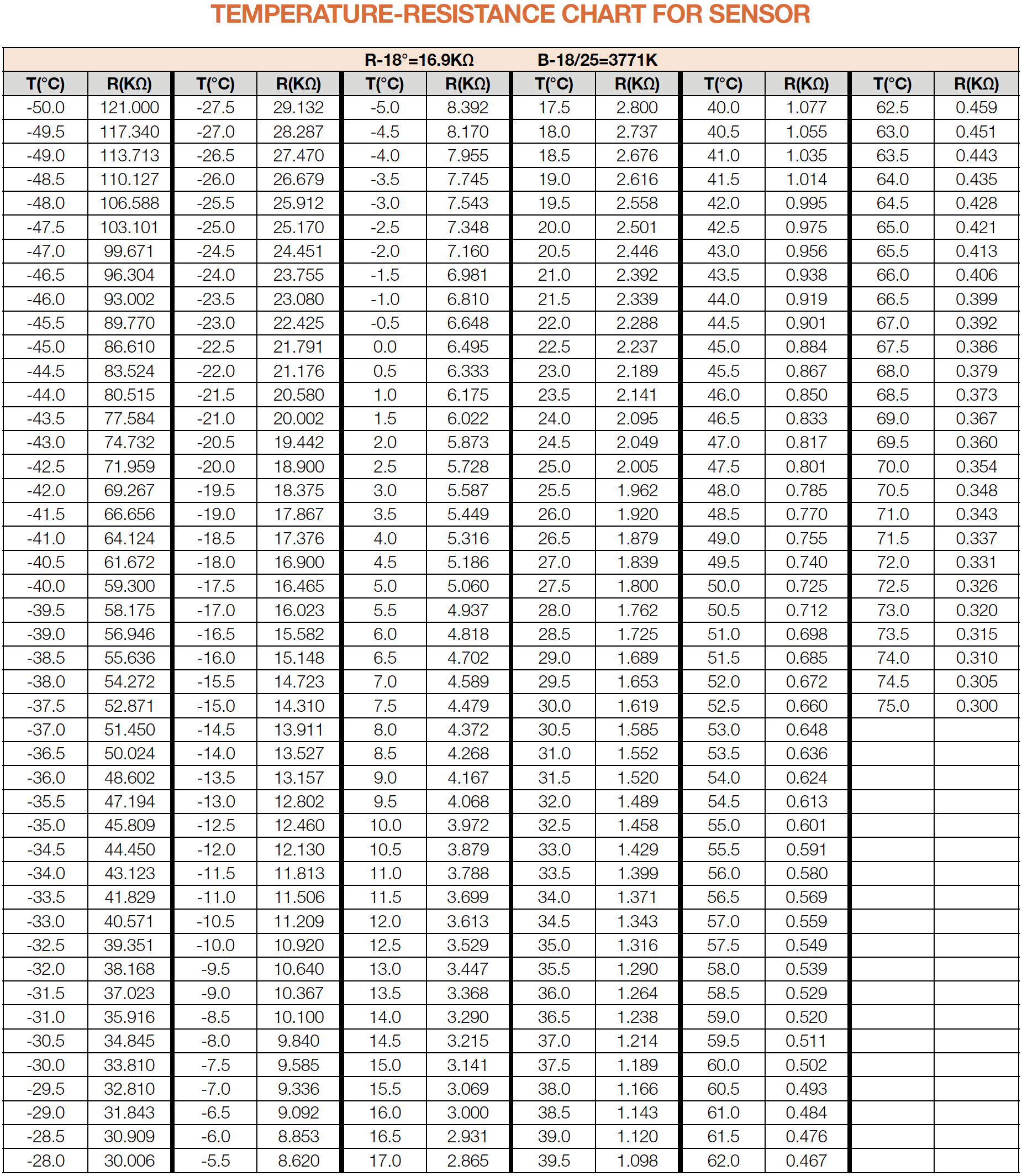

Step 7

Measure the temperatureof freezer air duct, close to

sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove the drawers

Step 2

Remove the glasspartition.

Step 3

Remove the 3 screwcovers.

Step 4

Remove the 3 screws.Step 5

Pull air duct out.

Step 6

Disconnect the terminalof fan motor.

Step 7

Remove the air duct.

CHECK AND TEST 2

Check if terminal is

inserted to final position.

If not, please re-insert it

to final position.

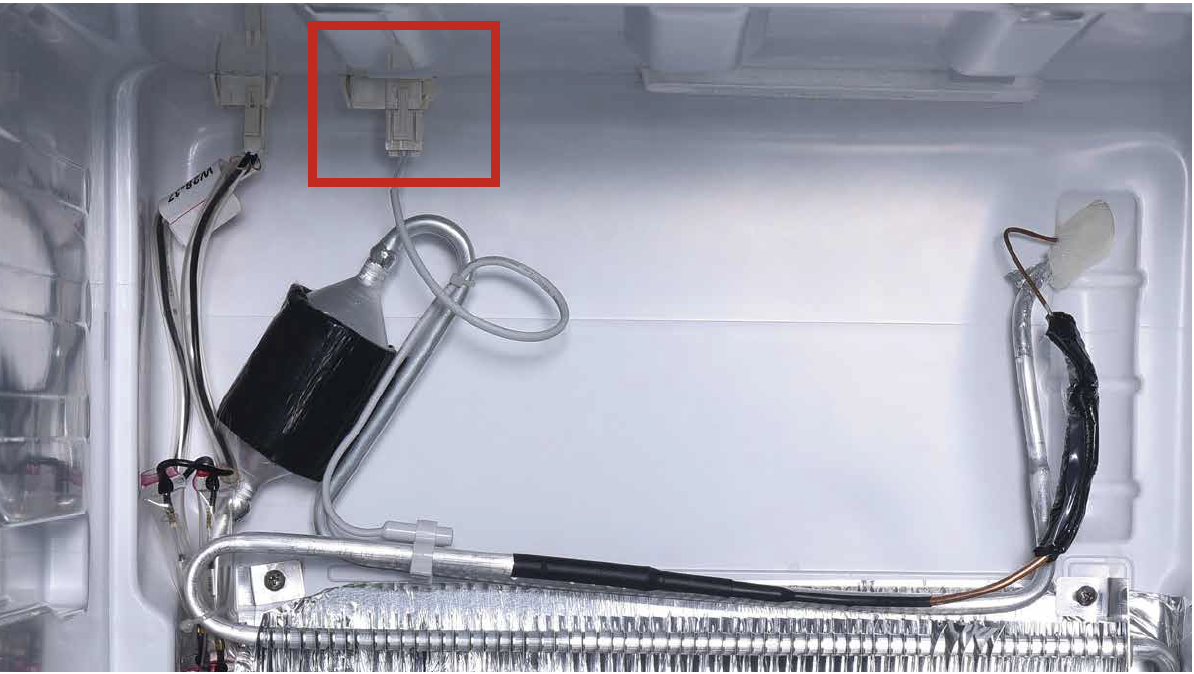

Step 2

Check if sensor is fixto correct position, as

showing in picture.

If not, correct it.

Step 3

Check if wire of defrostsensor is broken.

IF YES, REPLACE IT

WITH A NEW ONE.

Step 4

Disconnect terminal ofdefrost temp. sensor.

Step 5

Check if the terminal isstuffed with foam.

If so, use tweezers to

smash it and remove.

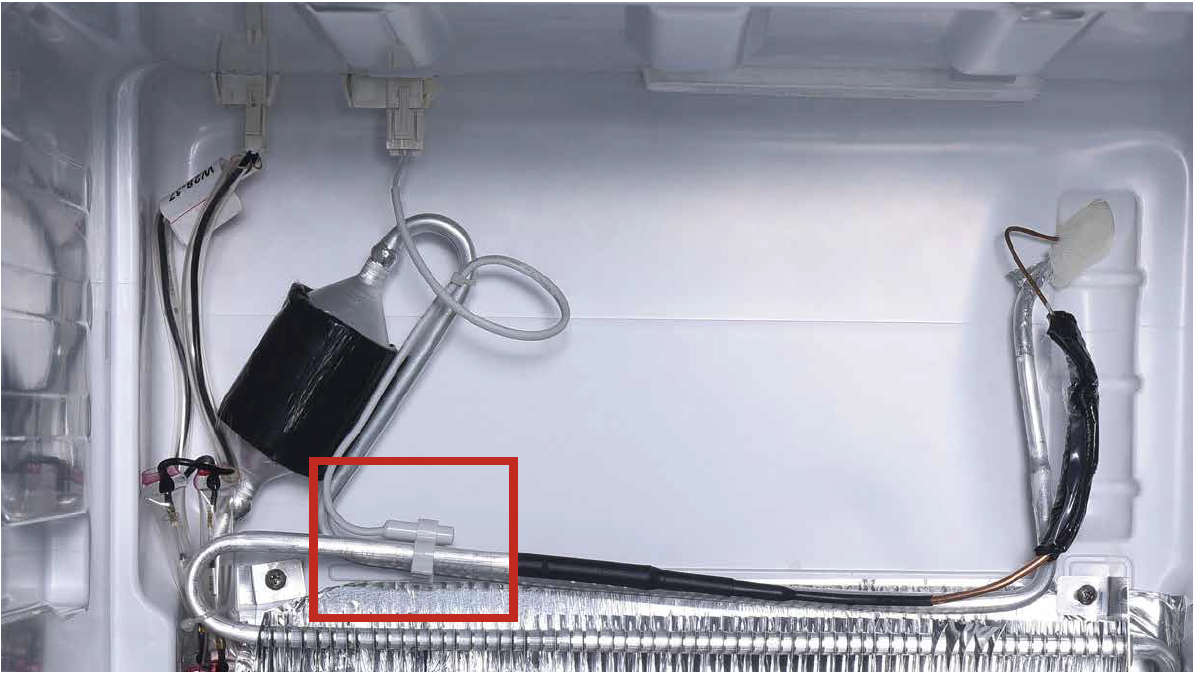

Step 6

Measure resistance ofdefrost temp. sensor

from terminal in freezer,

and take note of it.

Step 7

Measure the temperatureof defrost temp. sensor.

DIAGNOSIS 2

Tip 1

When reassembling theair duct, move wires to

prevent crushing with

edge of air duct.

Tip 2

Tip 2After pushing air duct

into position, it should

make a click sound. If no

click is heard, do it again.

Tip 3

Check to see if there is

a large gap between air

duct and cabinet.

If there is, re-install

air duct again.

CHECK AND TEST 3

Step 1

Set multimeter toresistance gear.

Step 2

Use a wire to connectthe terminals in PCB

area and measure the

resistance in foam side

(as shown in photo).

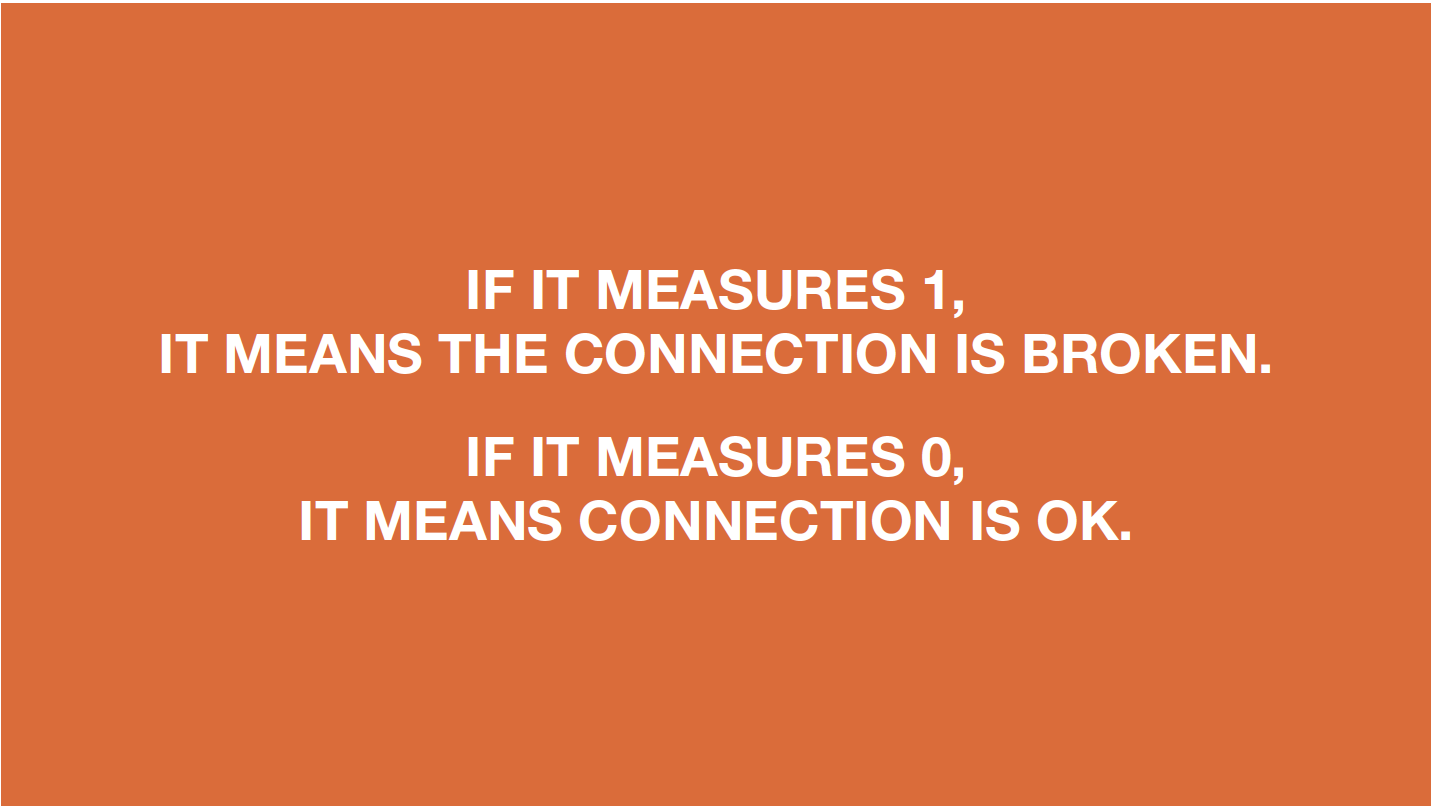

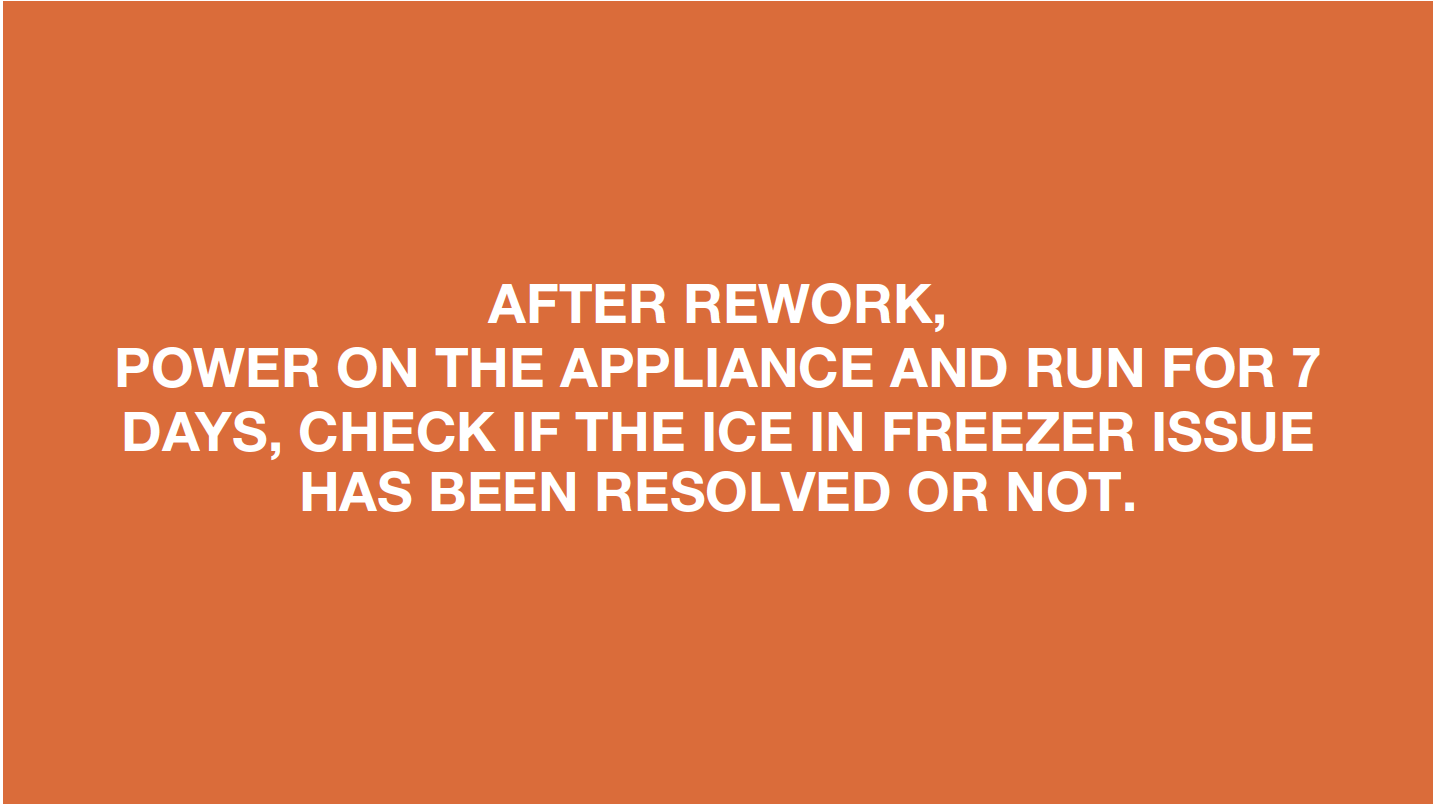

DIAGNOSIS.