CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

In mainboard area, check if terminal is pushed into proper final position.

Step 3

Set multimeter to resistance gear.

Step 4

Measure resistance of fridge temp. sensor from terminal in PCB area.

Step 5

Take note of value.

Step 6

Measure the temperature of fridge temp. sensor. Use the measured temperature to find the standard resistance value in Temperature- Resistance Chart for Sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove crispers.

Step 2

Remove shelves.

Step 3

Loosen the decorative plate and remove.

Step 4

Remove the screw covers on the air duct with slotted screw driver.

Step 5

Unscrew the screws (total of three) with Cross-head screw driver.

Step 6

Lift the air duct up slightly and pull it out.

CHECK AND TEST 2

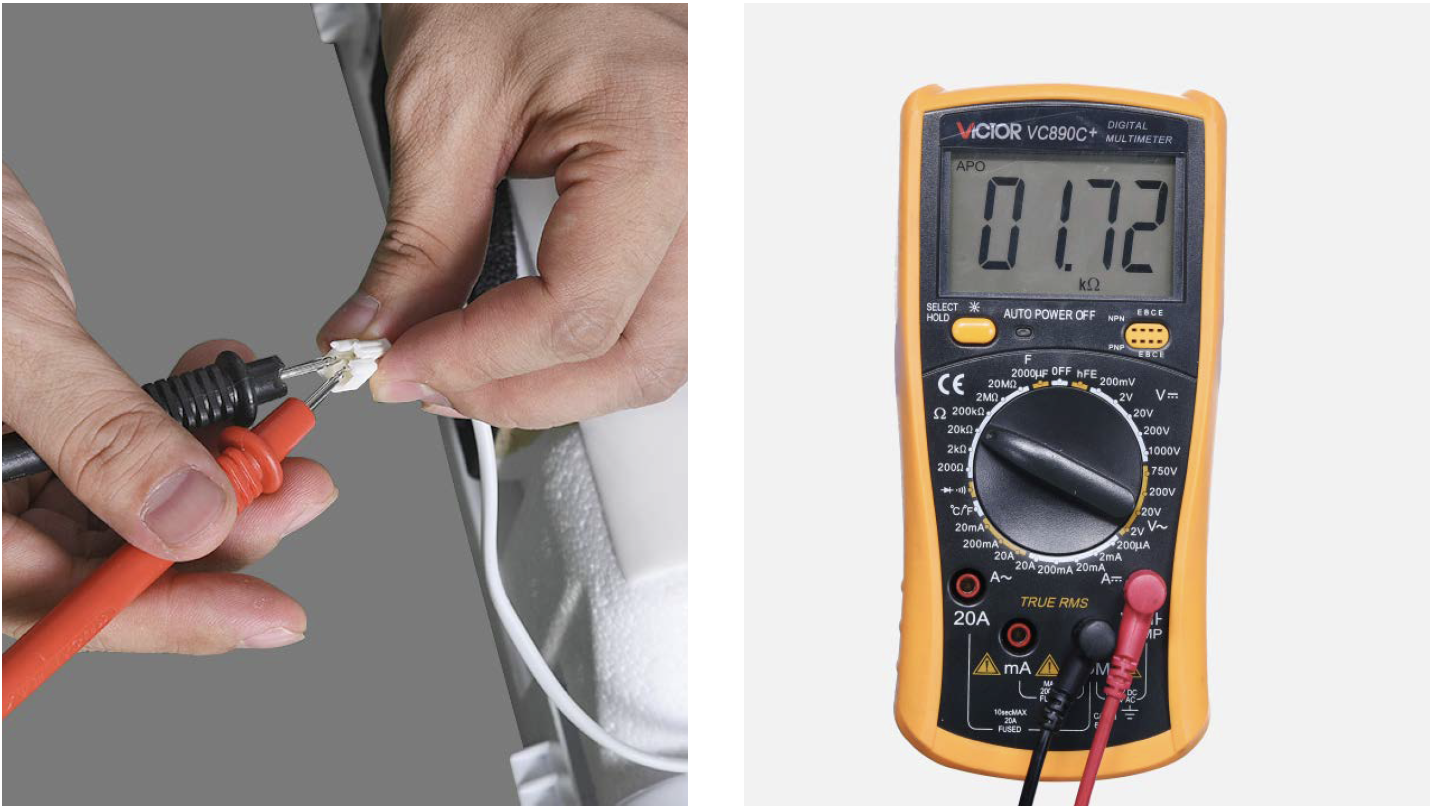

Step 1

Check if terminal is

properly inserted to final

position.

If not, reinsert it.

Step 2

Check if wires of fridge temp. sensor are damaged or not.

PROCEDURE 2

Step 1

Cut wire off.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and reconnect them.

Step 4

Tin soldering.

Step 5

Cover connecting point with electrical tape.

CHECK AND TEST 3

Step 1

Disconnect terminal of fridge temp. sensor.

Step 2

Measure resistance of fridge sensor from terminal in fridge air duct cover.

Step 3

Measure the temperature of fridge temp. sensor. Use the measured temperature to find the standard resistance value in Temperature- Resistance Chart for Sensor.

DIAGNOSIS 3

PROCEDURE 2

Step 1

Release the clasp.

Step 2

Remove the foam air duct.

Step 3

Remove tape.

Step 4

Remove the broken sensor, and replace it with a new one.

PROCEDURE 3

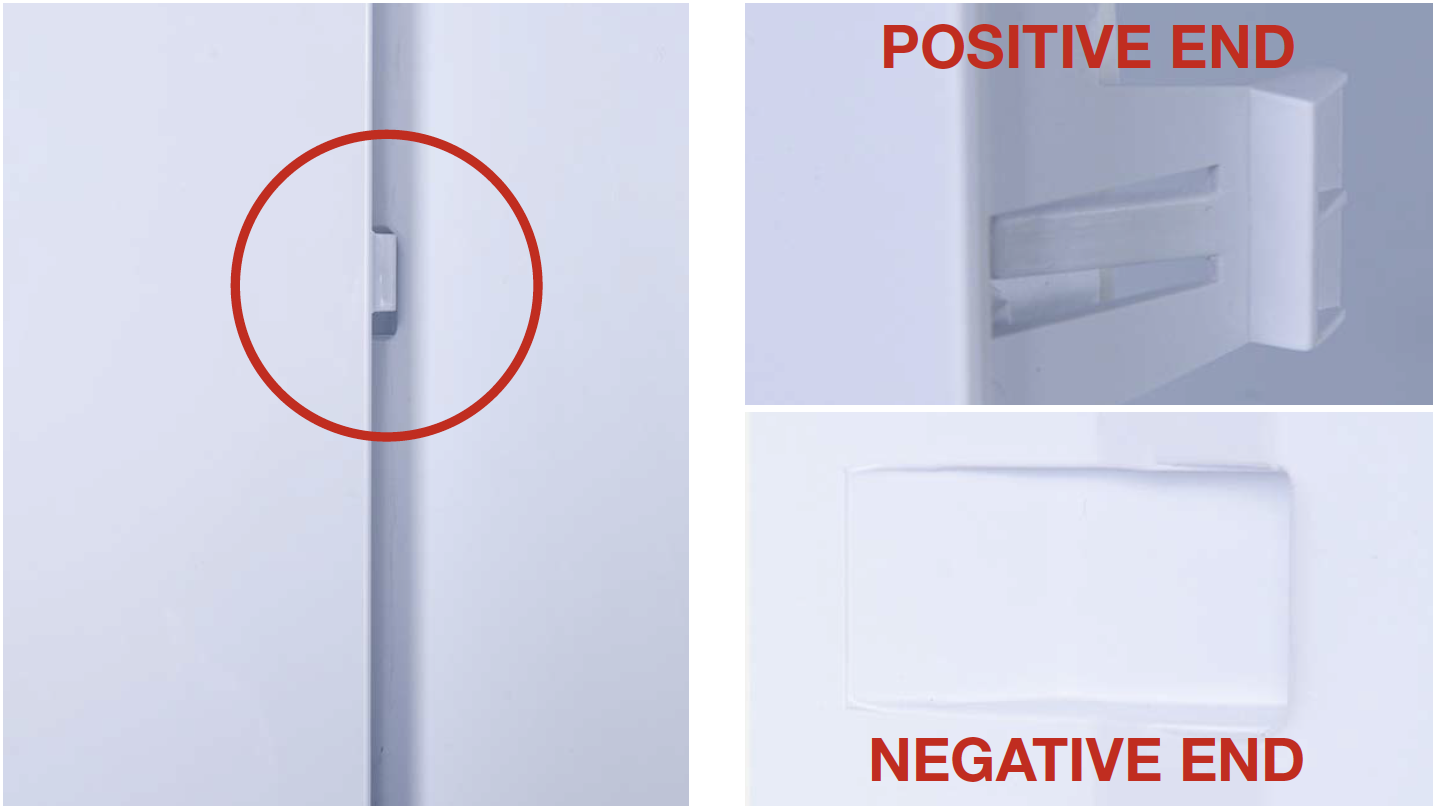

Tip 1

Attach the sensor properly onto the air duct cover as shown in picture on right.

Tip 2

Make sure the sealing sponge is in good condition.

Tip 3

Make sure back cover of the air duct is not broken.

Tip 4

Make sure chiller temperature controller is installed in correct position.

CHECK AND TEST 4

Step 1

Set multimeter to resistance gear.

Step 2

Put one detector into one end of wires in PCB area, and another detector into one end of wires in fridge air duct cover.

Tip 1

Push terminals into final position, and then move wires onto cavity to avoid crushing wires with edge of air duct.

Tip 2

When reinstalling the air duct, first put the positive end of buckle (on the bottom) into the negative end.

Tip 3

Later, fasten the buckles on the top with same method.

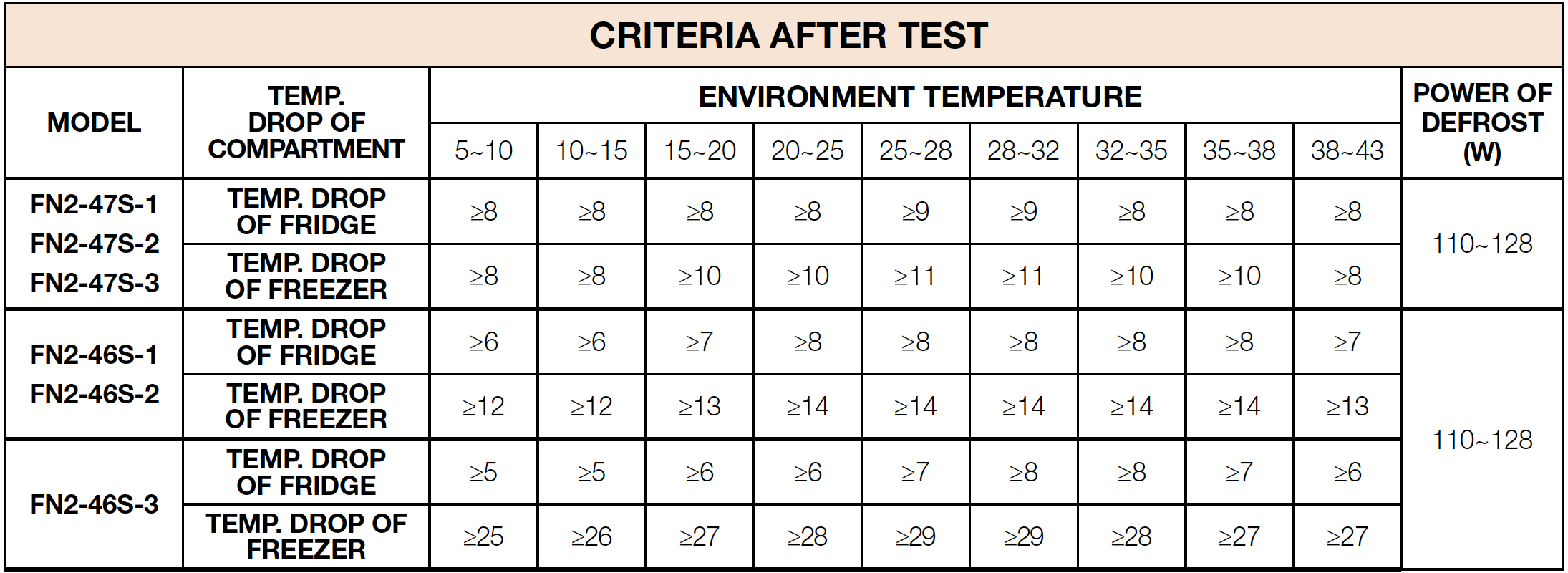

CHECK AND TEST 5

Step 1

After complete procedures

above, follow procedures to conduct performance test.

DIAGNOSIS 5