Step 2

Discharge all refrigerant toward the exhaust vent..

Step 3

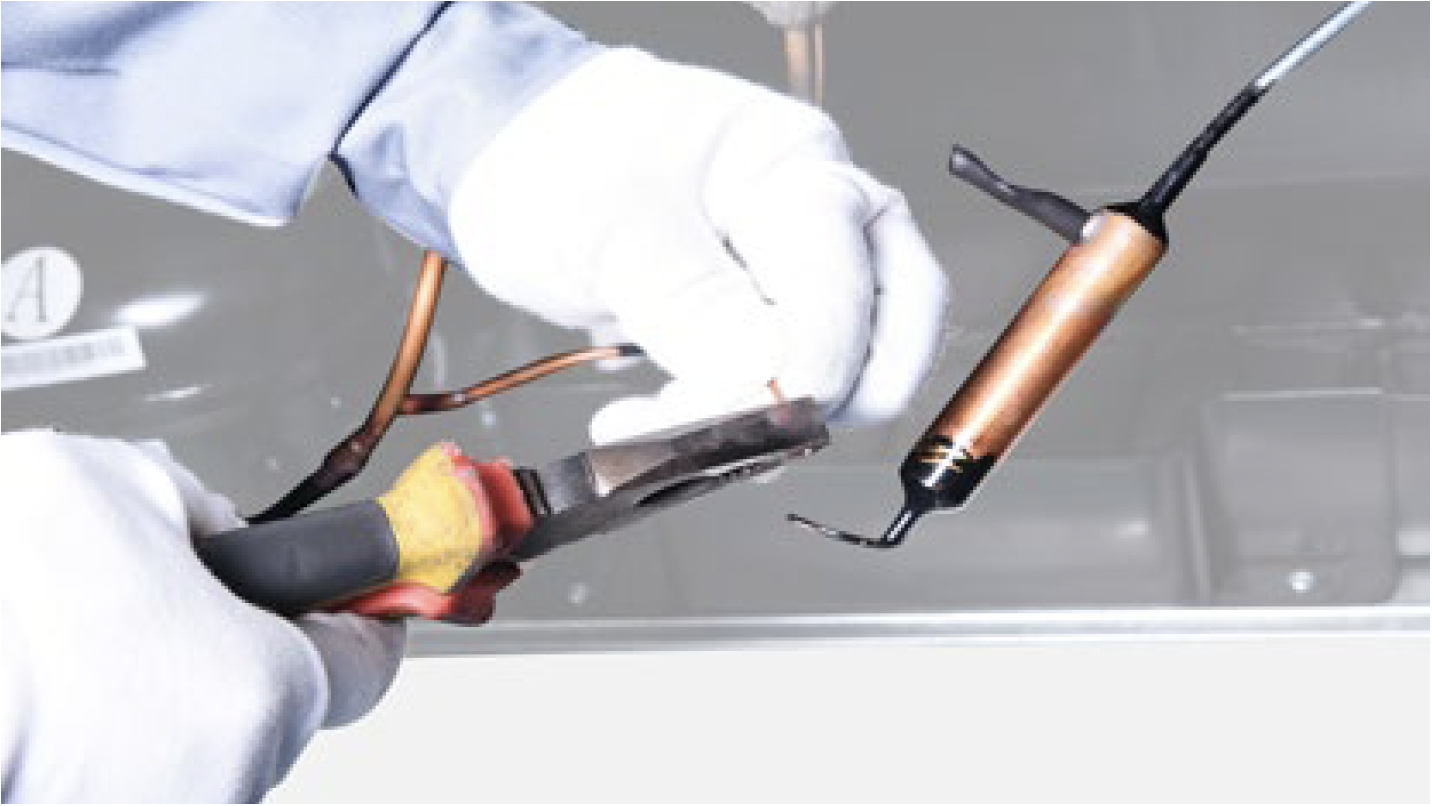

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 4

Re-braze a copper tube onto compressor processing tube. Click below link to get more details for brazing requirements, go to Annex B1

Note

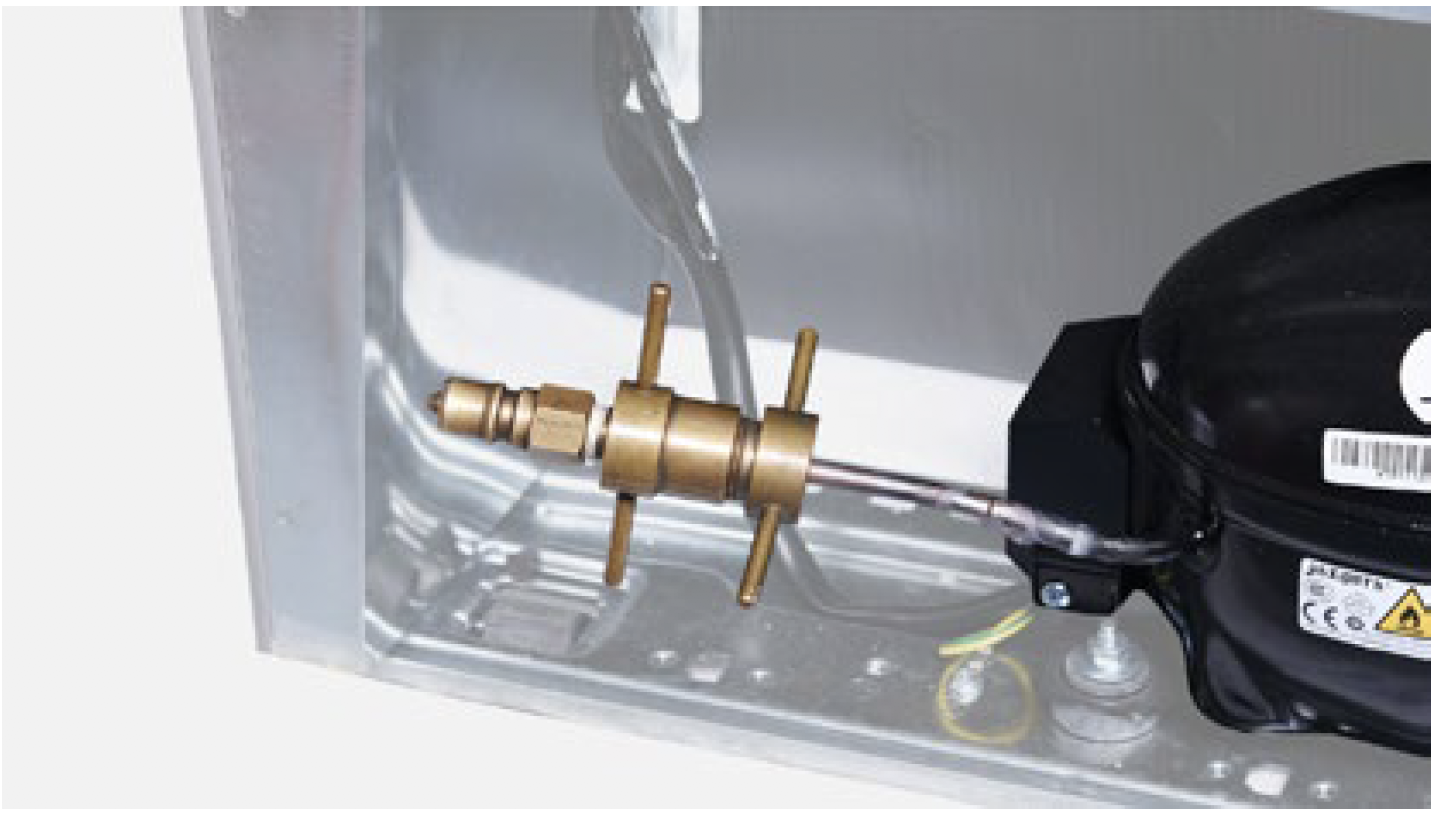

Step 5

Install quick connector onto rebrazed pipe.

Step 6

Use a pliers to cut the capillary off.

Step 7

Inject nitrogen gas with 1.57Mpa pressure through quick connector into pipe.

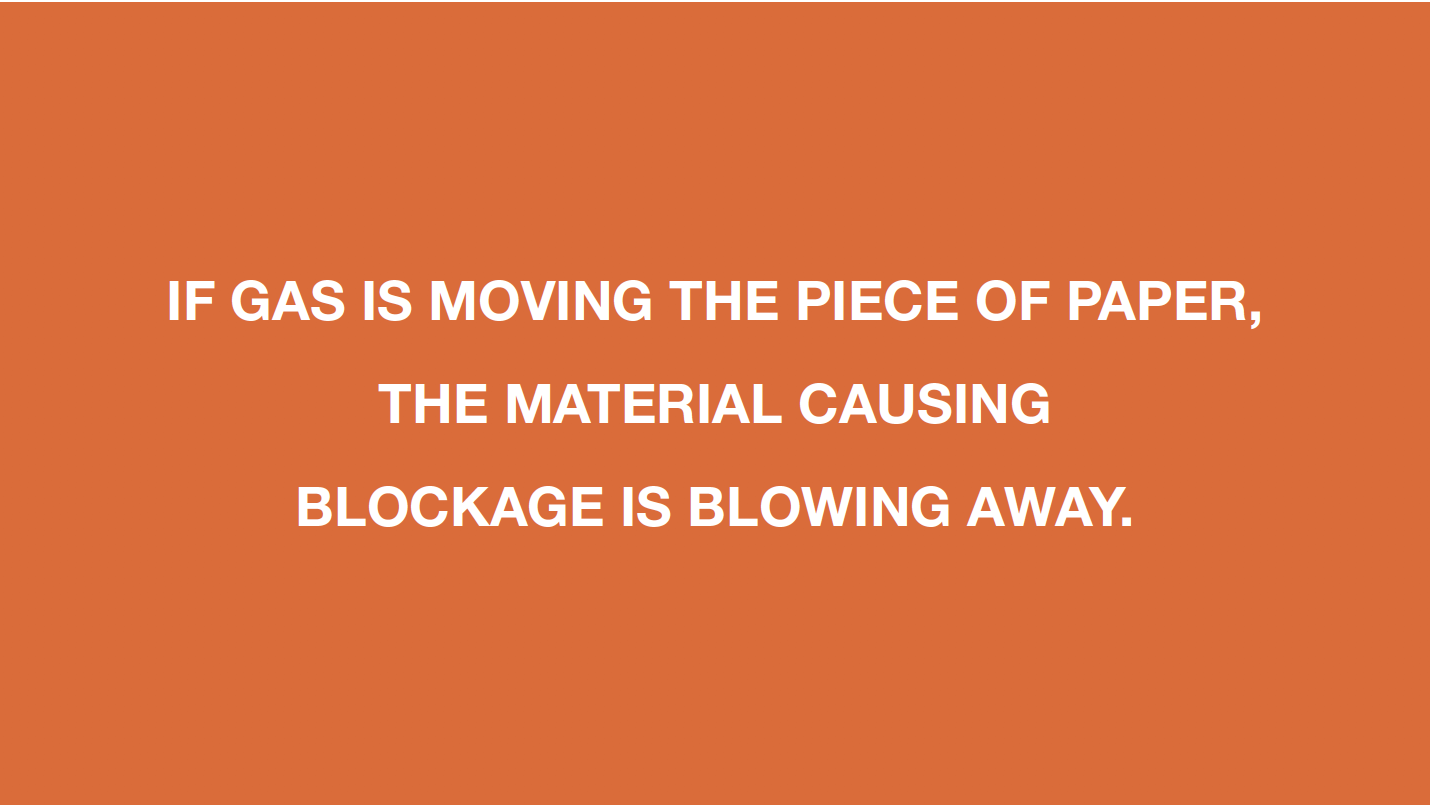

Step 8

Check if gas is blowing out from capillary.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Clean paint from brazed joint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and shake to remove the cut end.

Step 4

Braze on a new dryingfilter.

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Test for leaks on brazed joints of drying-filter and processing pipe on compressor.

Step 8

Vacuum and recharge. Click below link to get more details for vocuuming and gas-charging requirements, go to Annex B2

Step 9

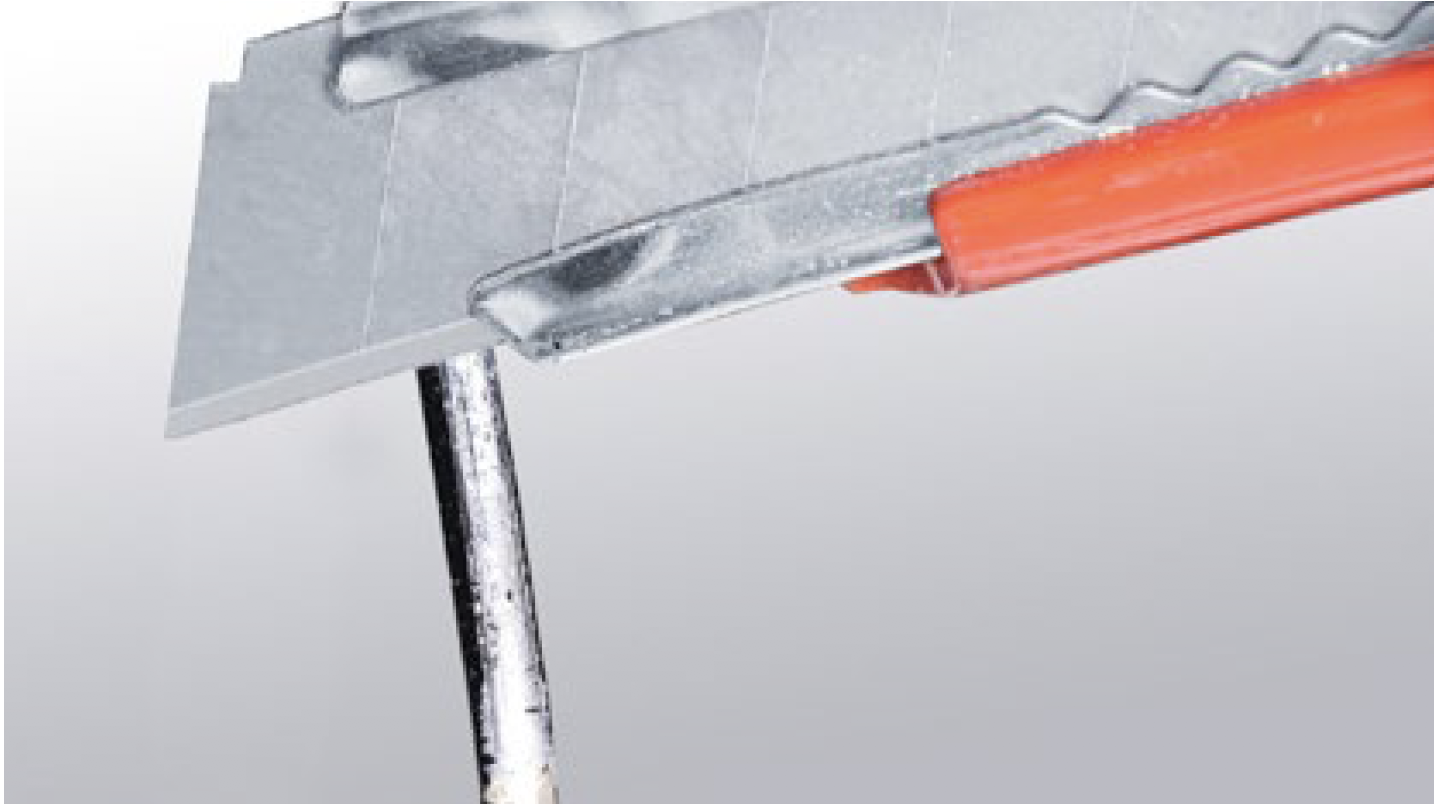

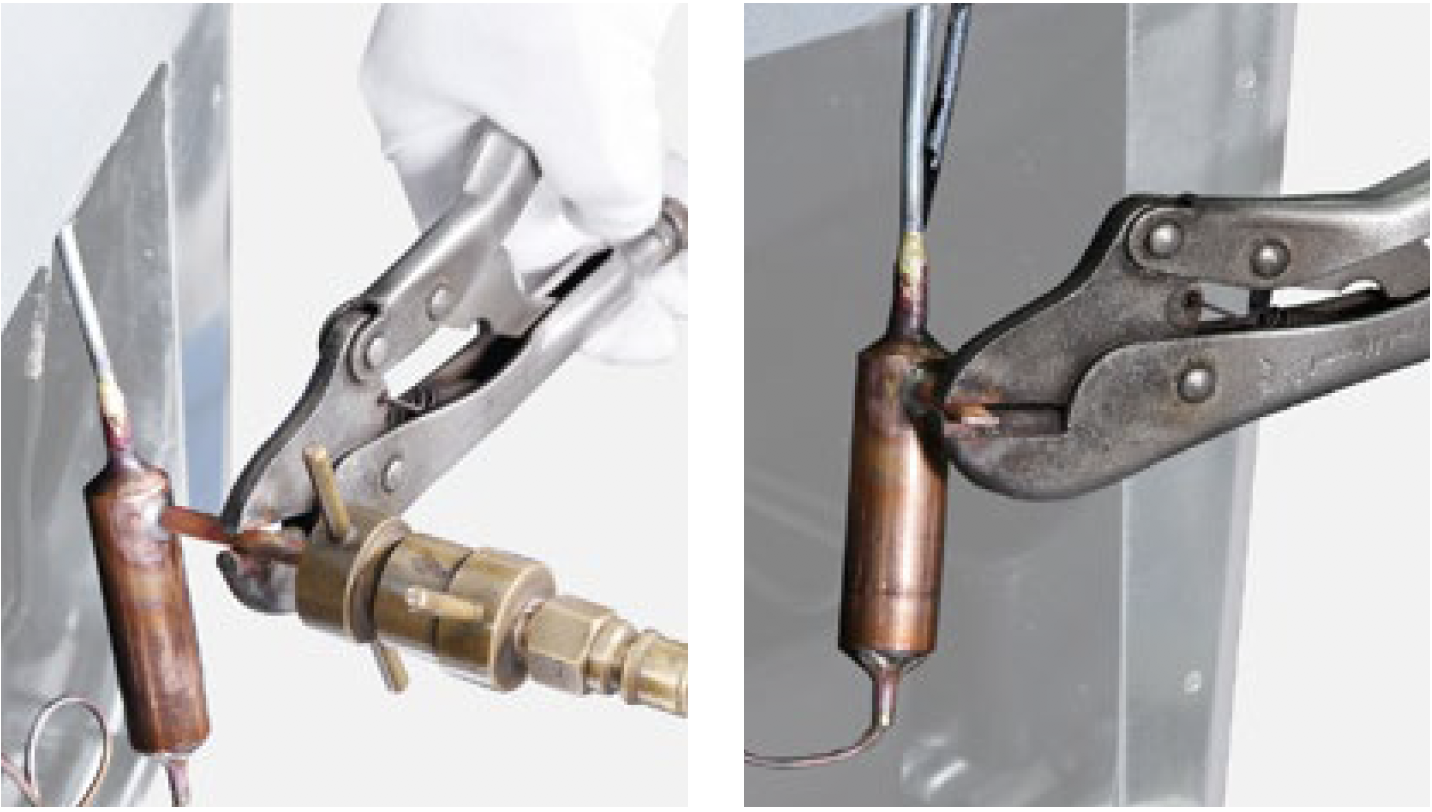

Block processing pipe twice by locking pliers.

Step 10

Step 11

Braze the ends and remove the pliers.

DIAGNOSIS 2