Step 1

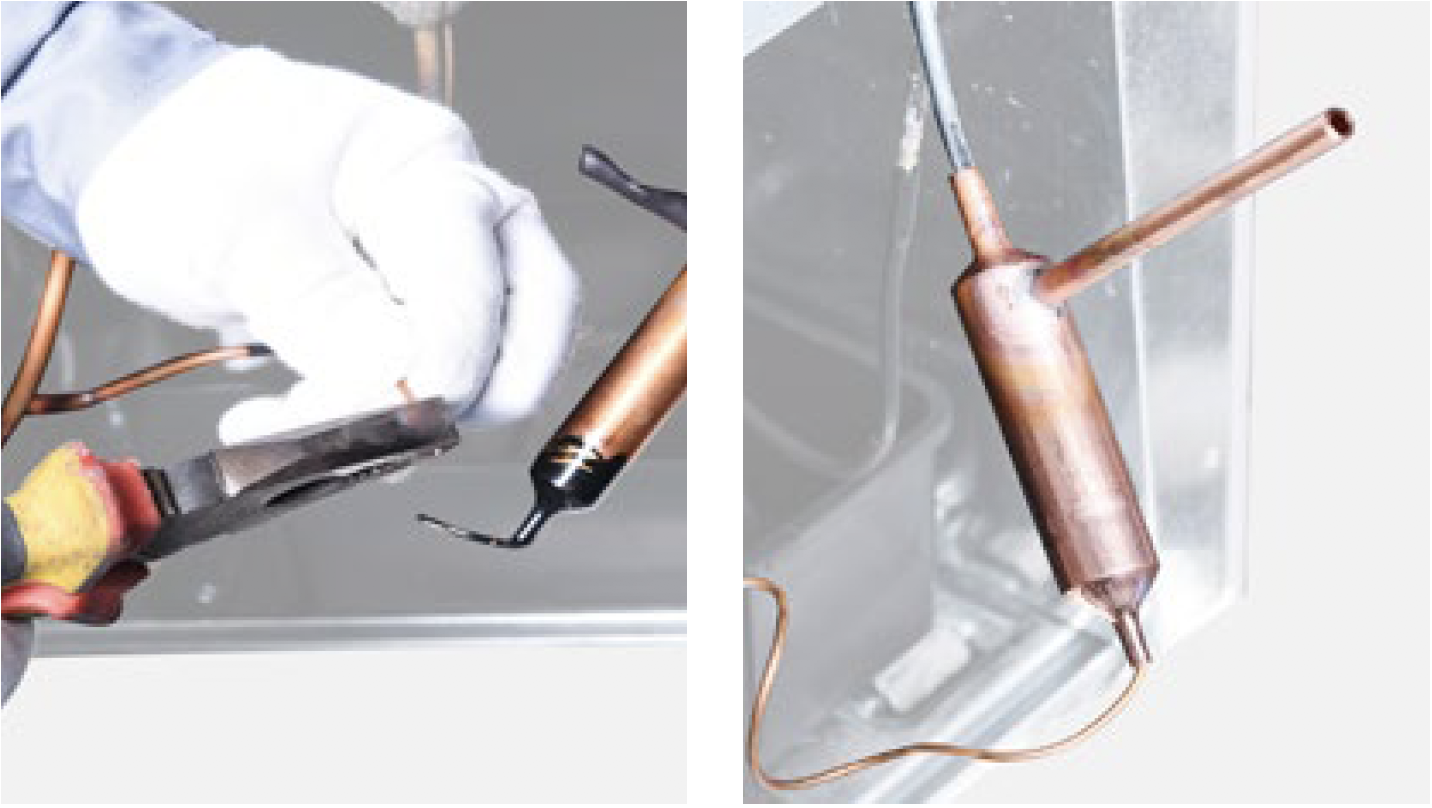

Cut off capillary to discharge refrigerant.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhaust pipe and suction pipe.

Step 4

Power up the compressor and feel the exhaust pressure from the exhaust pipe with a piece of paper.

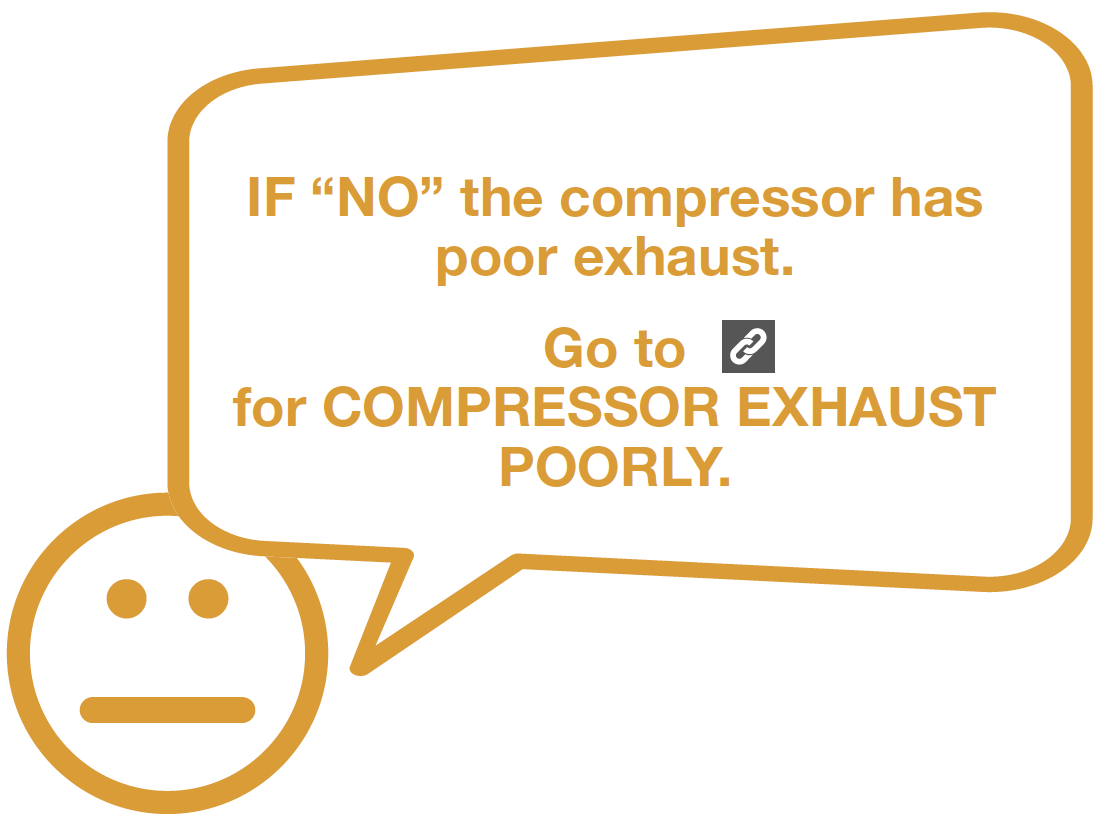

DIAGNOSIS 1

PROCEDURE 1

Step 1

Cut off capillary and shake to remove the cut end.

Step 2

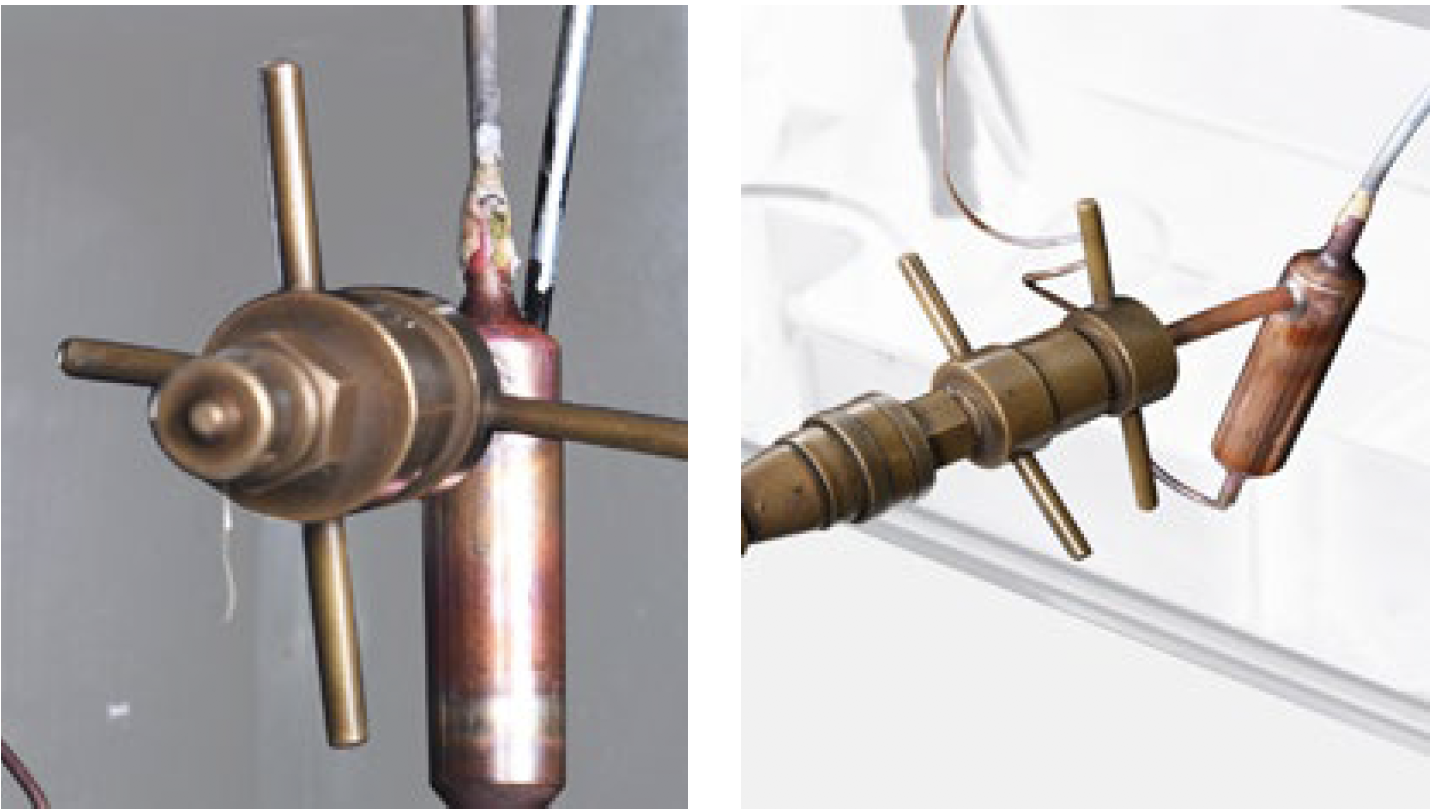

Braze on a new drying- filter.

Step 3

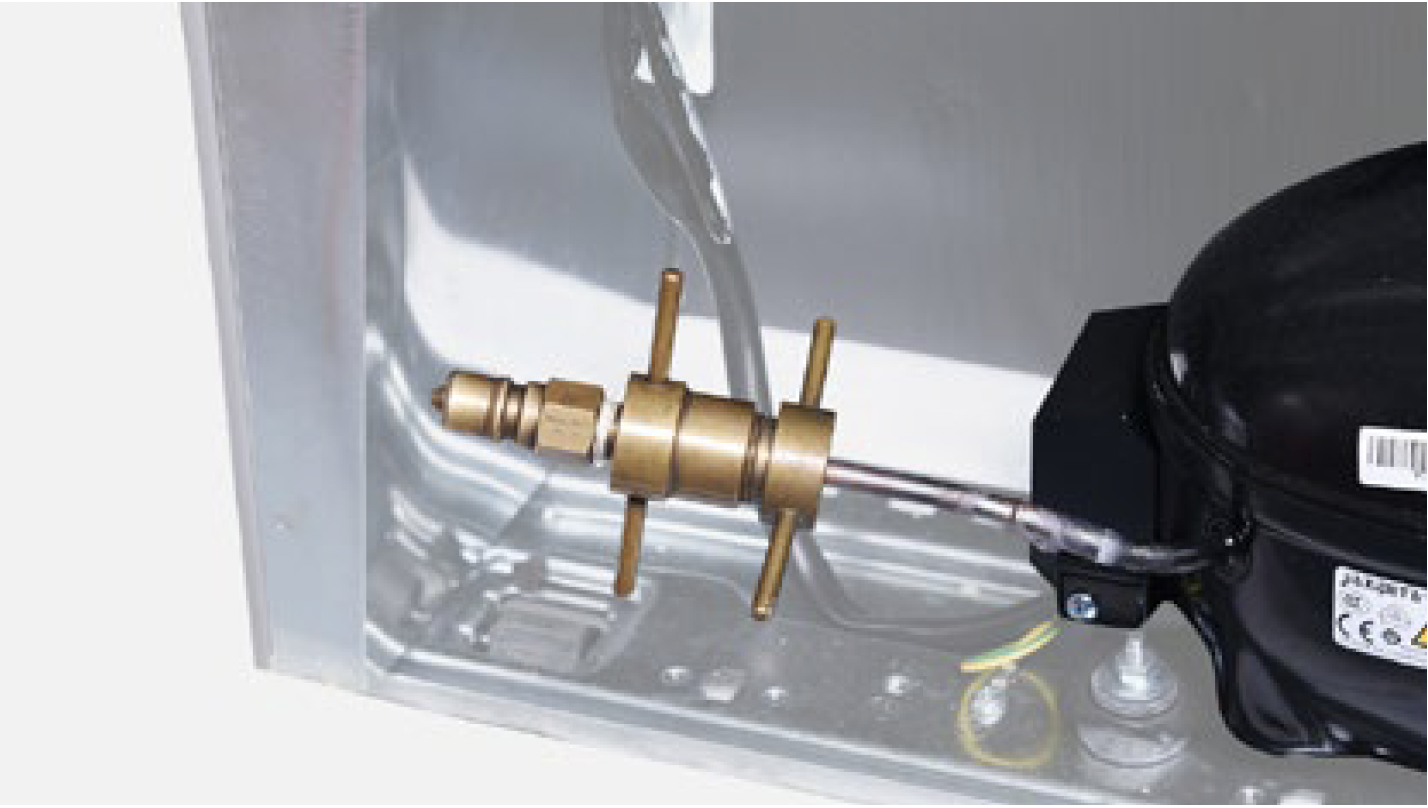

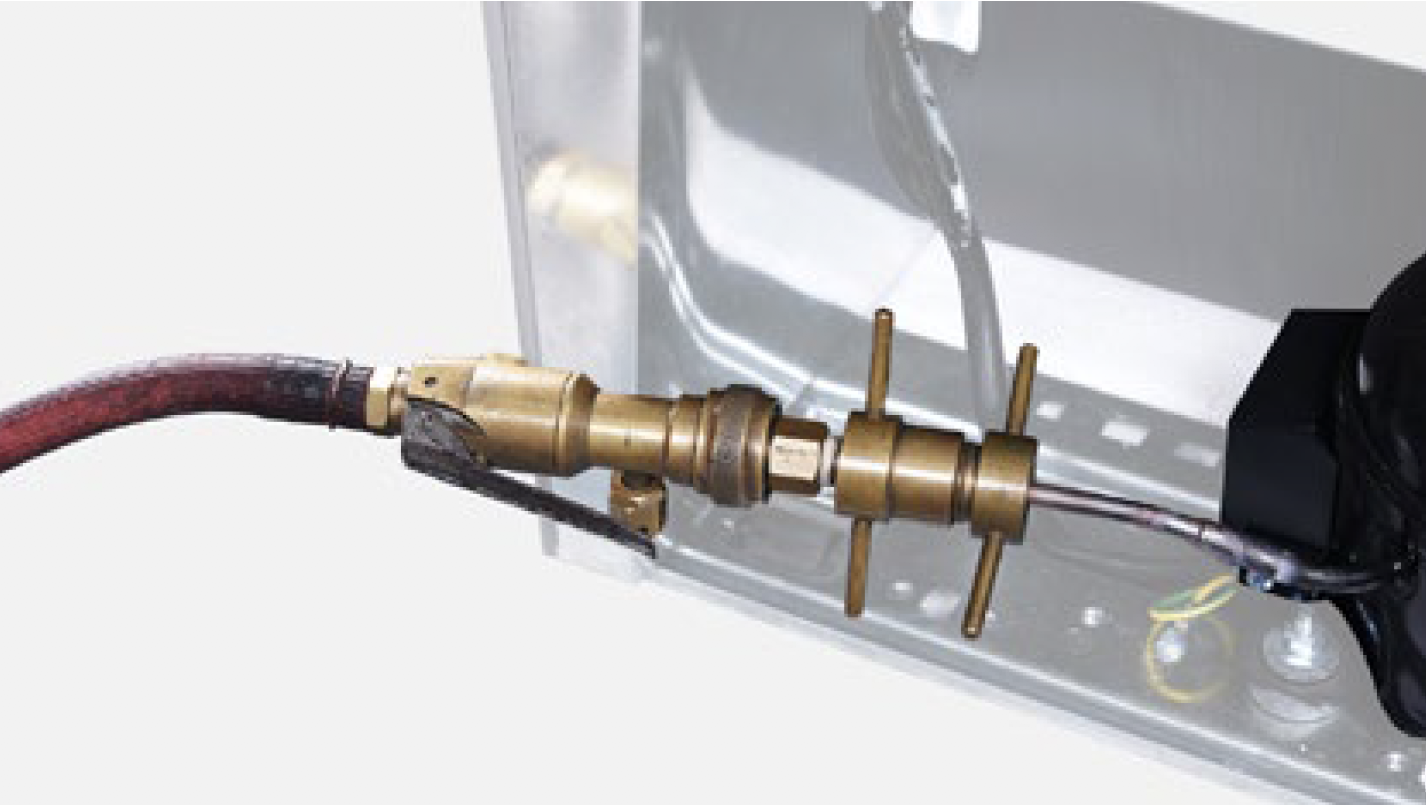

Add quick connector onto processing pipe of drying-filter.

Step 4

Inject nitrogen (1.57Mpa) through quick connector into pipe.

Step 5

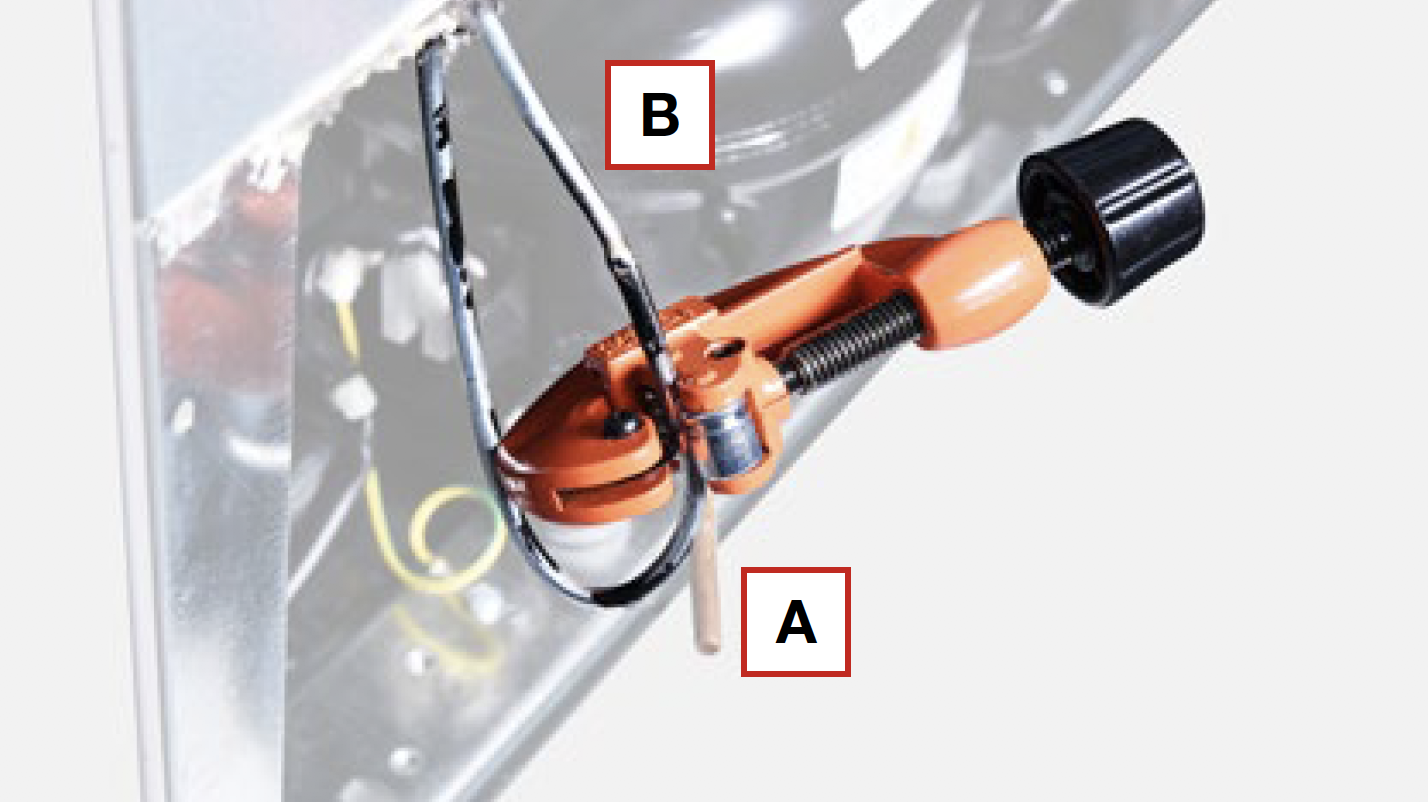

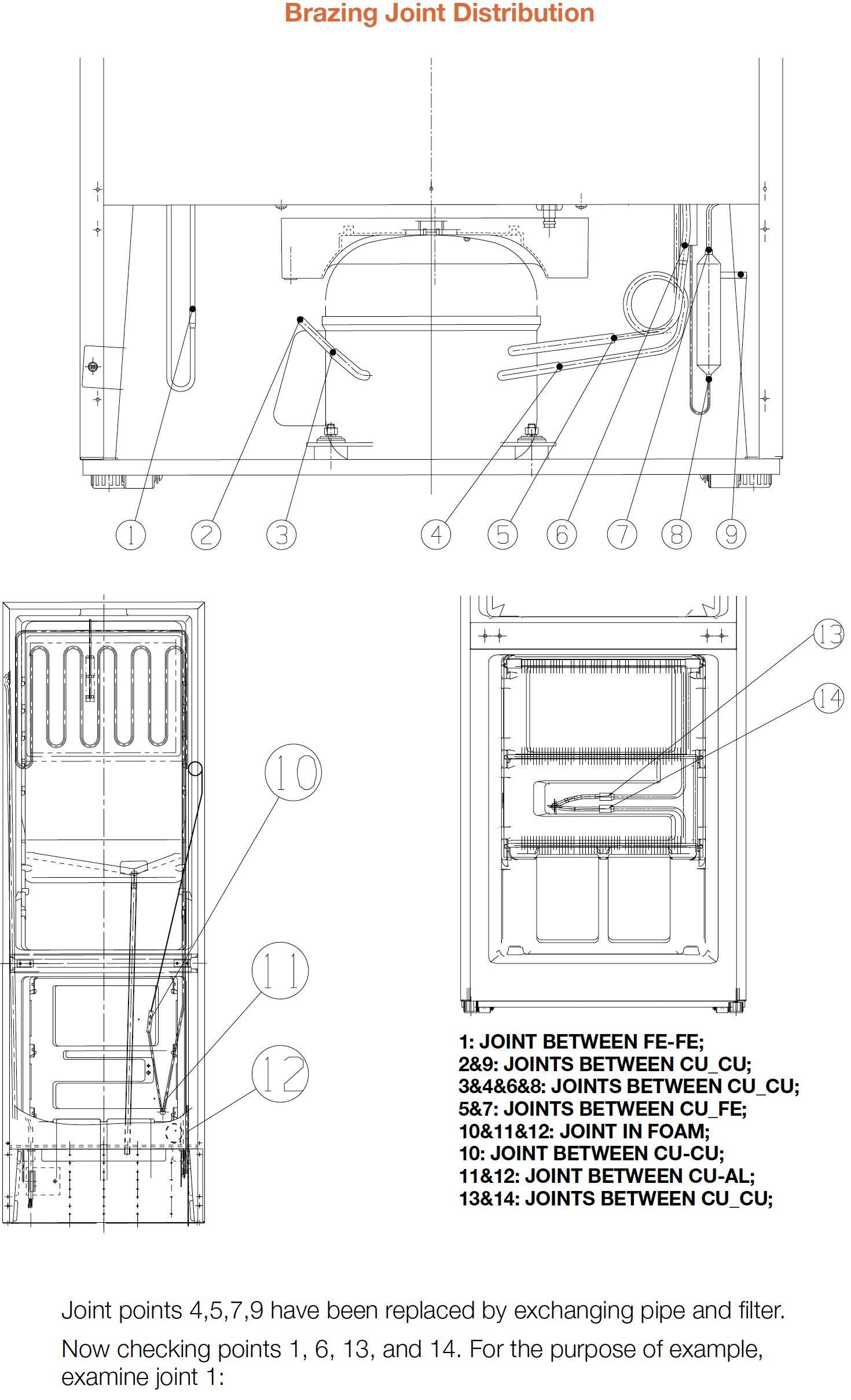

First, cut off the end closed to exhausting end (A in picture)

Step 6

Then, cut off the end closed to suction end, and check whether the pressure is reduced or not.

NOTE

Step 7

Cut off brazed joints, one by one, to find blockage point.Every time you cut off one joint, check whether the gas pressure from suction pipe has dropped or not.

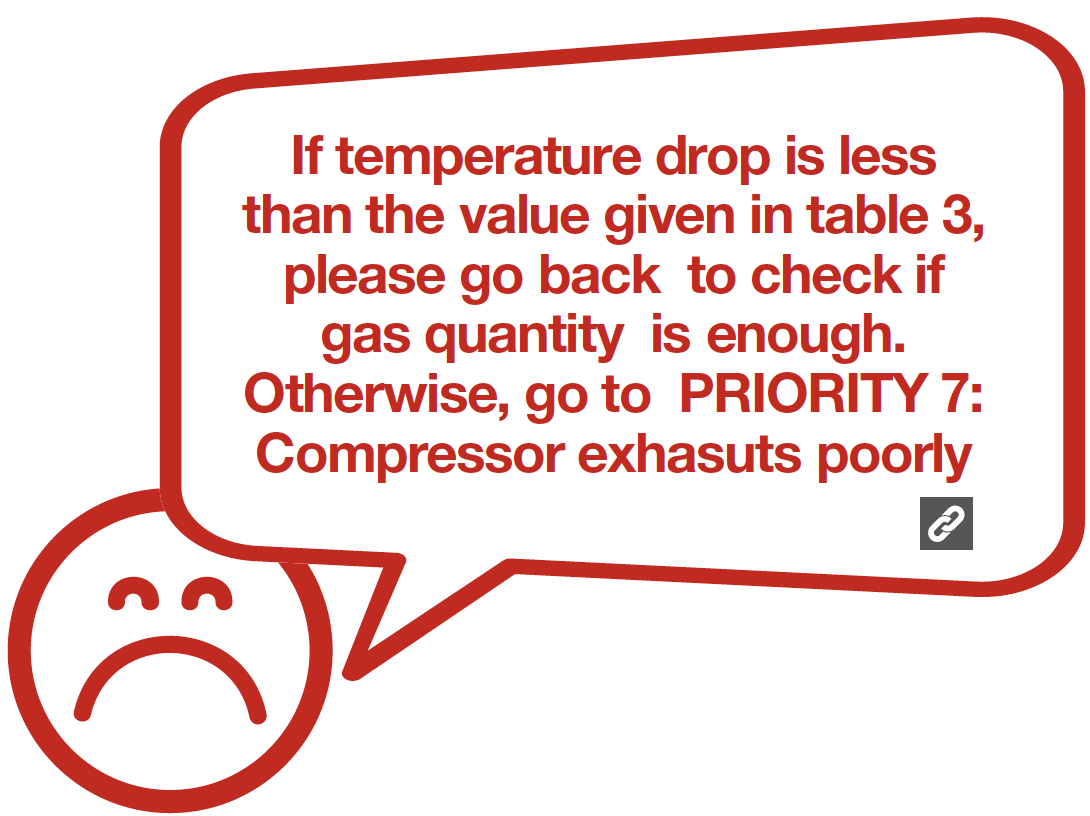

DIAGNOSIS 2

NOTE

PROCEDURE 1

Step 1

Use a larger copper tube to connect 2 ends of brazed joint.

Step 2

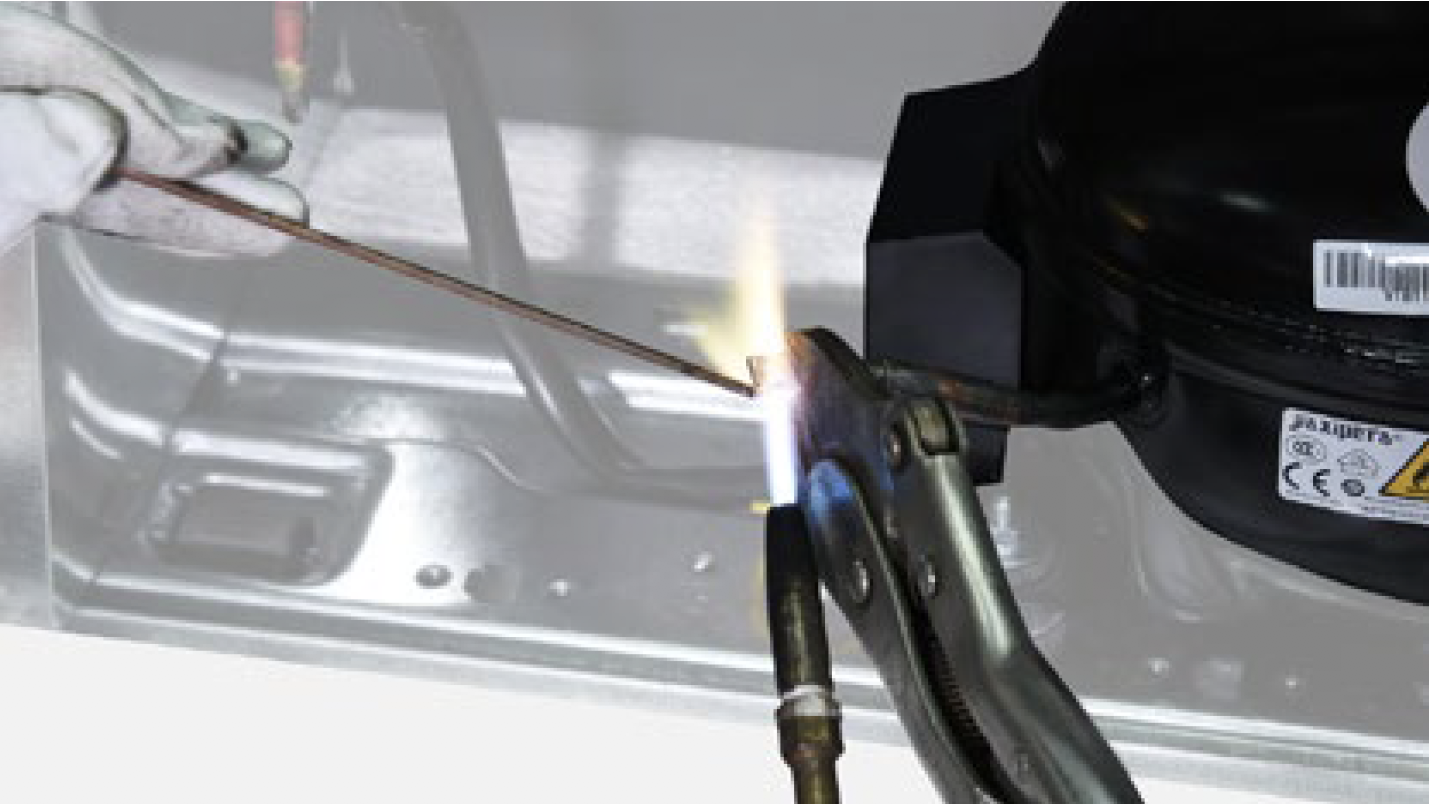

Braze the 2 ends. Click below link to get more details for brazing requirements, go to Annex B1

NOTE

PROCEDURE 2

Step 1

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 2

Re-braze a copper tube onto compressor processing tube.

Step 3

Install quick connector onto rebrazed pipe.

Step 4

Braze the joints of suction and exhasuting pipes.

Step 5

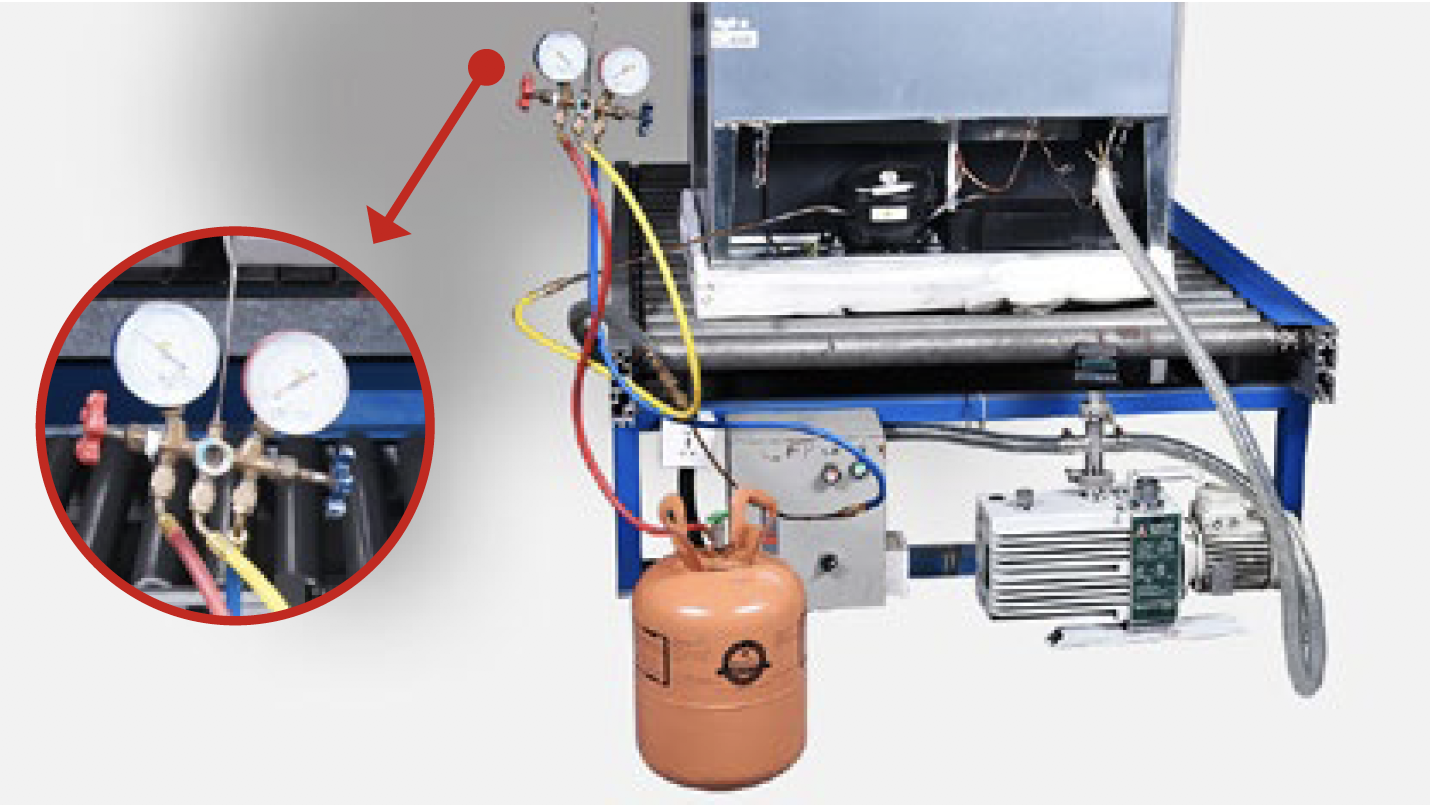

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow left refrigerant away.

Step 6

Perform a leakage test on all re-brazed joints of drying-filter and processing pipe on compressor.

Step 7

Vacuum and recharge.

Click below link to get more details for vocuuming and gas-charging requirements, go to Annex B2

Step 8

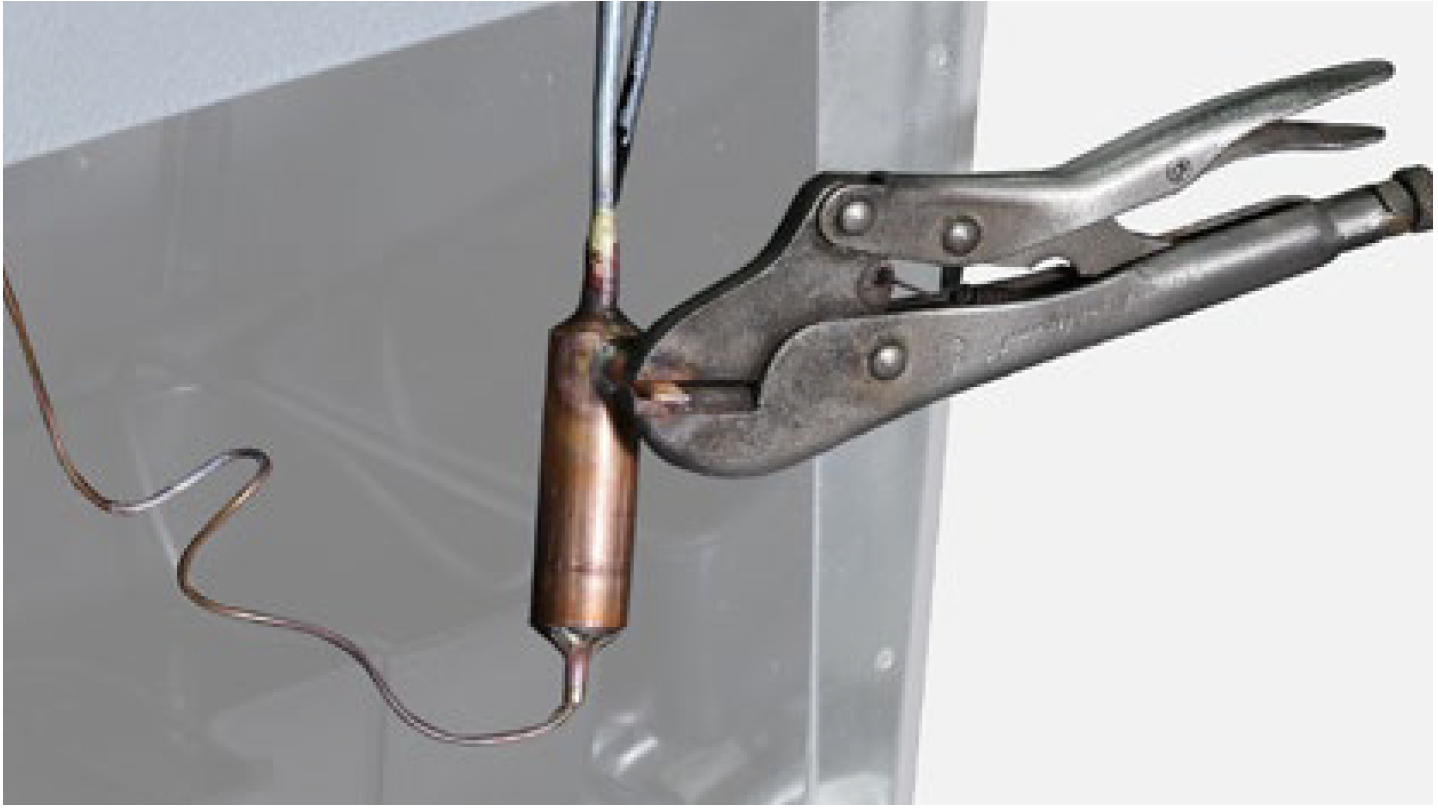

Block processing pipe twice with locking pliers.

Step 9

Leave locking pliers on the second block and cut off the rest of the pipe by shaking.

Step 10

Braze the ends and remove the pliers.

DIAGNOSIS 3