CHECK AND TEST 1

When listening, the compressor is clearly louder than normal.

If you hold compressor firmly with your hand, the noise can be reduced.

PROCEDURE 1

Step 1

Discharge refrigerant. Cut charging tube off with pliers.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off suction pipe and exhaust pipe.

Step 4

Unscrew terminal cover.

Step 5

Remove terminal cover.

Step 6

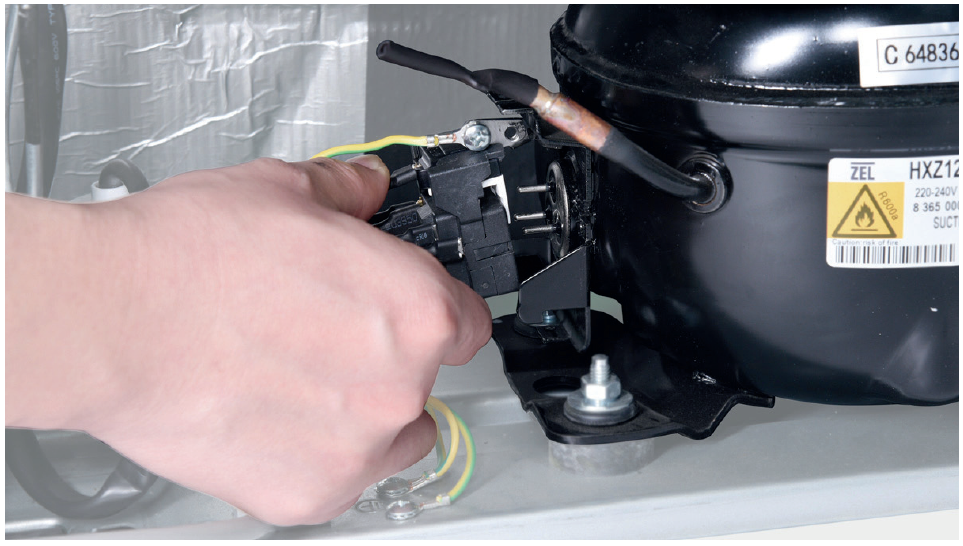

Remove protector and starter.

Step 7

Unscrew earthing wire.

Step 8

Unscrew nut on compressor.

Step 9

Step 10

Braze the joints of suction and exhaust pipes.

Step 11

Re-braze a copper tube onto compressor processing tube.

Step 12

Install quick connector onto re-brazed pipe.

Step 13

Melt brazing material with flame and pull out processing tube with pliers.

Step 14

Step 1

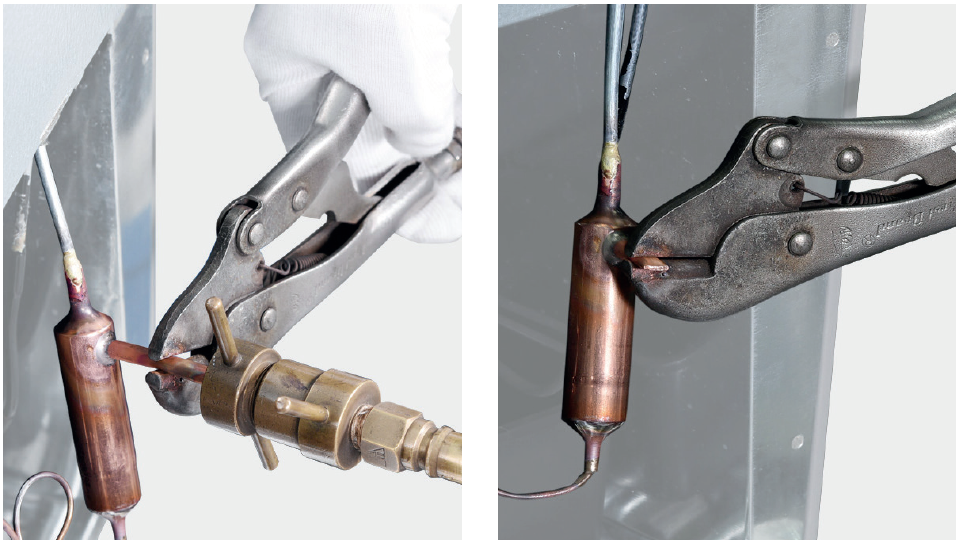

Clean paint off brazed joint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and remove the cut end by shaking.

Step 4

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Step 8

Vacuum and recharge. Please get more details of vacuuming and gascharging requirements on 10.5 Annex B2.

Step 9

Block processing pipe twice with locking pliers.

Step 10

Step 11

Braze the ends and remove the pliers.