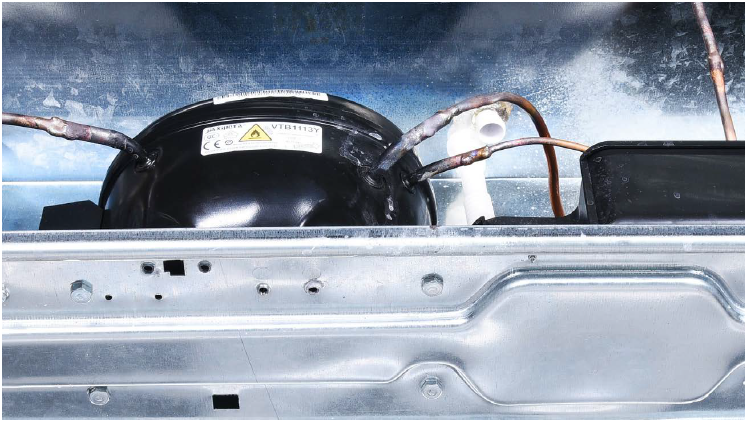

Step 1

Cut off capillary to discharge refrigerant.

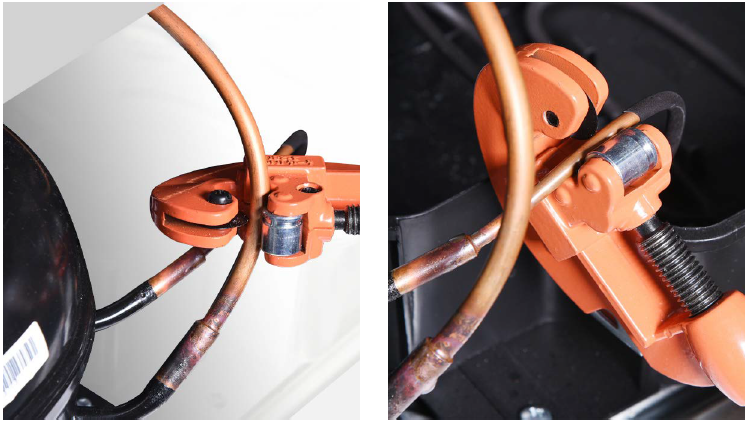

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhaust pipe and suction pipe.

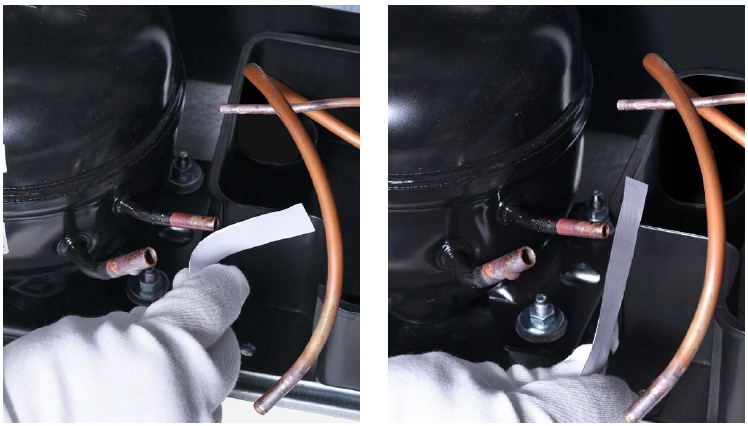

Step 4

Power up the compressor and feel the exhaust pressure from the exhaust pipe with a piece of paper.

DIAGNOSIS 1

CHECK AND TEST 2

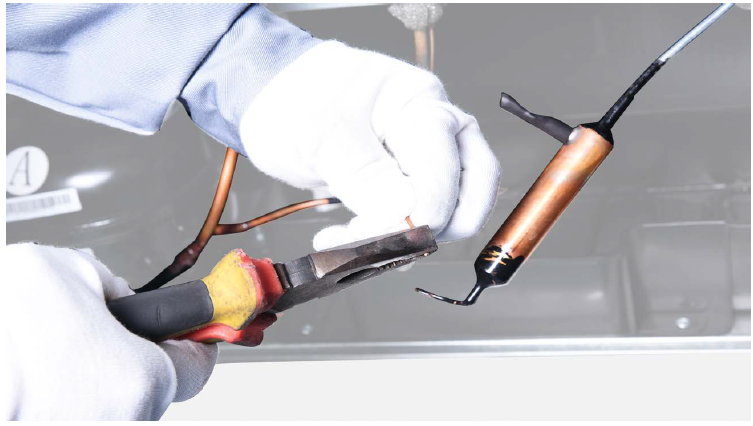

Step 1

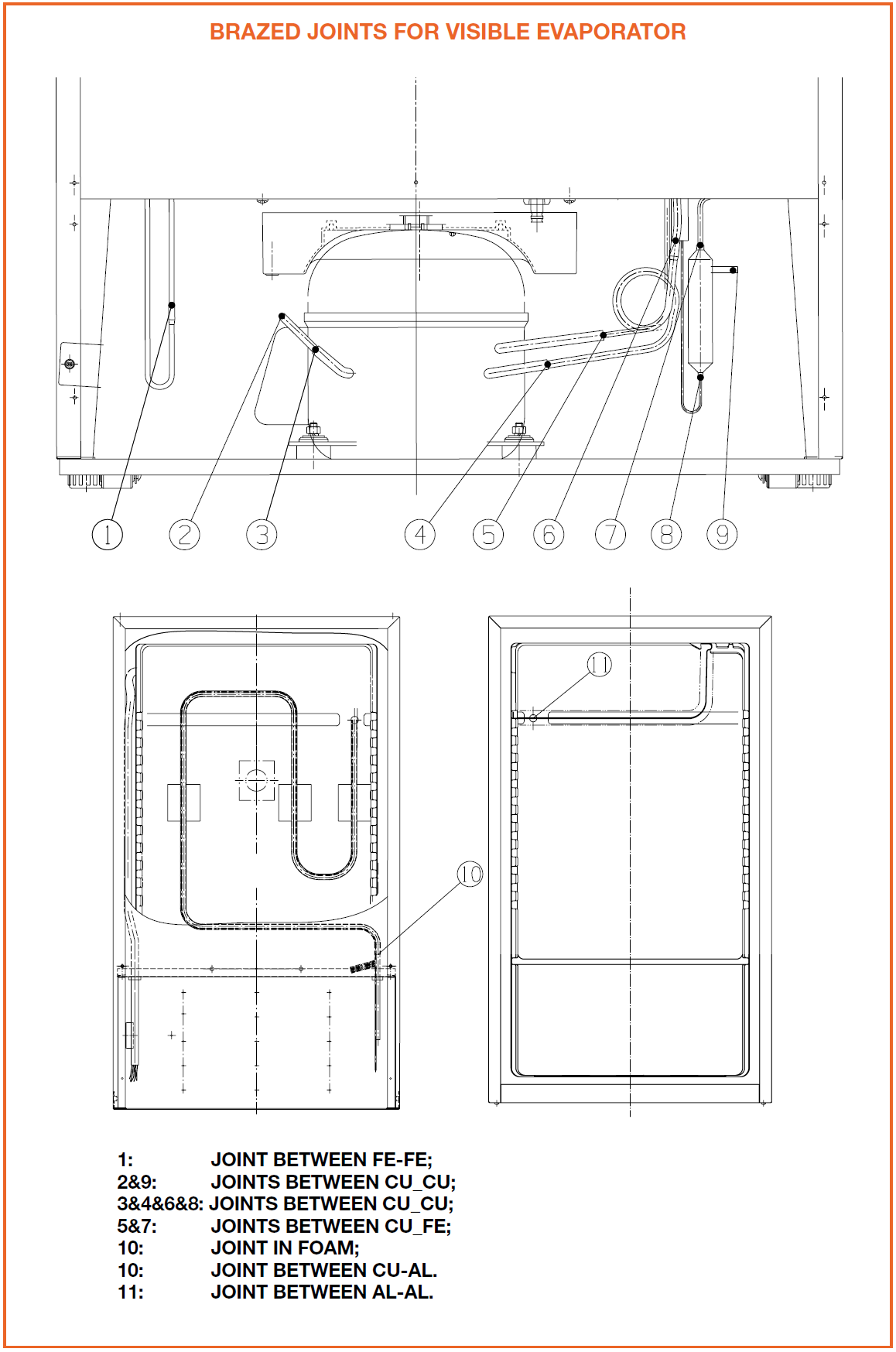

Braze the joints of suction and exhaust pipes.

Step 2

Melt brazing material with flame and pull out processing tube with pliers.

Step 3

Re-braze a copper tube onto processing tube of

compressor. Please find more details

of brazing requirements, on 10.4 Annex B1.

NOTE

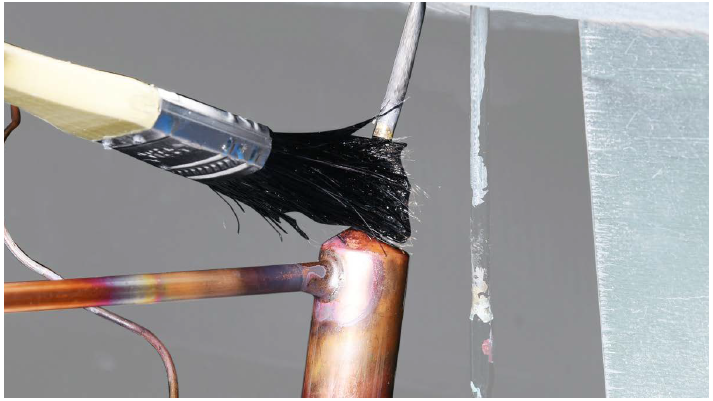

Step 4

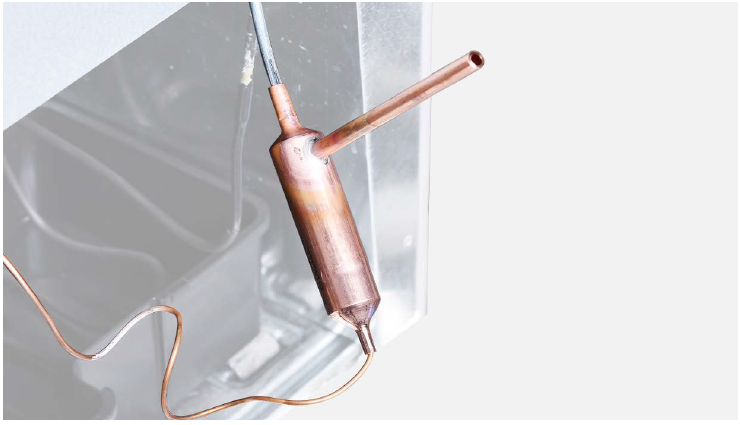

Exchange the filter. Clean paint off of brazed

joint of drying filter.

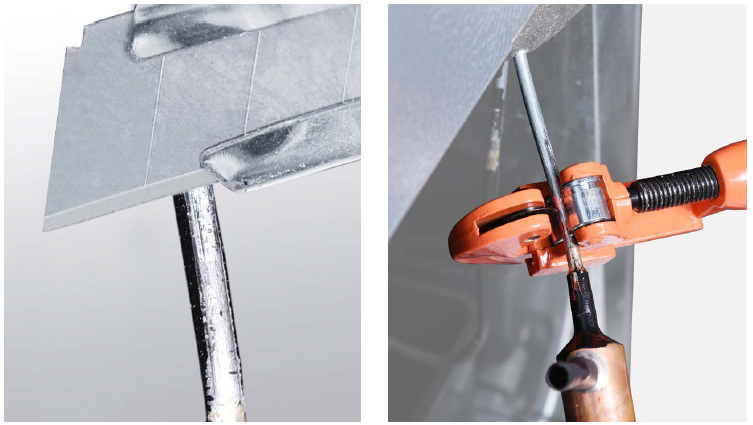

Step 5

Cut off drying-filter.

Step 6

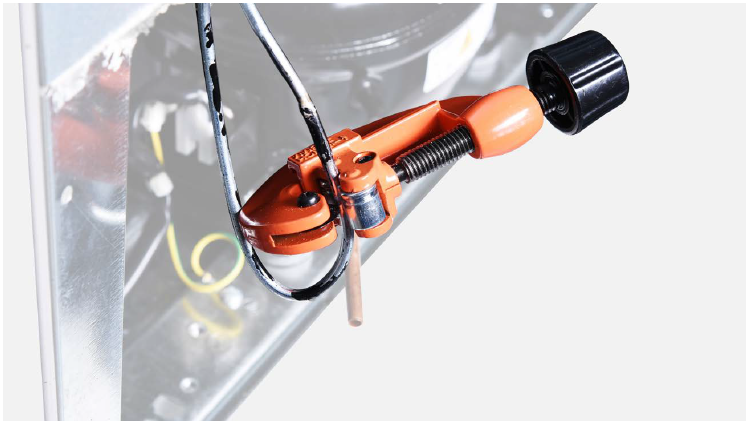

Cut off capillary and shake to remove the cut end.

Step 7

Braze on a new drying filter.

Step 8

Add quick connector onto processing pipe of drying-filter.

Step 9

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 10

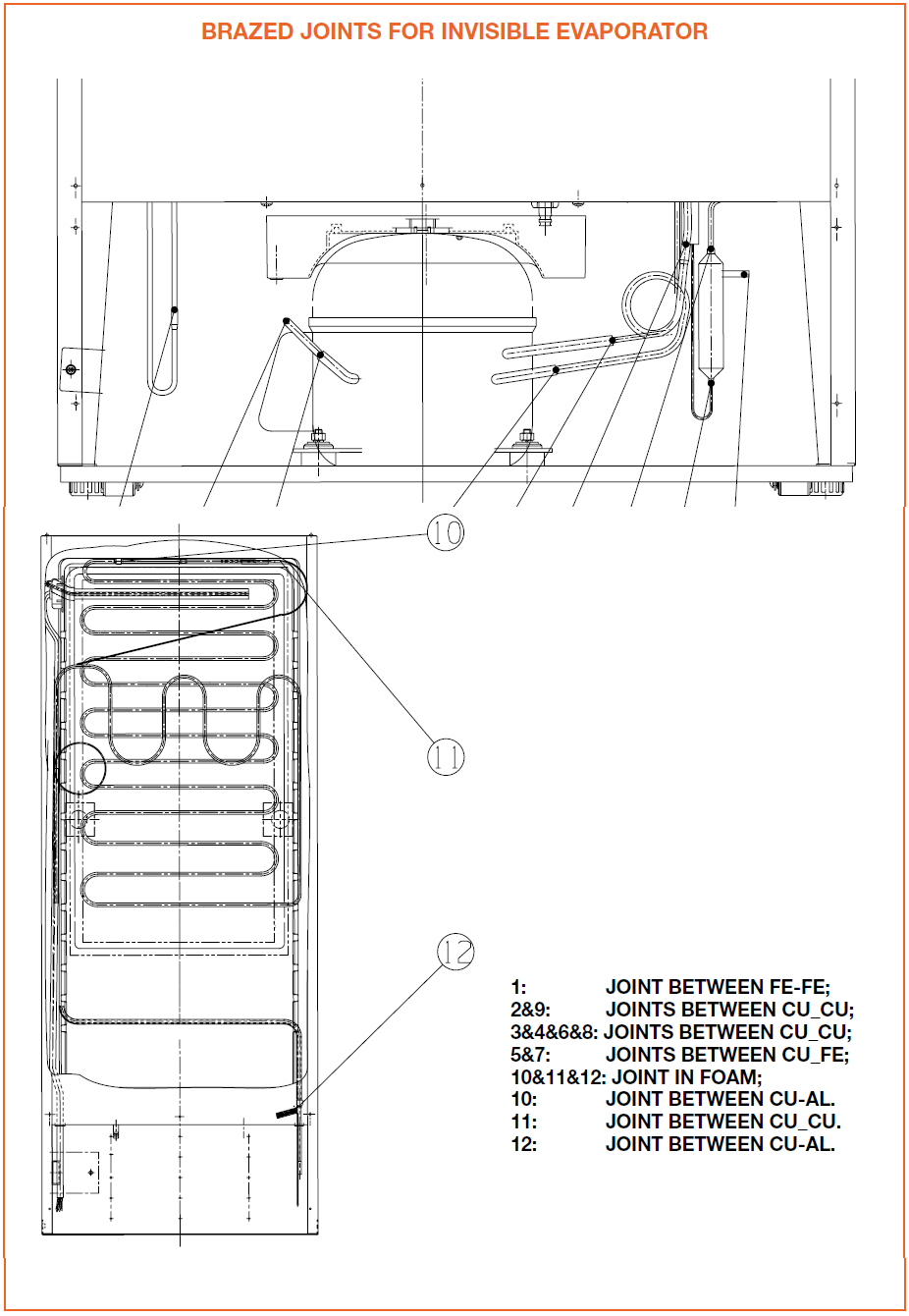

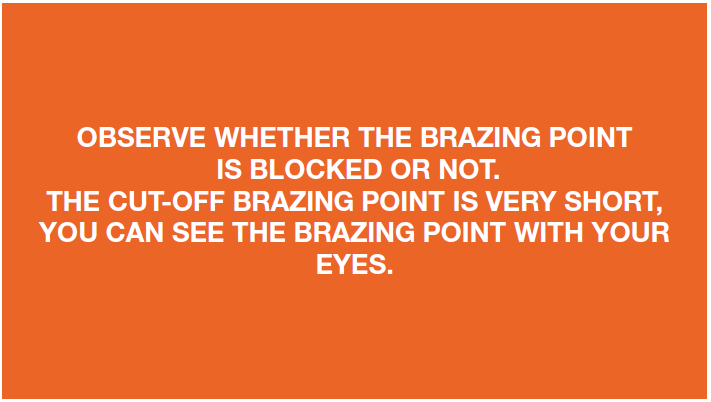

Cut off brazed joints, one by one, to find blockage point.

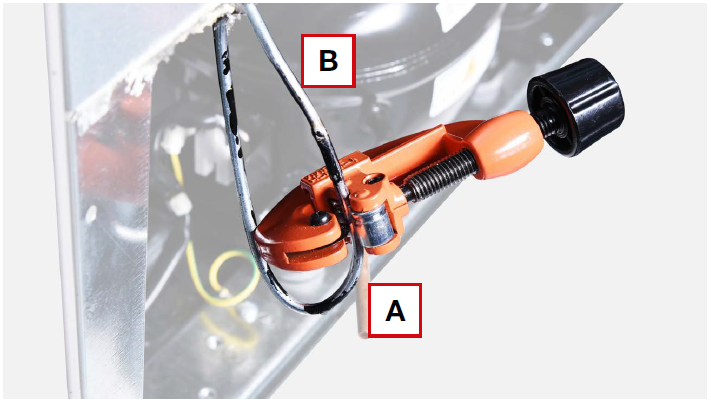

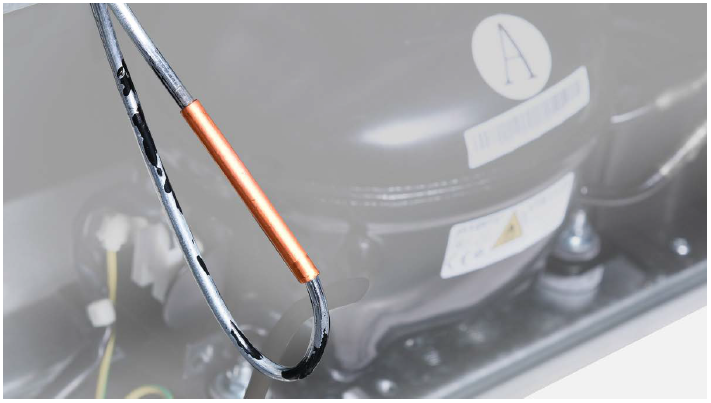

Step 11

First, cut off end closed to exhaust end (A in right picture).

Step 12

Then, cut off the end closed to suction end.

PROCEDURE 1

Step 1

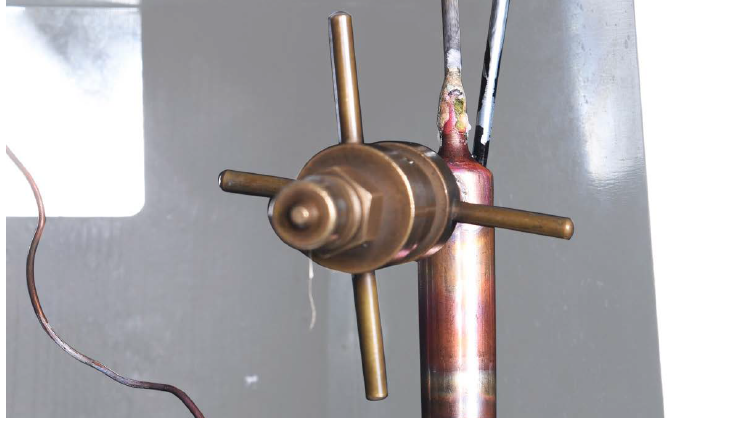

Use a larger copper tube to connect 2 ends of brazed joint.

Step 2

Braze the 2 ends.

Step 3

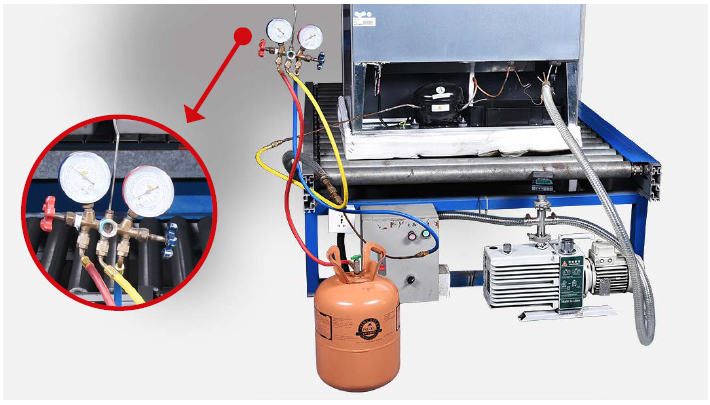

Perform a leakage test on all re-brazed joints of drying-filter and compressor processing pipe.

Step 4

Vacuum and recharge. Please get more details of vacuuming and gascharging requirements on 10.5 Annex B2.

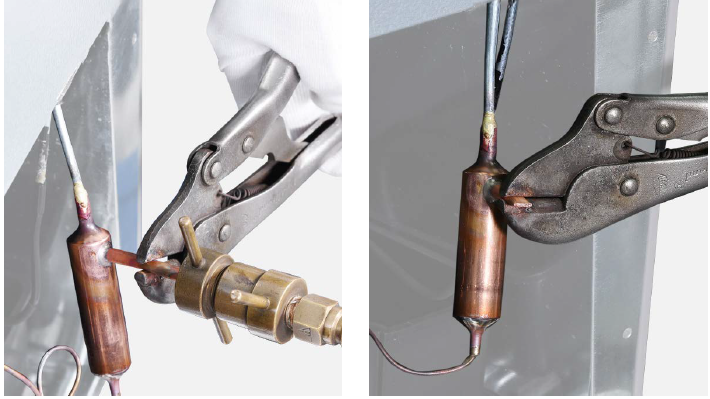

Step 5

Block processing pipe twice by locking pliers.

Step 6

Leave locked pliers attached to second

block and shake to cut off the remaining pipe.

Step 7

Braze the ends and remove the pliers.