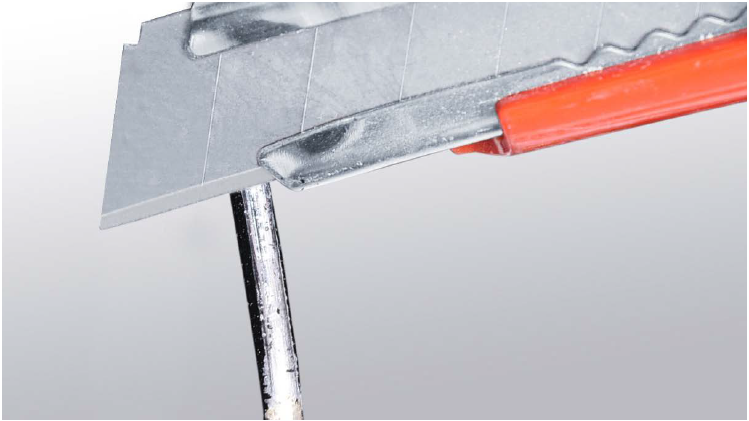

Step 1

Cut off capillary to discharge refrigerant.

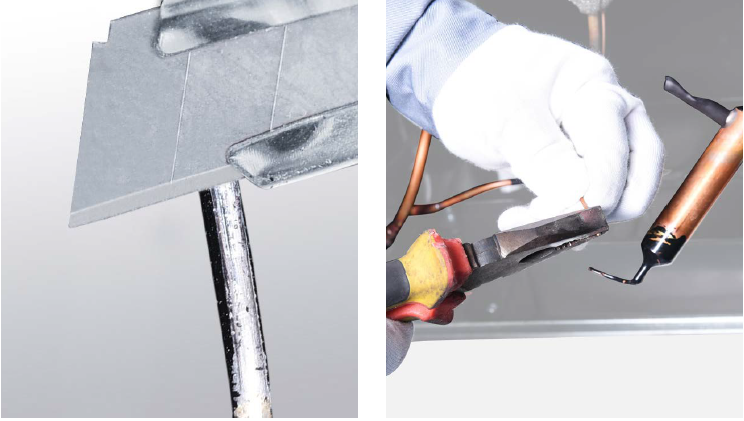

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhaust pipe and

suction pipe.

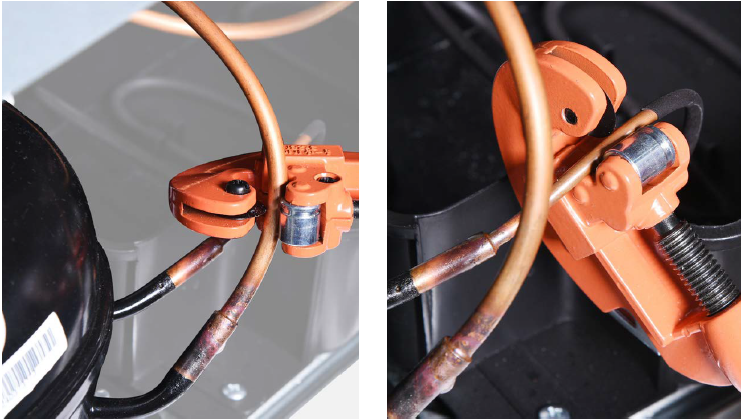

Step 4

Power up the compressor and feel the exhaust pressure from the exhaust pipe with a piece of paper.

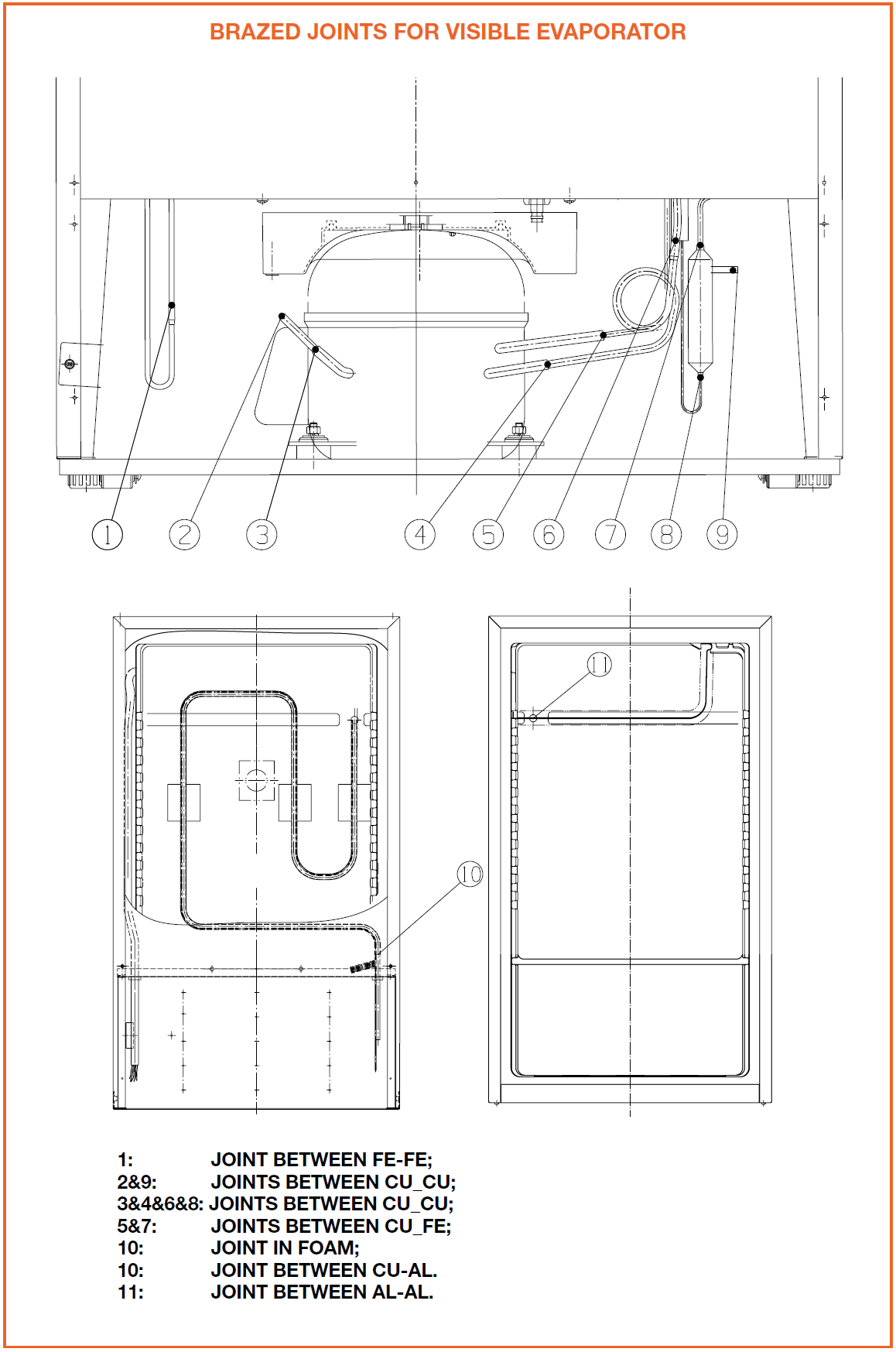

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

Braze the joints of suction and exhaust pipes.

Step 2

Melt brazing material with flame and pull out

processing tube with pliers.

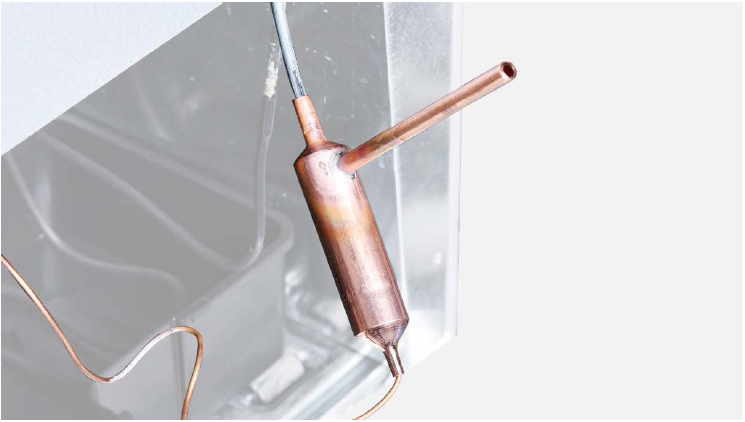

Step 3

Re-braze a copper tube onto processing tube of

compressor. Please find more details of brazing requirements, on 10.4 Annex B1.

NOTE

Step 4

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

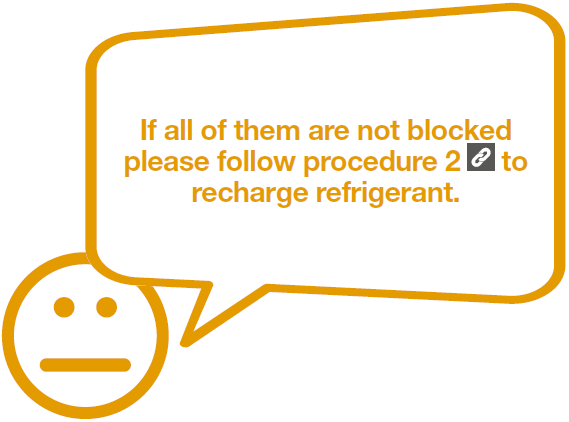

Step 5

Check to see if gas pressure from capillary is

normal or not.

Note:

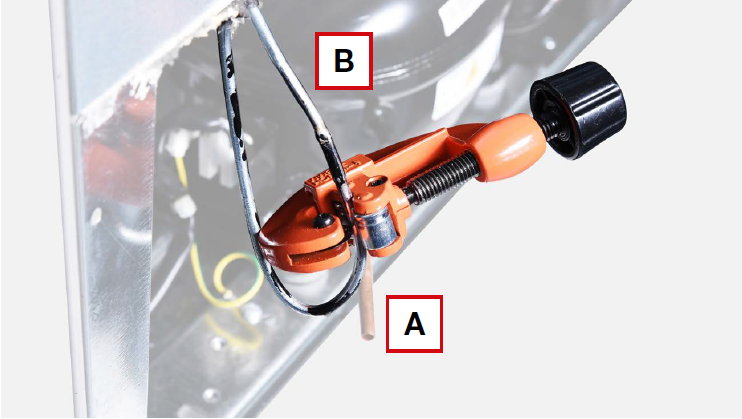

Measure the 2 ends of cutting points

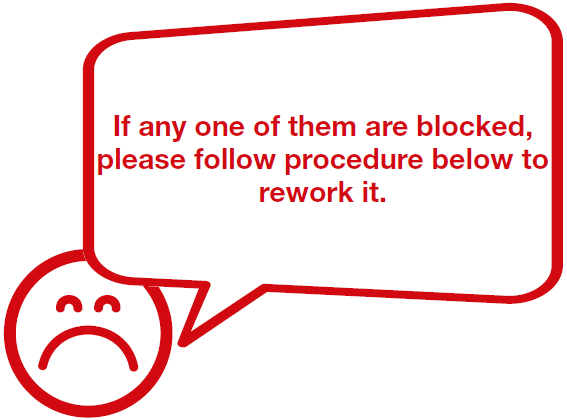

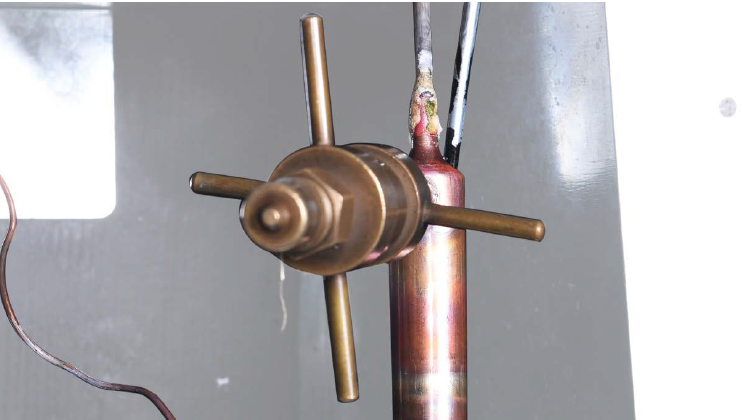

Step 1

First, cut off end closed to exhaust end (A in

below picture).

Step 2

Then, cut off the end closed to suction end, and check whether the pressure is reduced or not.

DIAGNOSIS 3

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Use a larger copper tube to connect 2 ends of

brazed joint.

Step 3

Braze the 2 ends.

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Cut off capillary and shake to remove the cut

end.

Step 3

Braze on a new drying-filter.

Step 4

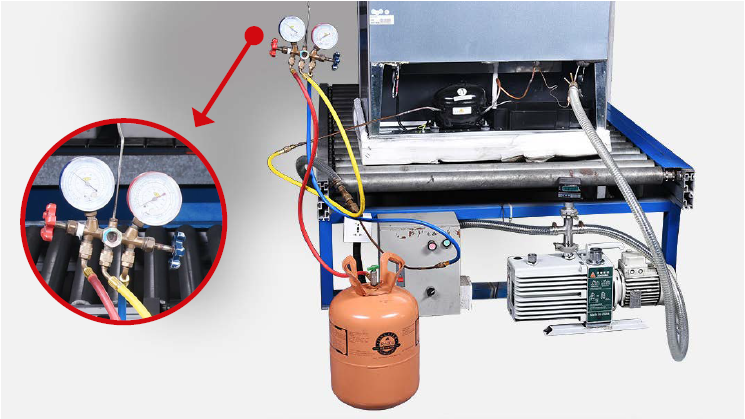

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 5

Add quick connector onto processing pipe of

drying-filter.

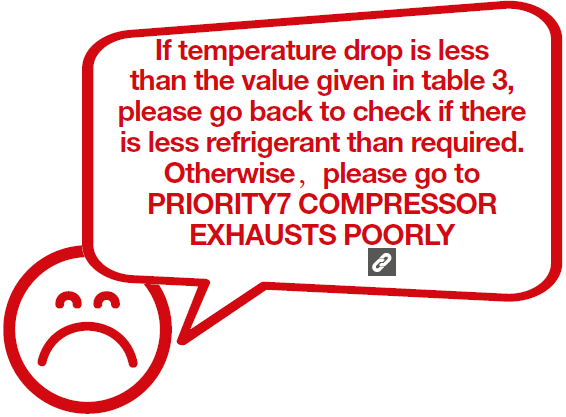

Step 6

Perform a leakage test on all re-brazed joints

of drying-filter and compressor processing pipe.

Step 7

Vacuum and recharge. Please get more details

of vacuuming and gascharging requirements

on 10.5 Annex B2

Step 8

Block processing pipetwice by locking pliers.

Step 9

Leave locked pliers attached to second

block and shake to cut off the remaining pipe.

Step 10

Braze the ends and remove the pliers.