CHECK AND TEST 1

Step 1

By listening, it is evident that the compressor is

louder than normal.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Discharge refrigerant. Cut charging tube off with pliers.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off suction pipe and exhaust pipe.

Step 4

Unscrew terminal cover.

Step 5

Remove terminal cover.

Step 6

Remove protector and starter.

Step 7

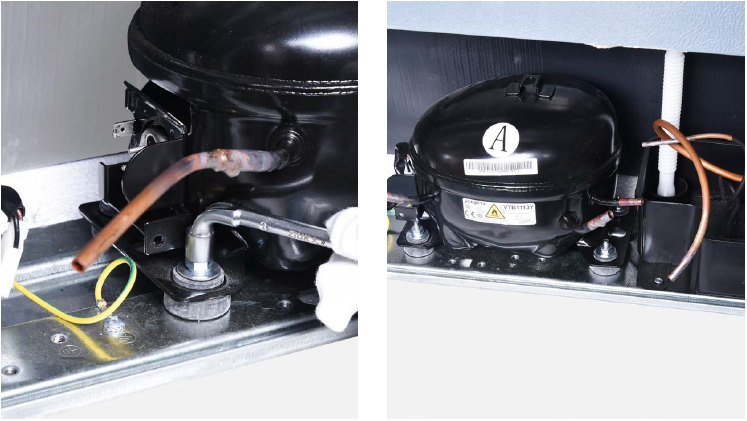

Unscrew earthing wire.

Step 8

Unscrew nut on compressor.

Step 9

Install a new compressor and tighten the nuts onto compressor.

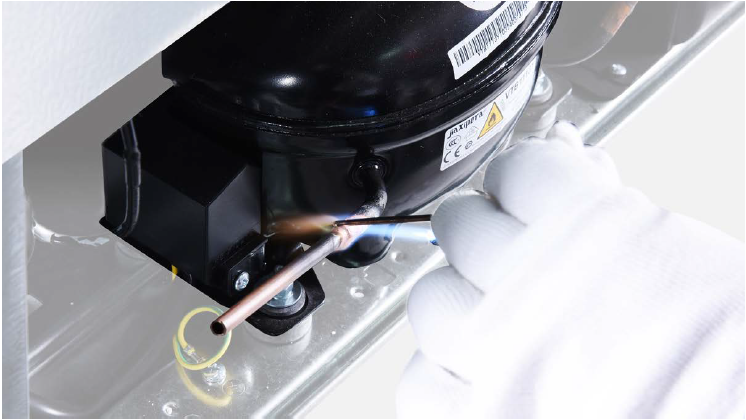

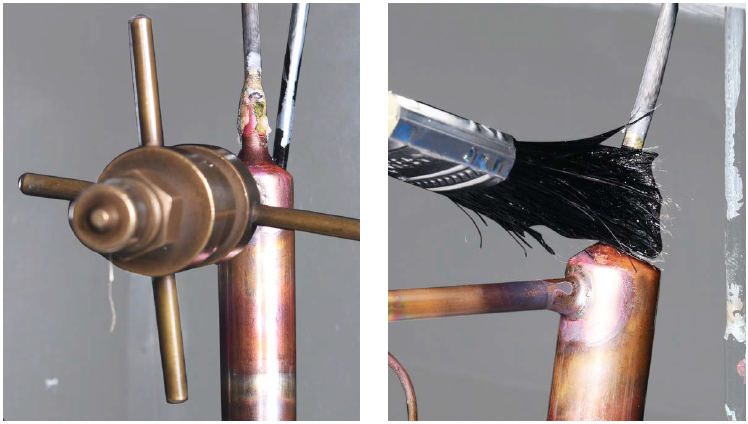

Step 10

Braze the joints of suction and exhaust pipes.

Step 11

Re-braze a copper tube onto processing tube of

compressor. To get more details on brazing requirements, please go to 10.4 Annex B1.

Note

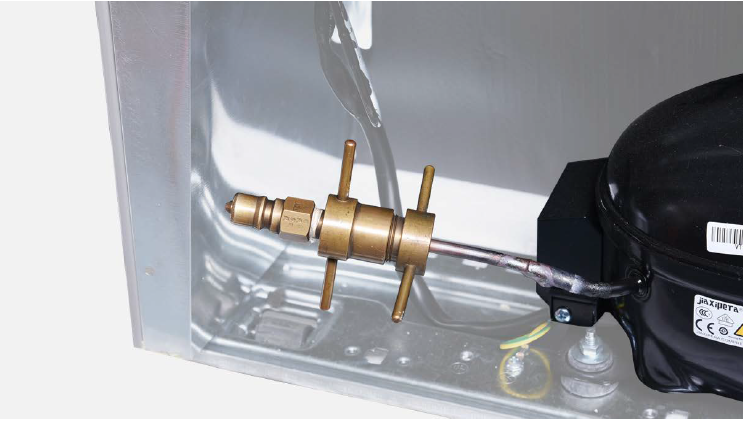

Step 12

Install quick connector onto re-brazed pipe.

Step 1

Clean paint off brazed joint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and remove the cut end by

shaking.

Step 4

Braze on a new drying-filter.

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Perform leakage test on brazed joints of dryingfilter and compressor processing pipe.

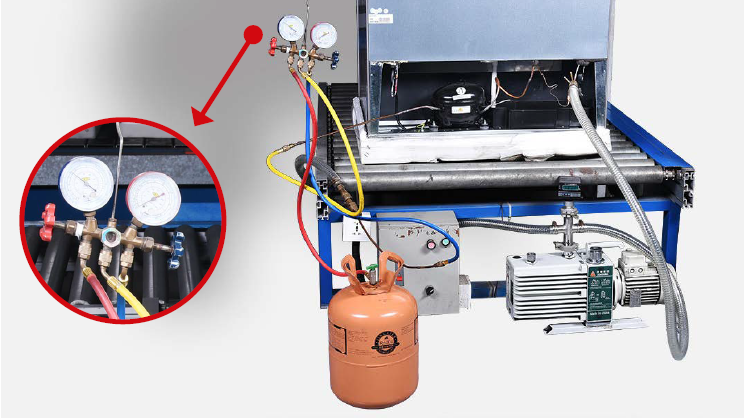

Step 8

Vacuum and recharge. Please get more details

of vaccuming and gascharging requirements

on 10.5 Annex B2.

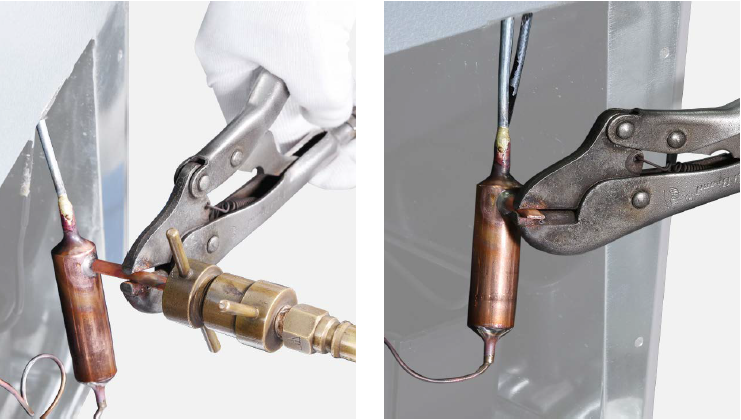

Step 9

Leave locked pliers attached to second

block and shake to cut off the remaining pipe.

Step 10

Braze the ends and remove the pliers.