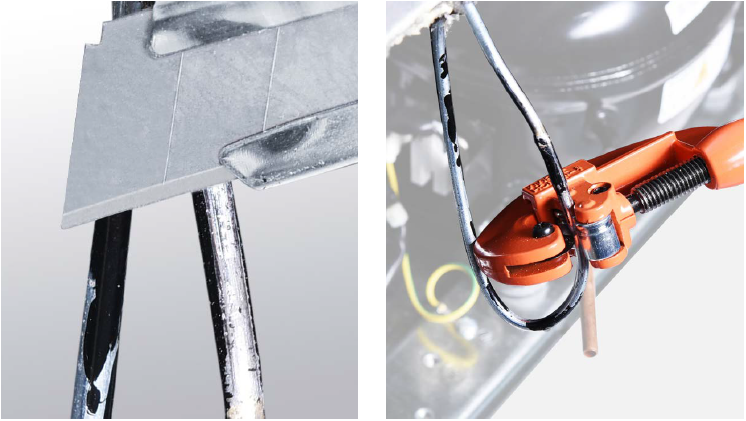

Step 1

Discharge refrigerant. Cut off the charging tube with pliers.

Step 2

Discharge all refrigerant toward the exhaust vent.

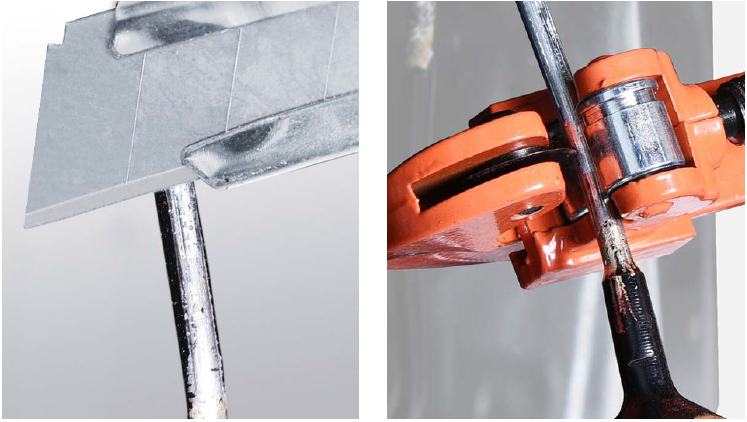

Step 3

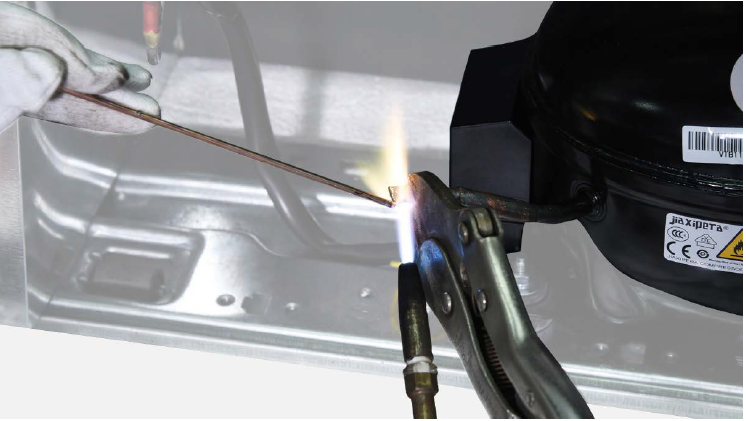

Melt brazing material with flame and pull out

processing tube using a pair of pliers.

Step 4

Re-braze a copper tube onto compressor

processing tube. Please find more details

of brazing requirements, on link .

NOTE

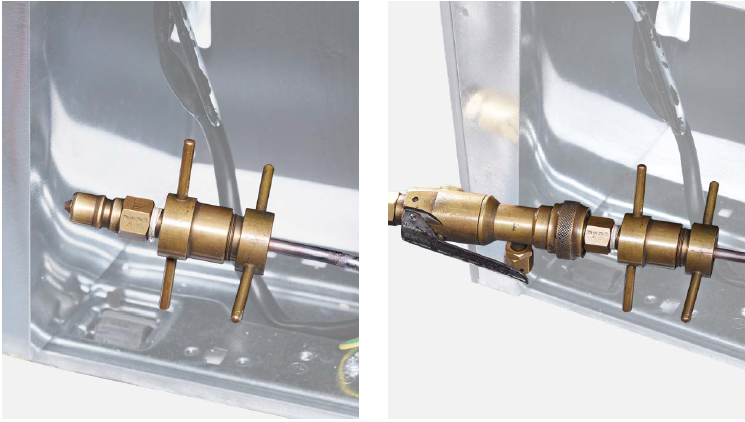

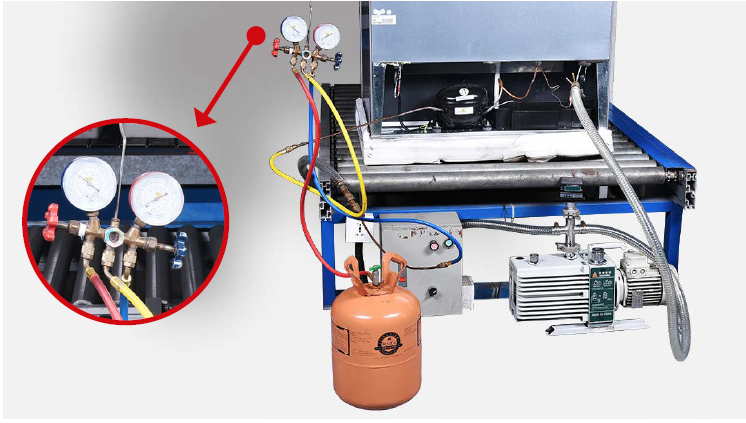

Step 5

Install quick connector onto re-brazed pipe.

Step 6

Inject nitrogen gas with 1.57Mpa pressure

through quick connector into pipe.

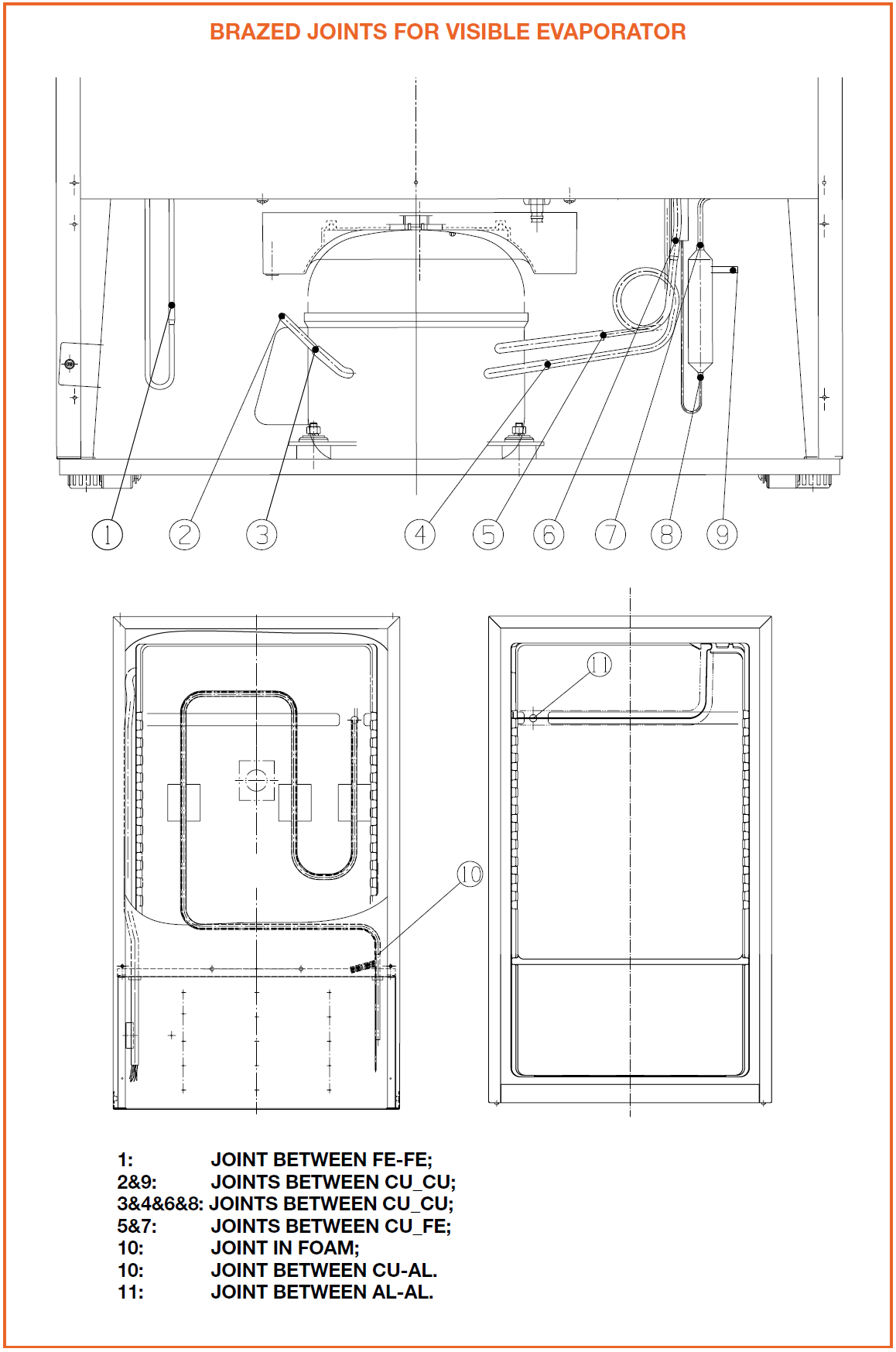

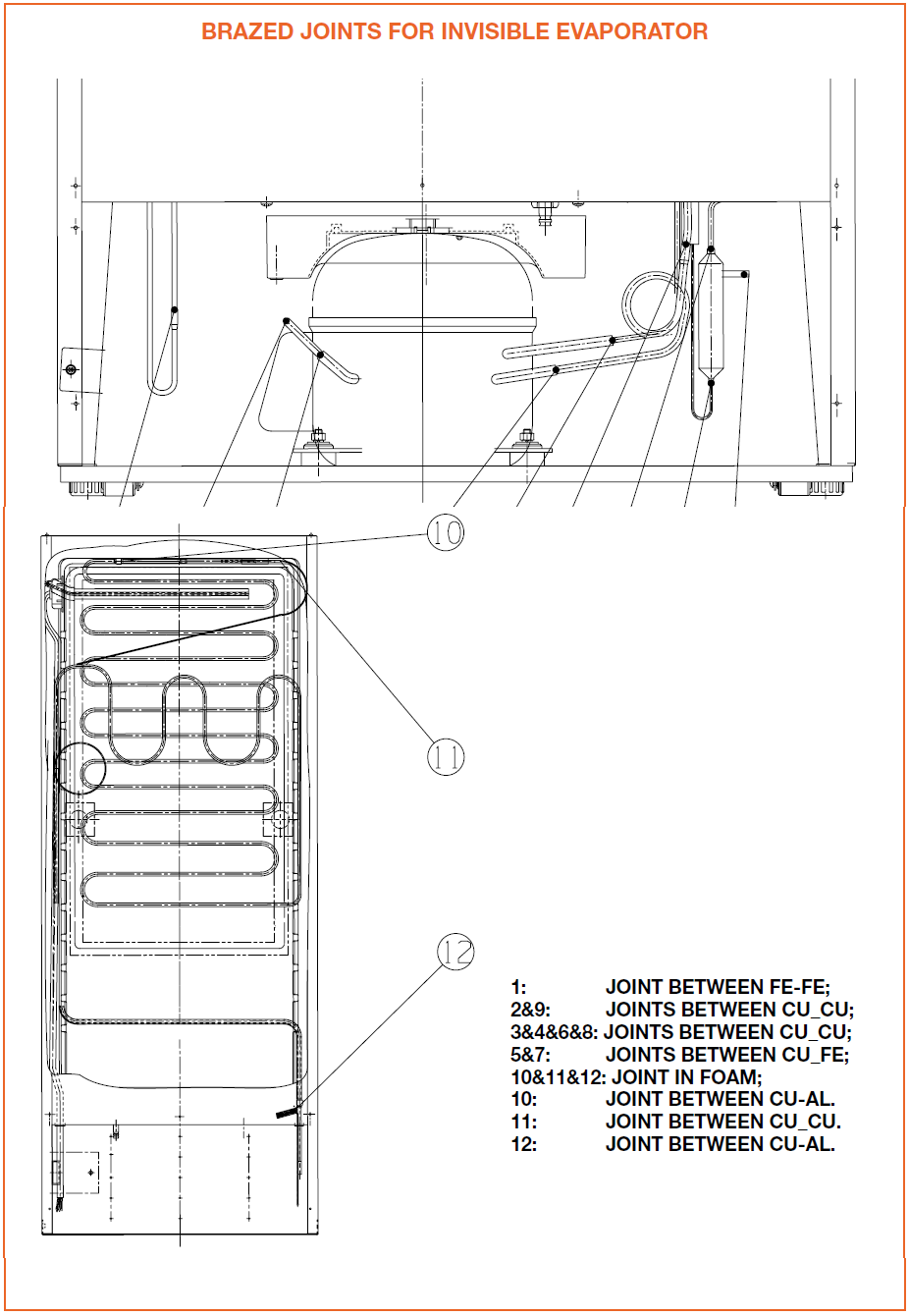

Step 7

Please follow drawing below to perform a

leakage test for brazed joints in the compressor

niche.

Step 8

Leakage test for brazed joints in evaporating

area.

PROCEDURE 1

NOTE

Step 1

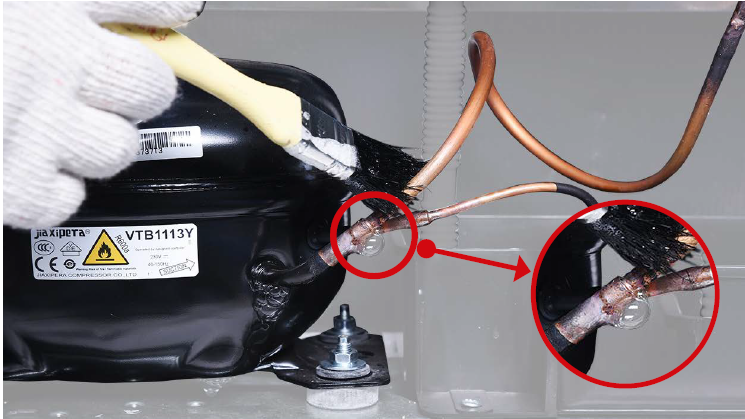

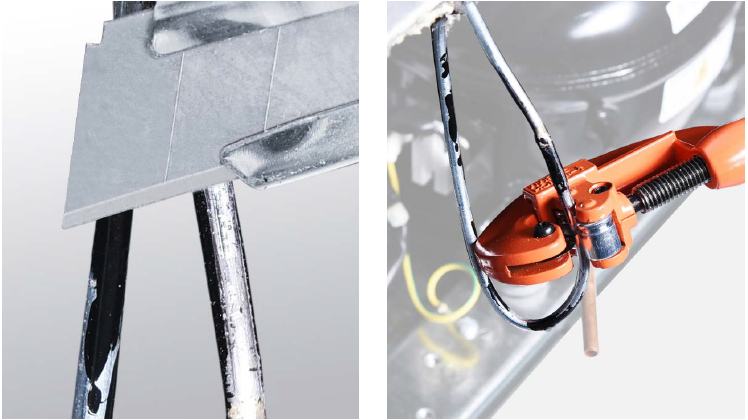

Clean paint off of brazed joint.

Step 2

Cut off brazed joint with leakage.

Step 3

Use a larger copper tube to connect 2 ends of brazed joint.

Step 4

Braze the 2 ends.

CHECK AND TEST 2

Step 1

Inject nitrogen at 1.57Mpa through quick connector into pipe and use soapy water to perform leakage test again.

DIAGNOSIS 2

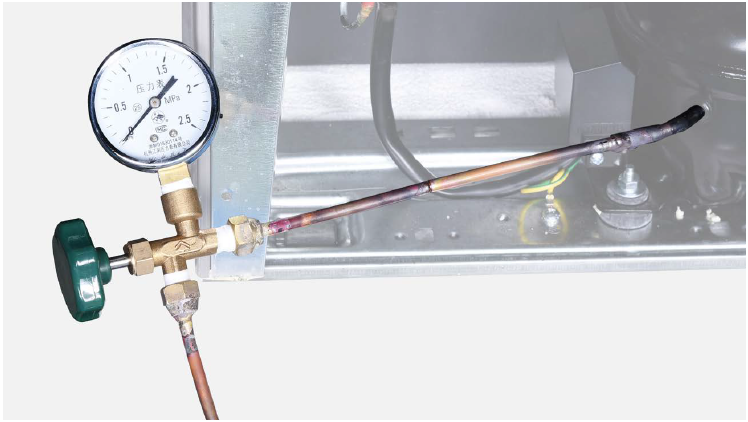

Step 1

Braze a piezometer onto processing tube

of compressor.

Step 2

Charge nitrogen at 1.57Mpa through quick

connector into pipe.

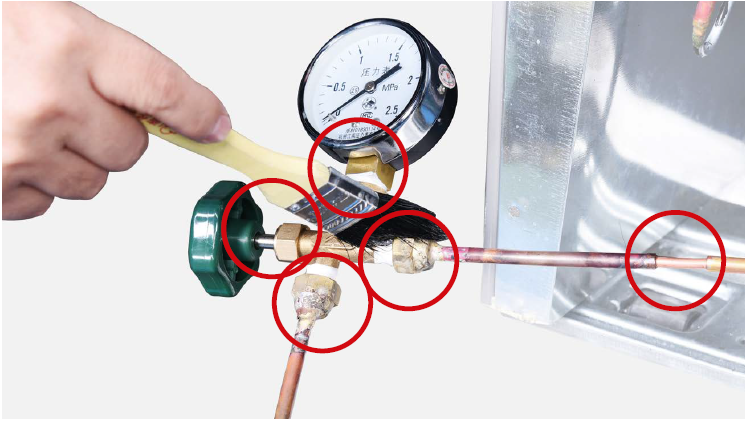

Step 3

Perform a leakage test on brazing points and

piezometer.

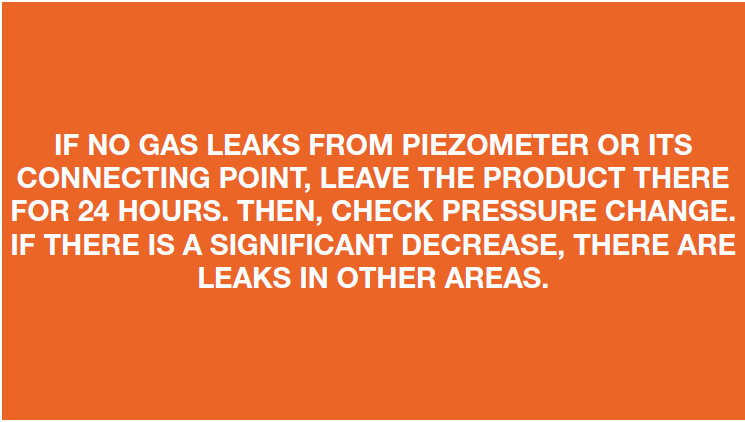

CHECK AND TEST 4

Step 1

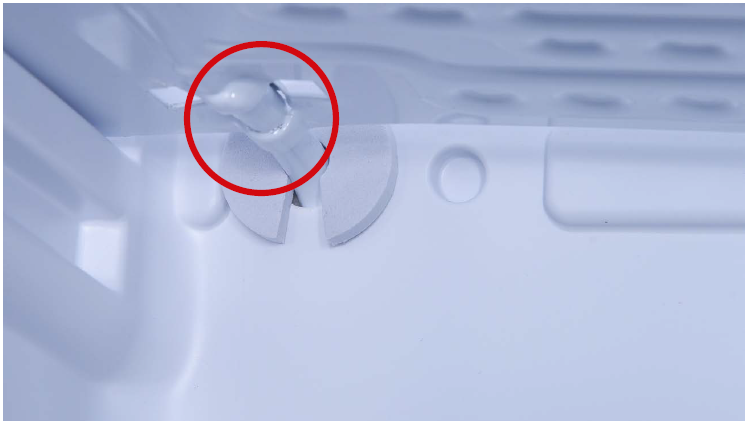

Give the system 1.57Mpa Nitrogen, and then observe if there is rust and/or spotted holes on pipes of compressor niche.

Note

Photo is not accurate, but just to show the technique.

Step 2

Apply soapy water to rusty area to test for leaks.

PROCEDURE 2

Step 1

Clean paint off of brazed joint.

Step 2

Cut off brazed joint with leakage.

Step 3

Use a larger copper tube to connect 2 ends of brazed joint.

Step 4

Braze the 2 ends

Step 1

Clean paint off brazed joint of drying-filter.

Step 2

Step 3

Cut off capillary and shake to remove the cut

end.

Step 4

Braze on a new dryingfilter.

Step 5

Perform leakage test on brazed joints of dryingfilter and compressor processing pipe.

Step 6

Vacuum and recharge. Please get more details

of vacuuming and gascharging requirements

on 10.5 Annex B2.

Step 7

Block processing pipe twice by locking pliers.

Step 8

Leave locked pliers attached to second

block and shake to cut off the remaining pipe.

Step 9

Braze the ends and remove the pliers.