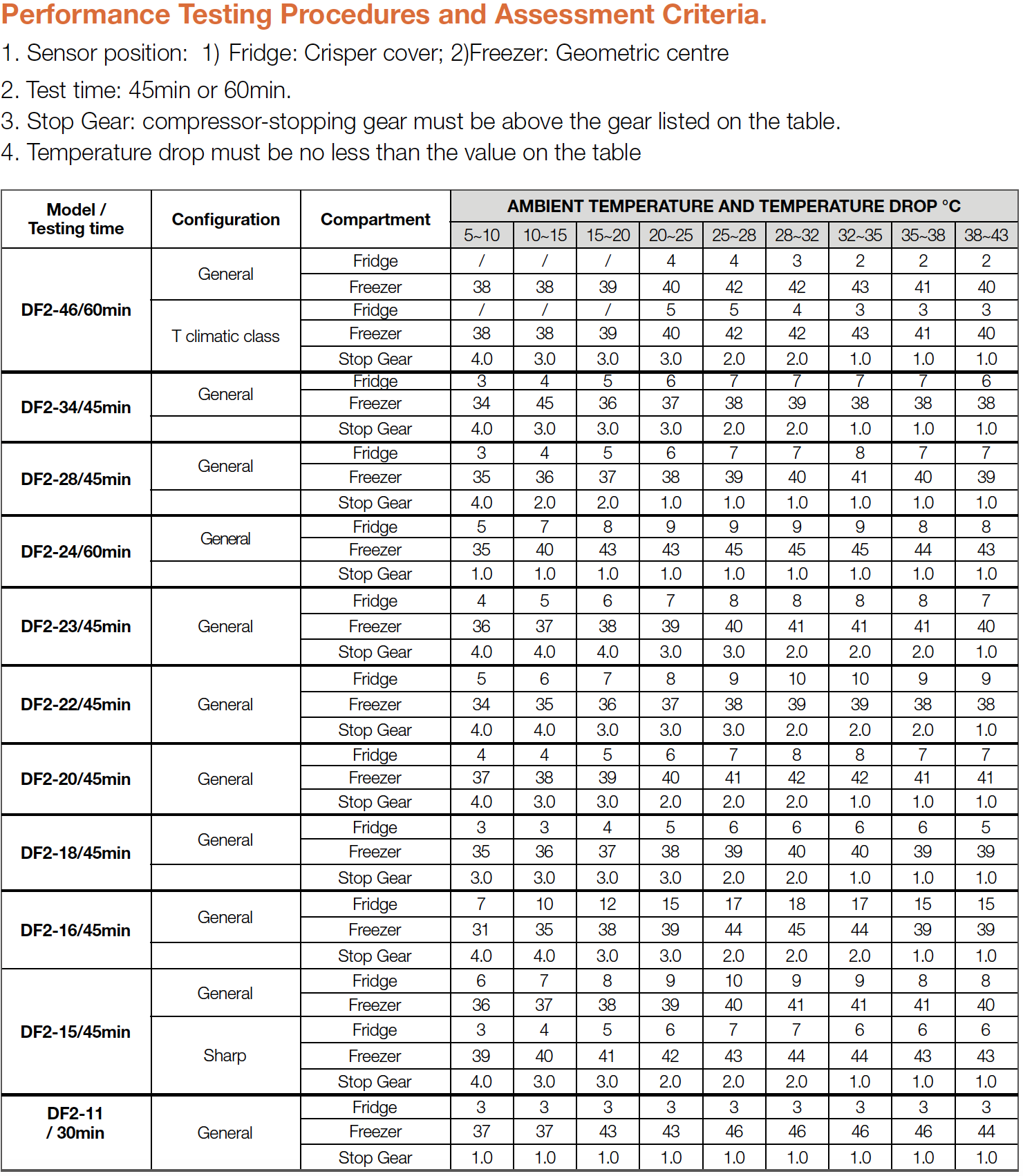

CHECK AND TEST 1

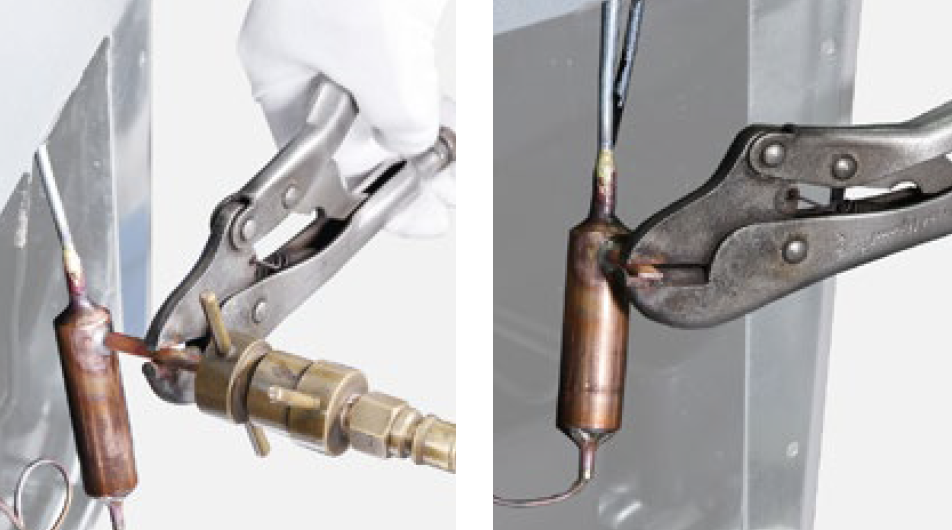

Step 1

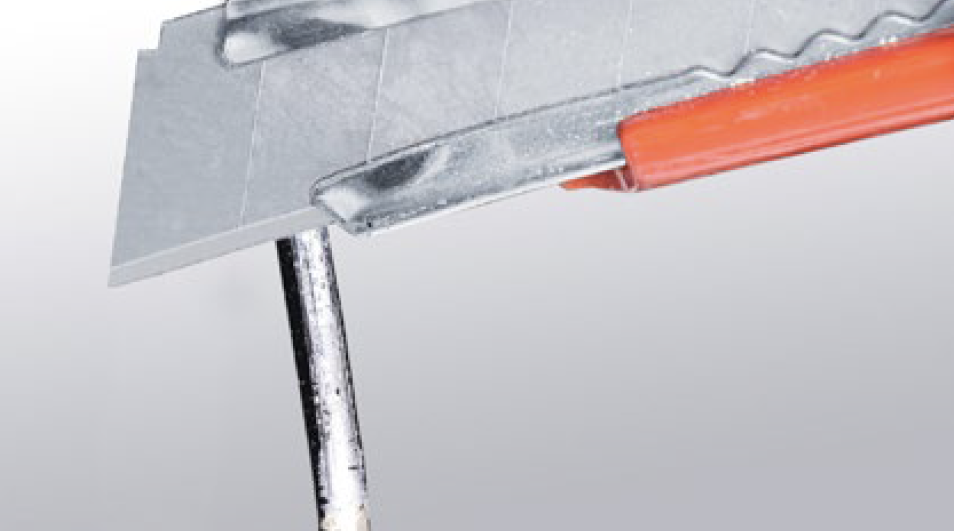

Discharge refrigerant. Cut off the charging tube with pliers

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

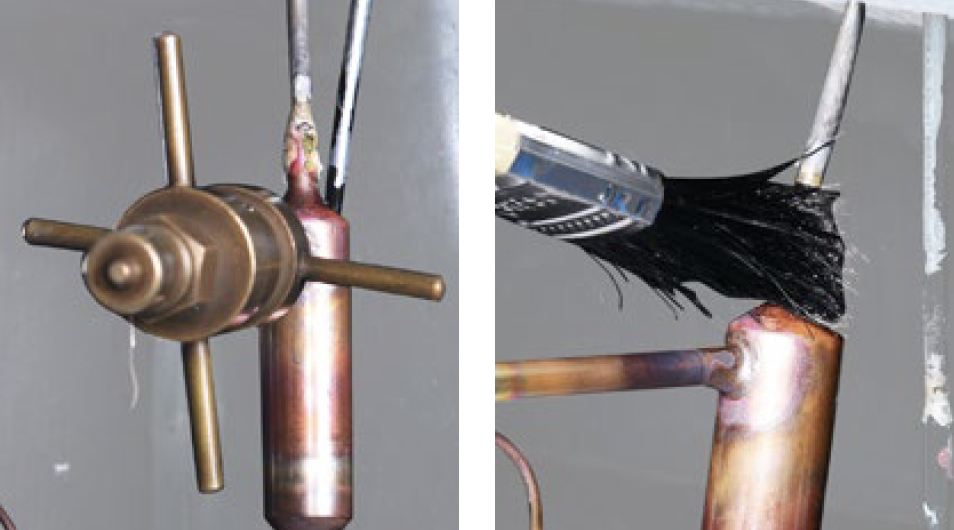

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 4

Re-braze a copper tube onto compressor processing tube.

To get more details on brazing requirements, please go to Annex B1

Note

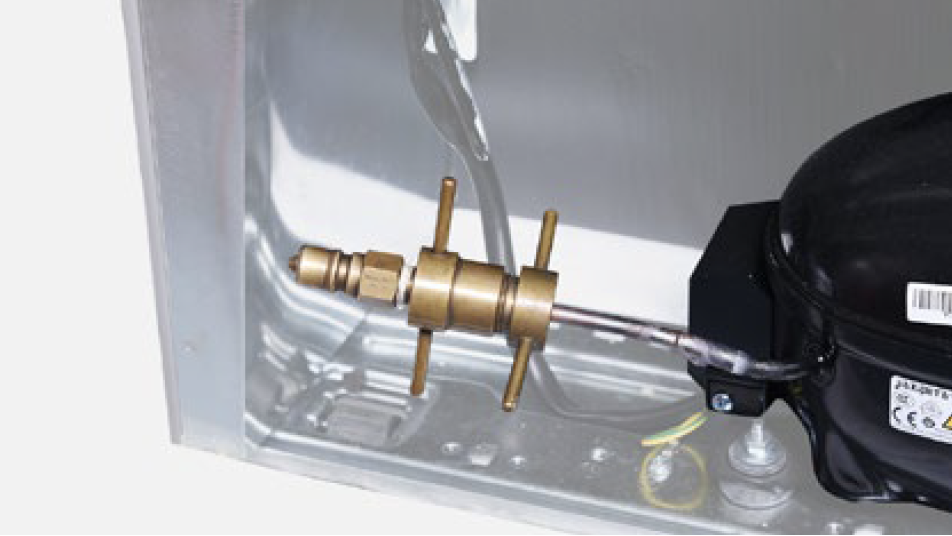

Step 5

Install quick connector onto re-brazed pipe.

Step 6

Use a pliers to cut the capillary off.

Step 7

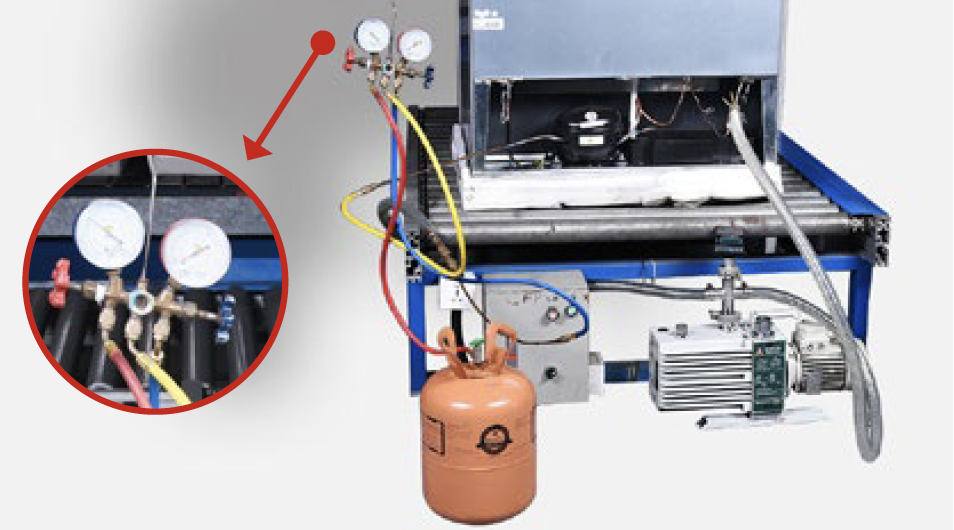

Inject nitrogen (1.57Mpa) through quick connector into pipe.

Step 8

Check if gas is blowing out from capillary.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Cut off drying-filter

Step 3

Cut off capillary and shake to remove the cut end

Step 4

Braze on a new drying- filter.

Step 5

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Perform leakage test on brazed joints of drying- filter and processing pipe on compressor.

Step 8

Vacuum and recharge.

Click below link to get more details for

vacuuming and gas-

charging requirements,

go to Annex B2

Step 9

Block processing pipe

twice by locking pliers.

Step 10

Leave locked pliers attached to second block and shake to cut off the remaining pipe.