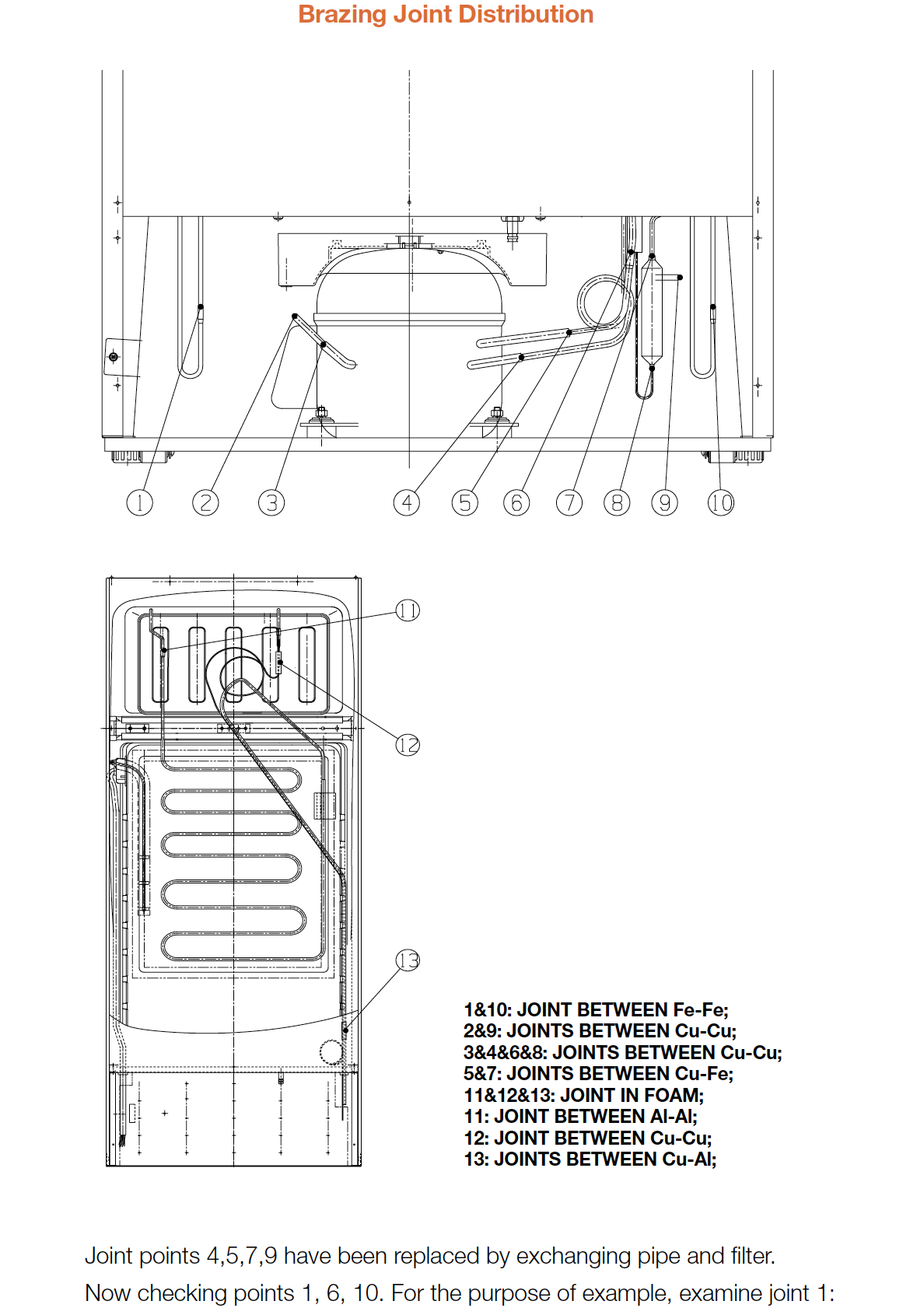

CHECK AND TEST 1

Step 1

Cut off capillary to discharge refrigerant.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhaust pipe.

Step 4

Power up the compressor and feel the exhaust pressure from the exhaust pipe with a piece of paper.

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

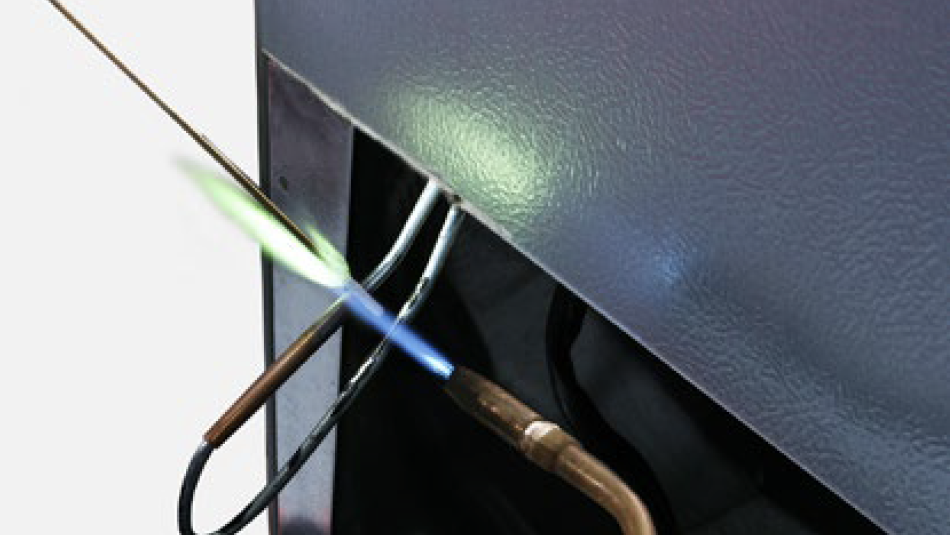

Braze the joints of suction and exhausting pipes.

Step 2

Melt brazing material with flame and pull out processing tube with pliers.

Step 3

Re-braze a copper tube

onto processing tube of

compressor.

Click below link to get

more details of brazing

requirements, on Annex B1

Step 4

Clean paint from brazed joint of drying-filter.

Step 5

Cut off drying-filter.

Step 6

Cut off capillary and

shake to remove the cut

end.

Step 7

Braze on a new drying-filter.

Step 8

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 9

Add quick connector onto processing pipe of drying-filter.

Step 10

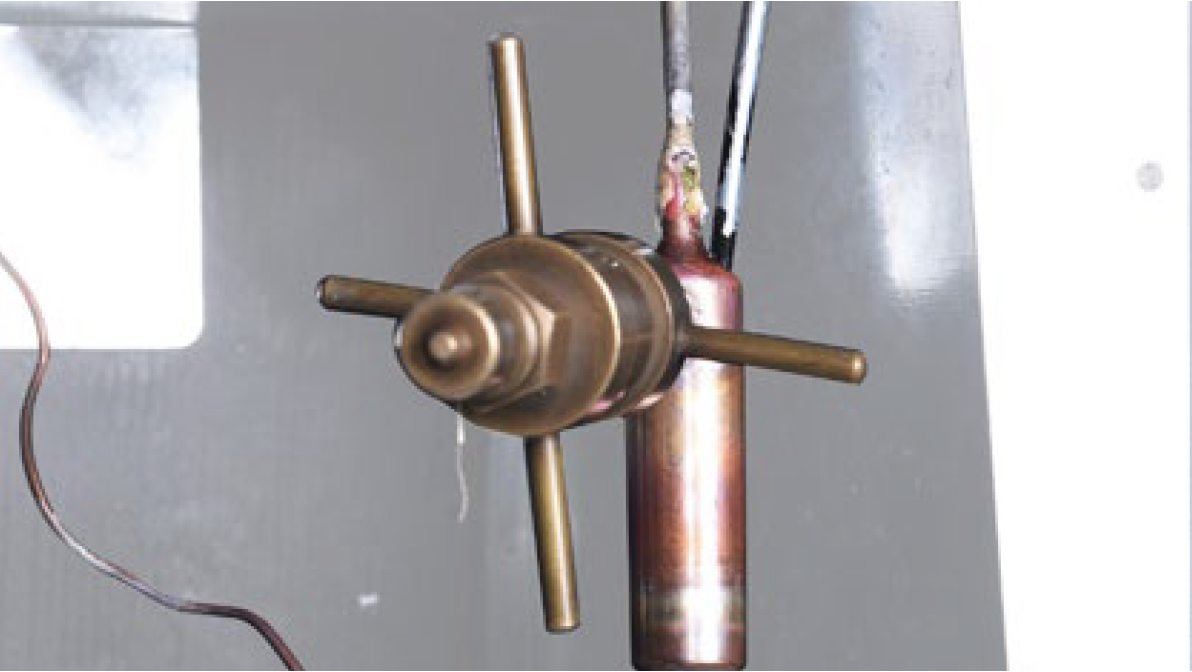

Cut off brazed joints, one by one, to find blockage point.

a) First, cut off end closed to exhausting end (A in below picture).

b) Then, cut off the end closed to suction end.

DIAGNOSIS 2

PROCEDURE 1

Step 1

Use a larger copper tube to connect 2 ends of brazed joints that you have cut off.

Step 2

Braze the 2 ends.

Step 3

Perform a leakage test on all re-brazed joints of drying-filter and compressor processing pipe.

Step 4

Vacuum and recharge.

Click below link to get more details for

vocuuming and gas-

charging requirements,

go to Annex B2

Step 5

Block processing pipe twice by locking pliers.

Step 6

Leave locking pliers on the second block and shake to cut off the rest of the pipe.

Step 7

Braze the ends and remove the pliers.

CHECK AND TEST 3

DIAGNOSIS 3