Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhausting pipe and suction pipe.

Step 4

Power up the compressor and feel the exhaust pressure from the exhausting pipe with a piece of paper.

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

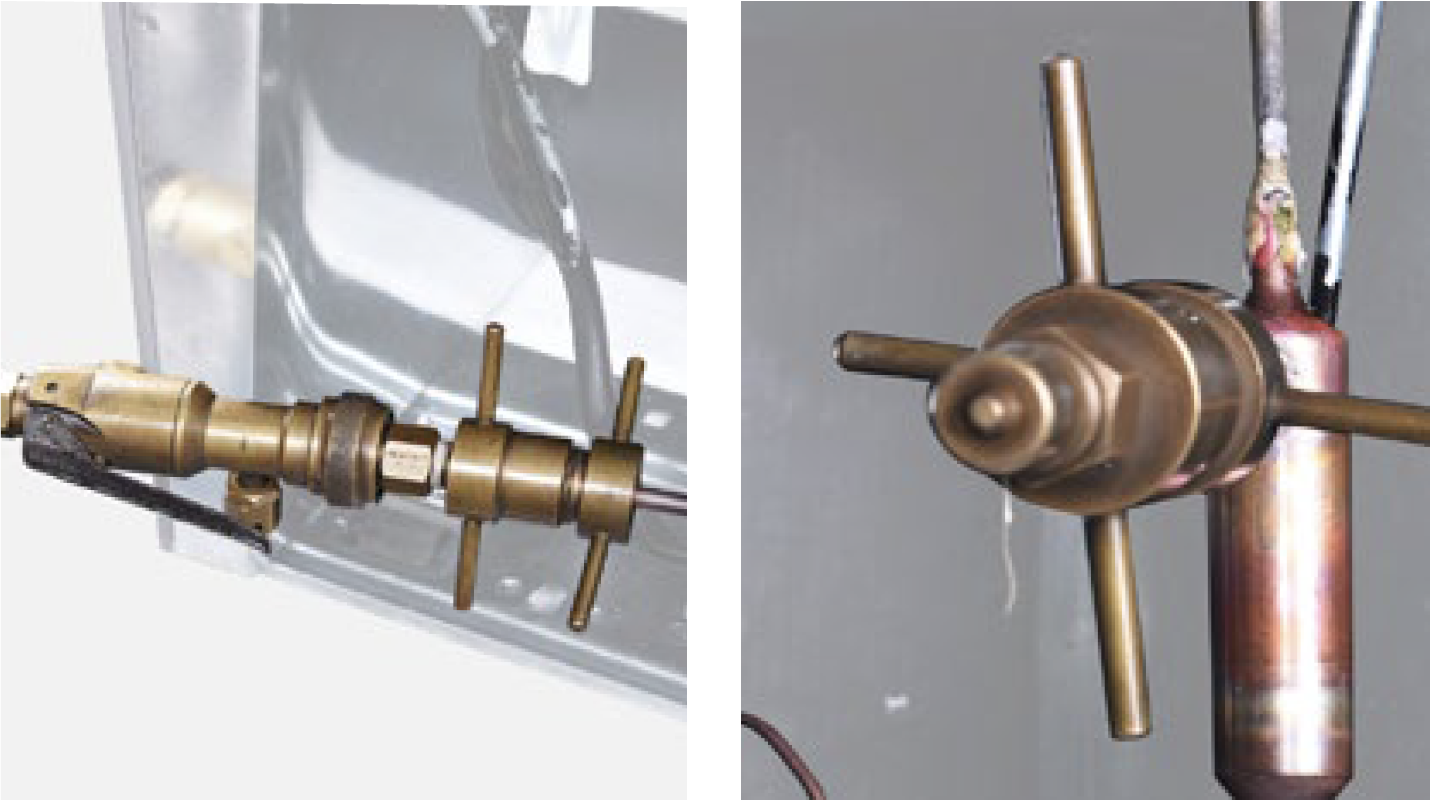

Braze the joints of suction and exhaust pipes.

Step 2

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 3

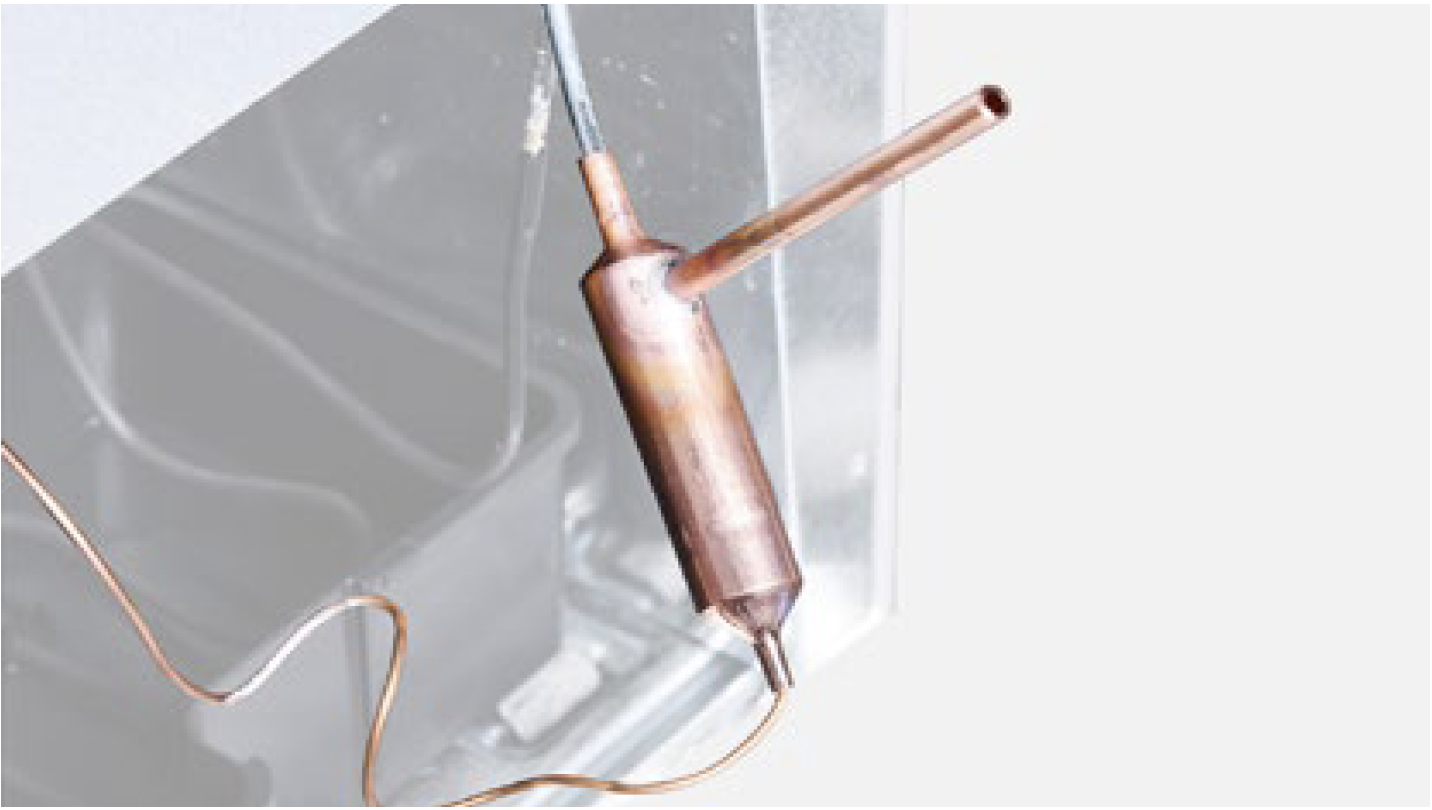

Re-braze a copper tube onto compressor processing tube.

Click below link to get

more details of brazing

requirements, on Annex B1

Step 4

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 5

Check to see whether a piece of white paper is waving by gas from capillary.

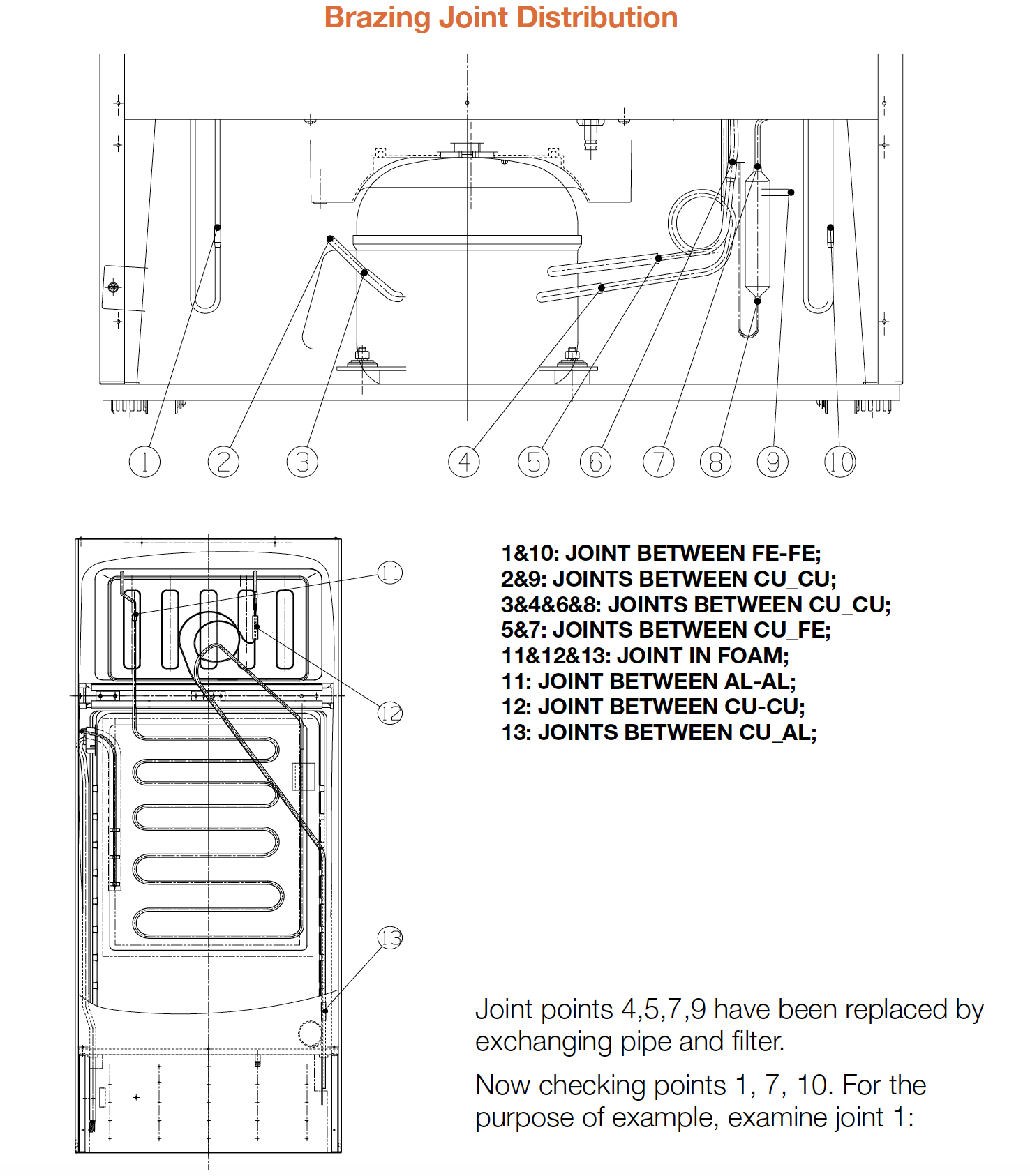

DIAGNOSIS 2

CHECK AND TEST 3

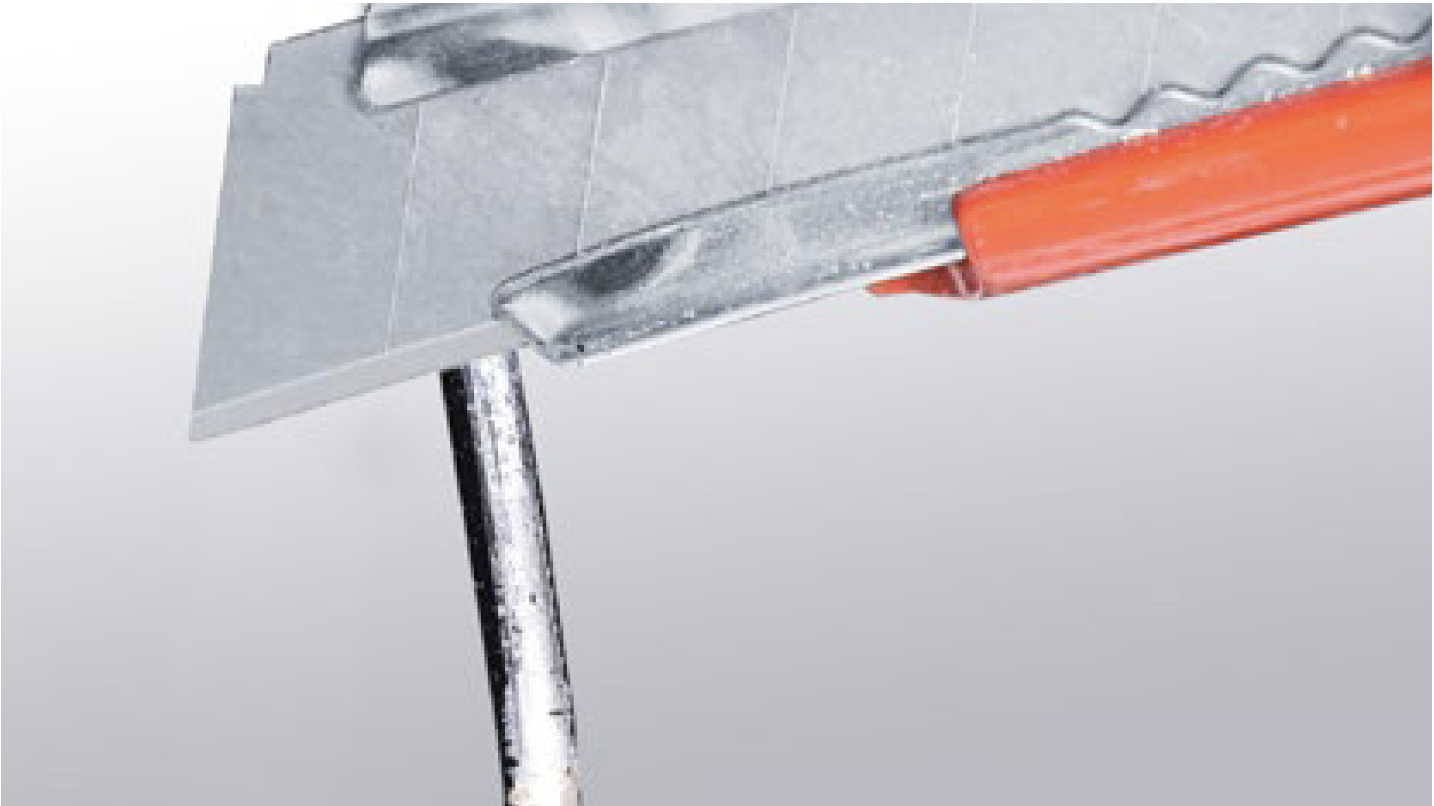

Step 1

Cut off one end of brazed joints.

Step 2

Then, cut off another end of brazed joints

DIAGNOSIS 3

PROCEDURE 1

Step 1

Clean paint off of brazed joint.

Step 2

Use a larger copper tube to connect 2 ends of brazed joint.

Step 3

Braze the 2 ends.

Step 4

Cut off capillary and shake to remove the cut end.

PROCEDURE 2

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Cut off drying-filter.

Step 3

Braze on a new drying-filter.

Step 4

Add quick connector onto processing pipe of drying-filter.

Step 5

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 6

Perform a leakage test on all re-brazed joints.

Step 7

Vacuum and recharge.

Click below link to

get more details for

vacuuming and gas-

charging requirements,

go to Annex B2

Step 8

Block processing pipe twice with locking pliers.

Step 9

Leave locking pliers on the second block and cut off the rest of the pipe by shaking.

Step 10

Braze the ends and remove the pliers.

CHECK AND TEST 4

DIAGNOSIS 4