CHECK AND TEST 1

Step 1

Plug in. The compressor starts, but the protection is activated immediately, and it cannot work normally. Put hand onto compressor, no shaking can be felt.

Step 2

Measure the AC voltage

of the compressor with a

multimeter. If voltage of

three terminals is almost

the same (100V~200V), it

means power is transferred

to compressor.The power

supply of compressor is

good.

NOTE

Step 3

Wait a few minutes, repeatedly power on and off several times, the compressor starts but activates protection.

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

Cut off capillary to discharge refrigerant.

Step 2

Cut off exhaust pipe.

Step 3

Power up the compressor and feel the exhaust pressure of the exhaust pipe with a piece of paper.

DIAGNOSIS 2

PROCEDURE 1

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover.

Step 3

Move out protector and starter.

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut of compressor.

Step 6

Put on a new compressor and fix nuts onto compressor.

Step 7

Braze the joints of suction and exhaust pipes.

PROCEDURE 2

Step 1

Clean away paint on brazed joint of drying- filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and remove the cut end by shaking.

Step 4

Braze on a new drying-filter.

Step 5

Re-braze a copper tube

onto processing tube of

compressor.

To get more details on

brazing requirements,

please go to Annex B1

Step 6

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant.

Step 7

Add quick connector onto processing pipe of drying-filter.

Step 8

Do leakage test on brazed joints of drying- filter and compressor processing pipe.

Step 9

Vacuum and recharge.

Click below link to get more details for

vacuuming and gas-

charging requirements,

go to Annex B2

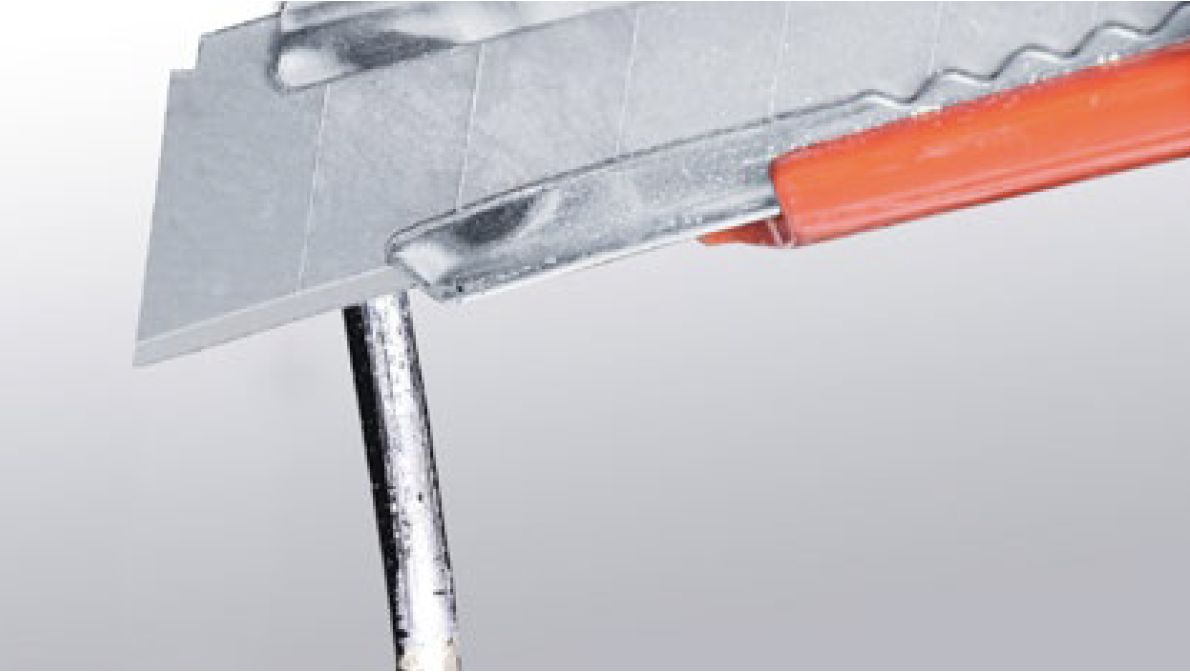

Step 10

Block processing pipe twice with locking pliers.

Step 11

Leave locking pliers on the second block and shake to cut off the rest of pipe.

Step 12

Braze the ends and remove the pliers.

DIAGNOSIS 3