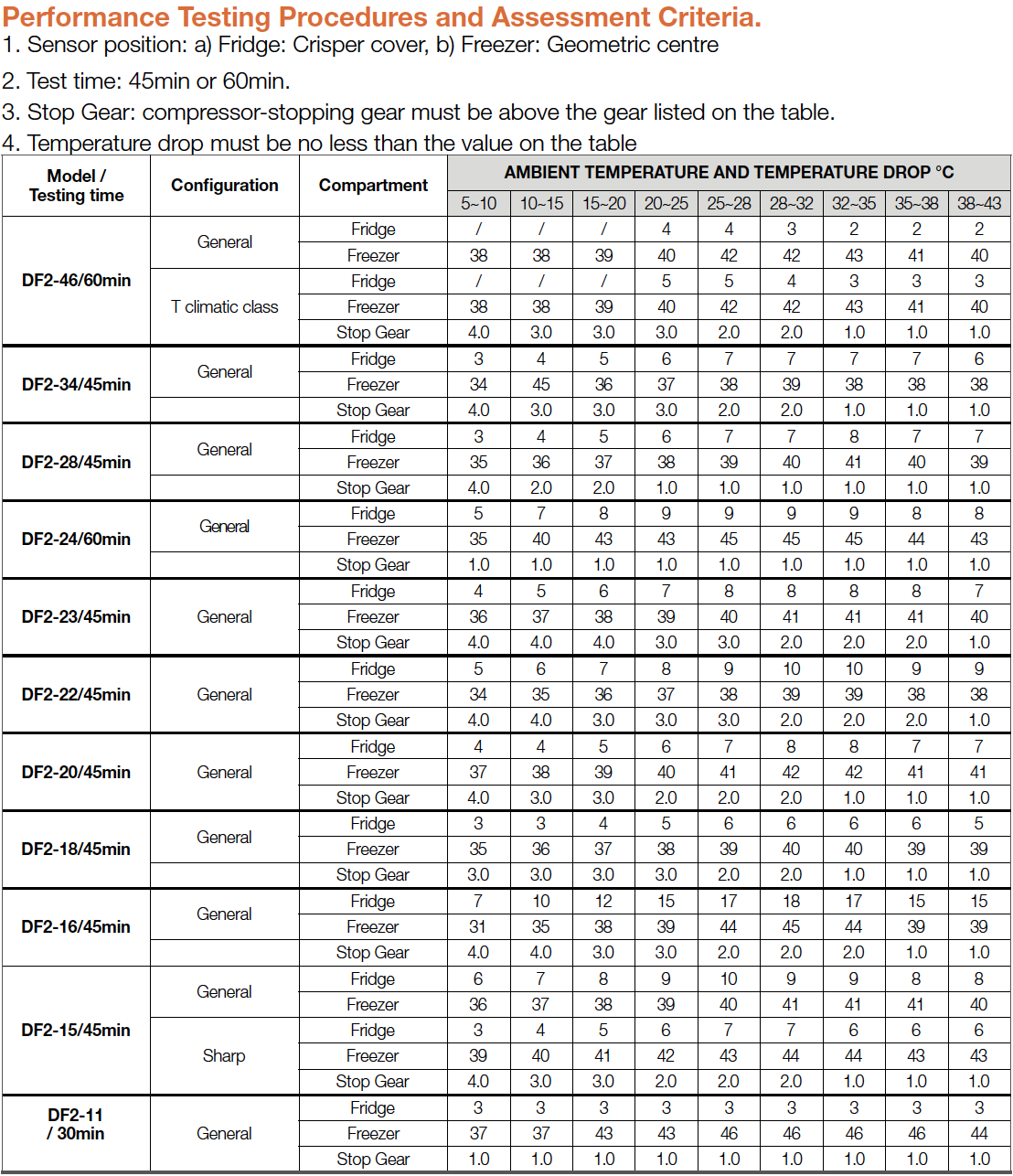

CHECK AND TEST 1

Step 1

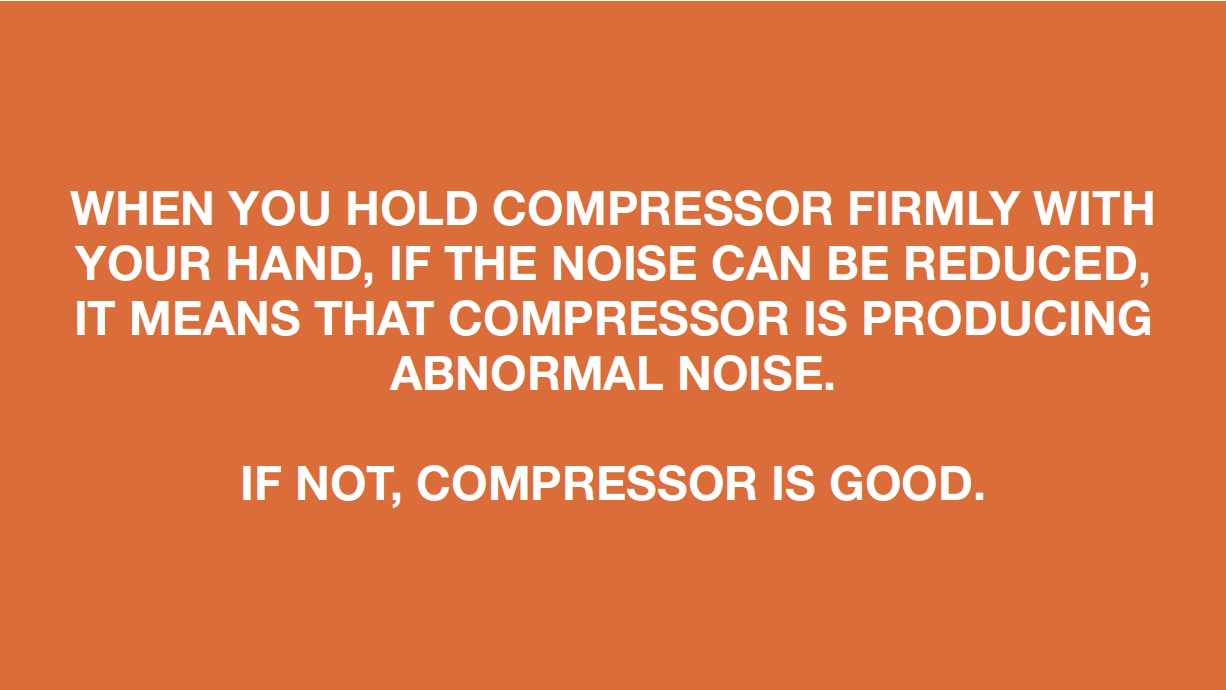

By listening, it is evident that the compressor is louder than normal. If you hold compressor firmly with your hand, the noise can be reduced.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Discharge refrigerant.

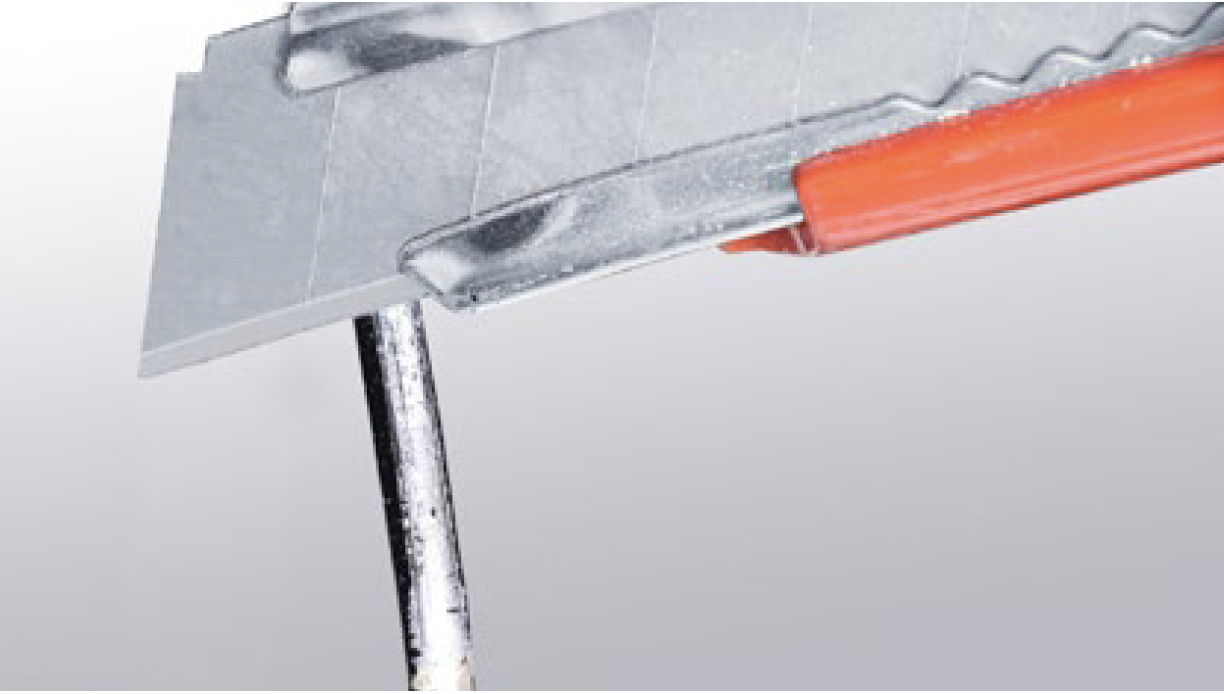

Cut off the charging tube

with a pair of pliers.

Step 2

Discharge all refrigerant toward the exhausting vent.

Step 3

Cut off suction pipe and exhaust pipe.

Step 4

Unscrew terminal cover.

Step 5

Remove terminal cover.

Step 6

Remove protector and starter.

Step 7

Unscrew earthing wire.

Step 8

Unscrew 4 nuts of compressor.

Step 9

Install a new compressor and tighten the nuts onto compressor.

Step 10

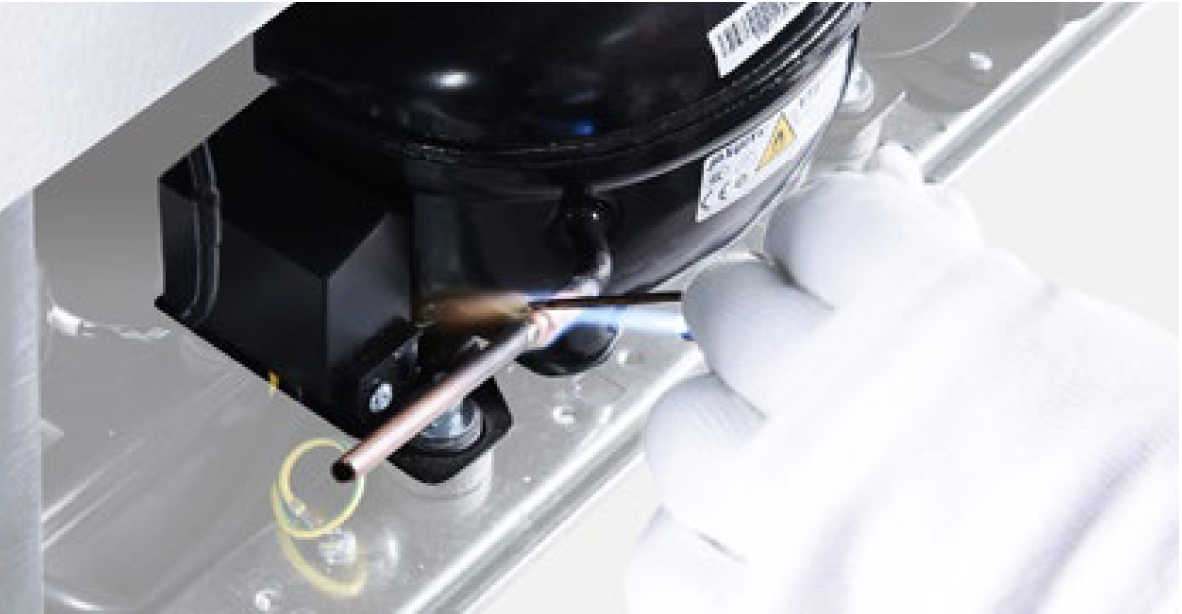

Braze the joints of

suction

and exhausting pipes.

PROCEDURE 2

Step 1

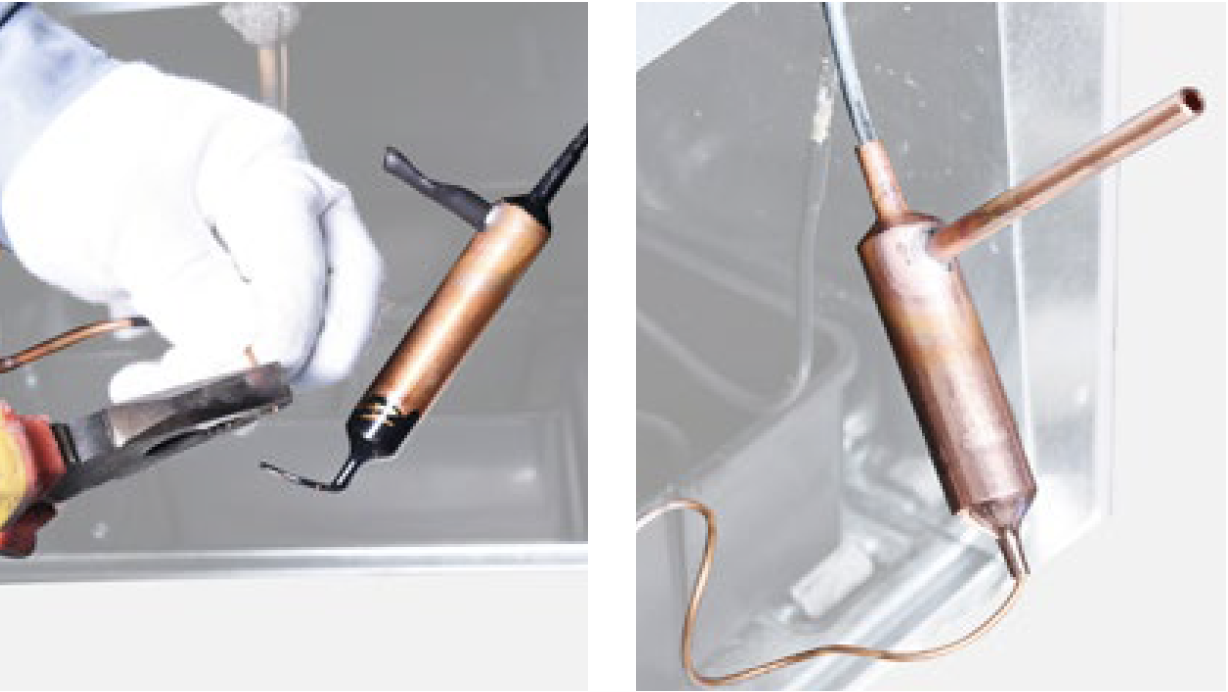

Re-braze a copper tube onto compressor processing tube.Click below link to get more details of brazing requirements, on Annex B1

NOTE

Step 2

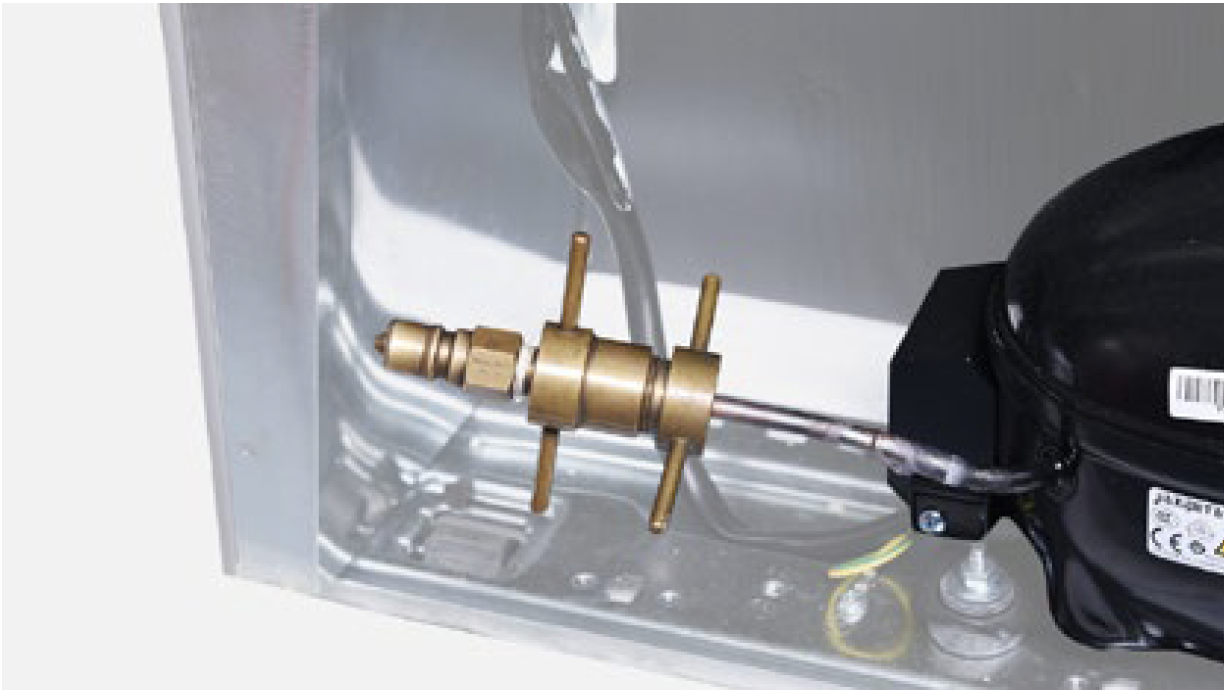

Install quick connector onto re-brazed pipe.

Step 3

Clean paint off brazed joint of drying-filter.

Step 4

Cut off drying-filter.

Step 5

Cut off capillary and shake to remove the cut end.

Step 6

Braze on a new drying-filter.

Step 7

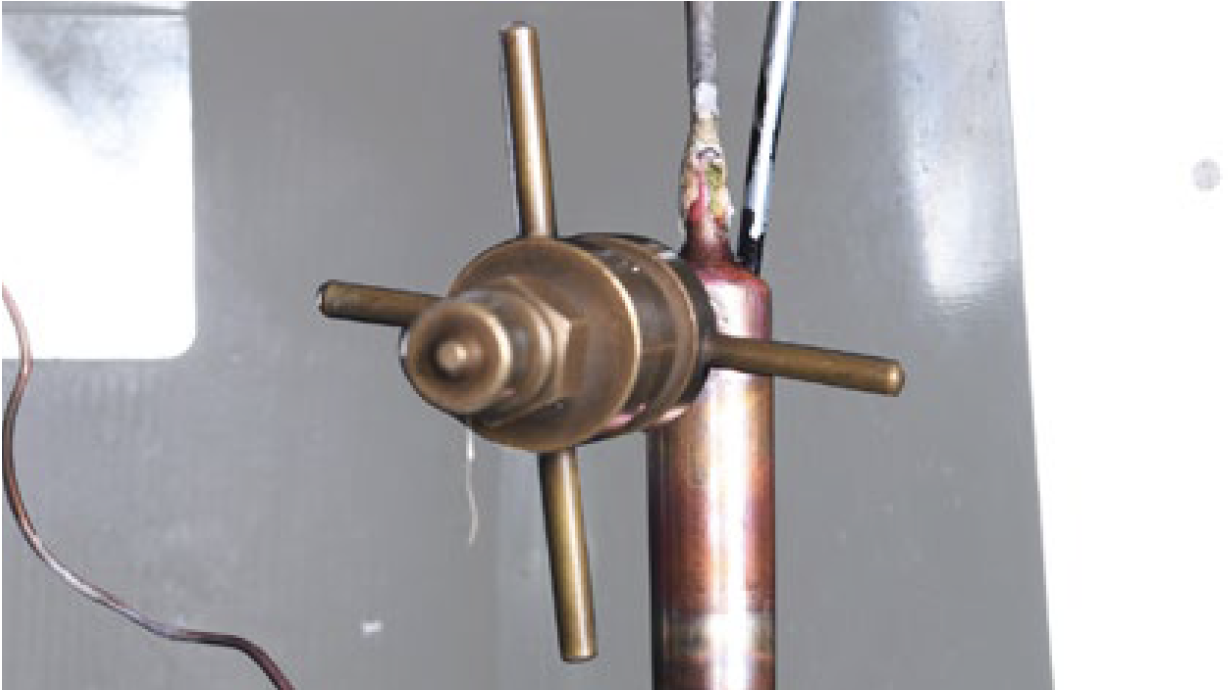

Add quick connector onto processing pipe of drying-filter.

Step 8

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 9

Perform leakage test on brazed joints of drying- filter and compressor processing pipe.

Step 10

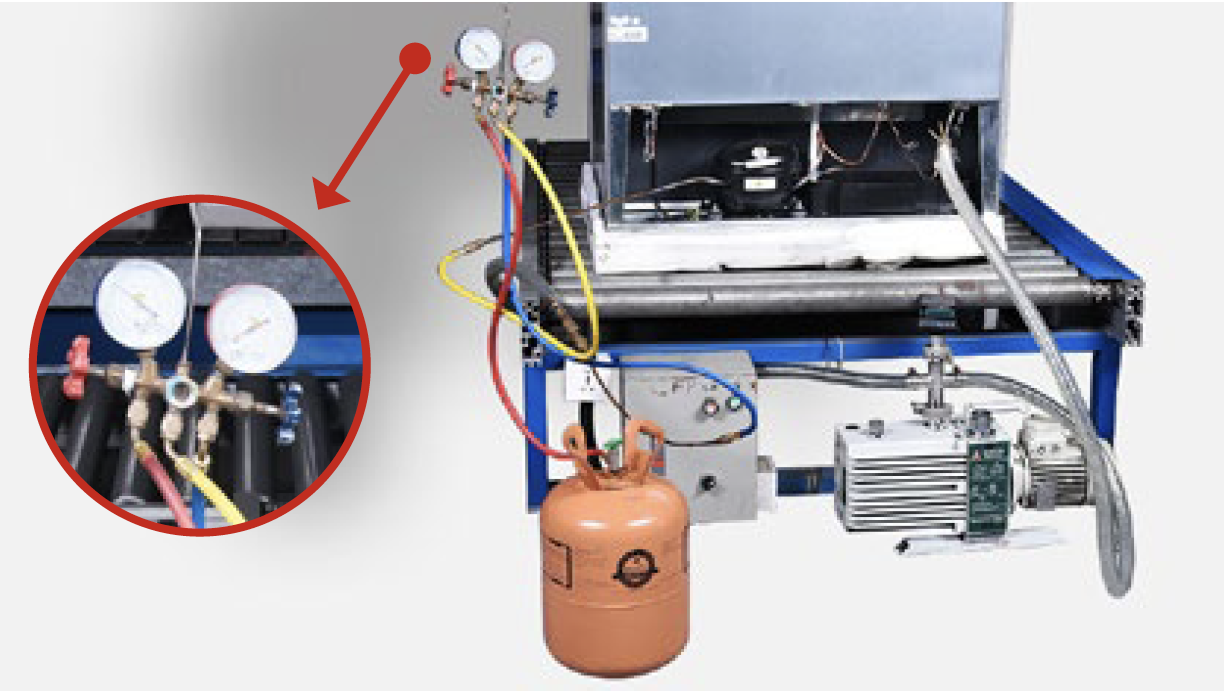

Vacuum and recharge.

Click below link to

get more details for

vacuuming and gas-

charging requirements,

go to Annex B2

Step 11

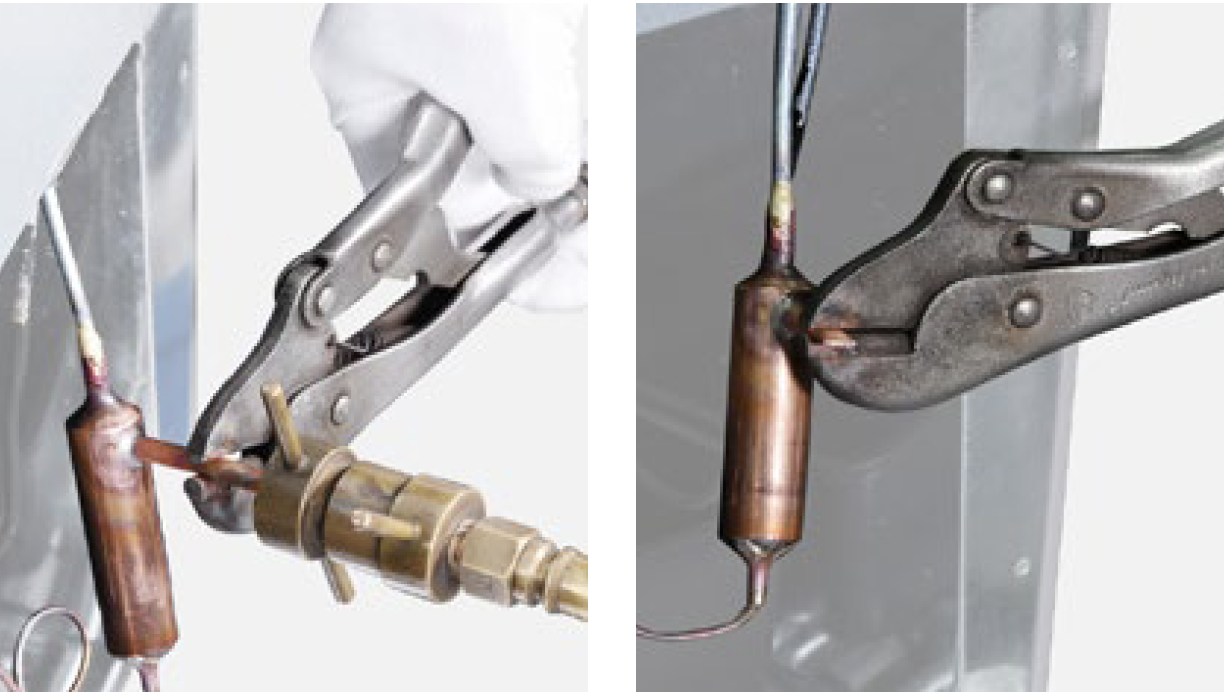

Block processing pipe twice with locking pliers.

Step 12

Leave locking pliers on the second block and cut off the rest of the pipe by shaking.

DIAGNOSIS 2