PROCEDURE 1

Step 1

Unscrew bottomattachment.

Step 2

Unscrew topattachment.

Step 3

Unscrew the plasticguider.

Step 4

Hold cabinet and pullappliance out.

CHECK AND TEST 2

Step 1

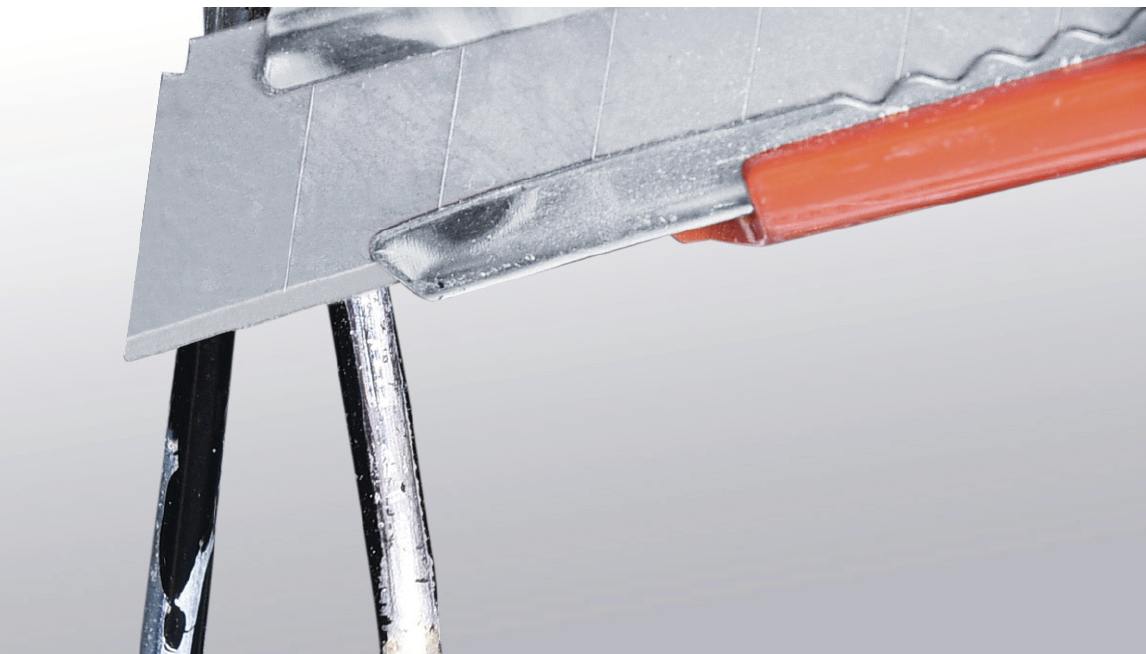

Discharge refrigerant.Cut off the charging

tube with pliers.

Step 2

Discharge all refrigeranttoward the exhaust vent.

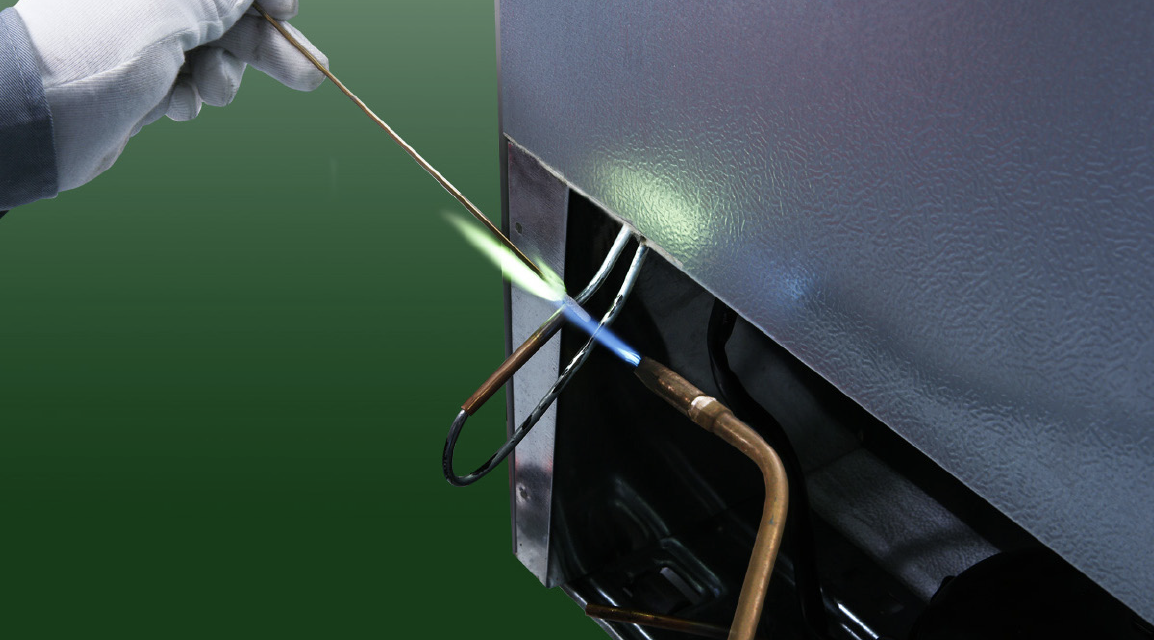

Step 3

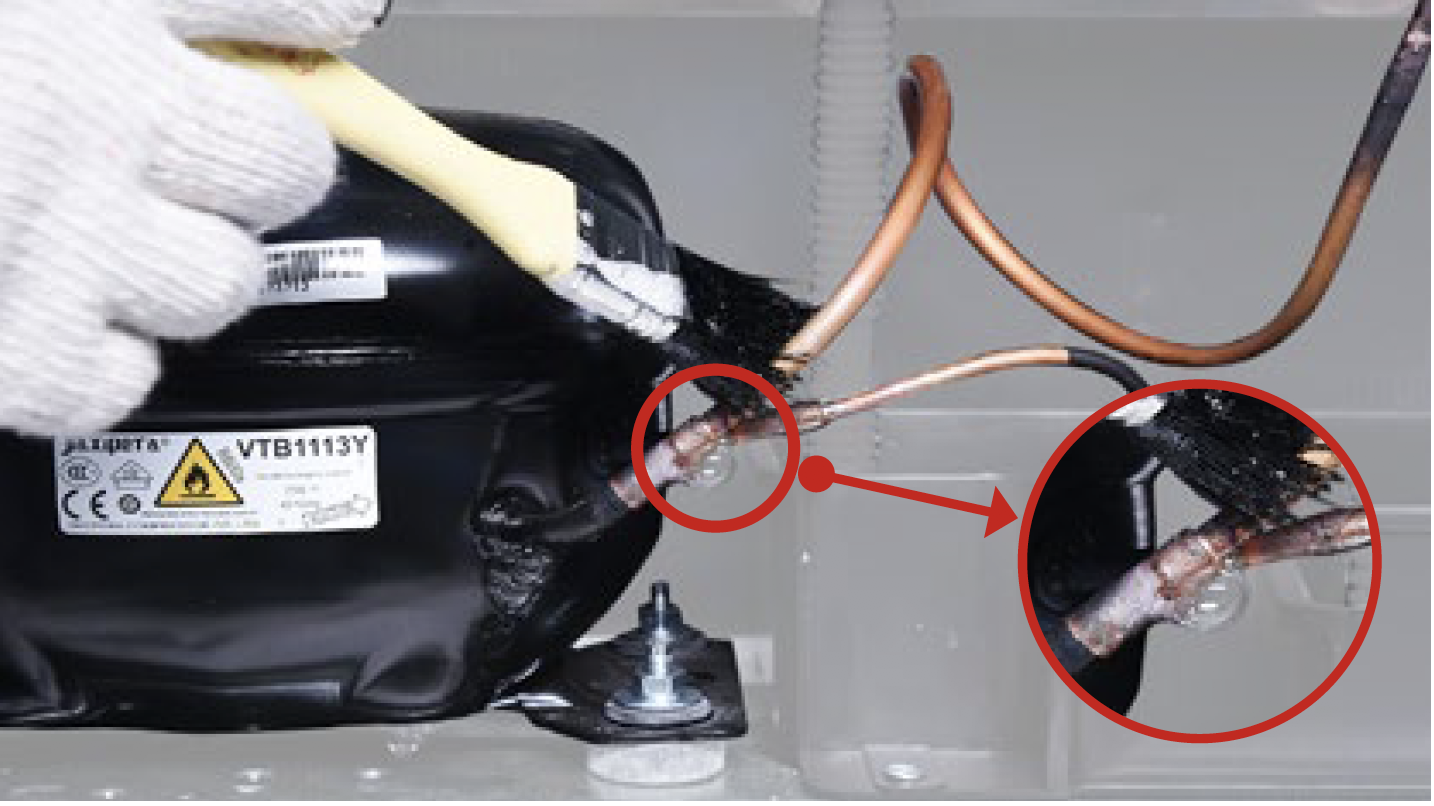

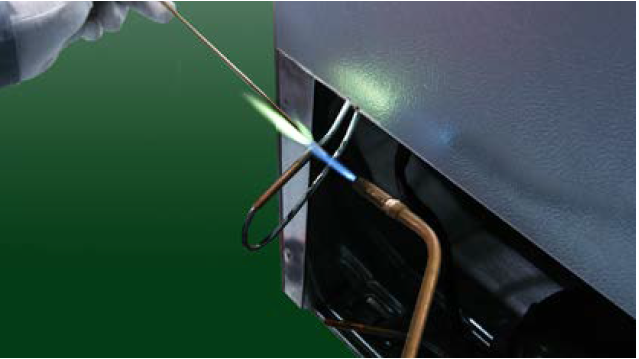

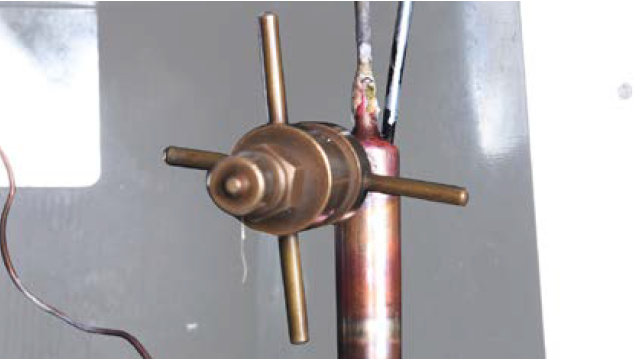

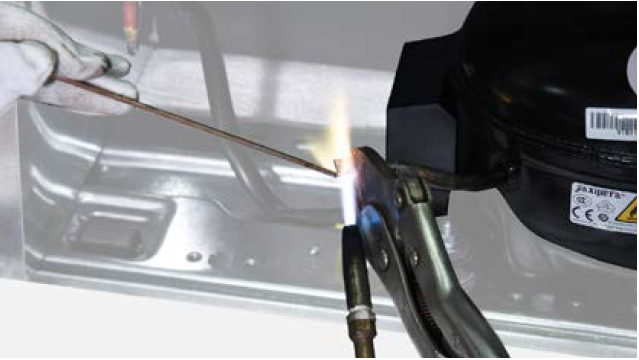

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 4

Re-braze a copper tube onto compressor processing tube.Click below link to get more details for brazing requirements, go to Annex B1

NOTE

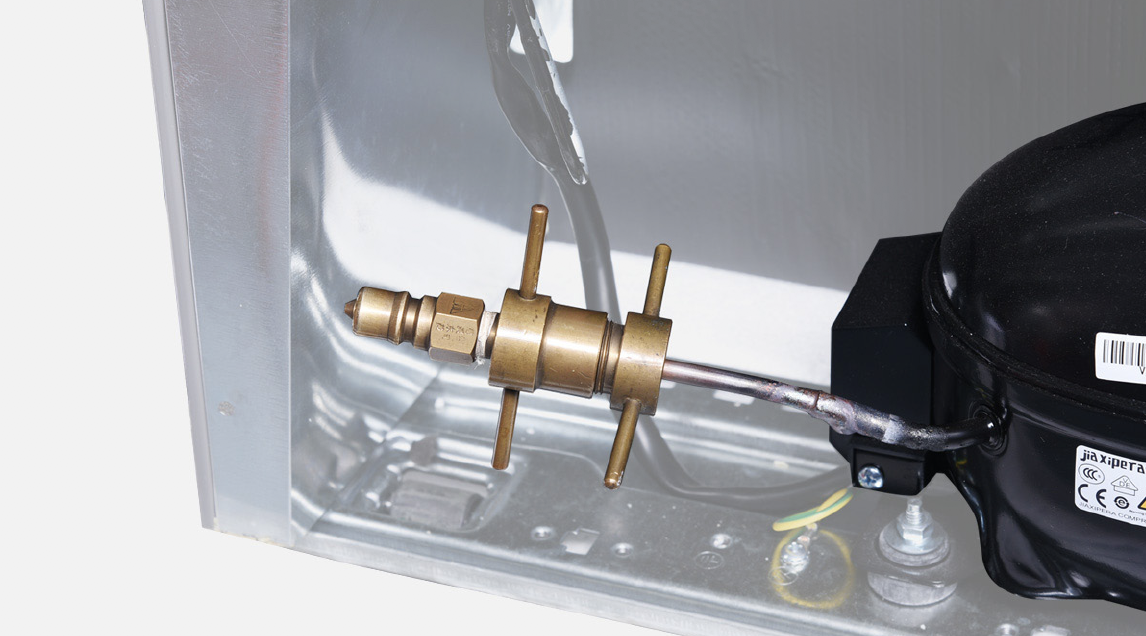

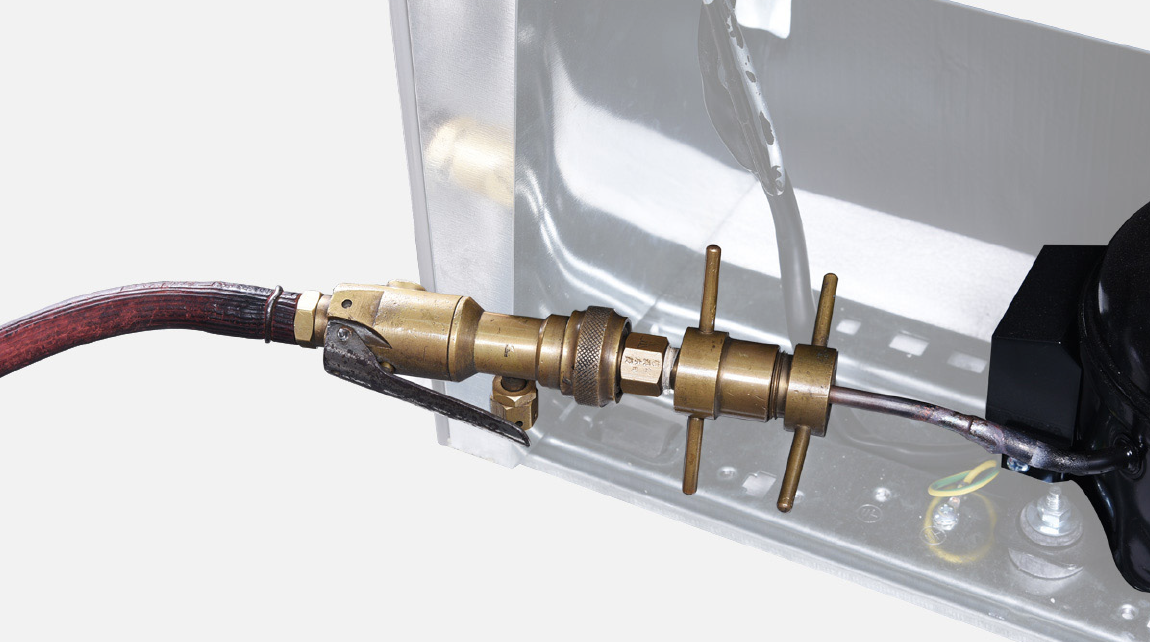

Step 5

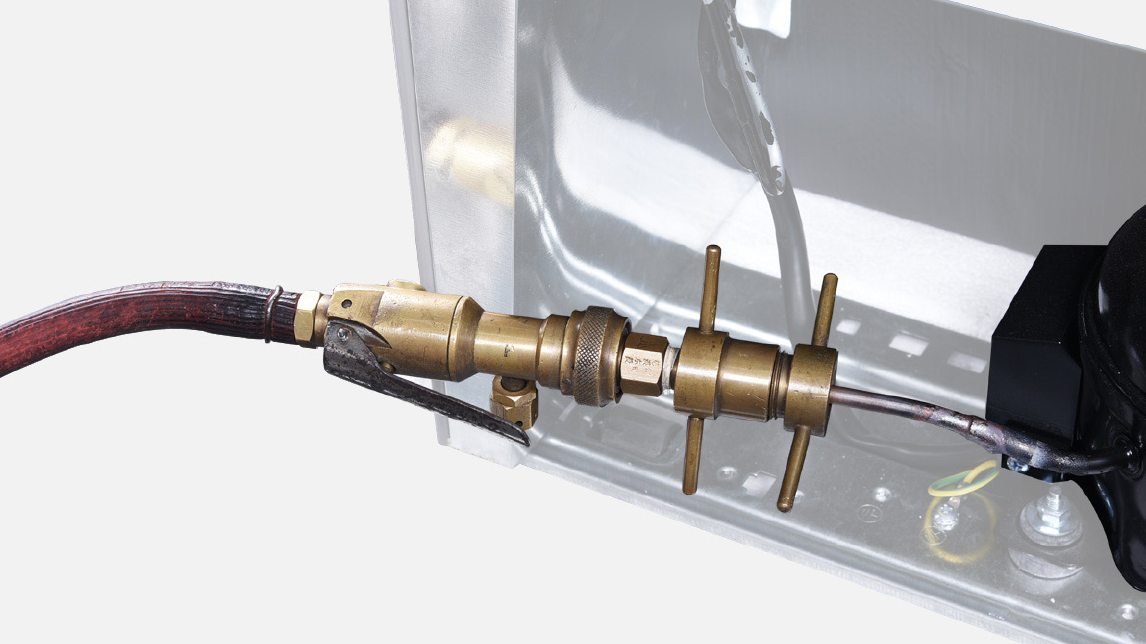

Install quick connectoronto re-brazed pipe.

Step 6

Inject nitrogen gas with 1.57Mpa pressure through quick connector into pipe.

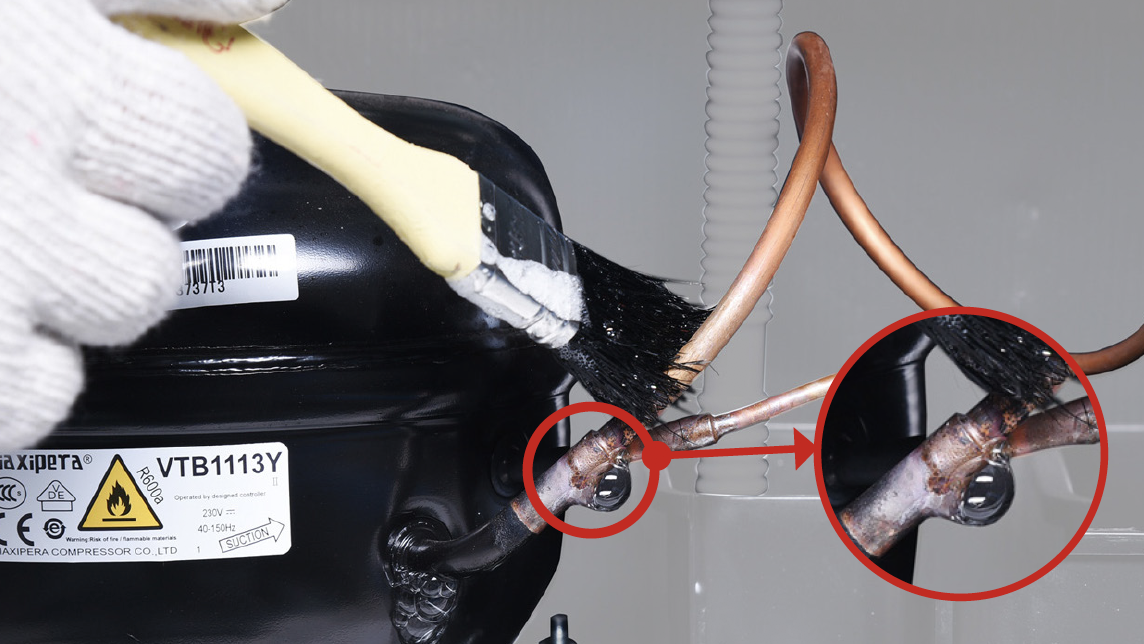

Step 7

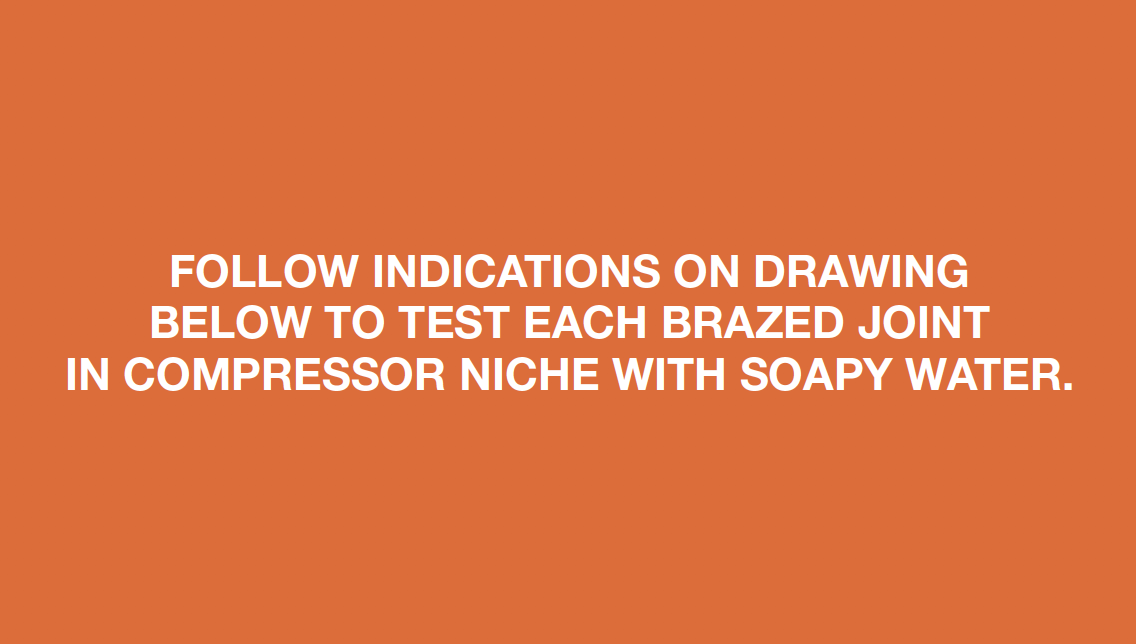

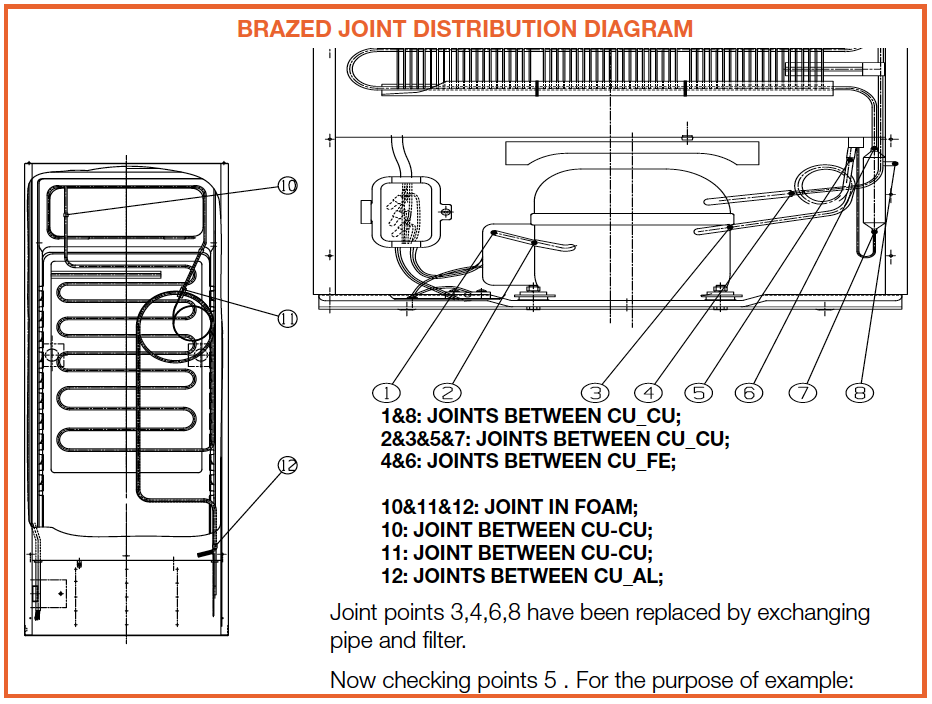

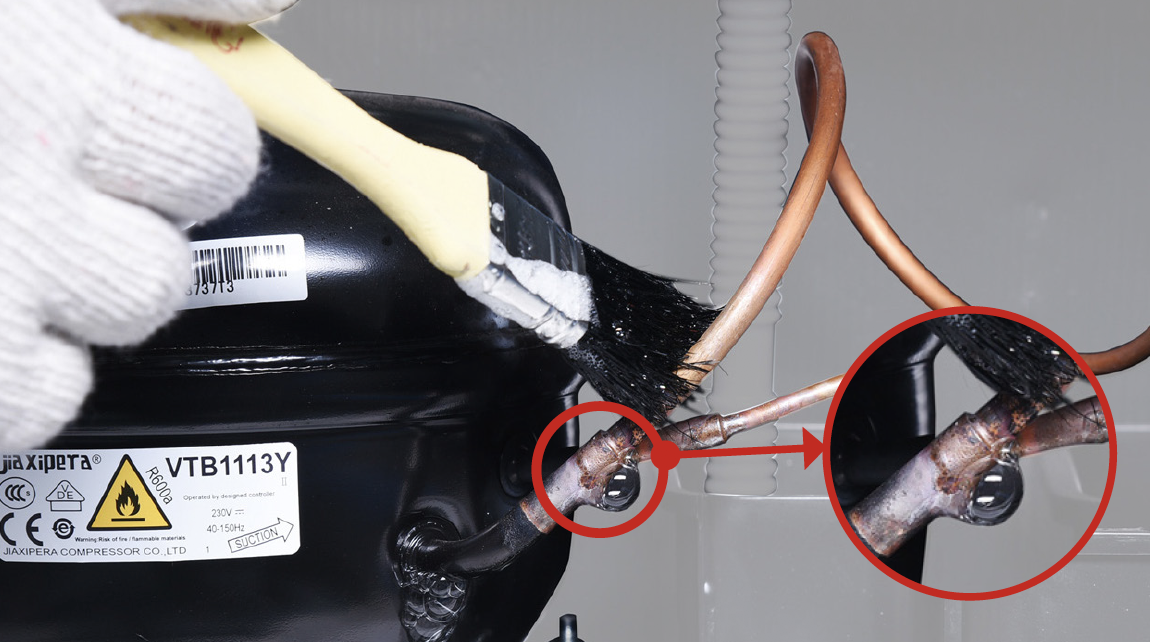

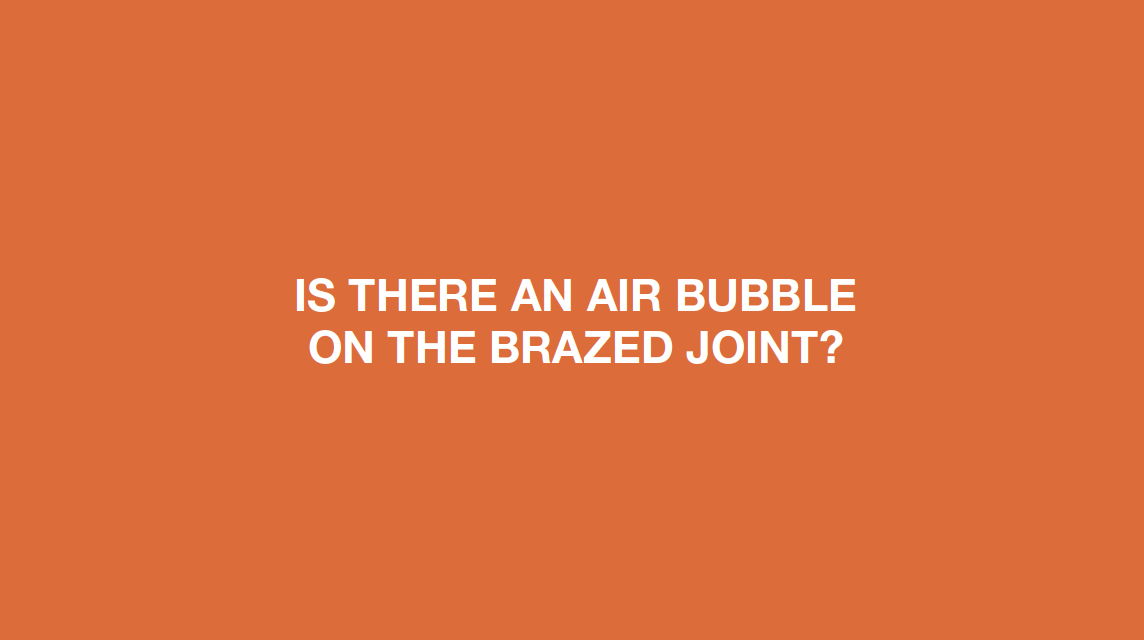

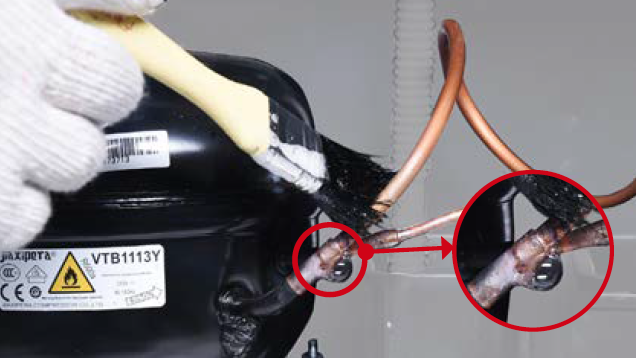

Please follow drawing below to perform a leakage test for brazed joints in the compressor niche.

DIAGNOSIS 2

PROCEDURE 2

Step 1

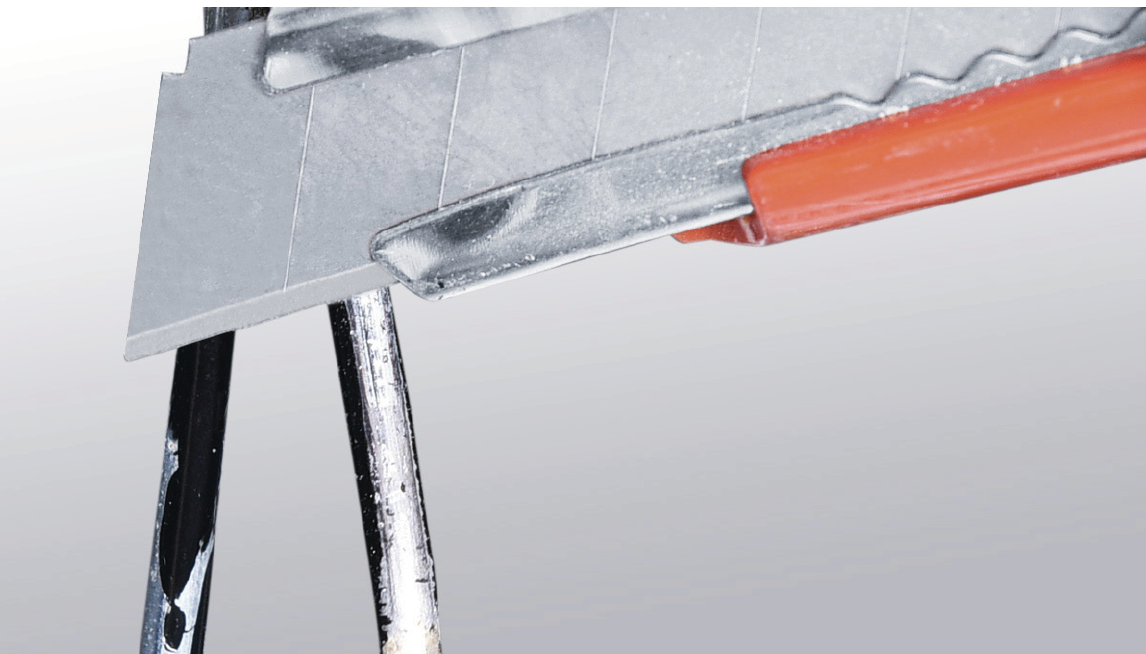

Clean paint from brazedjoint.

Step 2

Cut off brazed joint with leakage.

Step 3

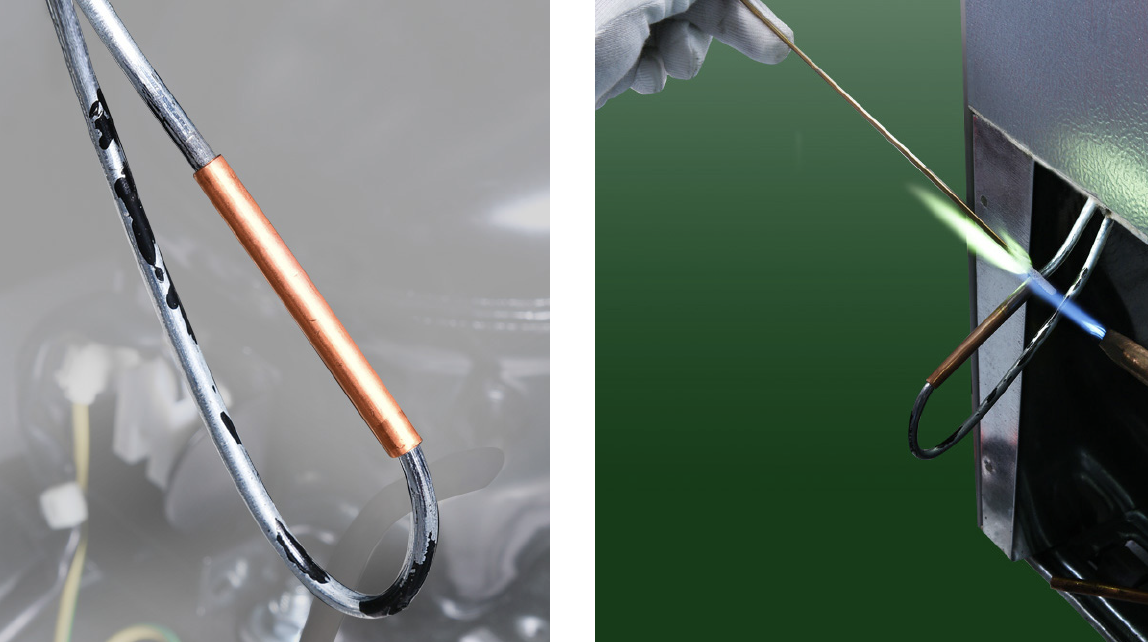

Use a larger copper tube to connect 2 ends of brazed joint.Step 4

Braze the 2 ends.

Step 5

Inject nitrogen at 1.57Mpathrough quick connector

into pipe.

Step 6

Use soapy water toperform leakage test

again.

DIAGNOSIS 3

CHECK AND TEST 3

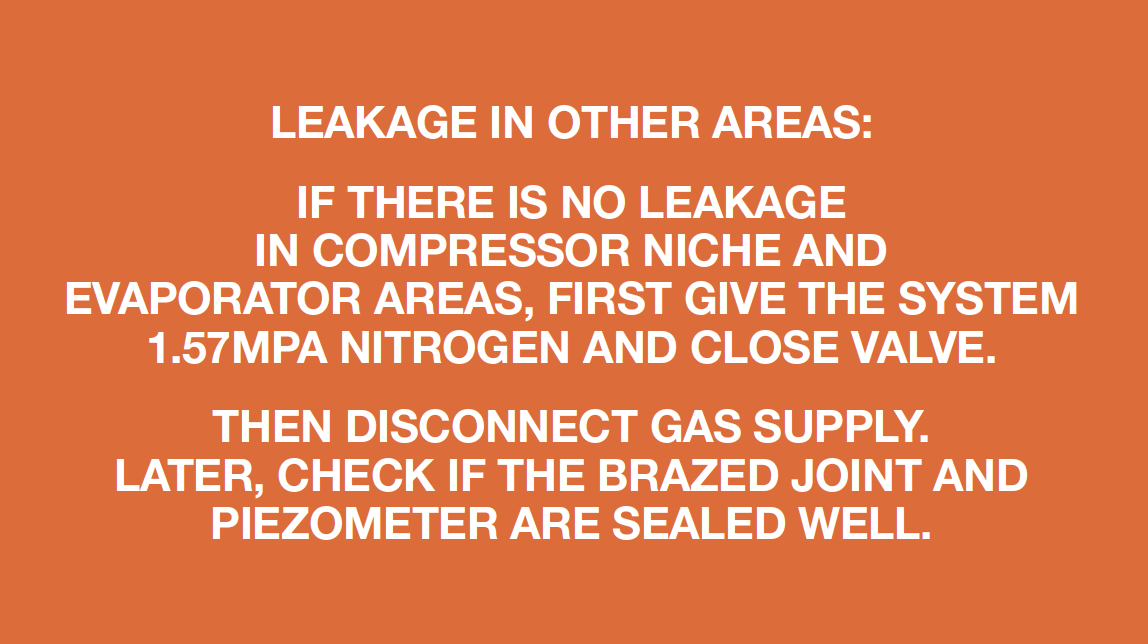

Step 1

Braze a piezometeronto processing tube of

compressor.

Step 2

Charge nitrogen at1.57Mpa through quick

connector into pipe.

Step 3

Do leakage test onbrazing points and

piezometer.

DIAGNOSIS 5

CHECK AND TEST 5

Step 1

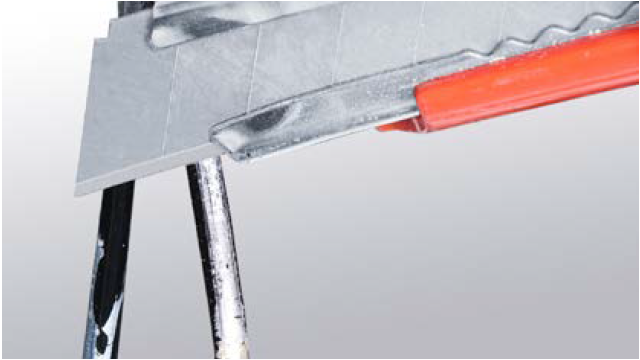

Try to find possibleleakage point.

DIAGNOSIS 6

PROCEDURE 3

Step 1

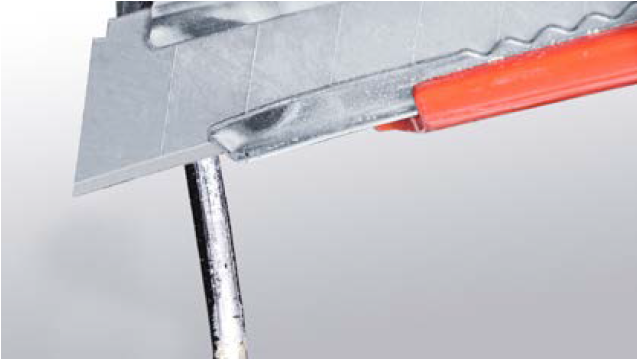

Clean paint off brazedjoint of drying-filter.

Step 2

Cut off brazed jointwith leakage.

Step 3

Use a larger coppertube to connect 2

ends of brazed joint.

Step 4

Braze the 2 ends.

Step 5

Inject nitrogen at1.57Mpa through quick

connector into pipe.

Step 6

Use soapy water toperform leakage test

again.

DIAGNOSIS 7

CHECK AND TEST 3

Step 1

Braze a piezometeronto processing tube of

compressor.

Step 2

Charge nitrogen of1.57Mpa through quick

connector into pipe.

Step 3

Do leakage test onbrazing points and

piezometer.

DIAGNOSIS 4

CHECK AND TEST 4

Step 1

Try to find possibleleakage point.

DIAGNOSIS 5

PROCEDURE 3

Step 1

Clean paint off brazedjoint of drying-filter.

Step 2

Cut off brazed jointwith leakage.

Step 3

Use a larger coppertube to connect 2

ends of brazed joint.

Step 4

Braze the 2 ends.

Step 5

Inject nitrogen at1.57Mpa through quick

connector into pipe.

Step 6

Use soapy water toperform leakage test

again.

DIAGNOSIS 6

CHECK AND TEST 5

Step 1

Clean paint off brazedjoint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary andshake to remove the cut

end.

Step 4

Braze on a newdrying-filter.

Step 5

Inject nitrogen (1.57Mpa)through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 6

Add quick connectoronto processing pipe of

drying-filter.

Step 7

Do leakage test onbrazed joints of dryingfilter

and processing pipe

on compressor.

Step 8

Vacuum and recharge.Click below link to

get more details for

vacuuming and gascharging

requirements,

go to page 10.4 Annex B1

Step 9

Block processing pipetwice with locking pliers.

Step 10

Leave locking pliers onthe second block and

cut off the rest of the

pipe by shaking.

Step 11

Braze the ends andremove the pliers.

DIAGNOSIS 7