CHECK AND TEST 1

Step 1

Unscrew cover of

mainboard with a

cross-head screwdriver.

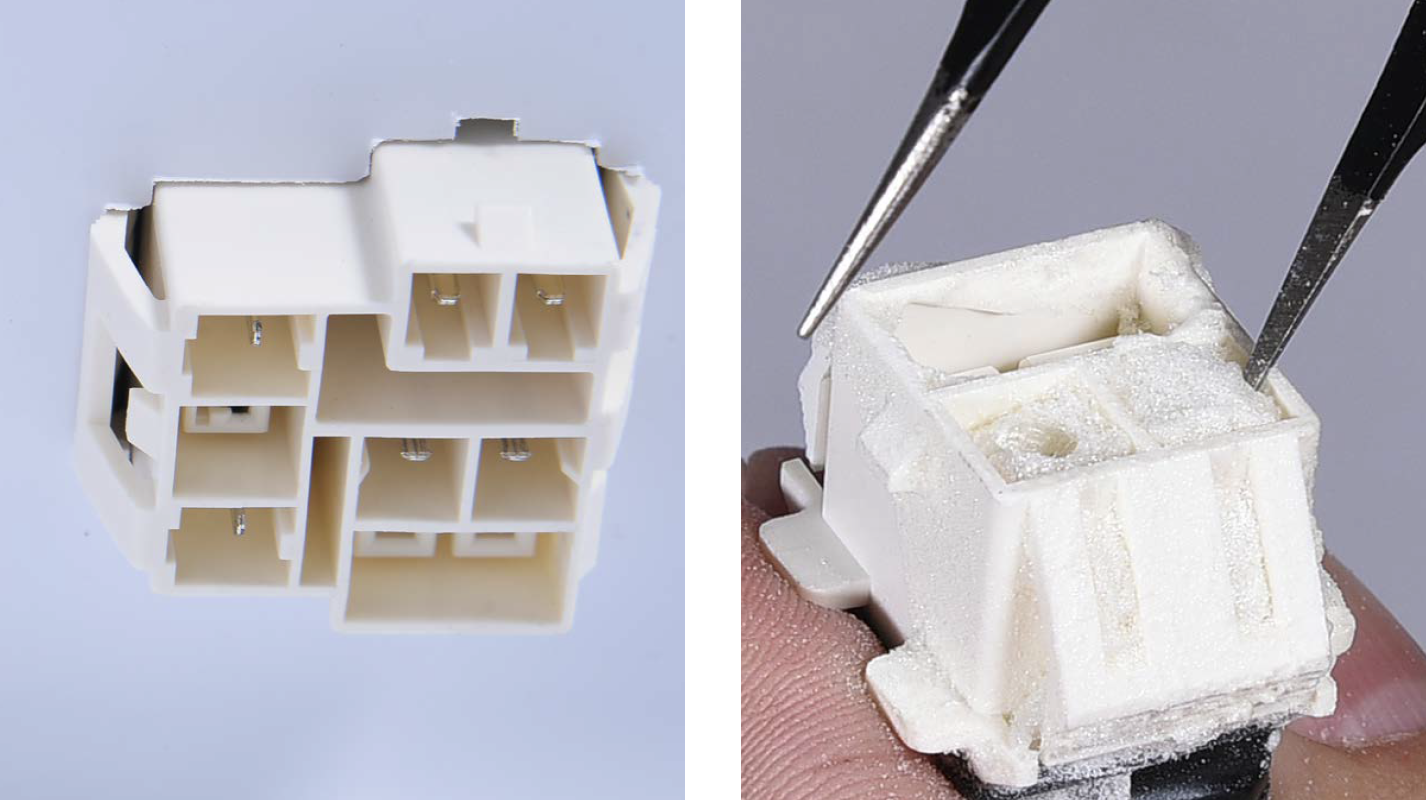

Step 2

In mainboard area, check if terminal is pushed into proper final position.

Step 3

In mainboard area, check if terminal is filled with foam.

Step 4

If so, use tweezers to

remove foam.

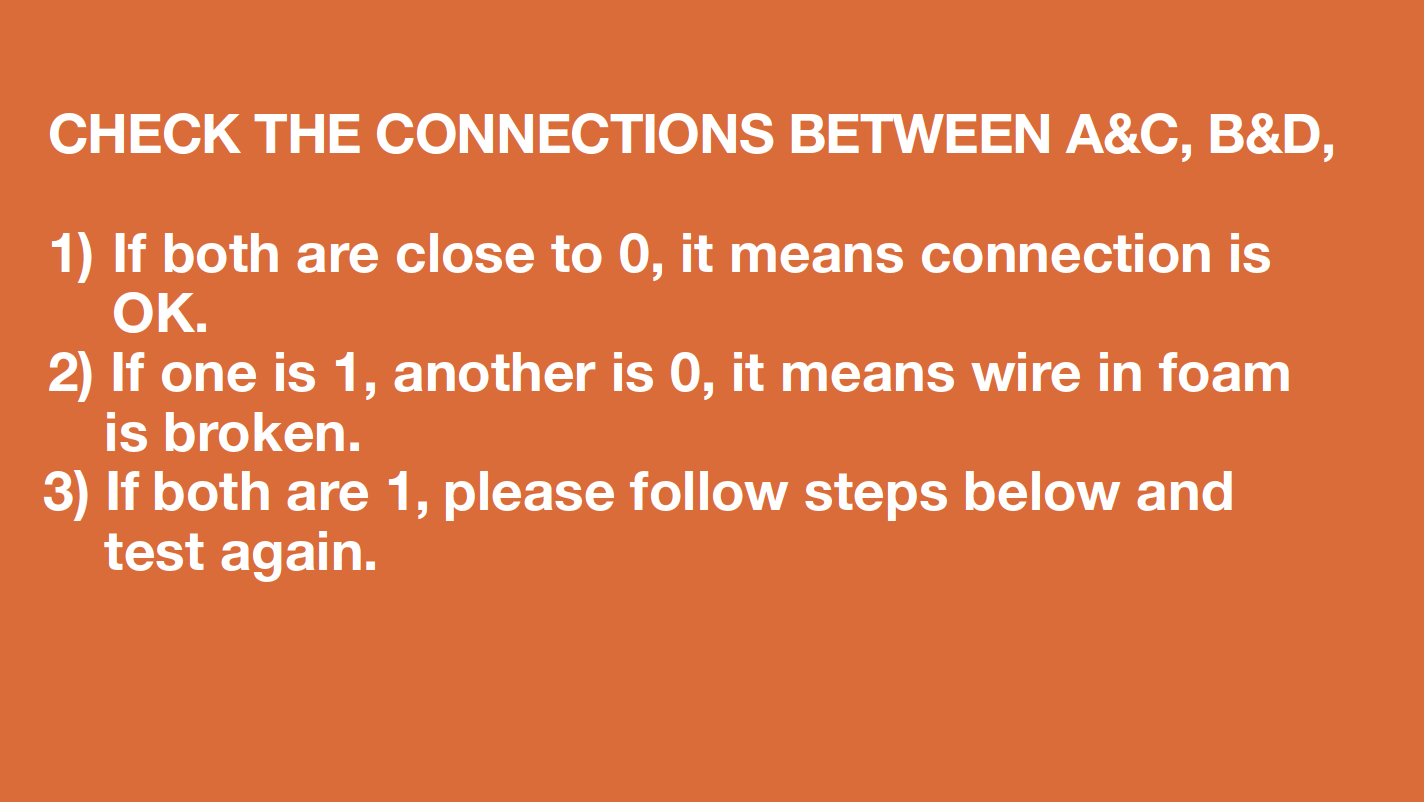

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

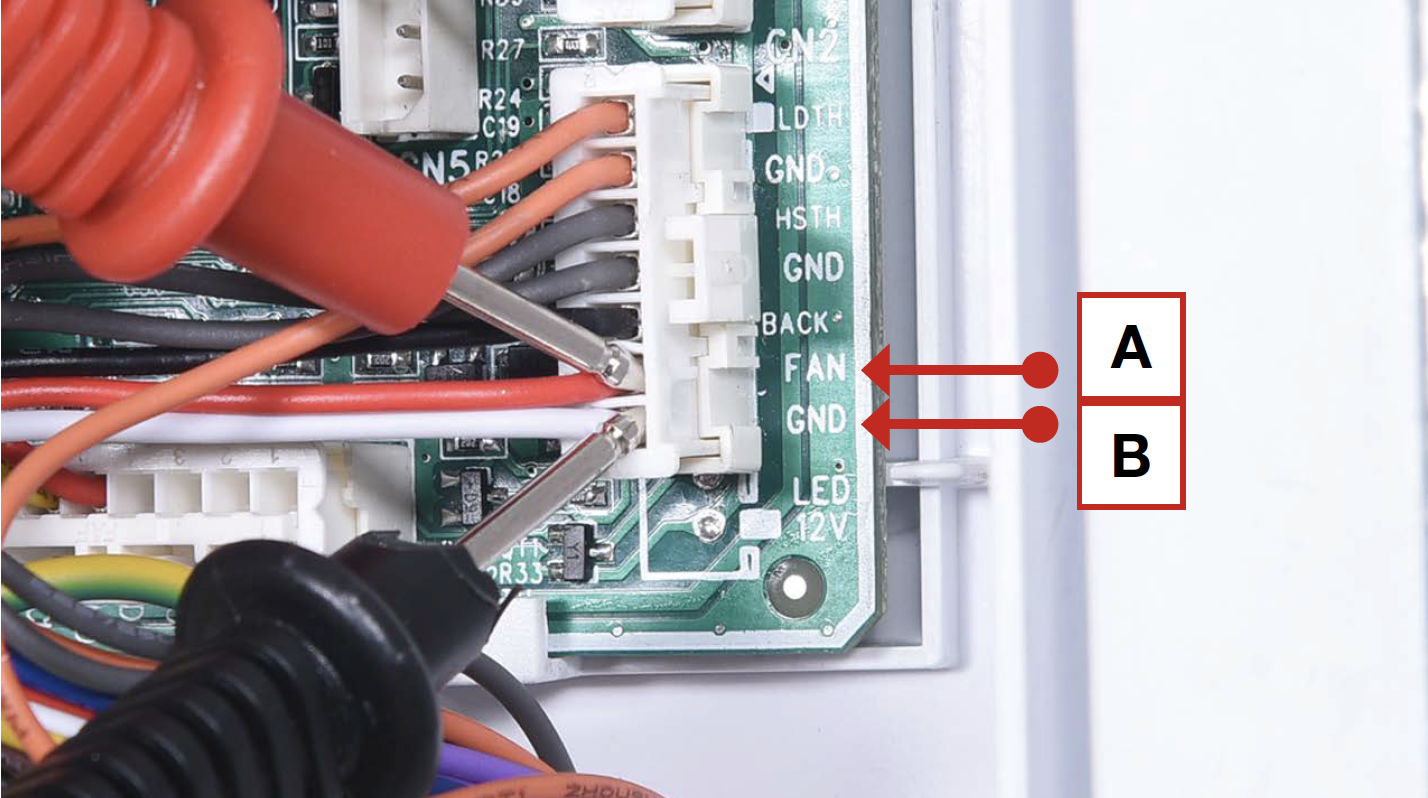

Turn power output of transformer to DC 12V.

Step 2

Supply power from terminal in PCB area (FAN & GND).

DIAGNOSIS 2

PROCEDURE 1

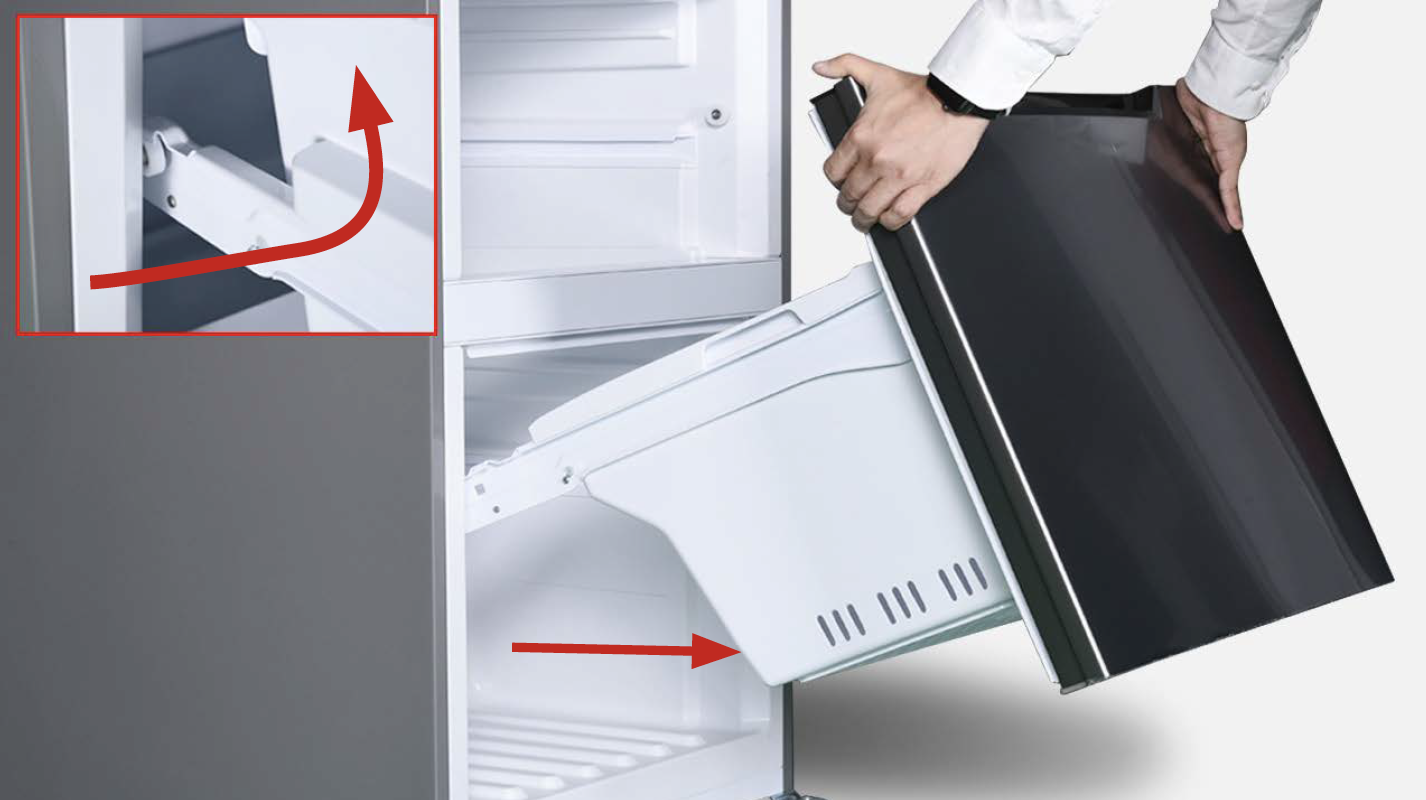

Step 1

Remove the upper freezer drawer.

Step 2

Remove the upper freezer drawer. Remove the upper freezer drawer.

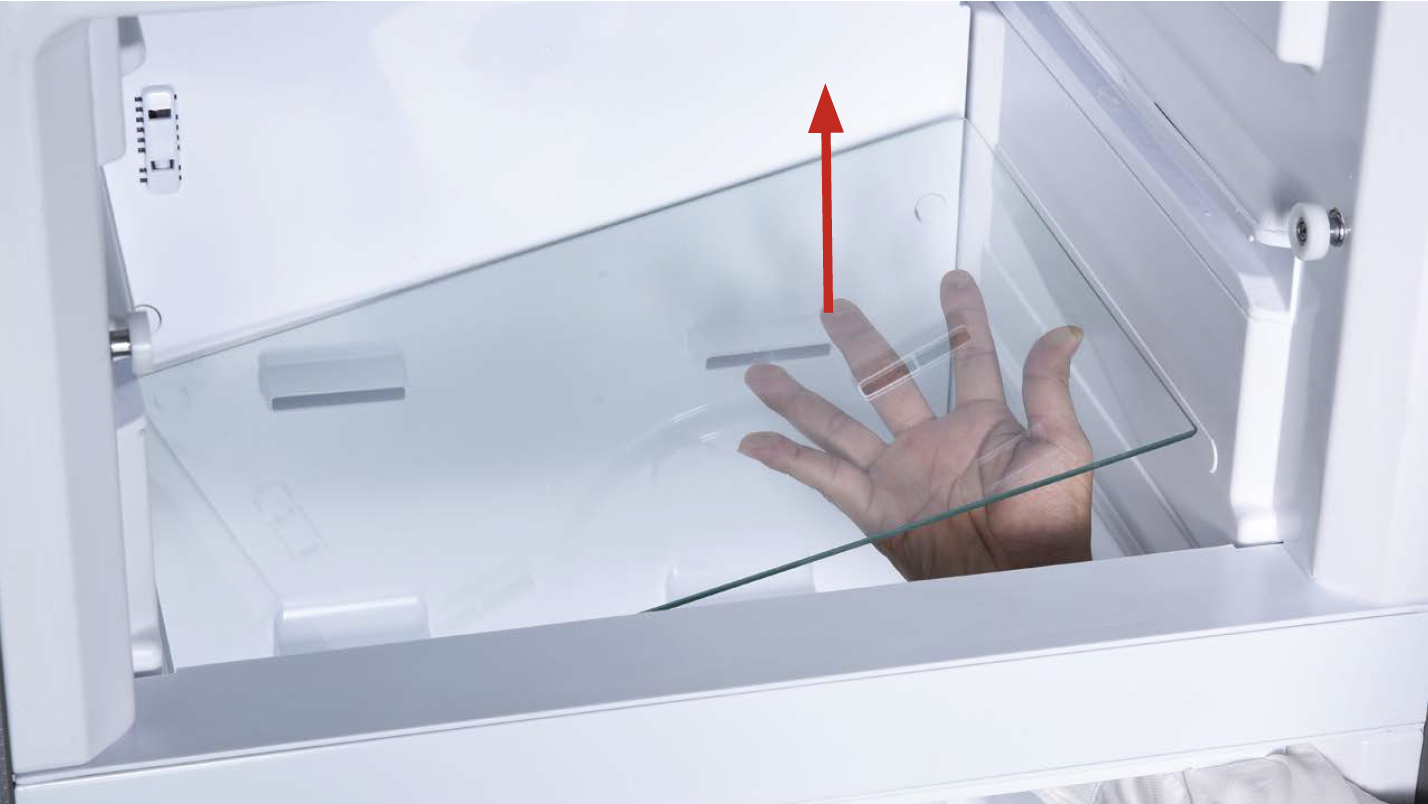

Step 3

Remove the middle glass shelf located between upper and bottom freezer drawer compartments.

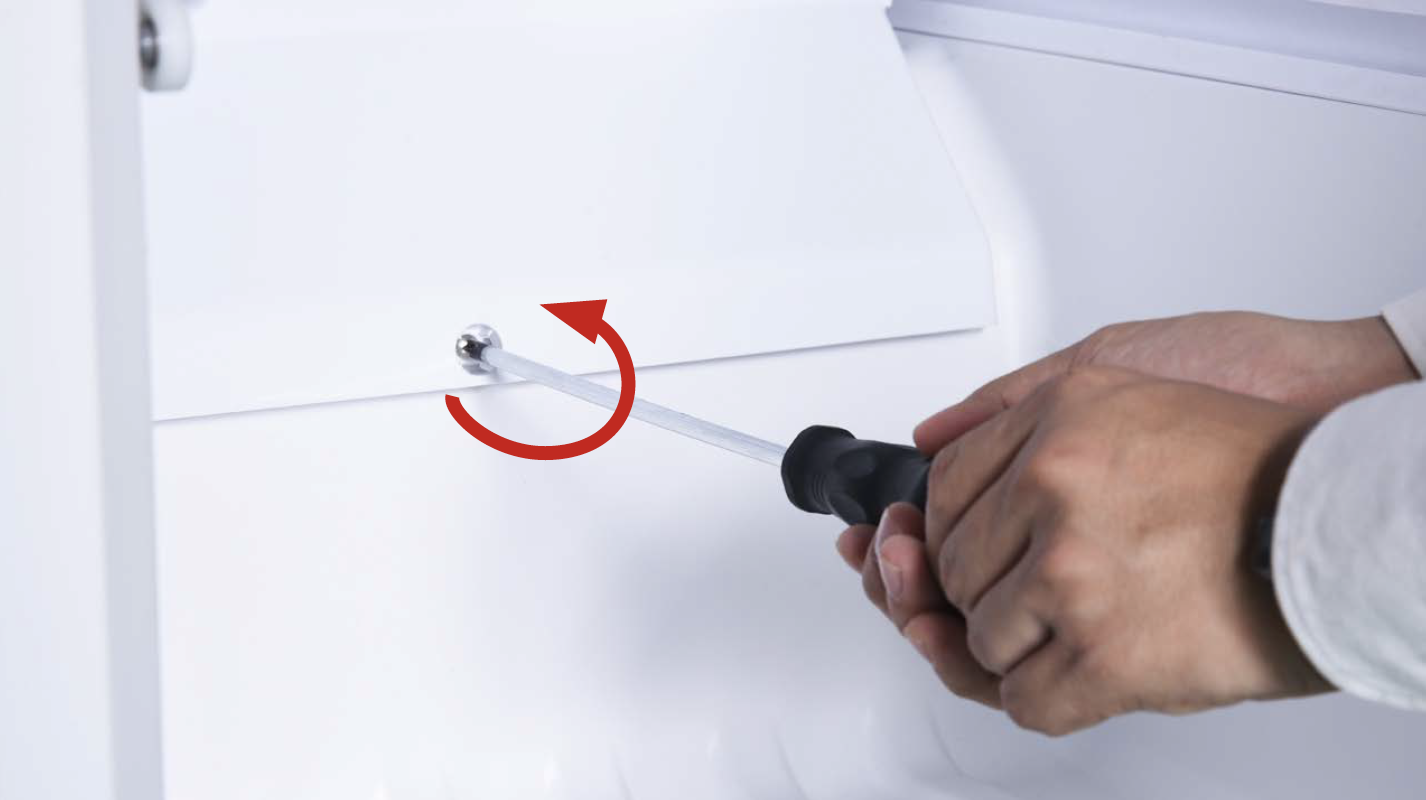

Step 4

Unscrew air duct.

Check the freezer air

duct to find the three

screw covers.

Step 5

Remove the screw covers (total of three) on the air duct with slotted screw driver.

Step 6

Unscrew all three screws with Cross-head screw driver.

Step 7

Dismantle the air duct.

Catch the bottom of air

duct.

Step 8

Pull air duct out from the bottom of air duct.

Step 9

Pay attention to the connectors when pulling out the air duct.

Tip 1

When re-installing the air duct, move the wires out of the way so that they won’t be crushed by air duct.

Tip 2

After pushing air duct into position, it should make a click sound. If no click is heard, do it again.

CHECK AND TEST 2

Step 1

In duct area, check if terminal is pushed into final position.

Note

A & C are not OK; B is OK..

Step 2

Check if terminal is filled with foam or not.

IF YES, please use a needle to clean and remove the foam.

Later, reconnect the terminals

Power off the appliance and turn the power output of transformer to DC 12V.

Step 4

Supply power from terminal in PCB area.

DIAGNOSIS 2

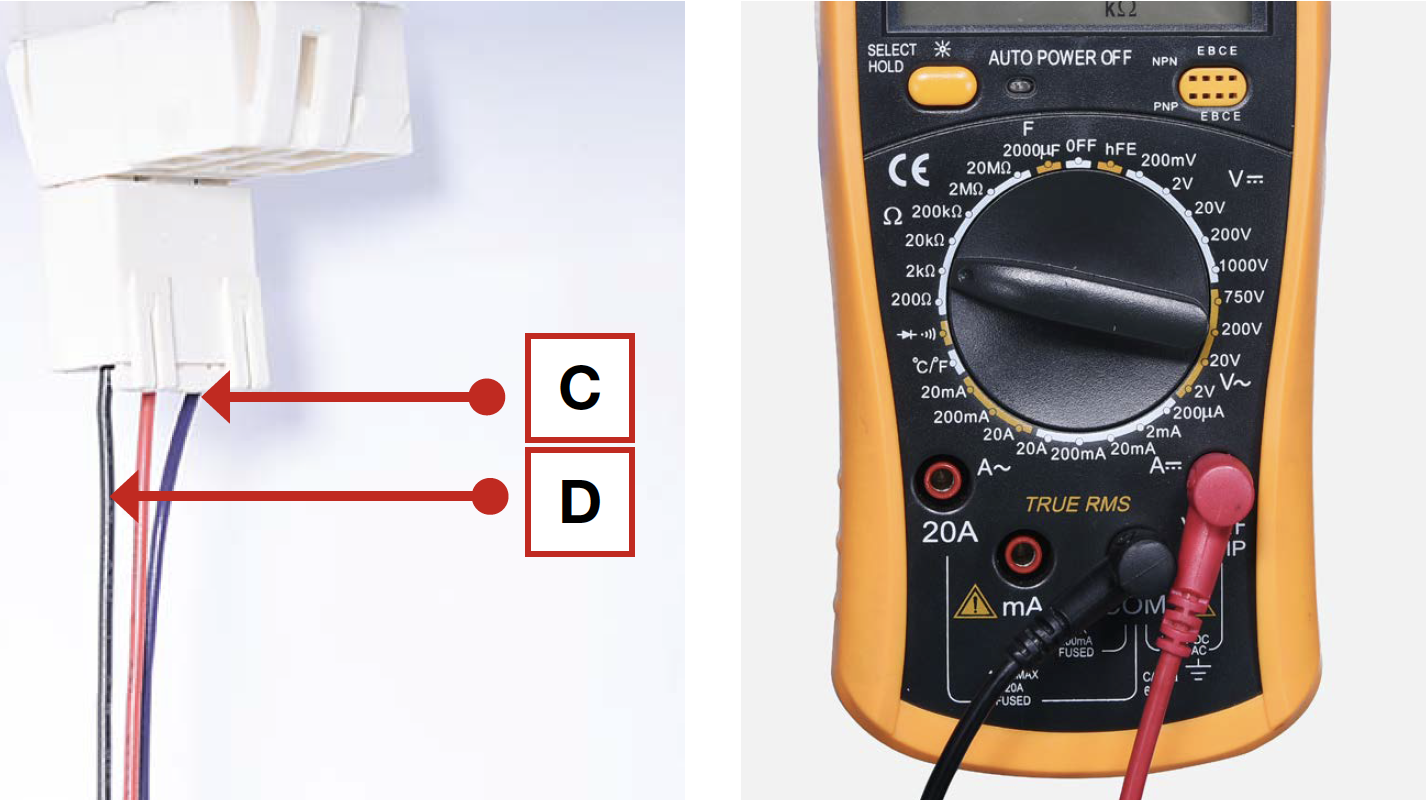

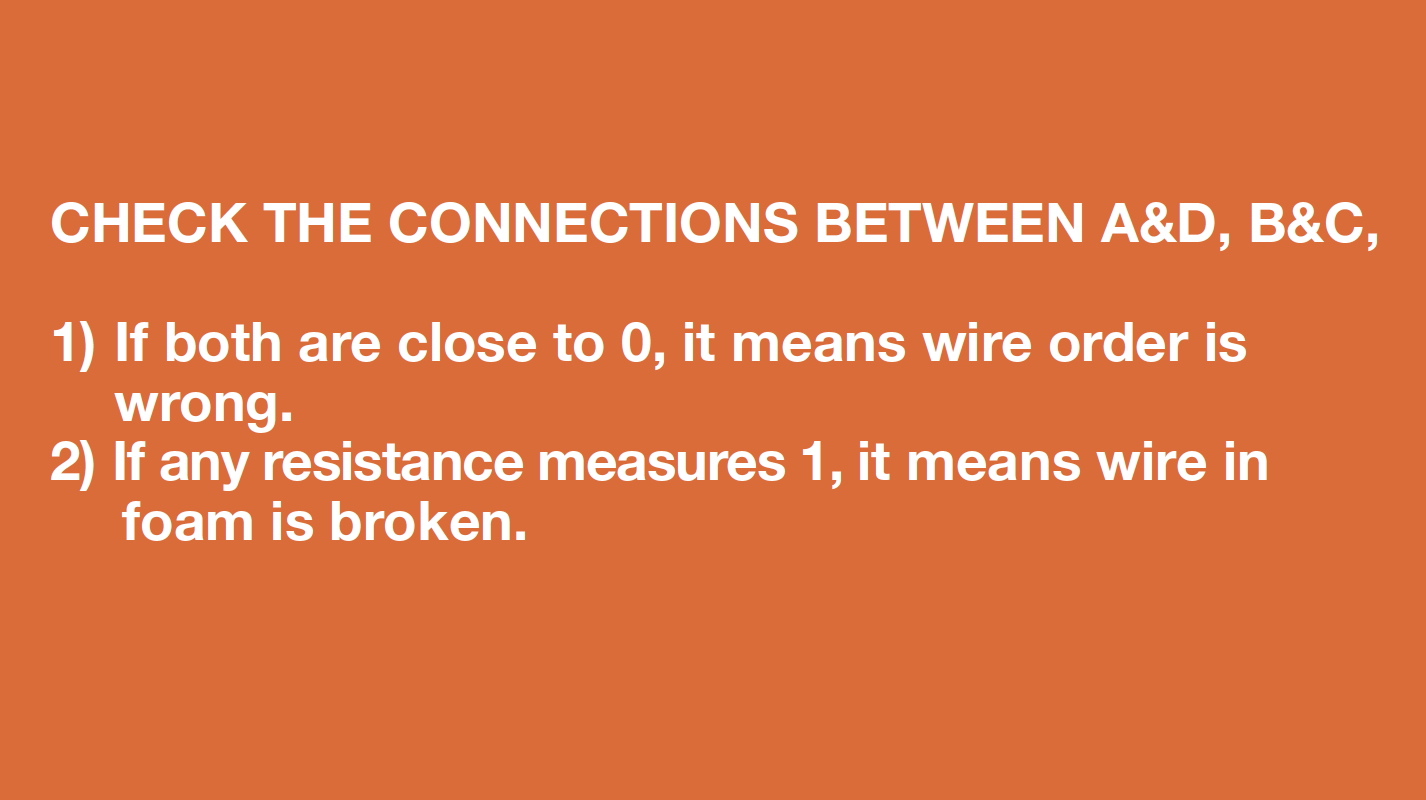

Step 2

Check to see if the wires

are in the correct order

and their connections in

the foam are correct:

1. Set multimeter to

resistance gear;

2. Put detector into one end of wires in PCB area;

3. Put another detector into end of wires behind air duct.

DIAGNOSIS 3

DIAGNOSIS 4

PROCEDURE 2

Step 1

Cut wire off.

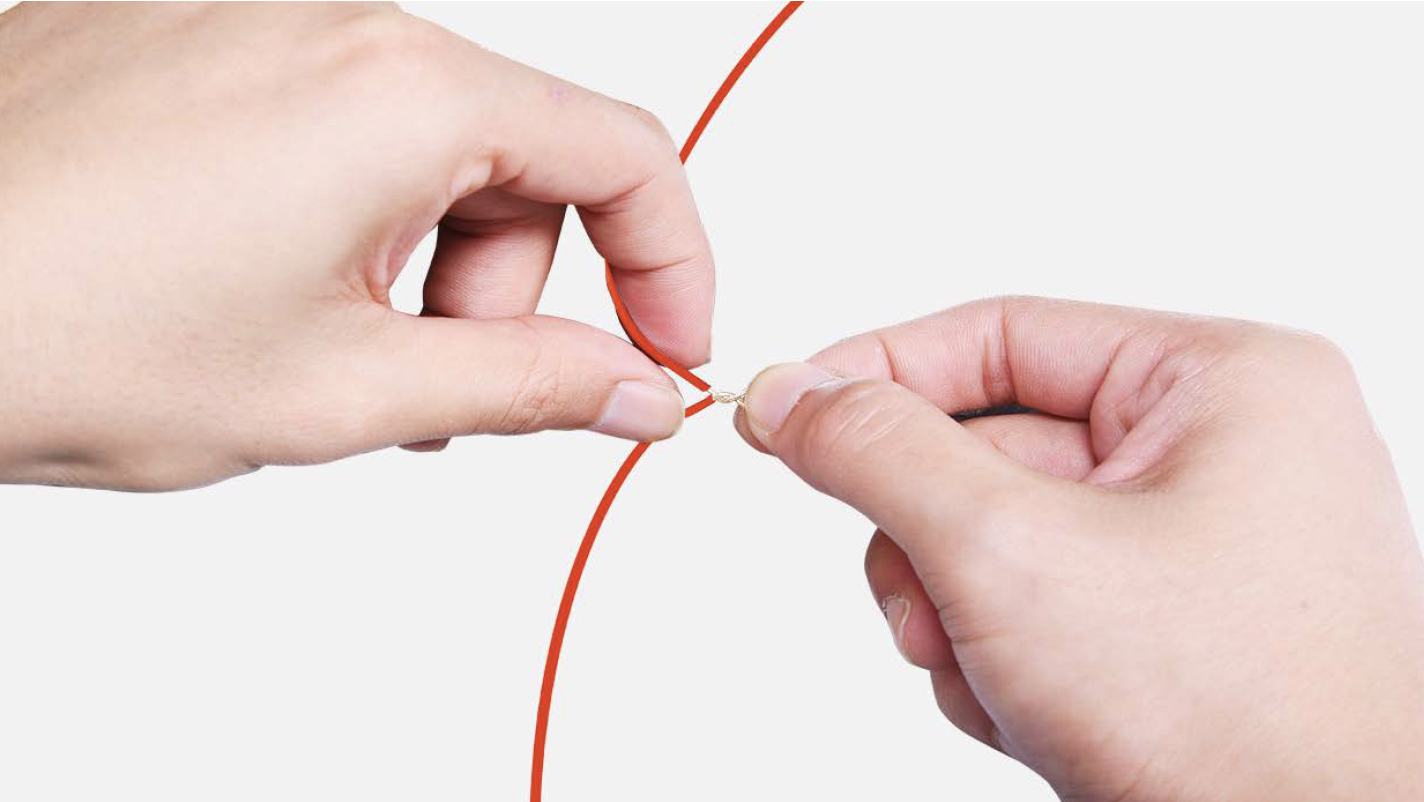

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and connect them.

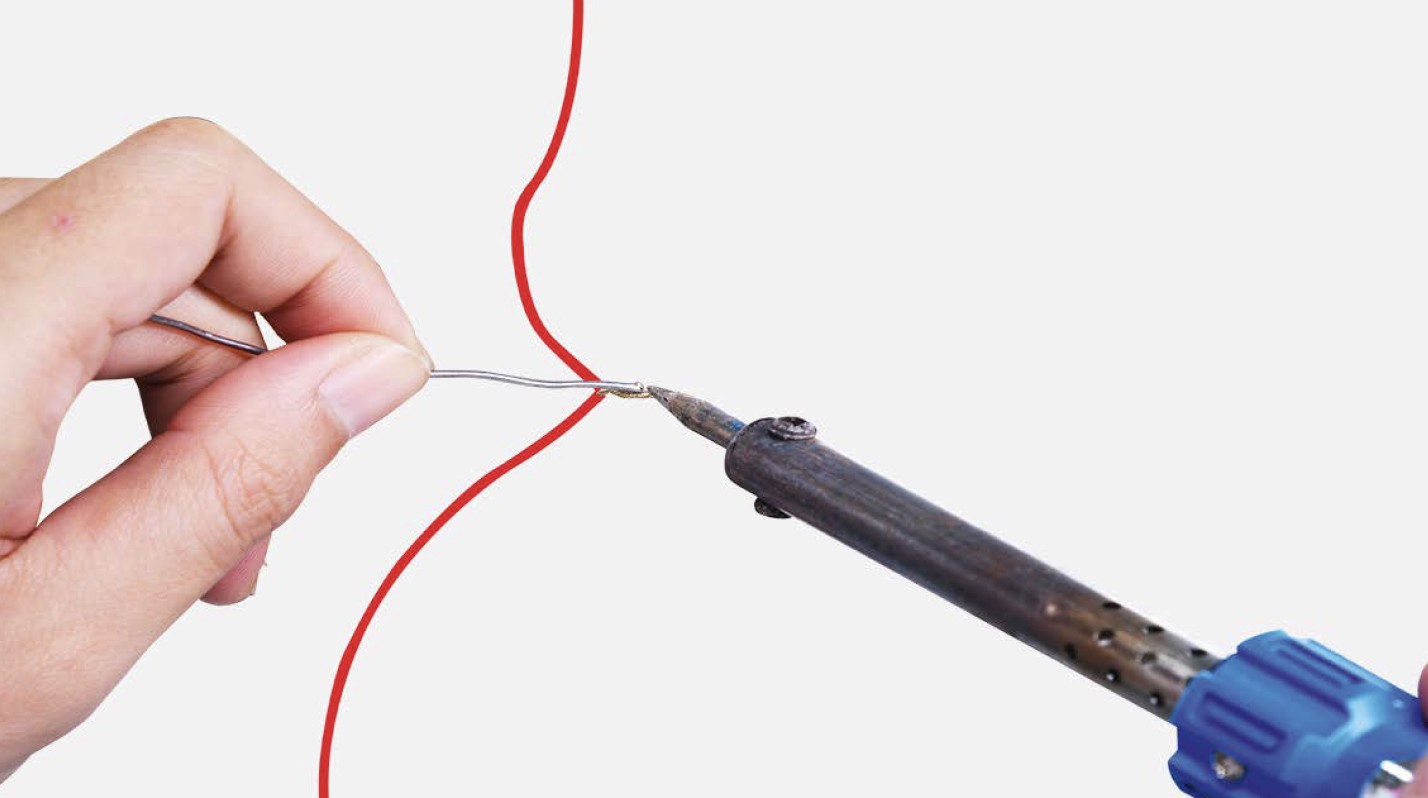

Step 4

Tin soldering.

Step 5

Cover connection with electrical tape.

CHECK AND TEST 4

Step 1

Set output of transformer to DC 12V to test fan from the terminal behind the air duct.

Step 2

Use power source to test fan from terminal in the back of air duct.

DIAGNOSIS 5

Note

Tip 1

When re-installing the air duct, move the wires out of the way so that they won’t be crushed by air duct.

After pushing air duct into position, it should make a click sound. If no click is heard, do it again.

CHECK AND TEST 5

Step 1

Open fridge door and freezer drawer, press the mechanical switch.

DIAGNOSIS 6