CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

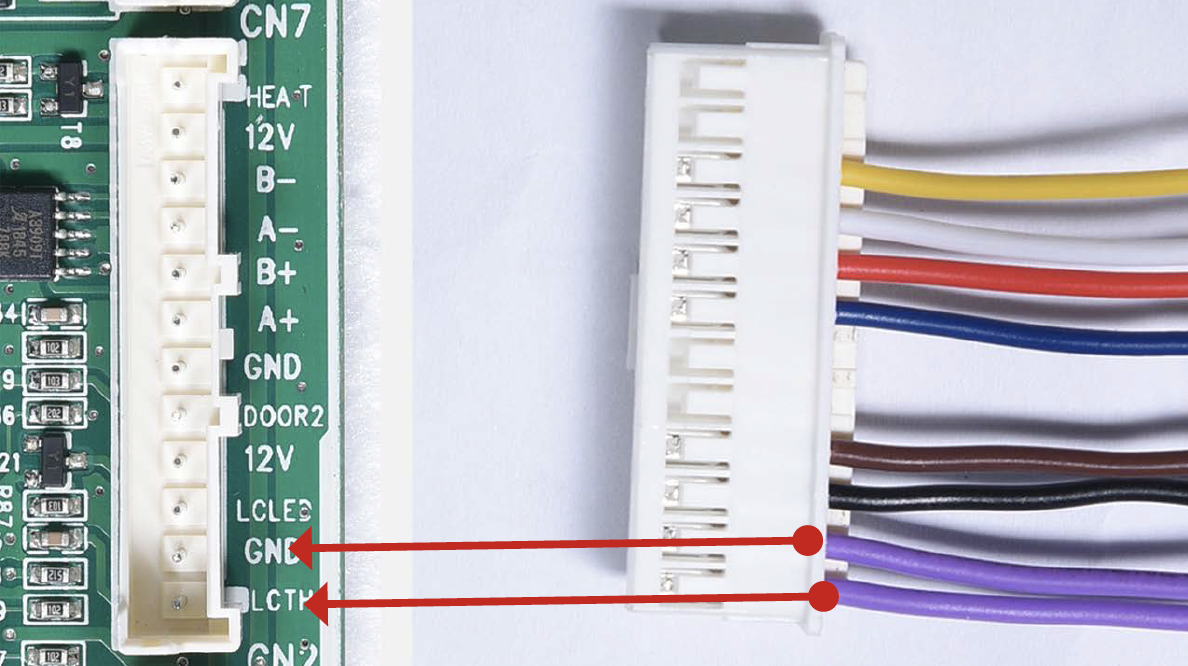

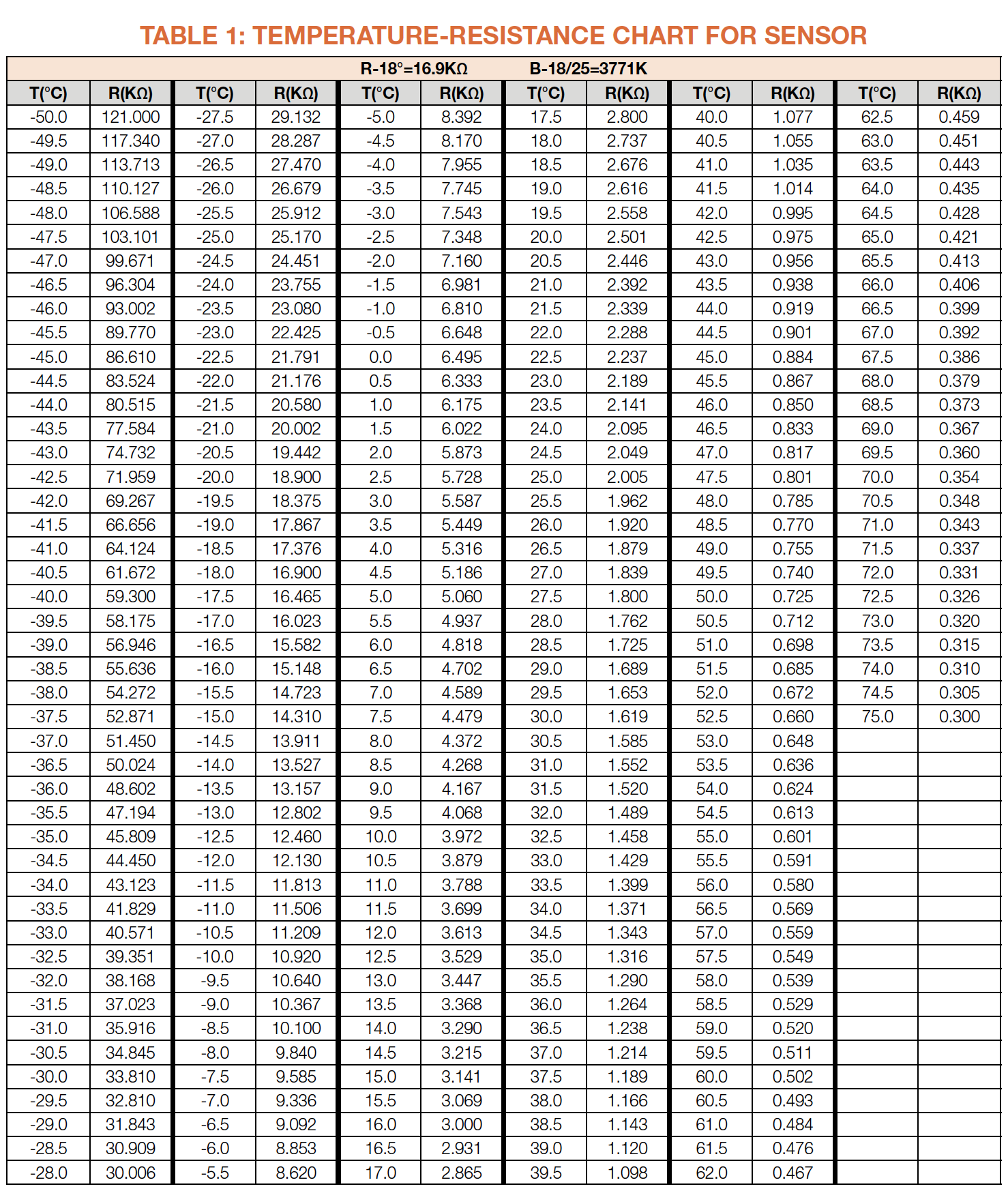

Step 2

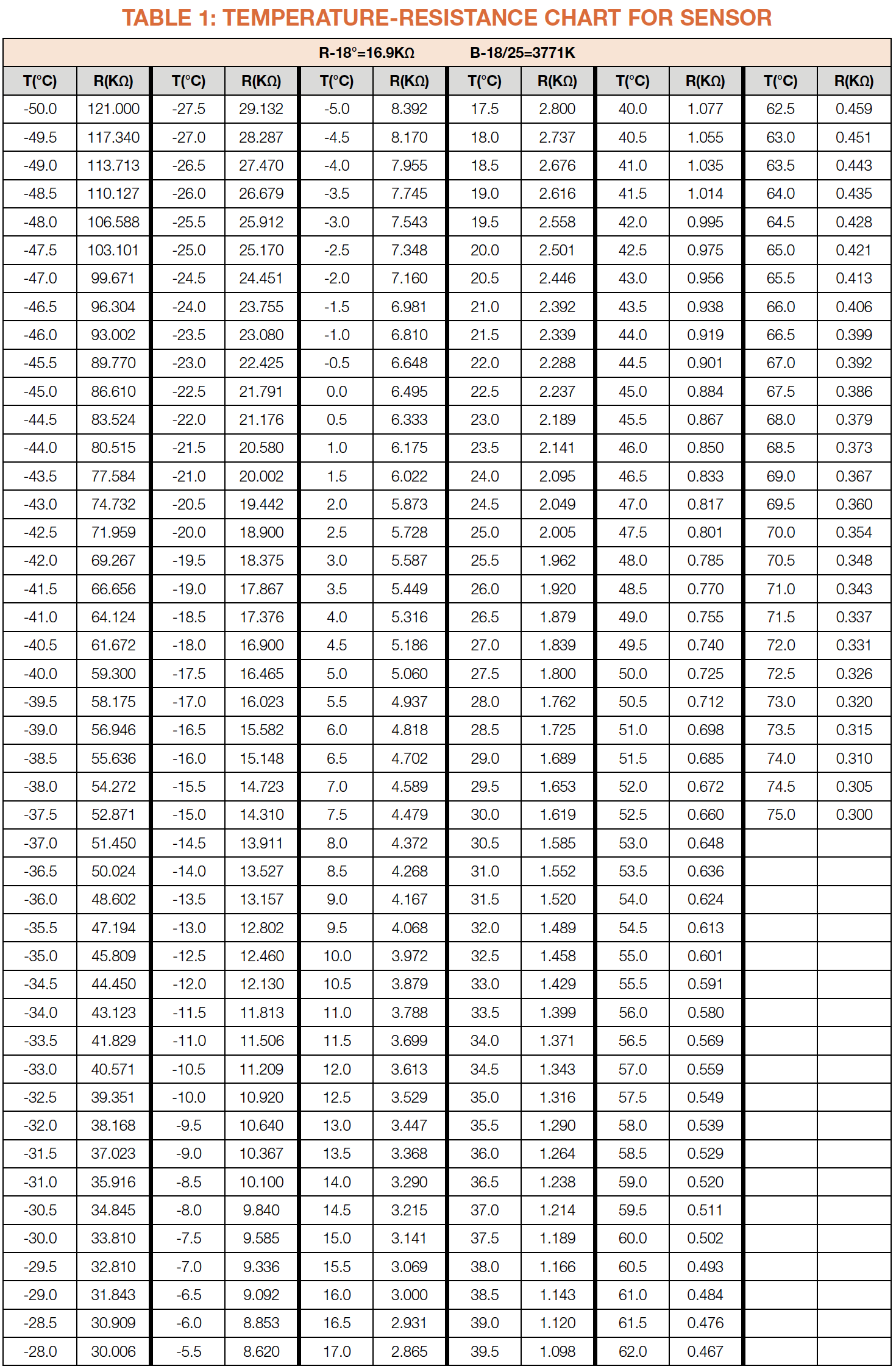

Test resistance of fridge temp. sensor from terminal in PCB area.

Step 3

Take note of value.

Step 4

Measure the temperature of sensor.

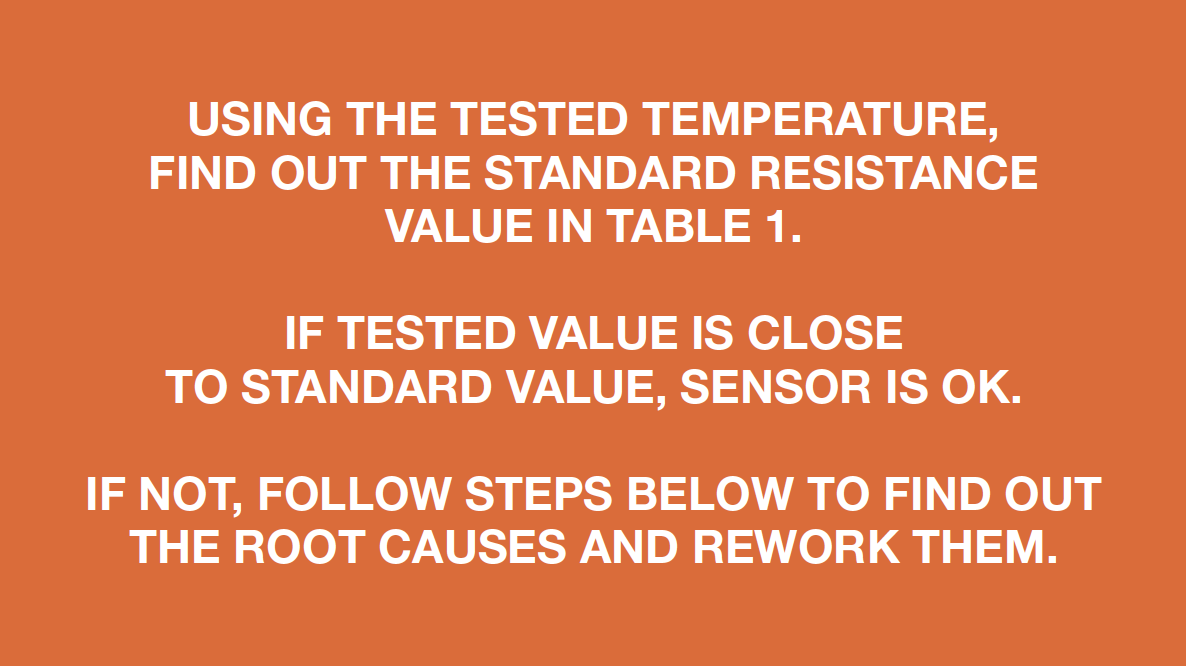

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove shelves.

Step 2

Remove crispers.

Step 3

Remove shelf cover

Step 4

Hold the cover and turn in counter-clockwise direction to loosen cover. Then, remove cover.

Step 5

Use 6mm Cross-head screwdriver to loosen the screw.

Step 6

Hold the edge of air duct to remove.

Step 7

Disconnect the terminals.

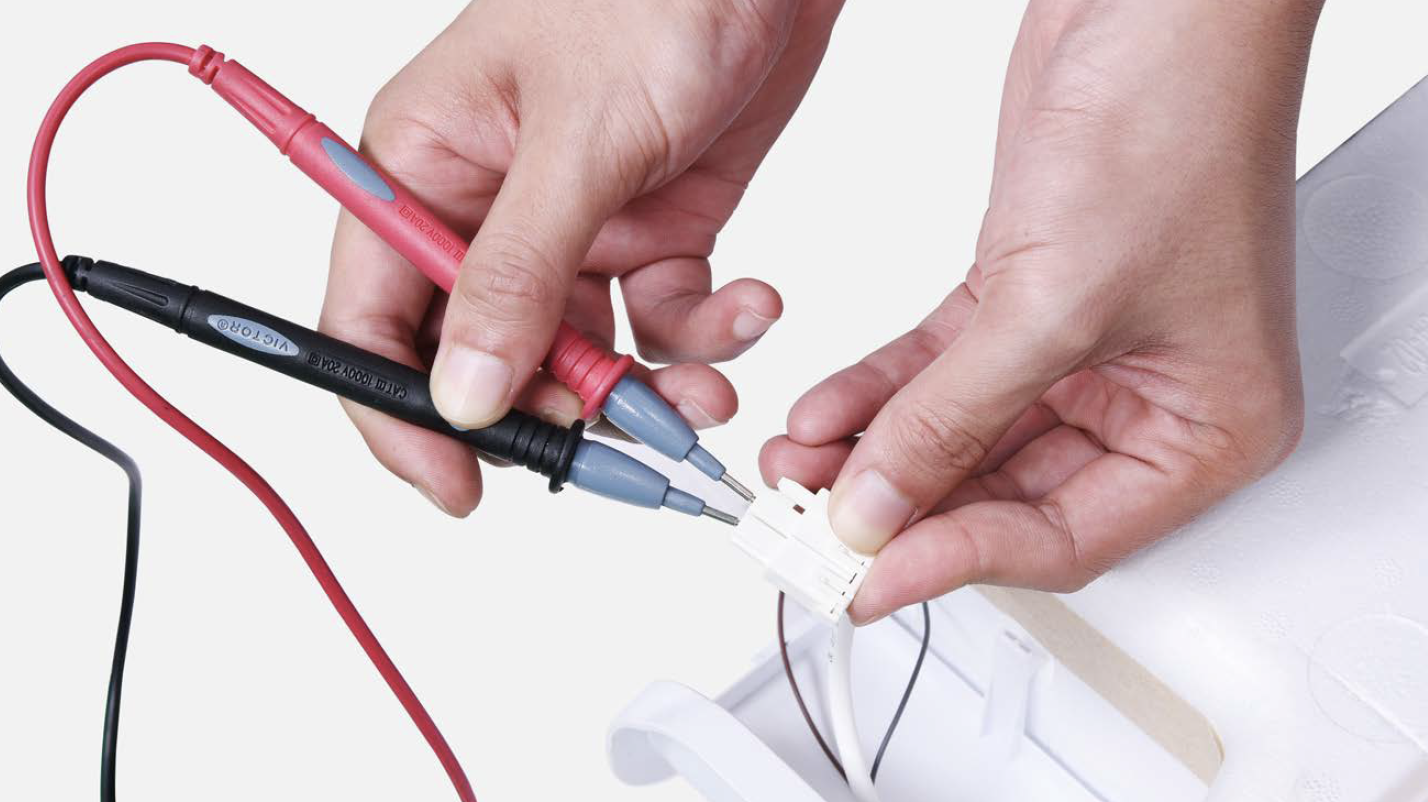

CHECK AND TEST 2

Step 1 Test resistance of sensor from terminal in duct cover.

Step 2

Measure temperature of fridge temp. sensor.

DIAGNOSIS 2

Note

PROCEDURE 2

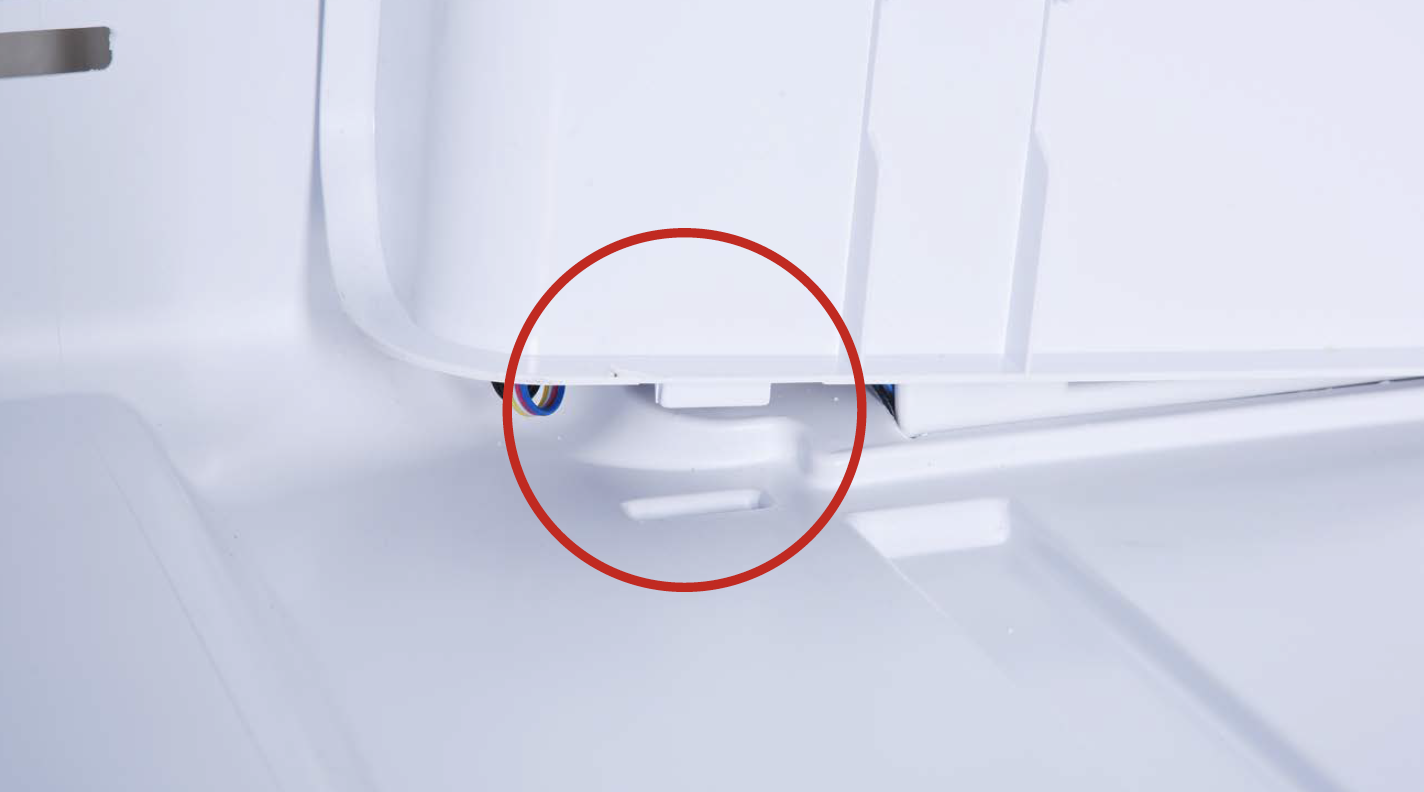

Step 1

Release the clasp.

Step 2

Remove the foam air duct.

Step 3

Remove tape.

Step 4

Remove the broken sensor.

Note

Reverse the procedures to install new sensor.

CHECK AND TEST 3

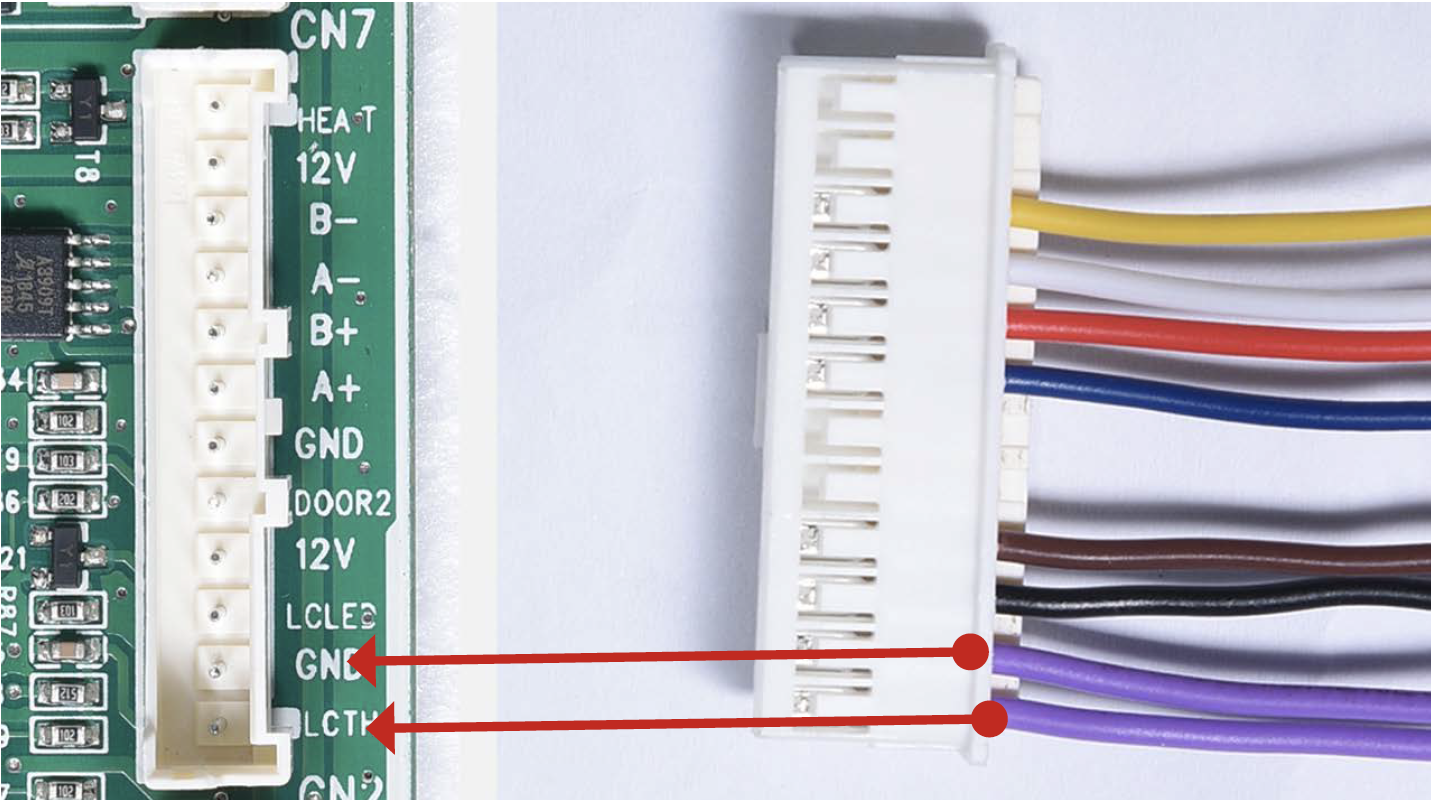

Step 1

Check to see if terminal is full of foam.

Step 2

Use a needle or tools with sharp tip to remove foam in terminal.

Step 3

Check to ensure that wires are connected properly.

Step 4

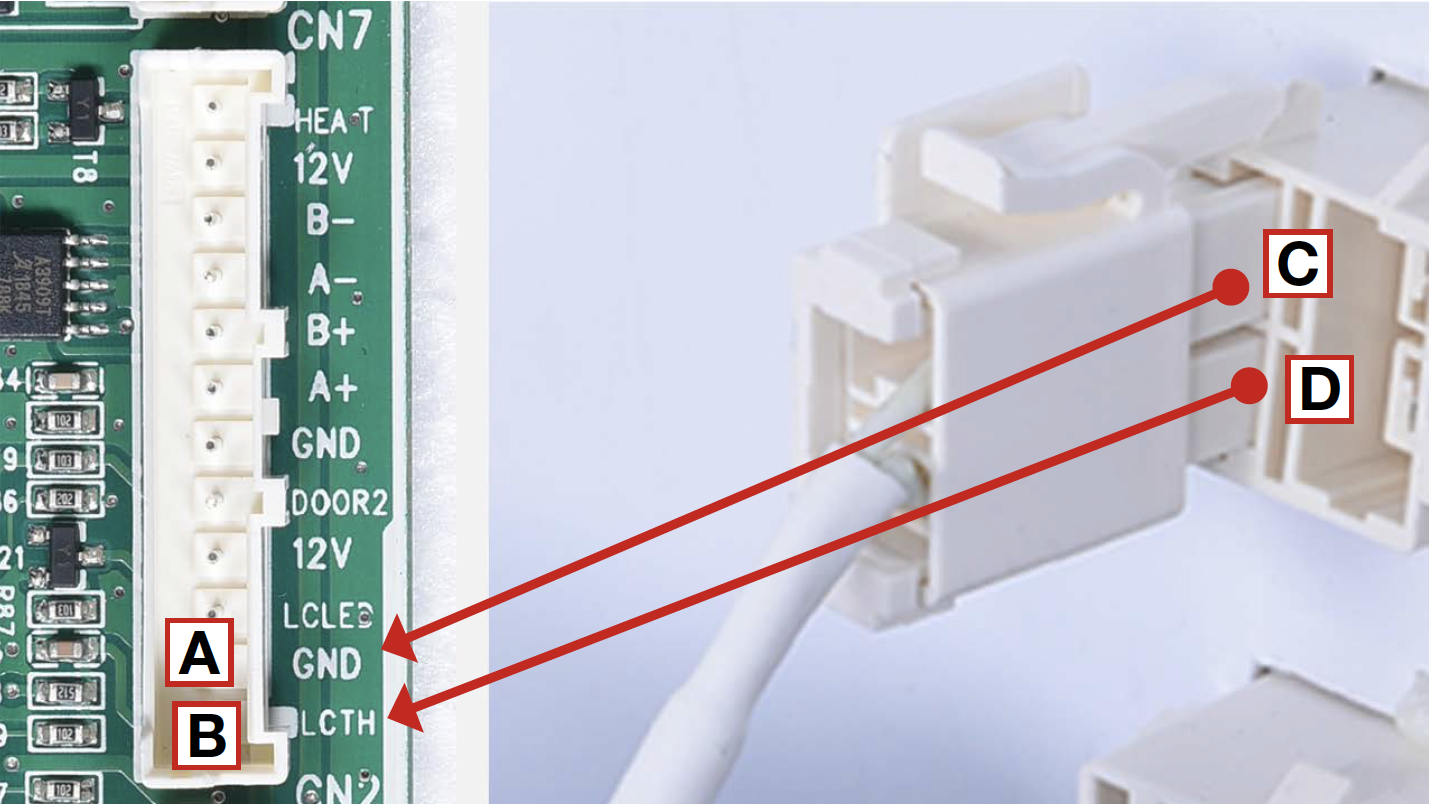

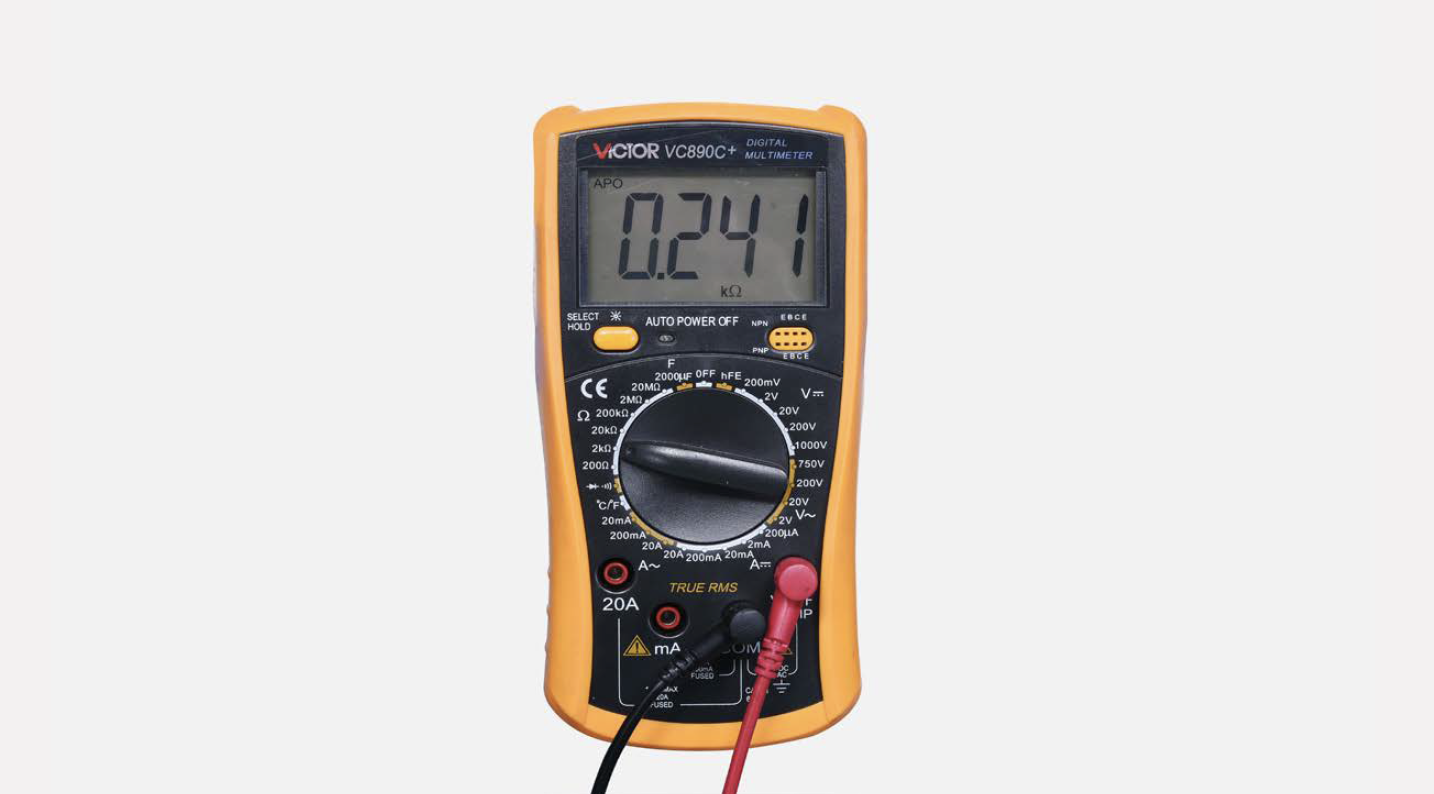

Use multimeter to test connections.

1. Put detector into one end of wires in PCB area;

2. Put another detector into end of wires behind air duct.

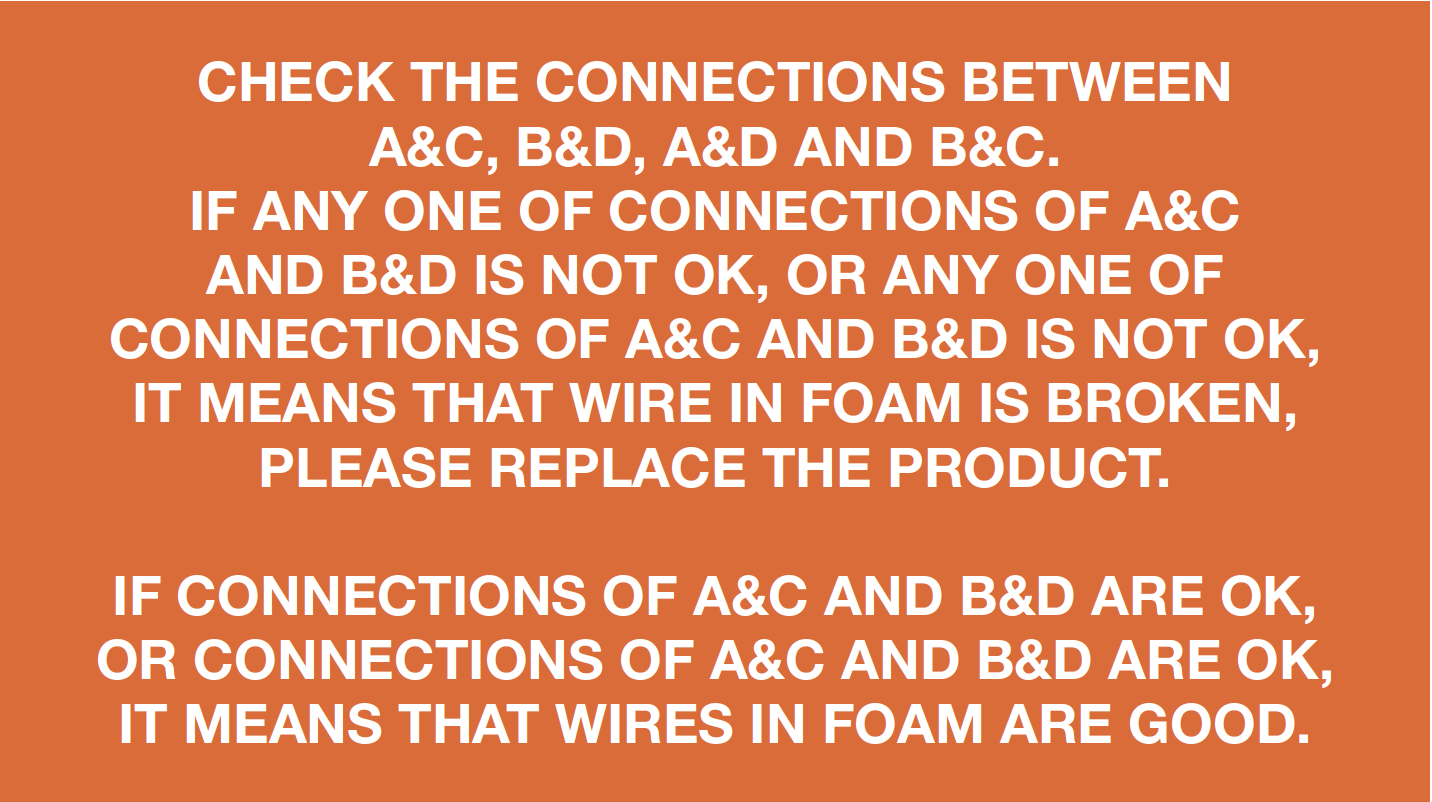

DIAGNOSIS 3

PROCEDURE 3

Step 1

Reinsert the terminals for sensor. Make sure that the terminal is pushed into final position

Step 2

Screw on the cover of mainboard with a cross-head screwdriver.

Step 1

Re-connect the terminals.

Step 2

Hold air duct by edges to put it back in place.

Step 3

Use a 6 mm cross-head screwdriver to tighten the screw clockwise.

Step 4

Hold the cover and turn it clockwise to tighten the lid, then pull outwards.

Step 5

Insert shelves.

TIPS DURING INSTALLATION PROCEDURES FOR FRIDGE AIR DUCT.

Tip 1

Connect the terminals.

Tip 2

Push terminals into place, then move wires to prevent crushing of wires with edge of air duct.

Tip 3

When reinstalling the air duct, first insert positive shaft into the negative hole.

Tip 4

Then, fasten the clasp on top using the same method.

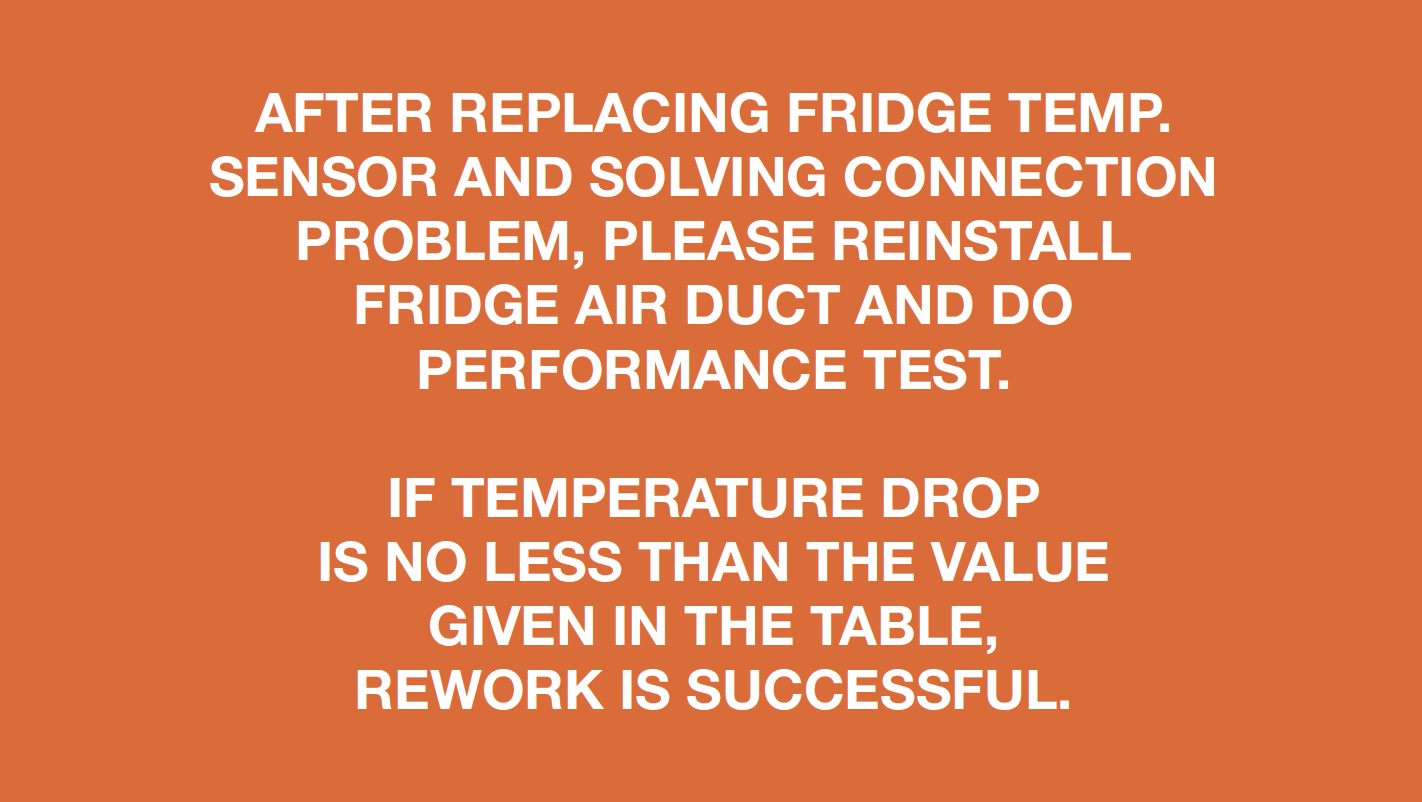

DIAGNOSIS 4