Step 1

Discharge refrigerant:

1) use pliers to cut off charging tube.

2) Discharge all refrigerant toward the

exhaust vent.

Step 2

Melt brazing material with flame and pull processing tube out with a pair of pliers.

Step 3

Re-braze a copper tube onto processing tube of compressor.

Please find more details

of brazing requirements,

on Annex B1

Note

Step 4

Install quick connector onto rebrazed pipe.

Step 5

Cut off exhaust pipe and suction pipe.

Step 6

Power on the compressor and test exhaust pressure coming from exhaust pipe with a piece of paper.

Step 7

Test the suction pressure of suction pipe with a piece of paper.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover.

Step 3

Disconnect all terminals.

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut of compressor.

Step 6

Install a new compressor on top.

Step 7

Braze the joints of suction and exhaust pipes.

PROCEDURE 2

Step 1

Re-braze a copper tube onto processing tube of compressor.

To get more details on

brazing requirements,

please go to Annex B1

Step 2

Install quick connector onto re-brazed pipe.

Step 3

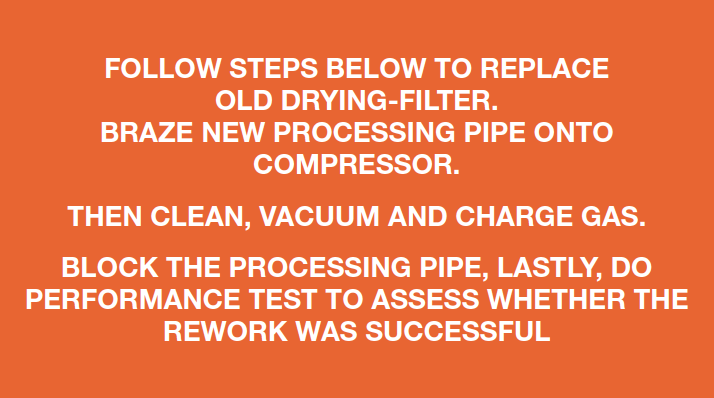

Clean paint off of brazed joint of drying filter.

Step 4

Cut off the brazed joint of drying filter.

Step 5

Cut off capillary and remove the cut end by shaking.

Step 6

Weld a new drying-filter.

Step 7

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 8

Add quick connector onto processing pipe of drying-filter.

Step 9

Do leakage test on brazed joints of drying-filter and processing pipe on compressor.

Step 10

Vacuum and recharge.

Please get more details

of vacuuming and gas-

charging requirements

on Annex B2

Step 11

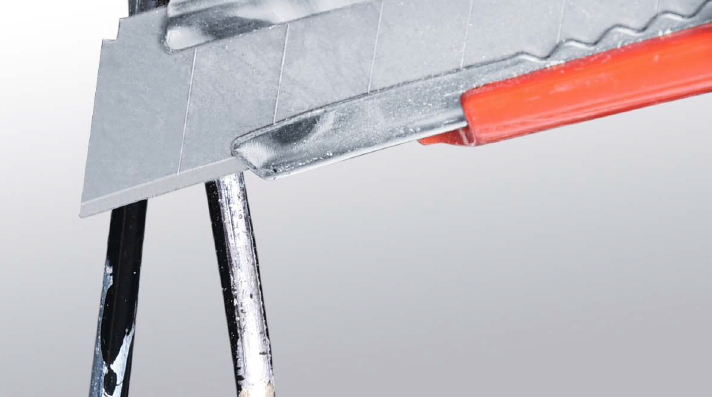

Block processing pipe twice by locking pliers.

Step 12

Leave locked pliers attached to second block and shake to cut off the remaining pipe.

Step 13

Braze the ends and remove the pliers.

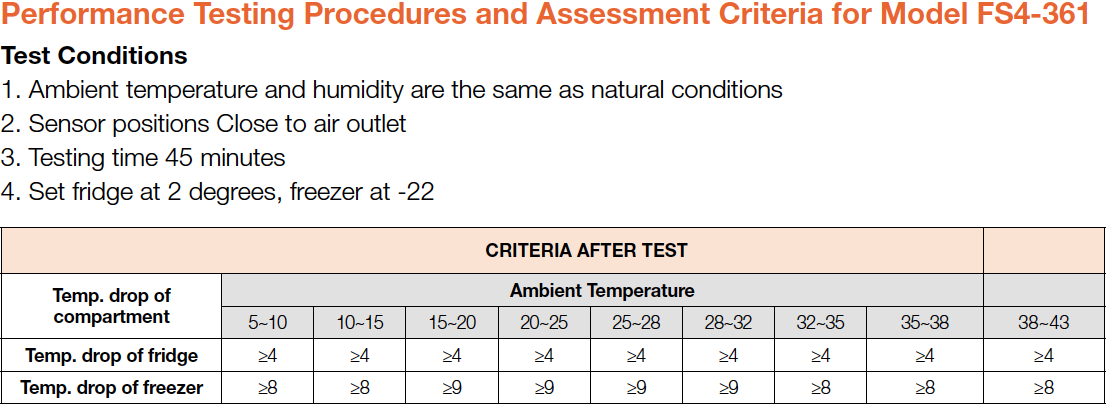

CHECK AND TEST 2

DIAGNOSIS 2