DIAGNOSIS 1

PROCEDURE 1

Step 1

Discharge refrigerant.

Cut charging tube off with pliers.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off suction pipe and exhaust pipe.

Step 4

Unscrew terminal cover.

Step 5

Remove terminal cover.

Step 6

Disconnect all terminals.

Step 7

Unscrew earthing wire.

Step 8

Unscrew nut on compressor.

Step 9

Install a new compressor on top.

Step 10

Braze the joints of suction and exhaust pipes.

PROCEDURE 2

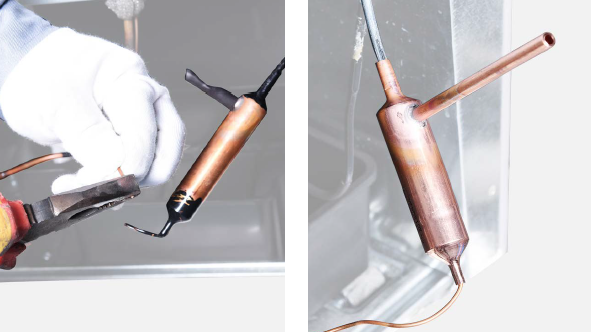

Step 1

Re-braze a copper tube onto processing tube of compressor.

To get more details on

brazing requirements,

please go to Annex B1

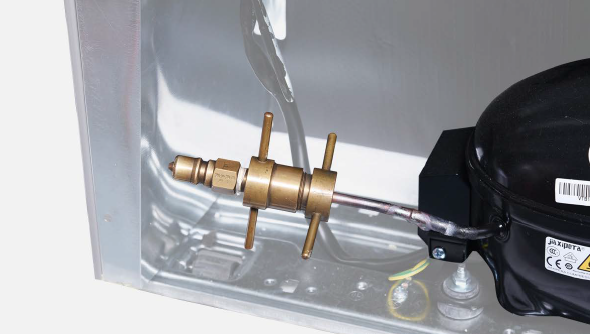

Step 2

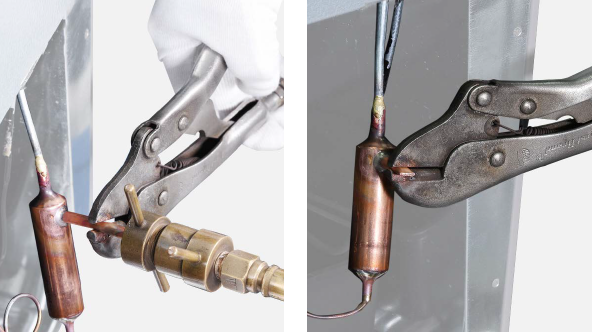

Install quick connector onto re-brazed pipe.

Step 3

Remove paint from brazed joint for drying- filter.

Step 4

Cut off the brazed joint of drying filter.

Step 5

Cut off capillary and remove the cut end by shaking.

Step 6

Braze on a new drying- filter.

Step 7

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 8

Add quick connector onto processing pipe of drying-filter.

Step 9

Test for leaks on brazed joints of drying-filter and processing pipe on compressor.

Step 10

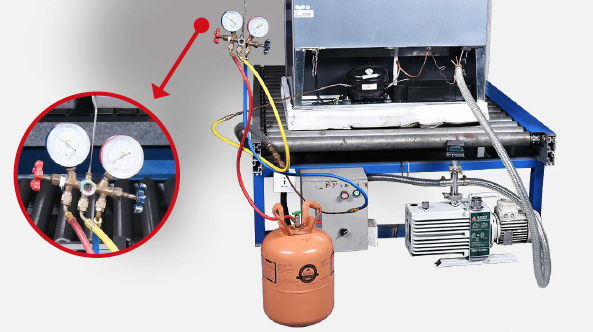

Vacuum and recharge.

Please get more details

of vacuuming and gas-

charging requirements

on Annex B2

Step 11

Leave locked pliers attached to second block and shake to cut off the remaining pipe.

Step 12

Leave locked pliers attached to second block and shake to cut off the remaining pipe.

DIAGNOSIS 2

DIAGNOSIS