CHECK AND TEST 1

Step 1

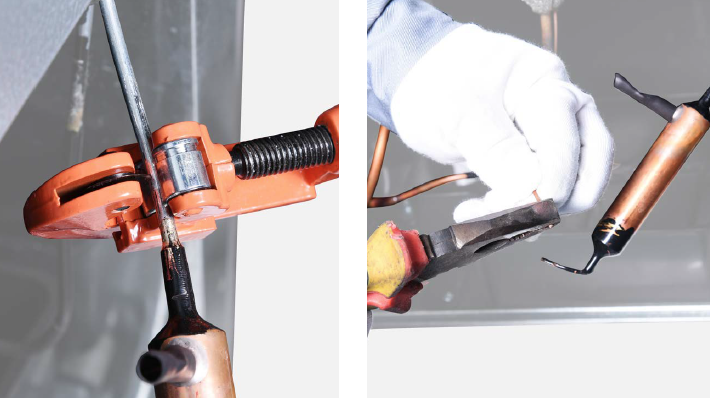

Discharge refrigerant:

1) use pliers to cut off charging tube.

2) Discharge all refrigerant toward the

exhaust vent.

Step 2

Melt brazing material with flame and pull processing tube out with a pair of pliers.

Step 3

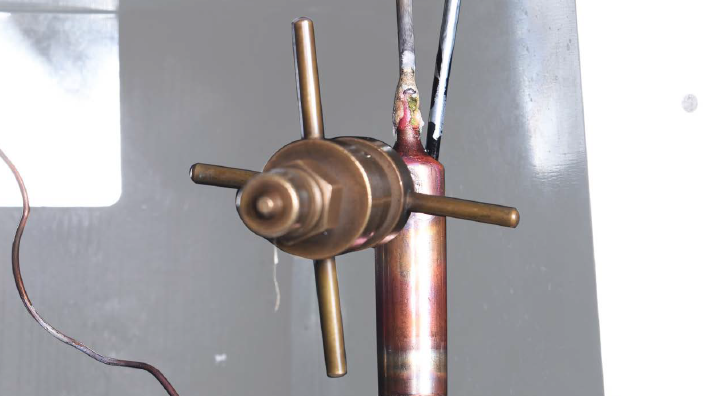

Re-braze a copper tube onto processing tube of compressor.

To get more details on

brazing requirements,

please go to Annex Annex B1

Note

Step 5

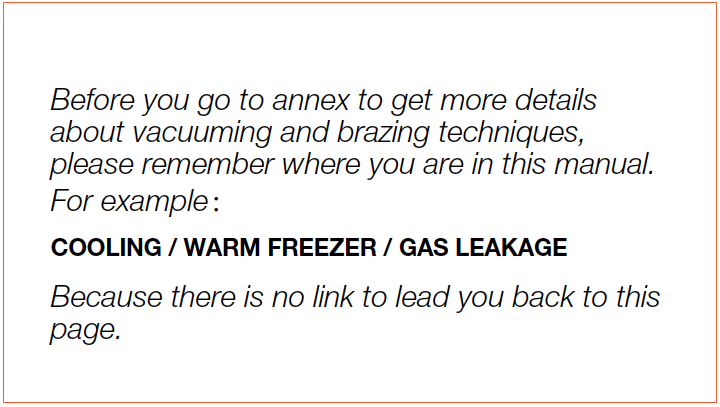

Install quick connector onto rebrazed pipe.

Step 6

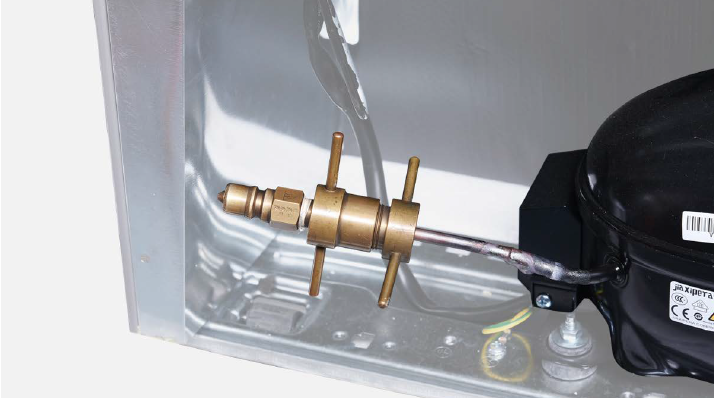

Use a pliers to cut the capillary off.

Step 7

Inject nitrogen (1.57Mpa) through quick connector into pipe.

Step 8

Check to see if gas is blowing out of capillary.

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

Cut off exhaust pipe to check whether oil is being ejected from compressor.

DIAGNOSIS 2

PROCEDURE 1

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover.

Step 3

Disconnect all terminals.

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut of compressor.

Step 6

Replace with a new compressor.

Step 7

Braze the joints of suction and exhasuting pipes.

Step 8

Re-braze a copper tube onto compressor processing tube

Please get more details

of brazing requirements on Annex B1

PROCEDURE 2

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Cut off the brazed joint of drying filter.

Step 3

Cut off capillary and remove the cut end by shaking.

Step 4

Braze a new drying-filter.

Step 5

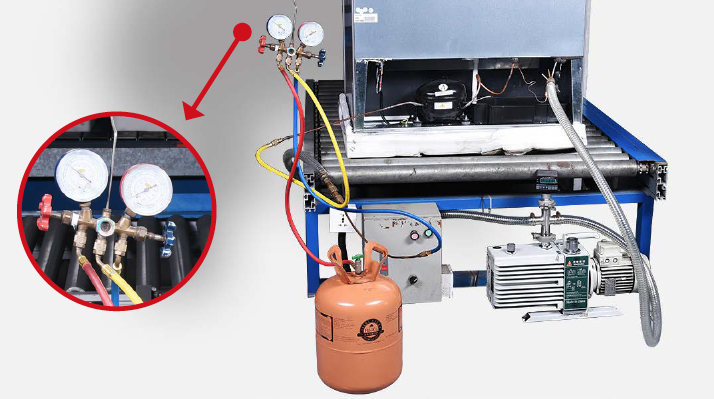

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Test for leaks on brazed

joints of drying-filter and

processing pipe

on compressor.

Step 8

Vacuum and recharge.

Please get more details

of vacuuming and gas-

charging requirements

on Annex B2

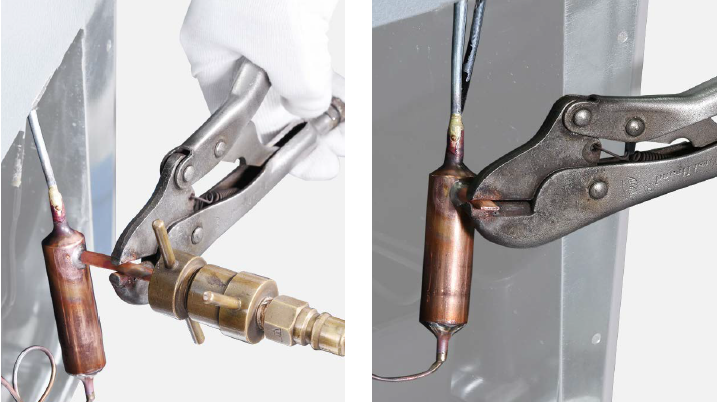

Step 9

Block processing pipe twice by locking pliers.

Step 10

Leave locked pliers attached to second block and shake to cut off the remaining pipe.

Step 11

Braze the ends and remove the pliers.

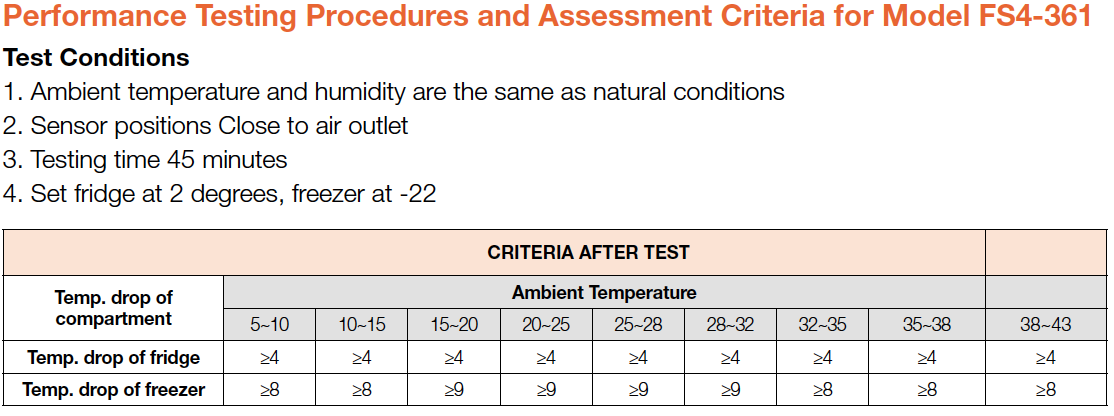

CHECK AND TEST 3

DIAGNOSIS 3