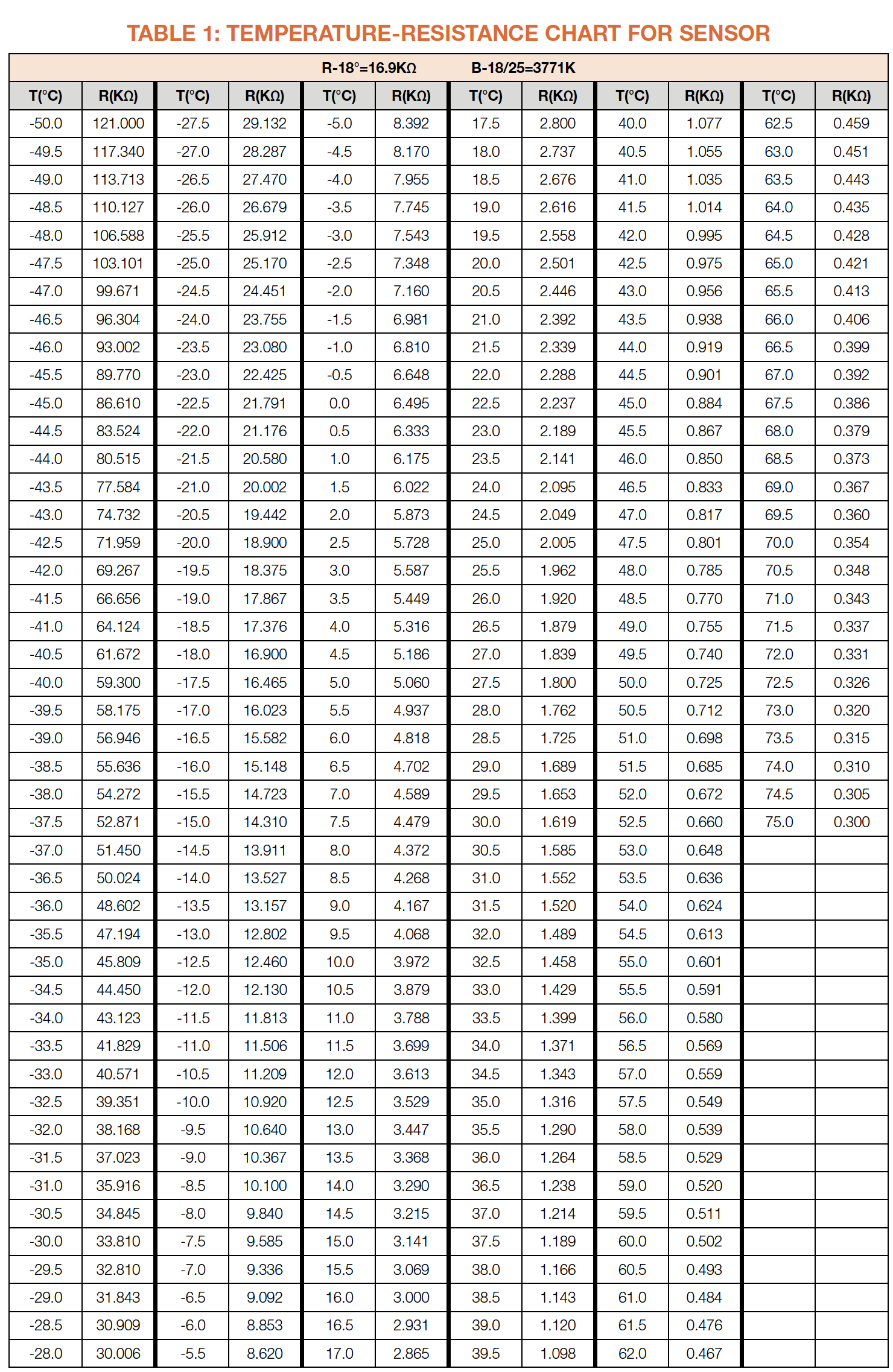

CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a cross-head screwdriver.

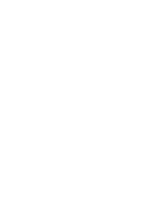

Step 2

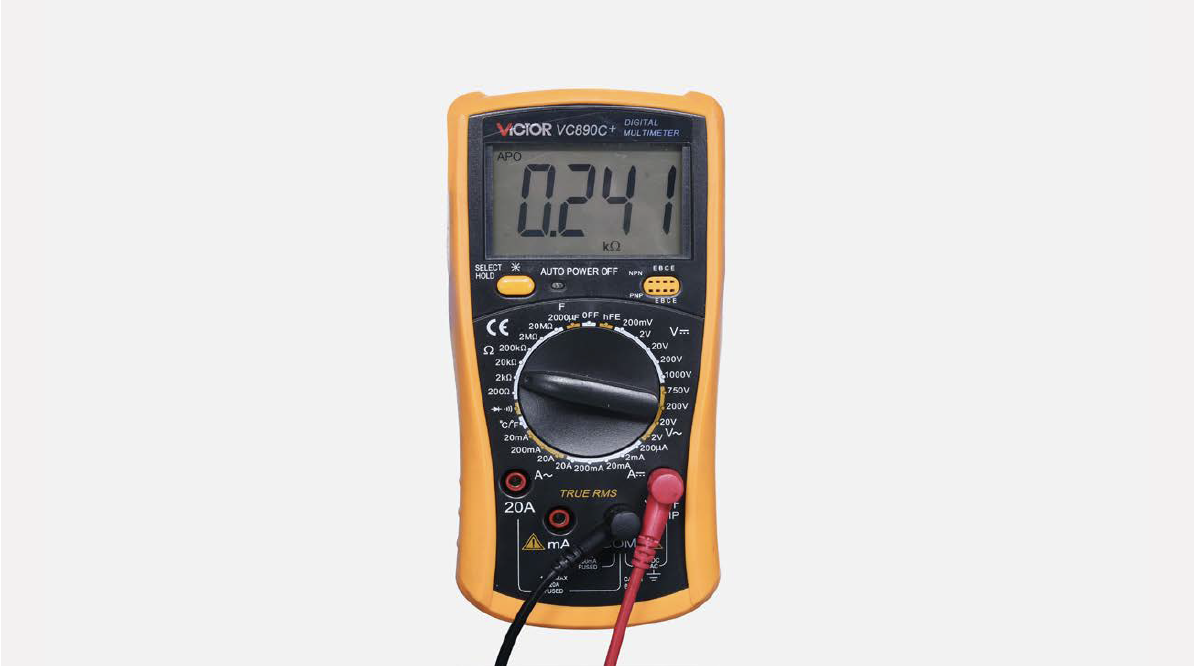

Test resistance of sensor from terminal in PCB area.

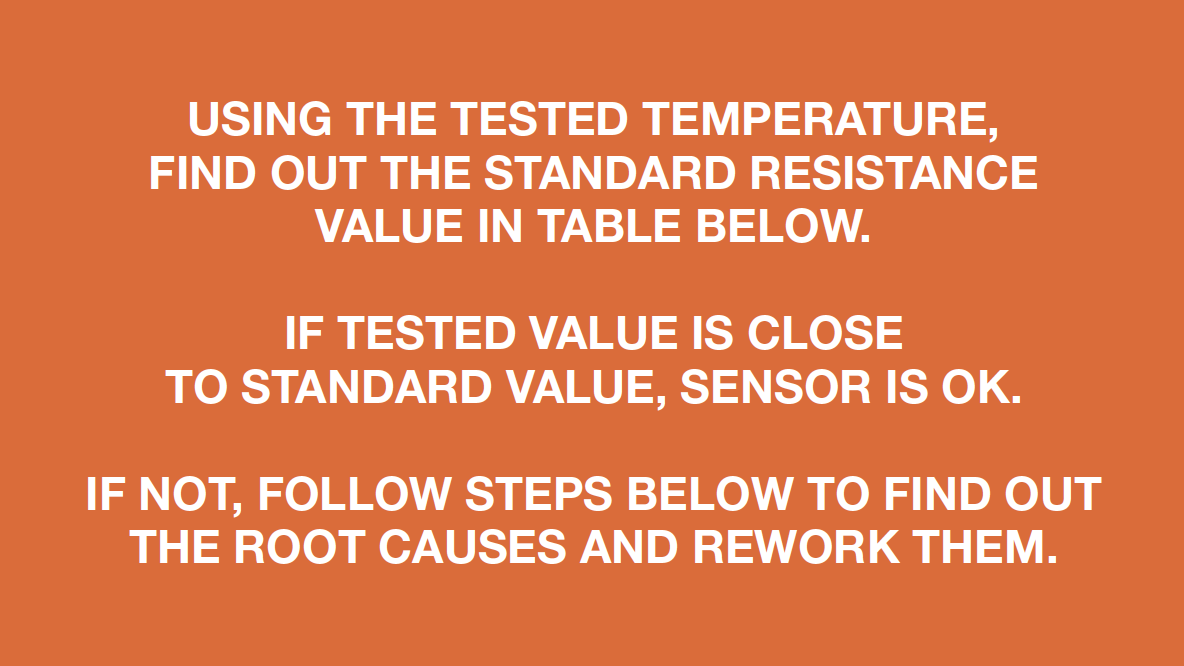

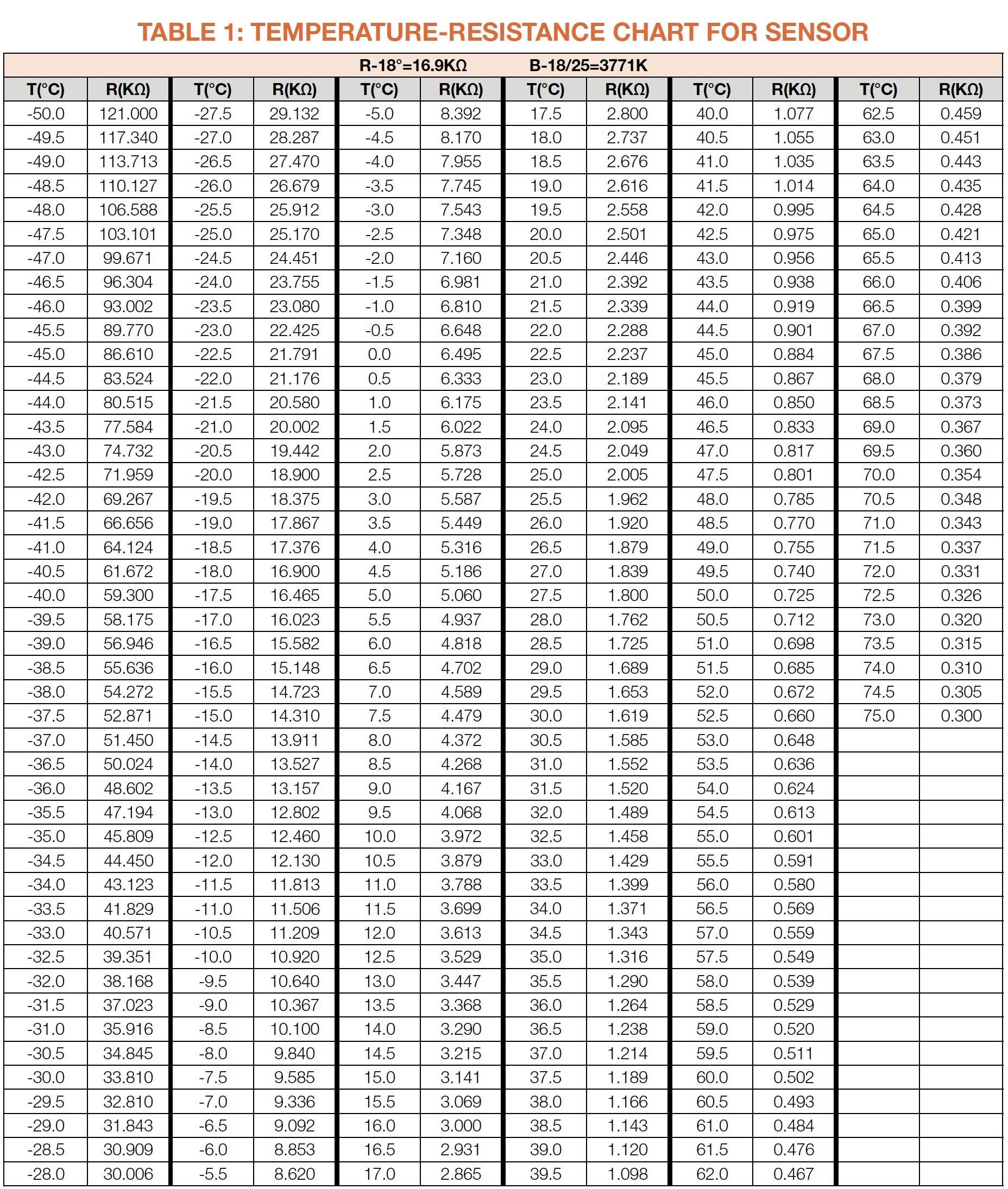

Step 3

Take note of value.

Step 4

Measure the temperature of sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove shelves.

Step 2

Remove crispers.

Step 3

Remove shelf cover.

Step 4

Hold the cover and turn In counter-clockwise to loosen cover. Then remove cover.

Step 4

Hold the cover and turn In counter-clockwise to loosen cover. Then remove cover.

Step 5

Use 6mm Cross-head

screwdriver to loosen the

screw.

Step 6

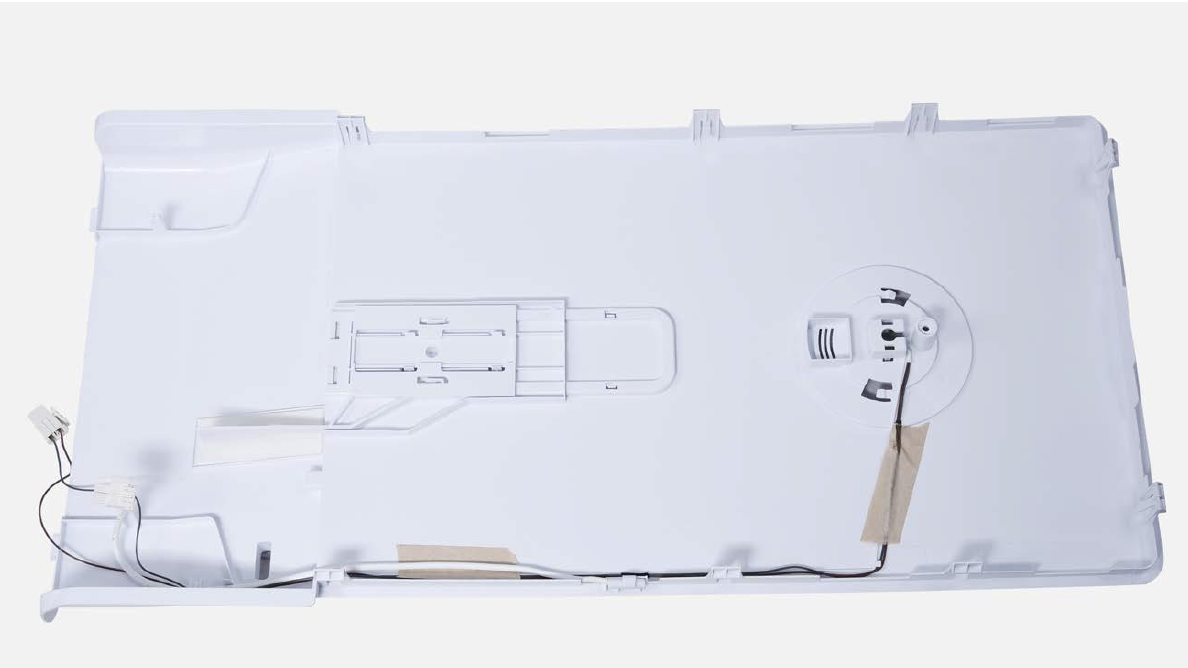

Hold the edge of air duct to remove.

Step 7

Disconnect the terminals.

CHECK AND TEST 2

Step 1

Test resistance of sensor from terminal in duct cover.

Step 2

Measure temperature of fridge temp. sensor.

DIAGNOSIS 2

NOTE

PROCEDURE 2

Step 1

Release the clasp.

Step 2

Remove the foam air duct.

Step 3

Remove tape.

Step 4

Remove the broken

sensor.

NOTE

Reverse the

procedures to install

new sensor.

CHECK AND TEST 3

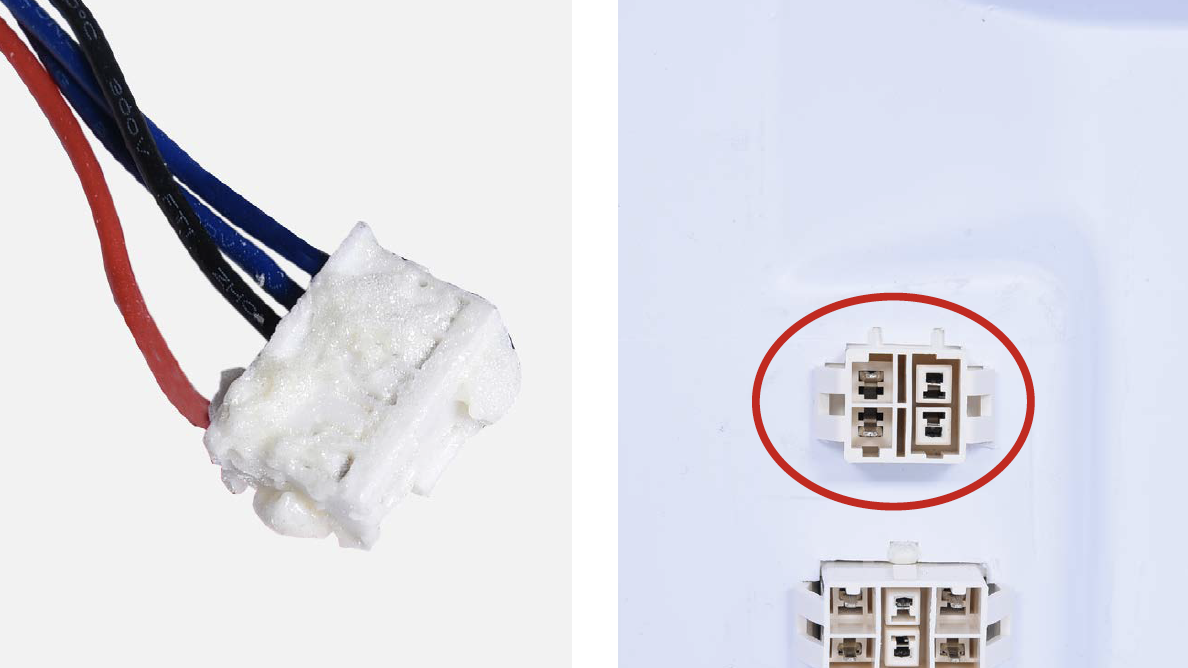

Step 1

Check to see if terminal is full of foam.

Step 2

Use a needle or tools with sharp tip to remove foam in terminal.

Step 3

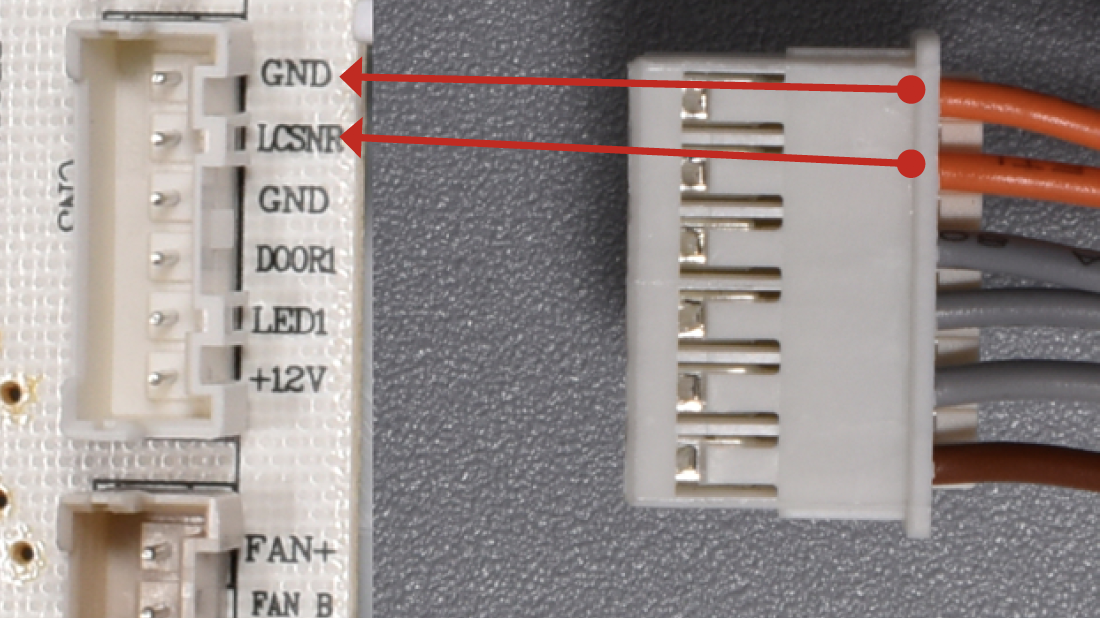

Check to ensure that wires are connected properly.

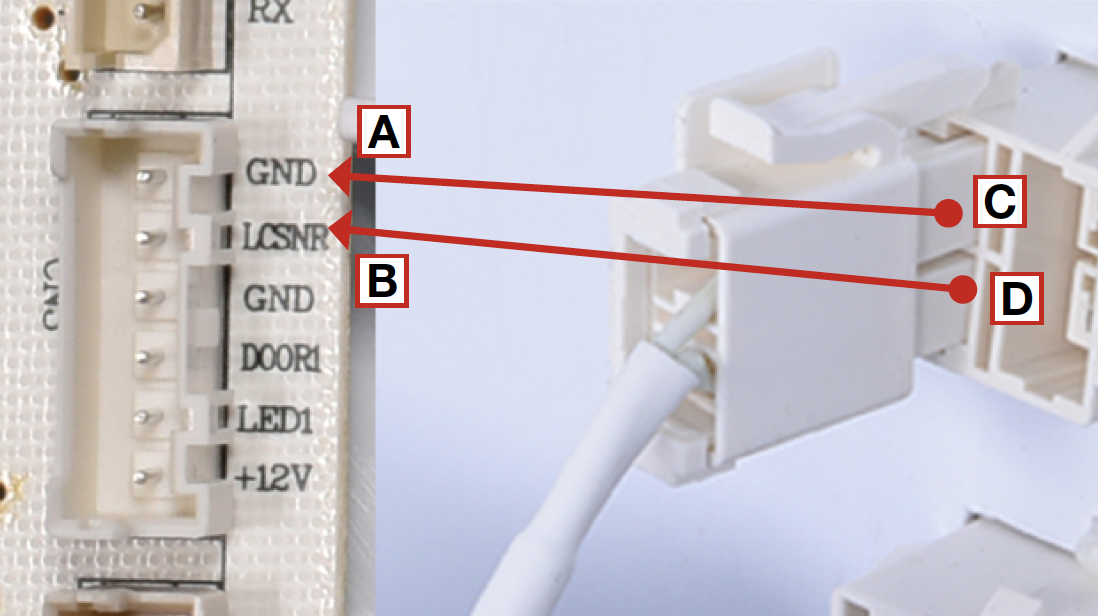

Step 4

1. Put detector into one

end of wires in PCB

area;

2. Put another detector into end of wires behind air duct.

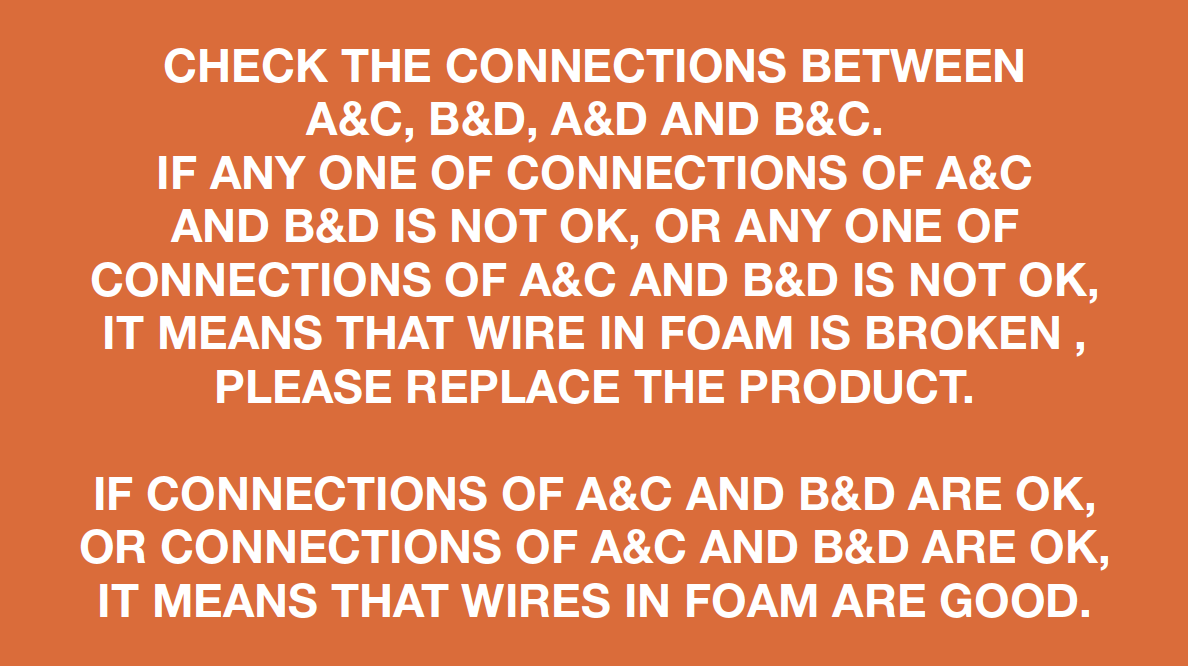

DIAGNOSIS

PROCEDURE 3

Step 1

Reinsert the terminals for sensor.

Make sure that the terminal is pushed into final position.

Step 2

Screw on the cover of mainboard with a cross-head screwdriver.

Step 3

Re-connect the terminals.

Step 4

Hold air duct by edges to put it back in place.

Step 5

Use a 6 mm cross-head screwdriver to tighten the screw clockwise.

Step 6

Hold the cover and turnit clockwise to tighten

the lid, then pull outwards.

Step 7

Insert shelves.

TIPS DURING INSTALLATION PROCEDURES FOR FRIDGE AIR DUCT.

Tip 1

Connect the terminals.

Tip 2

Push terminals into place, then move wires to prevent crushing of wires with edge of air duct.

Tip 3

When reinstalling the air duct, first insert positive shaft into the negative hole.

Tip 4

Then, fasten the clasp on top using the same method.

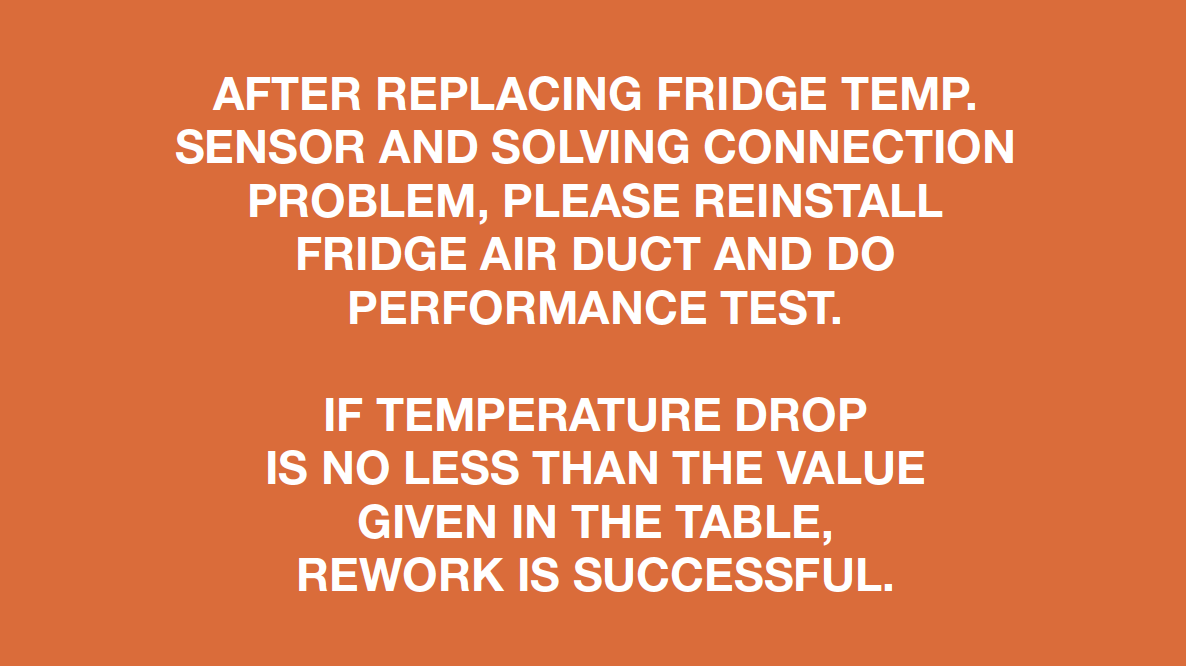

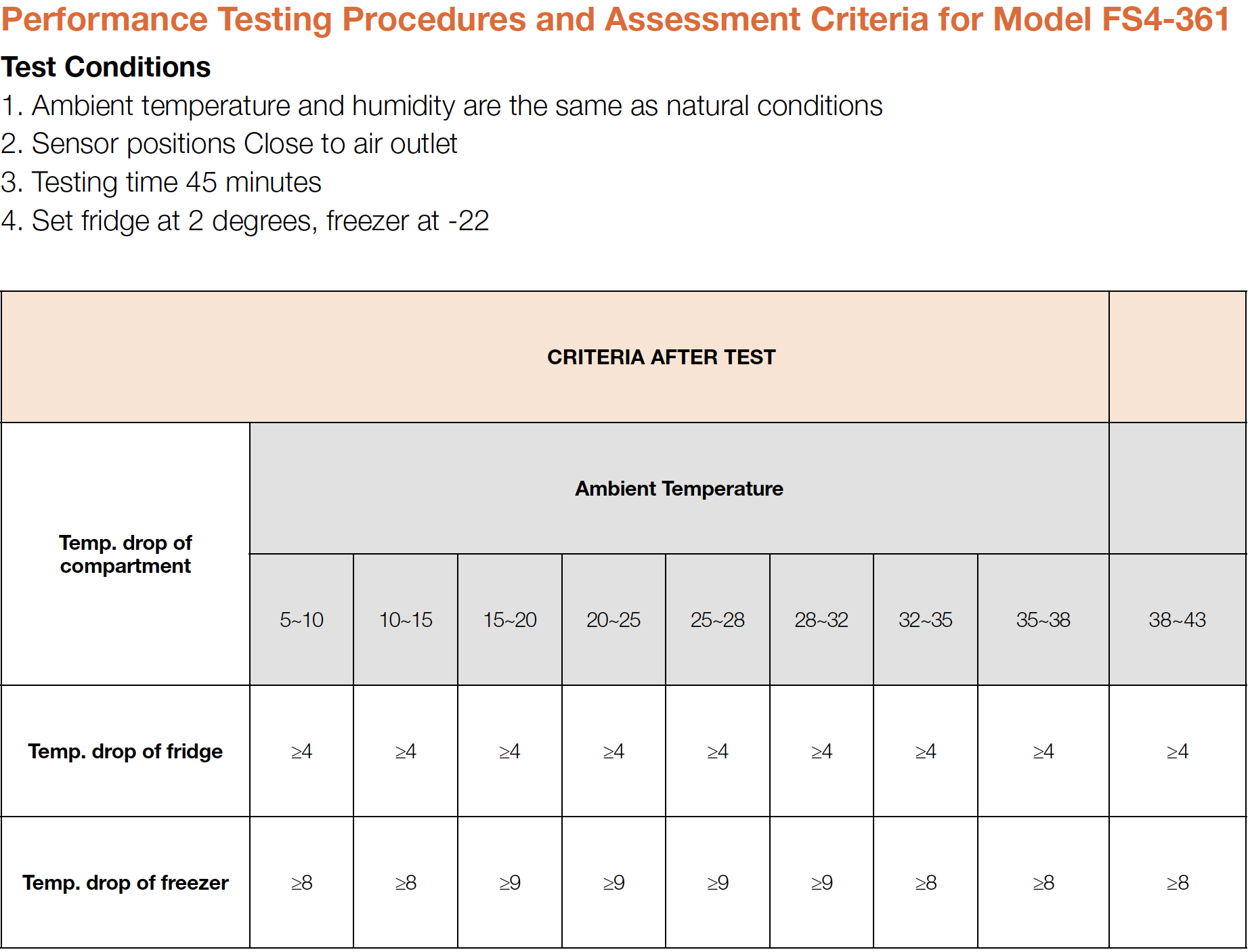

DIAGNOSIS 4