CHECK AND TEST 1

Step 1

Plug in - the compressor starts, but protection is activated immediately, and it cannot run normally.

Step 2

Put hand onto

compressor - no shaking

can be felt.

Step 3

Measure the AC voltage

of the compressor with a

multimeter.

Step 4

Wait a few minutes,

power on and off several

times consecutively - the

compressor starts but

activates protection.

Wait a few minutes,

power on and off several

times consecutively - the

compressor starts but

still activates protection.

DIAGNOSIS 1

SAFETY WARNING:

MAKE SURE

DETECTORS DO NOT

TOUCH EACH OTHER.

DO NOT TOUCH LIVE

PARTS WITH HANDS.

CHECK AND TEST 2

Step 1

Cut off capillary todischarge refrigerant.

Step 2

Cut off exhaust pipe andsuction pipe.

Step 3

Power on thecompressor and test

exhaust pressure coming

from exhaust pipe with a

piece of paper.

DIAGNOSIS 2

CHECK AND TEST 3

Step 1

Braze on a new dryingfilter.

Step 2

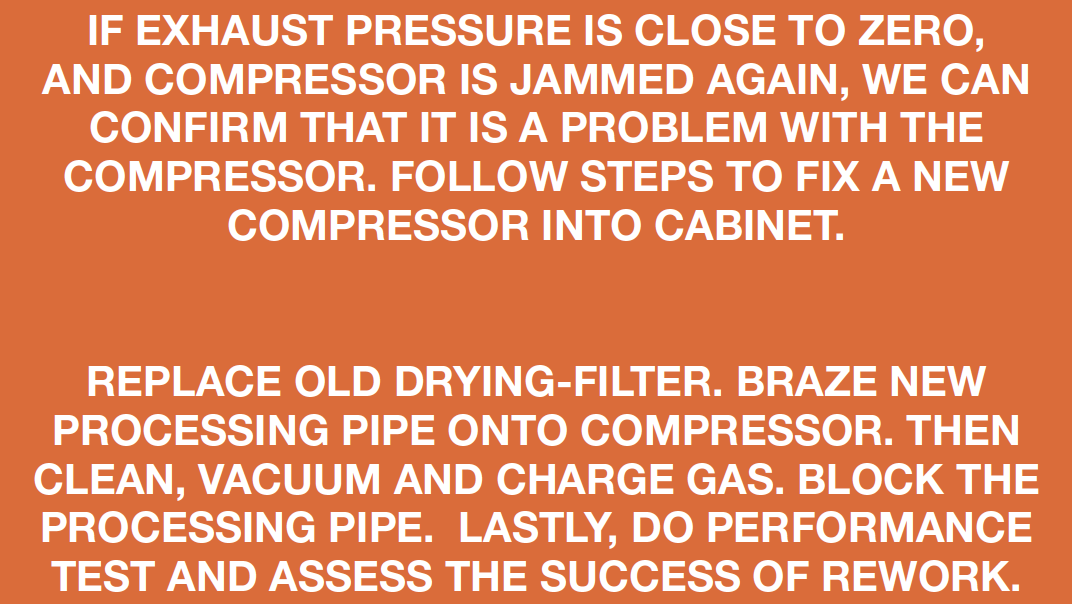

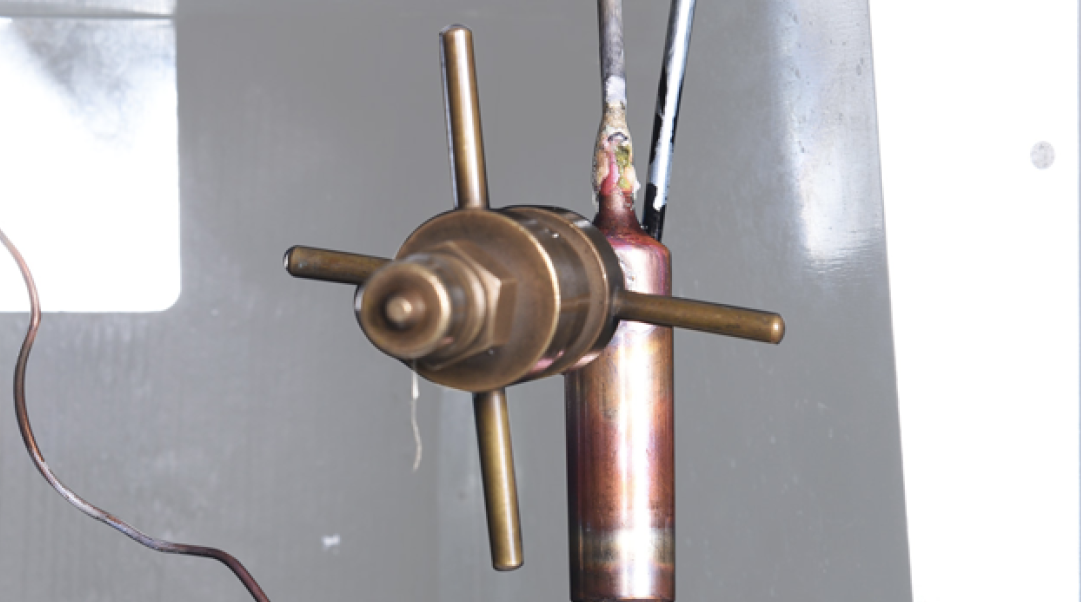

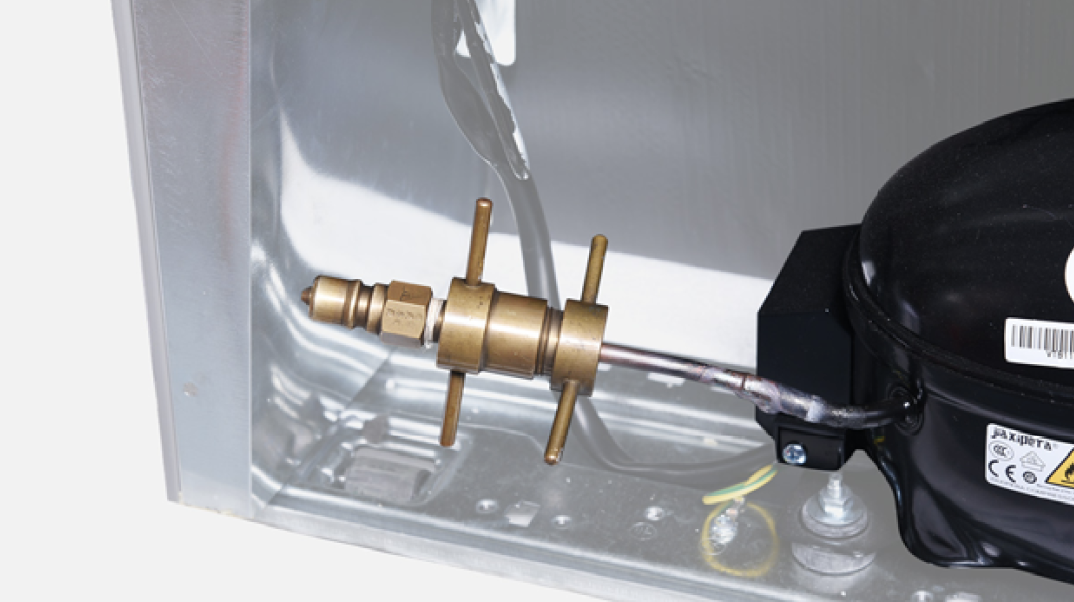

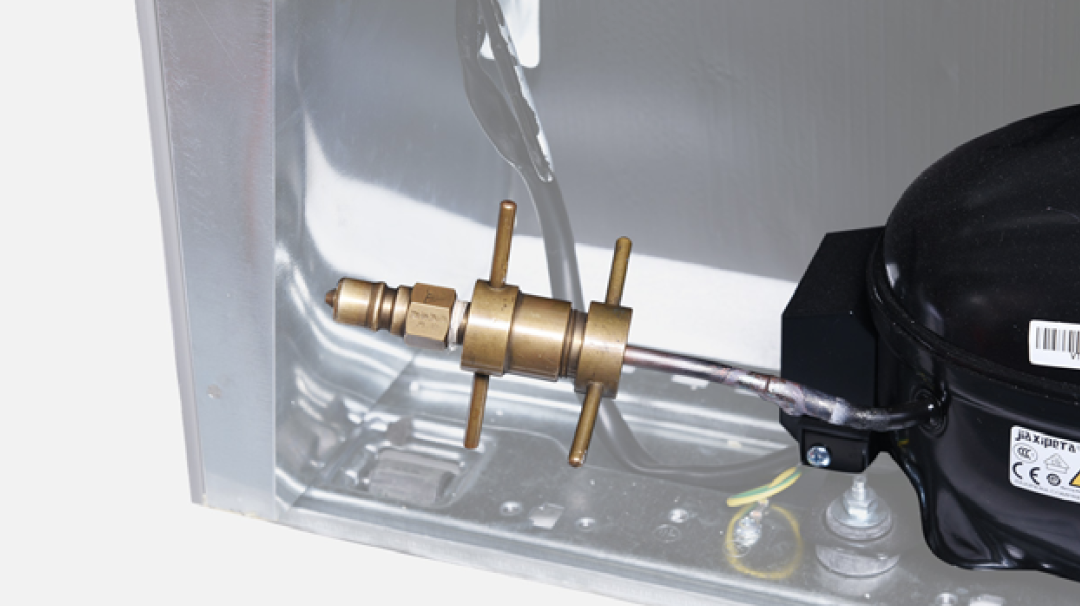

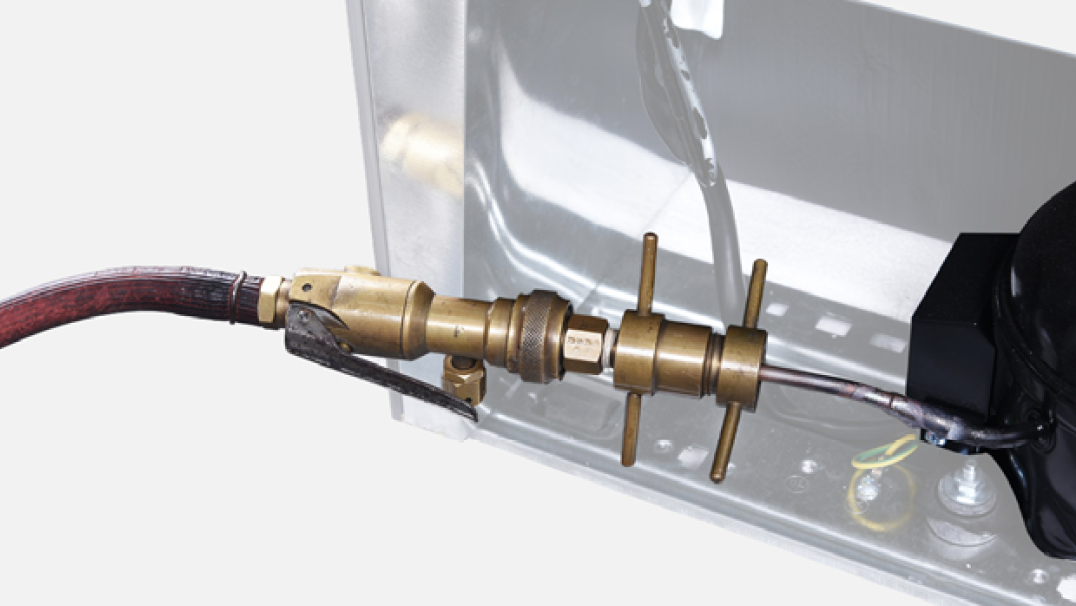

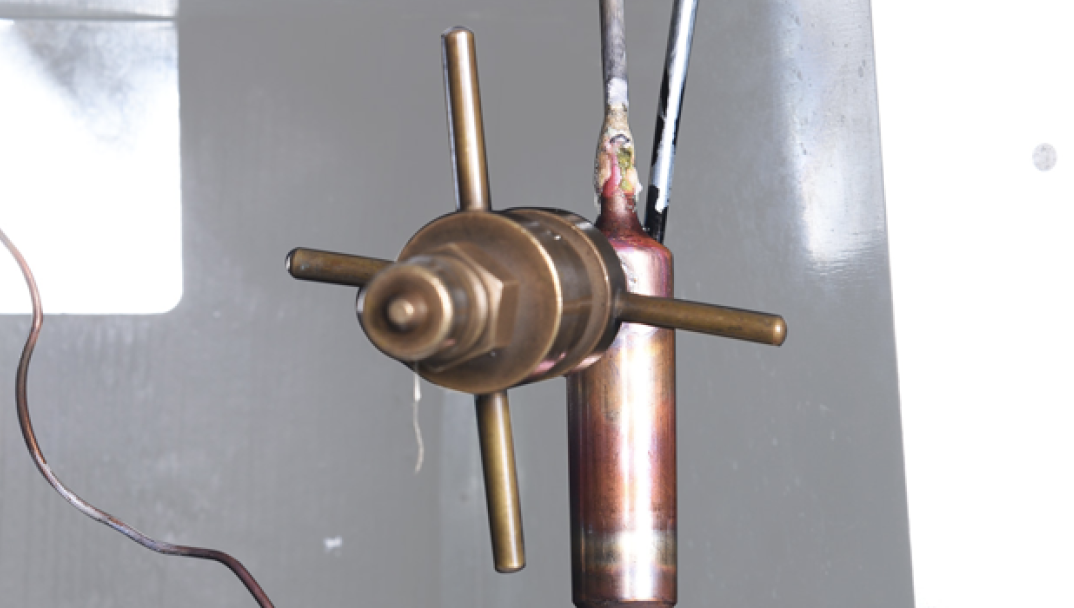

Add quick connector

onto processing pipe of

drying-filter.

Step 3

Inject nitrogen (1.57Mpa)

through quick connector

into pipe.

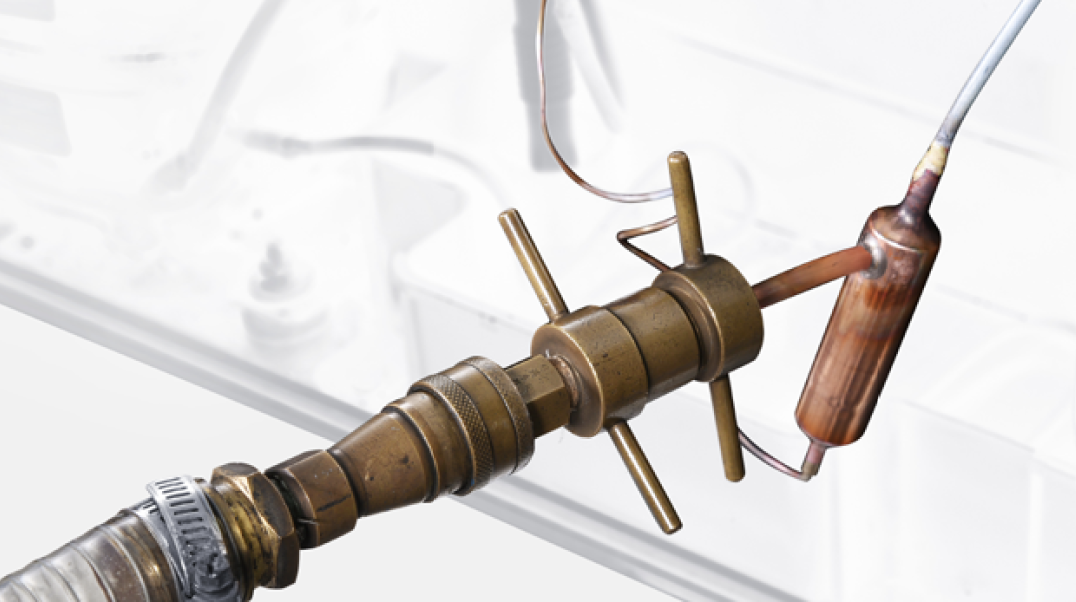

Step 4

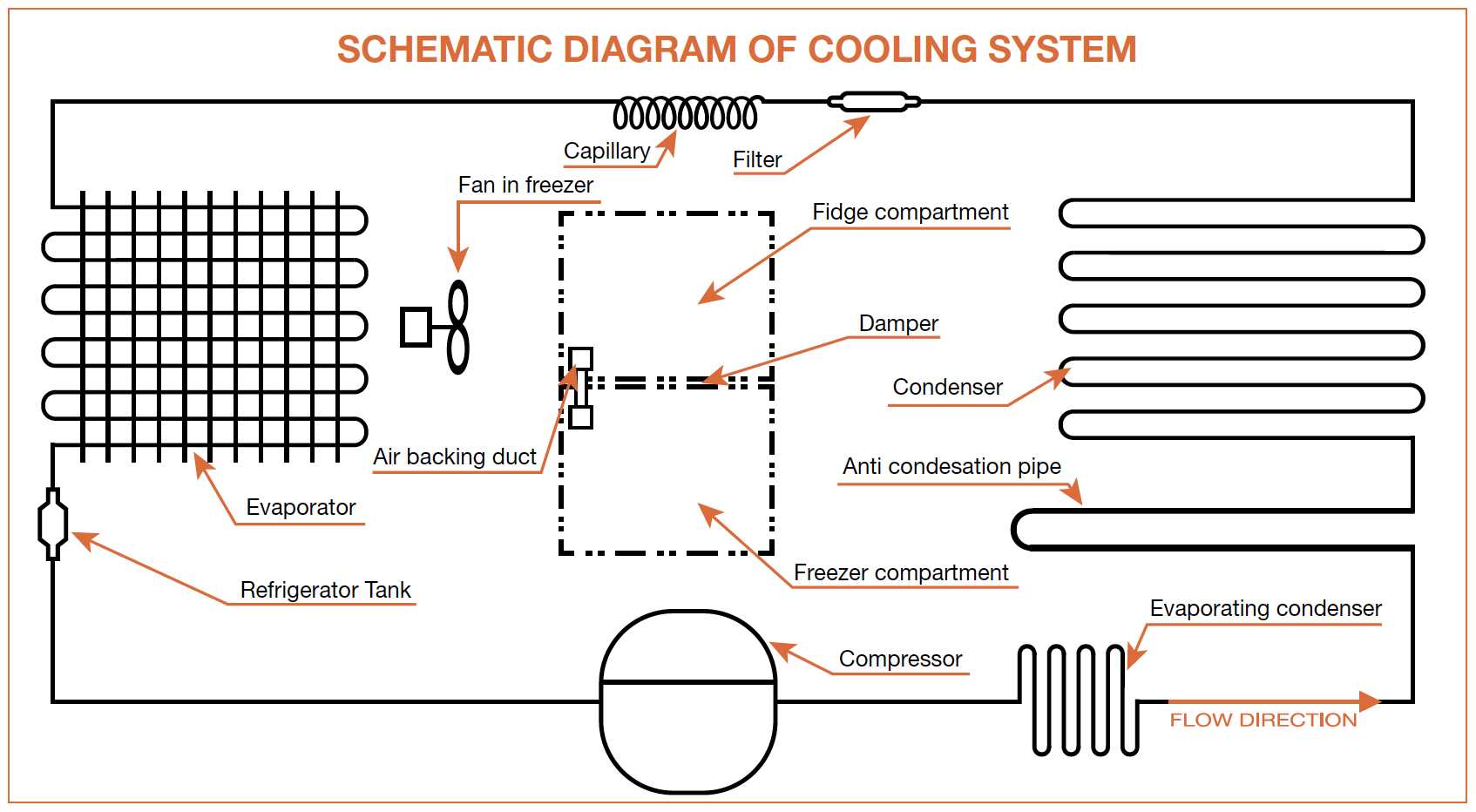

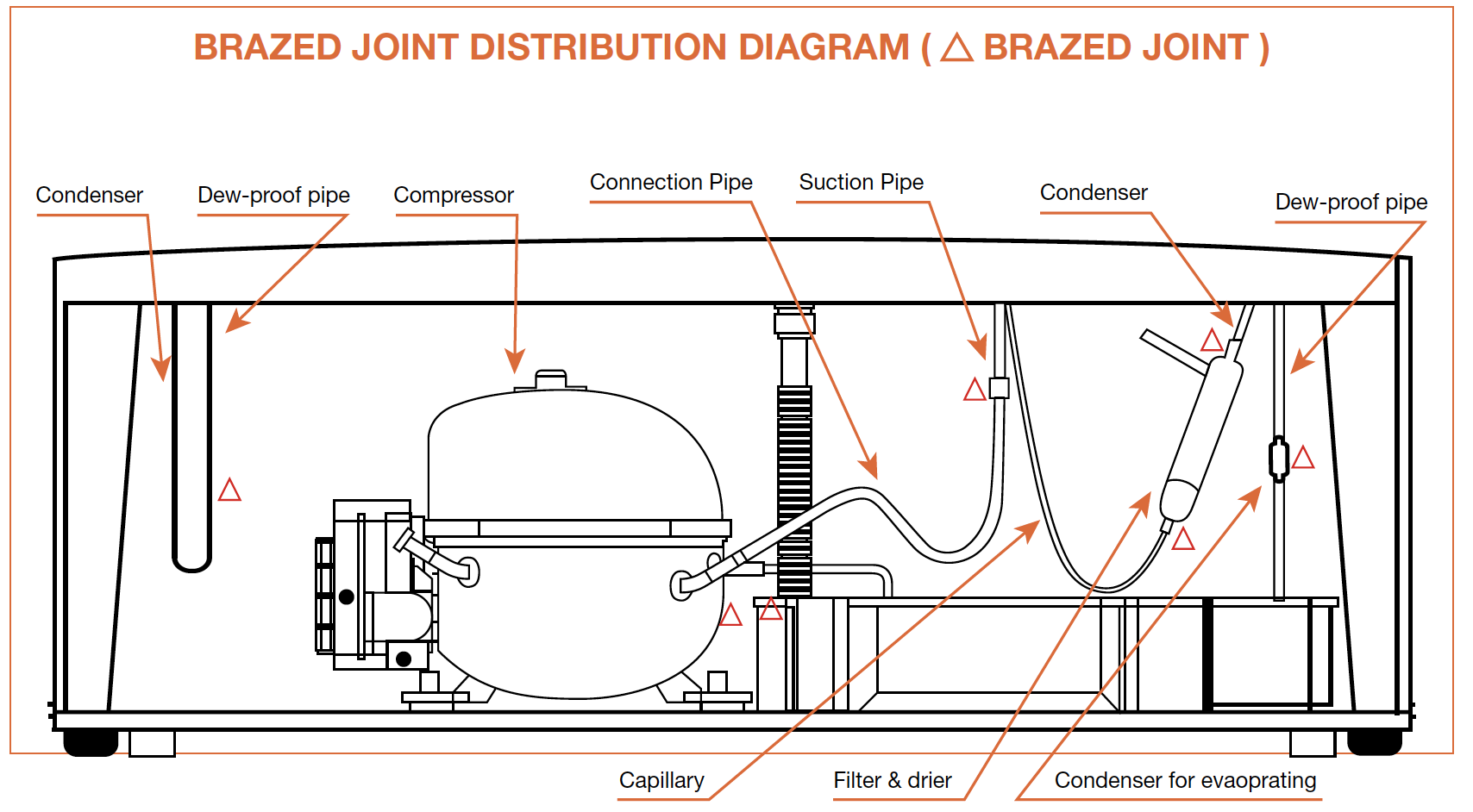

Follow the order on

drawing below to cut off

brazed joint, one by one,

at high pressure end.

Note

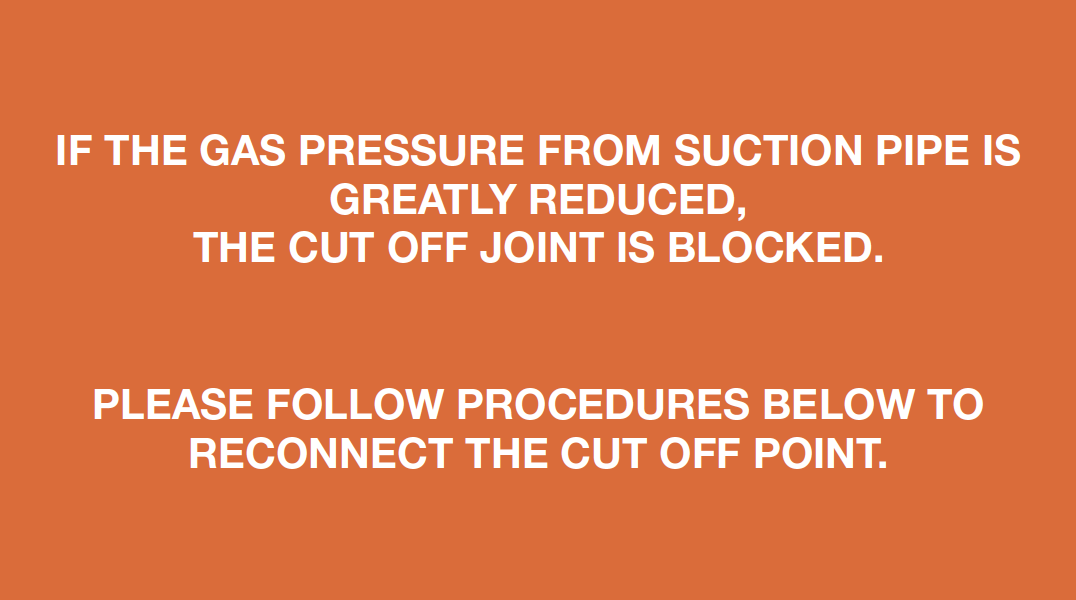

Step 5

Every time you cut off

one joint, check whether

the gas pressure

from suction pipe has

dropped or not.

DIAGNOSIS 3

PROCEDURE 1

Use a bigger copper

tube to connect 2 ends

of brazed joint.

Braze the 2 ends.

Please find more

details of brazing

requirements on Annex A3

Note

Step 3

Re-braze a copper tubeonto processing tube of

compressor.

Please find more details

of brazing requirements,

on Annex A3

Step 4

Install quick connectoronto re-brazed pipe.

PROCEDURE 2

Step 1

Braze exhaust pipe

and suction pipe onto

compressor.

Step 2

Inject nitrogen (1.57Mpa)through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 3

Test for leaks on brazedjoints of drying-filter

and processing pipe on

compressor.

Step 4

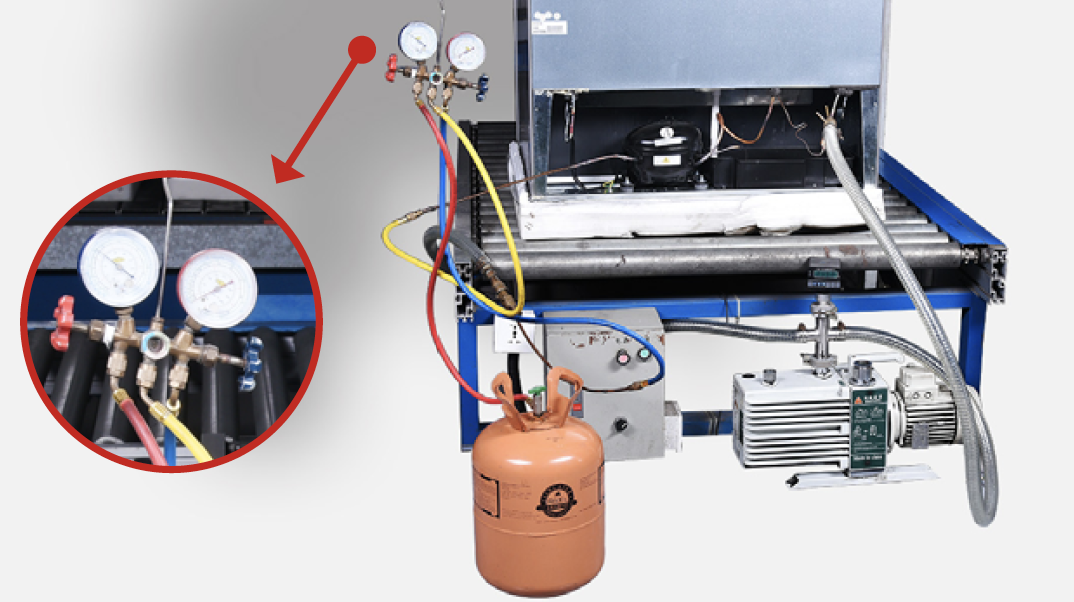

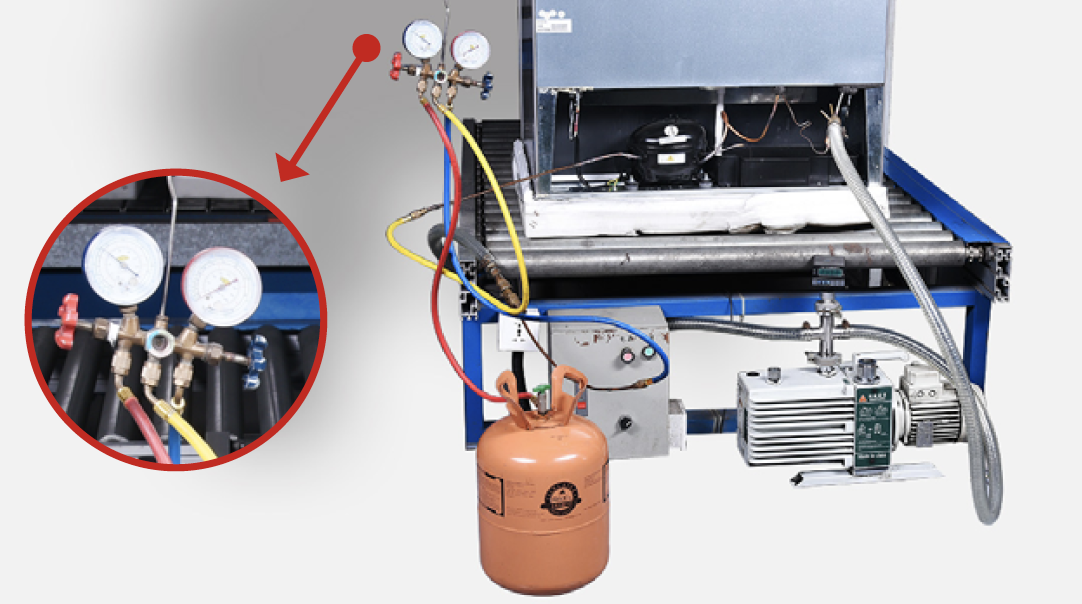

Vacuum and recharge.Please get more details

of vacuuming and gascharging

requirements

on Annex B1

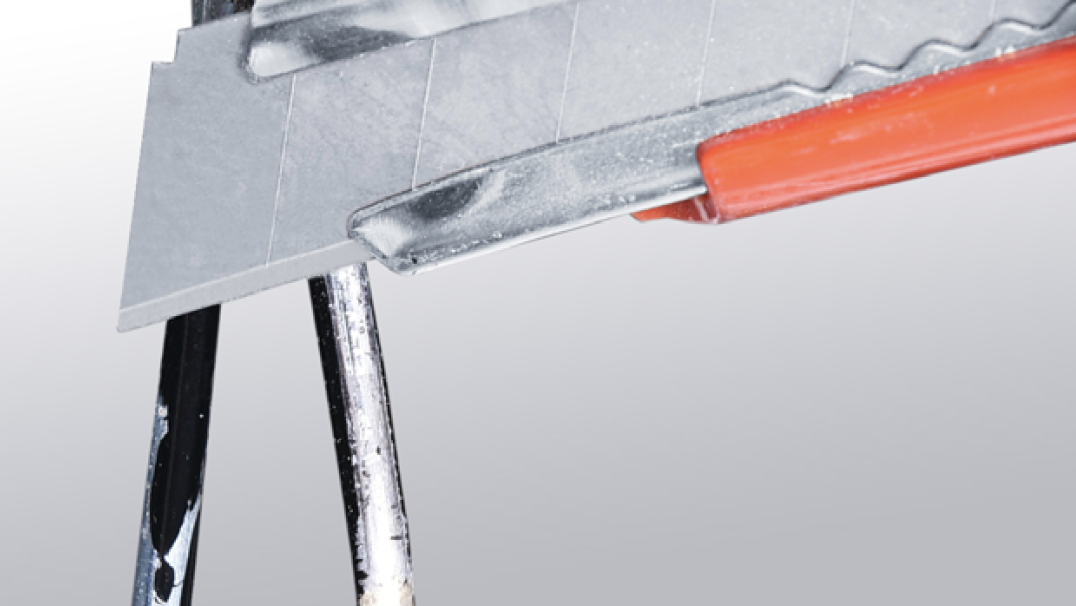

Step 5

Block processing pipetwice by locking pliers.

Step 6

Leave locked pliersattached to second

block and shake to cut

off the remaining pipe.

Step 7

Braze the ends andremove the pliers away.

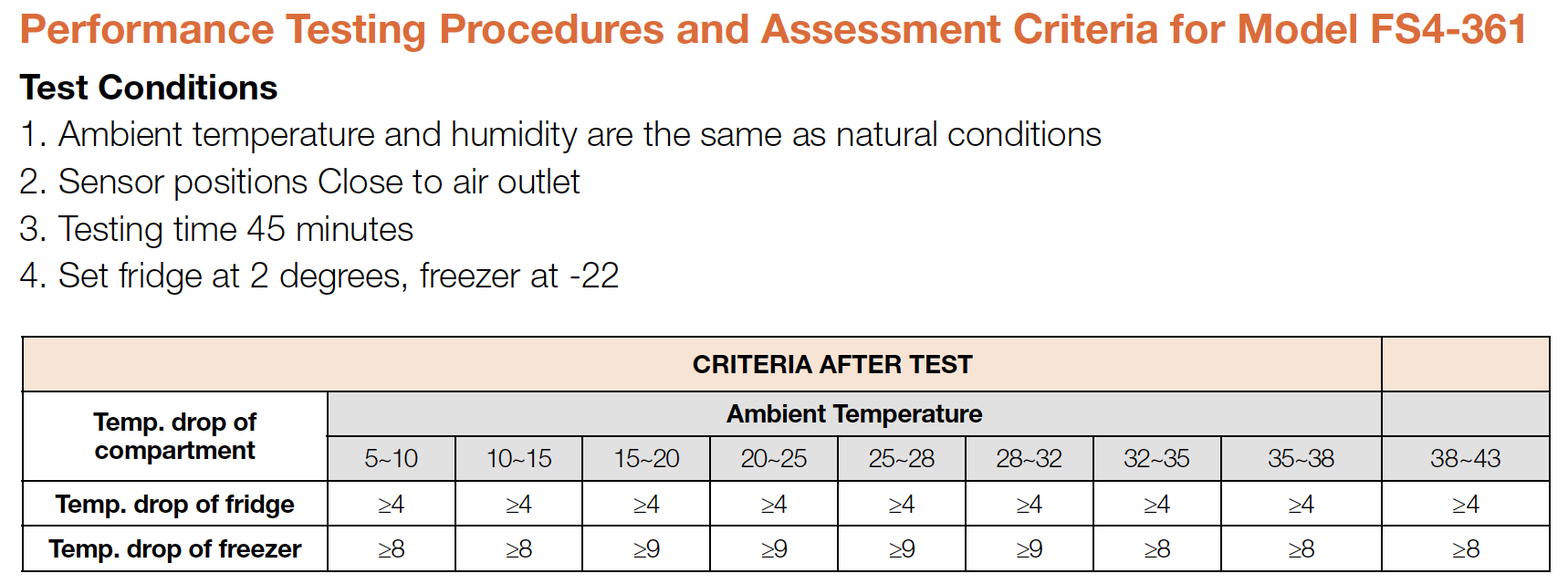

CHECK AND TEST 4

DIAGNOSIS 5

PROCEDURE 3

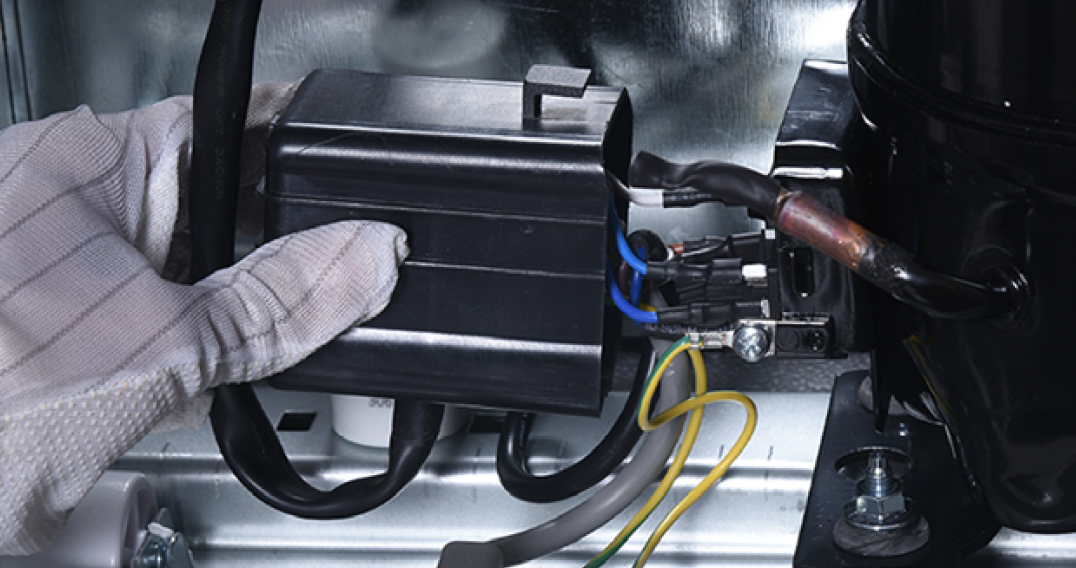

Step 1

Open the metal clasp.

Step 2

Remove terminal cover.

Step 3

Disconnect all terminals.

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut ofcompressor.

Step 6

Install a new compressoron top.

Step 7

Braze the joints ofsuction and exhaust

pipes.

PROCEDURE 4

Step 1

Re-braze a copper tubeonto processing tube of

compressor.

To get more details on

brazing requirements,

please go Annex A3

Note

Step 2

Install quick connectoronto re-brazed pipe.

Step 3

Clean away painton brazed joint of

drying-filter.

Step 4

Cut off the brazed joint ofdrying filter.

Step 5

Cut off capillary andremove the cut end by

shaking.

Step 6

Braze on a newdrying-filter.

Step 7

Inject nitrogen (1.57Mpa)through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 8

Add quick connectoronto processing pipe of

drying-filter.

Step 9

Test for leaks on brazedjoints of drying-filter

and processing pipe on

compressor.

Step 10

Vacuum and recharge.Please get more details

of vacuuming and gascharging

requirements

on Annex B1

Note

Block processing pipetwice by locking pliers.

Step 11

Block processing pipetwice by locking pliers.

Step 12

Leave locked pliersattached to second

block and shake to cut

off the remaining pipe.

Step 13

Braze the ends andremove the pliers.

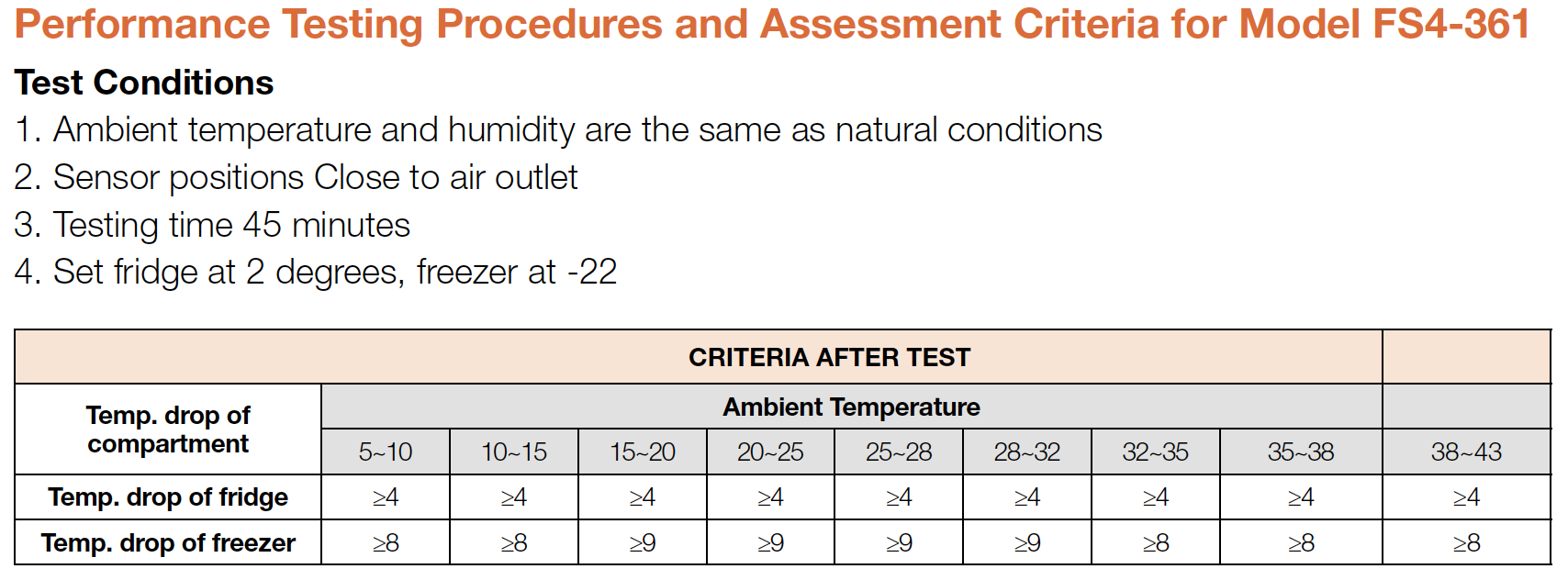

CHECK AND TEST 5

DIAGNOSIS 6