CHECK AND TEST 1

Step 1

Cut off capillary to discharge refrigerant.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhaust pipe and suction pipe.

Step 4

Power up the compressor and feel the

exhaust pressure from the exhaust pipe with a

piece of paper.

CHECK AND TEST 2

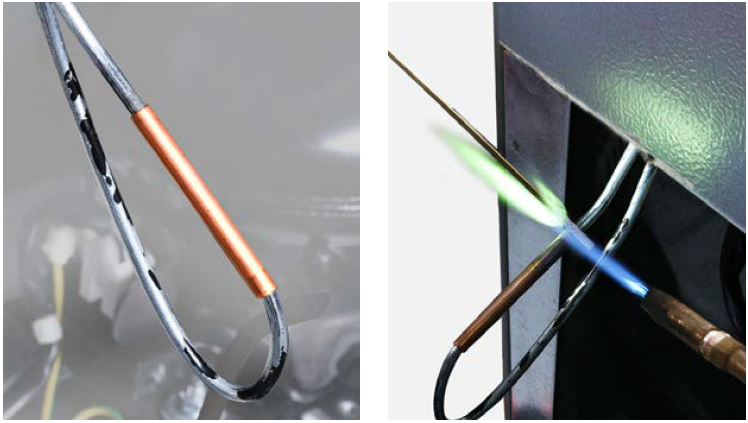

Step 1

Braze the joints of suction and exhausts pipes.

Step 2

Melt brazing material with flame and pull out

processing tube with pliers.

Step 3

Re-braze a copper tube onto processing tube of

compressor. Please find more details

of brazing requirements, on 10.4 Annex B1.

Step 4

Clean paint off of brazed joint of drying filter.

Step 5

Cut off drying-filter.

Step 6

Cut off capillary and shake to remove the cut end.

Step 6

Cut off capillary and shake to remove the cut end.

Step 7

Braze on a new drying-filter.

Step 8

Add quick connector onto processing pipe of

drying-filter.

Step 9

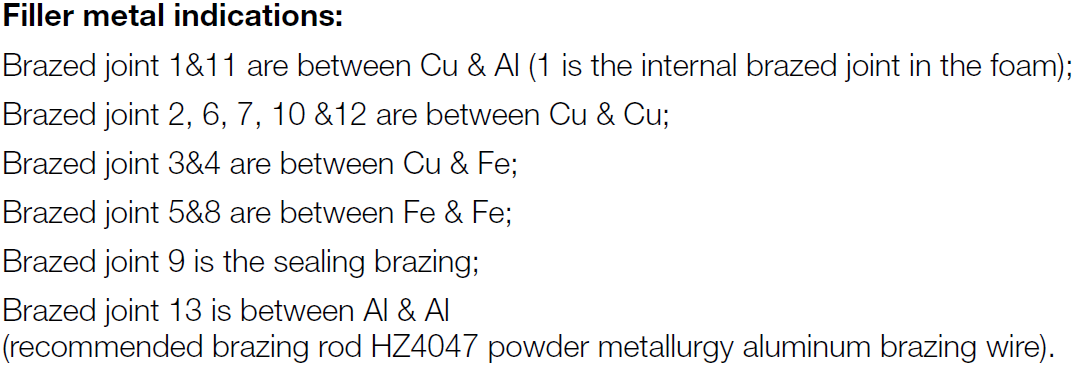

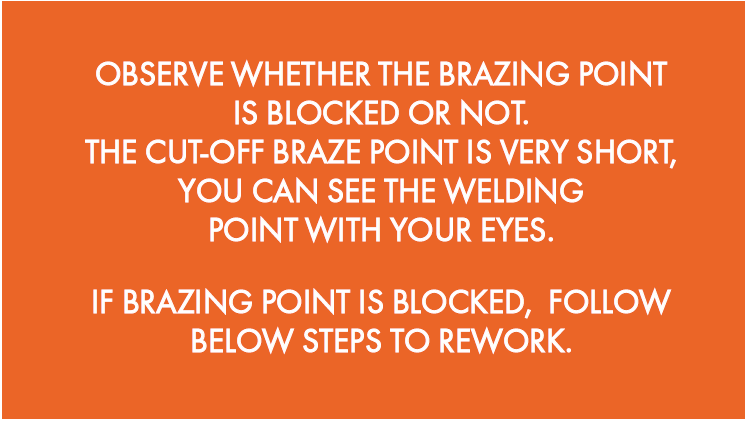

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away. Cut off brazed joints, one by one, to find blockage point.

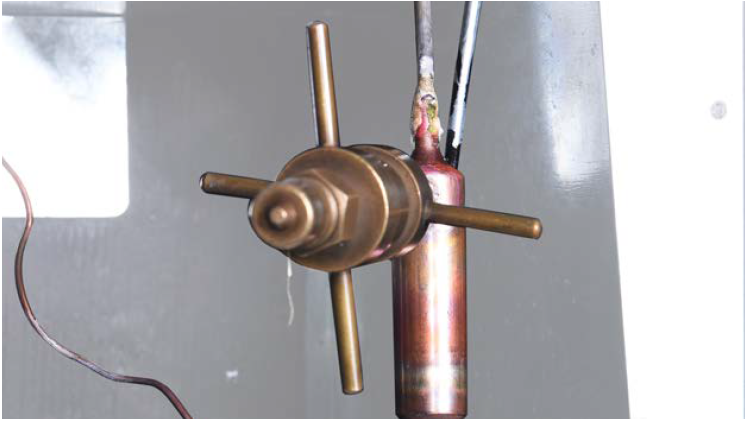

Step 10

First, cut off end closed to exhaust end (A in below picture).

Step 11

Then, cut off the end closed to suction end.

DIAGNOSIS 2

Step 1

Use a larger copper tube to connect 2 ends of brazed joint.

Step 2

Braze the 2 ends

Step 3

Perform a leakage test on all re-brazed joints

of drying-filter and compressor processing pipe.

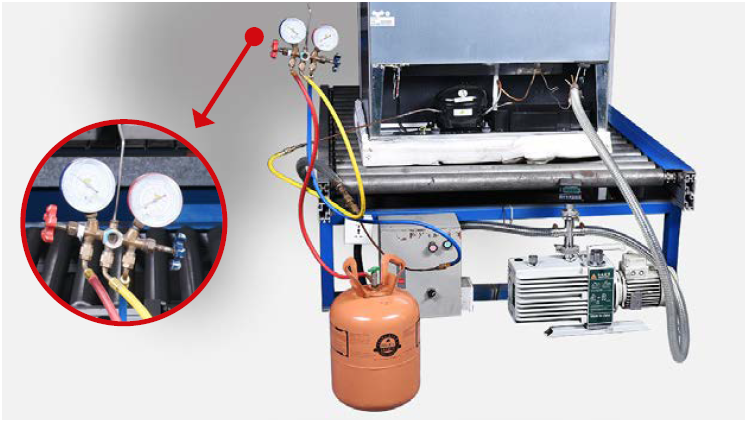

Step 4

Vacuum and recharge. Click below link to

get more details for vacuuming and gascharging requirements, on 10.5 Annex B2.

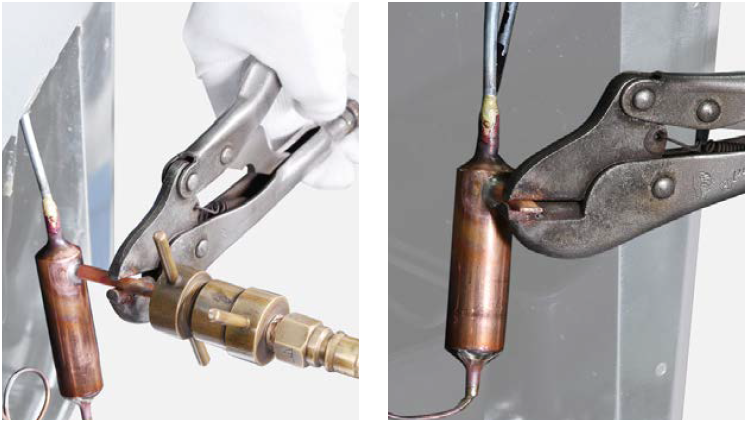

Step 5

Block processing pipe twice by locking pliers.

Block processing pipe twice by locking pliers.

Step 6

Leave locked pliers attached to second

block and shake to cut off the remaining pipe.

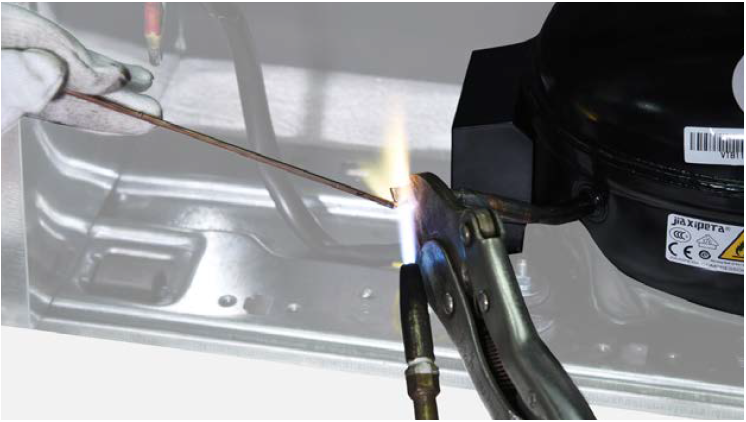

Step 7

Braze the ends and remove the pliers.

DIAGNOSIS 3