CHECK AND TEST 1

Step 1

Unscrew.

Step 2

Remove the mainboard cover.

Step 3

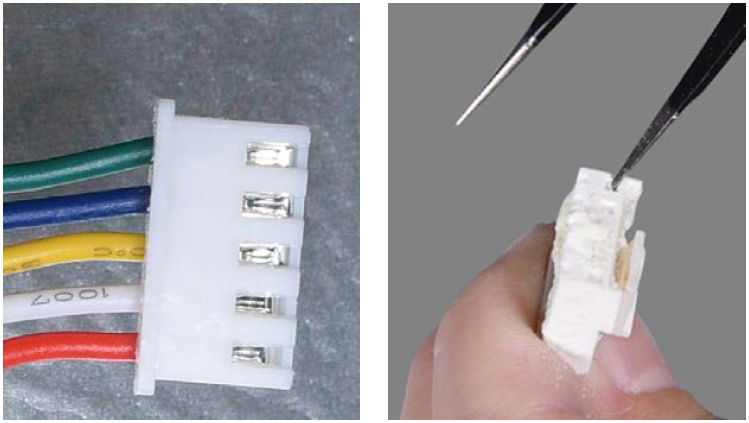

Check if terminal is pushed into final position.

Step 4

Check to see if terminal is full of foam. If so, use tweezers to remove foam.

Step 5

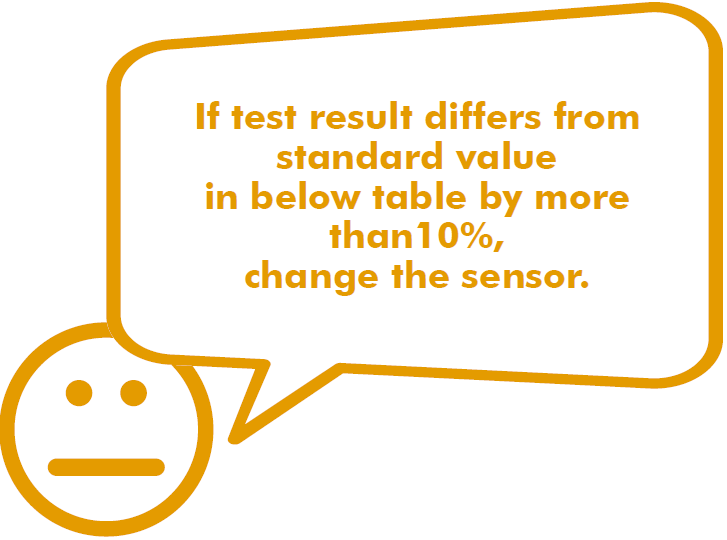

Use multimeter to measure resistance value.

Step 6

Record the value.

Step 7

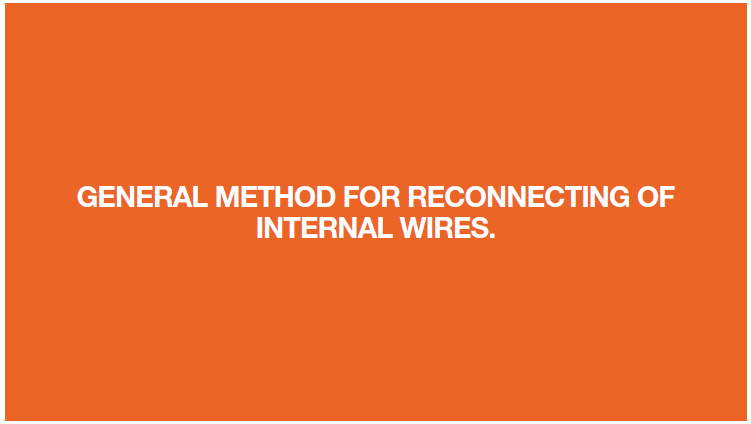

Test temperature on air duct close to sensor.

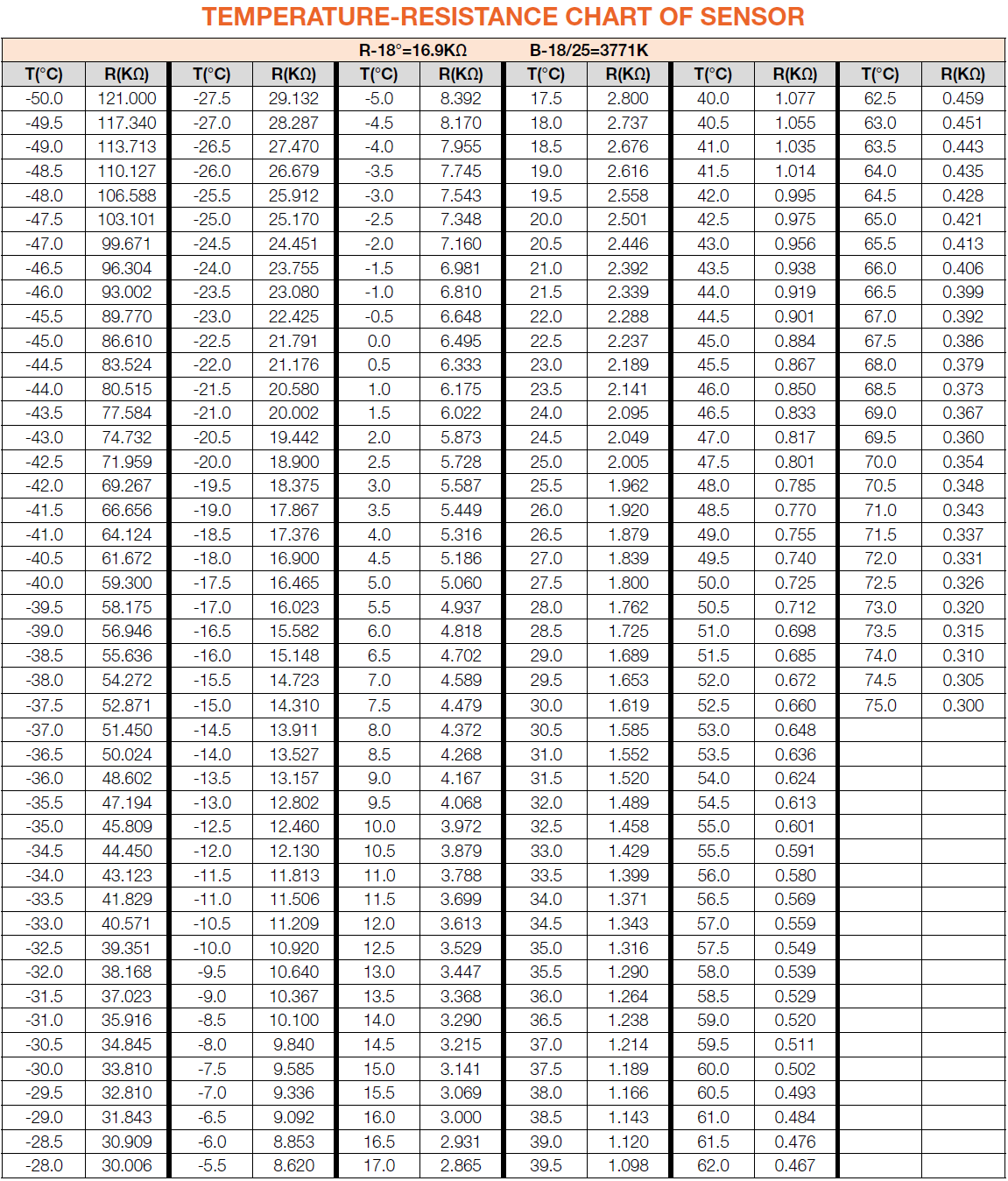

Use tested temperature to find out the reference resistance in following chart.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Pull out the drawers.

Step 2

Take out the shelves.

Step 3

Unscrew the 4 screws.

Step 4

Hold the bottom of air duct and pull it out.

Step 5

Disconnect the terminal of fan motor.

Step 6

Remove air duct.

CHECK AND TEST 2

Step 1

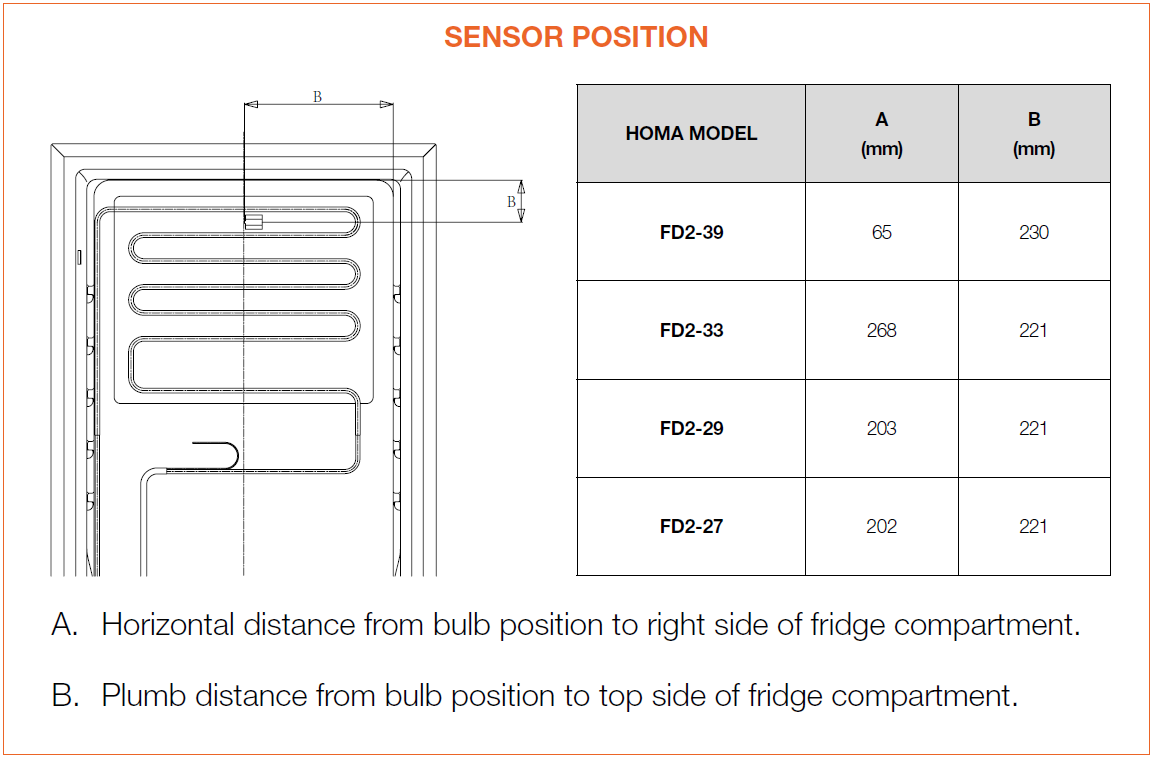

Check to see if sensor is in right position.

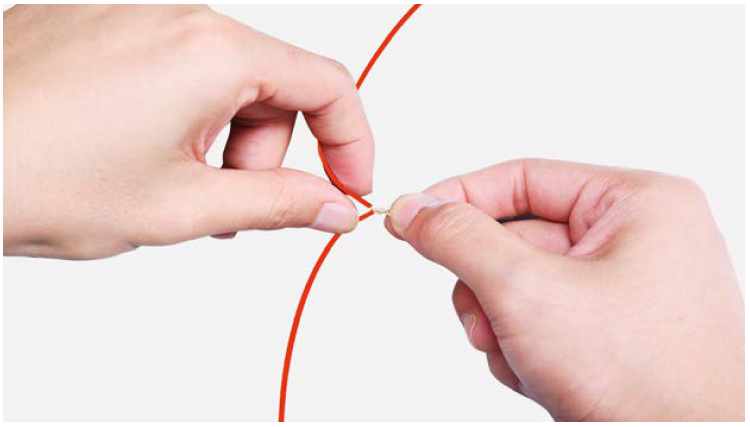

Step 1

Cut wire off from broken area.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and connect

them.

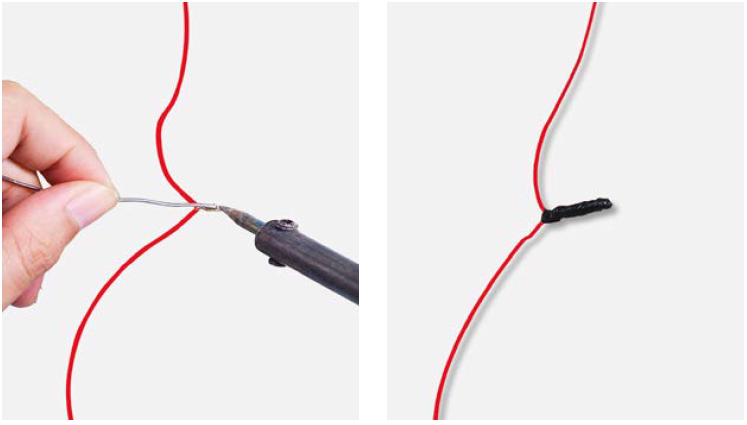

Step 4

Tin soldering.

Step 5

Cover connection with electrical tape.

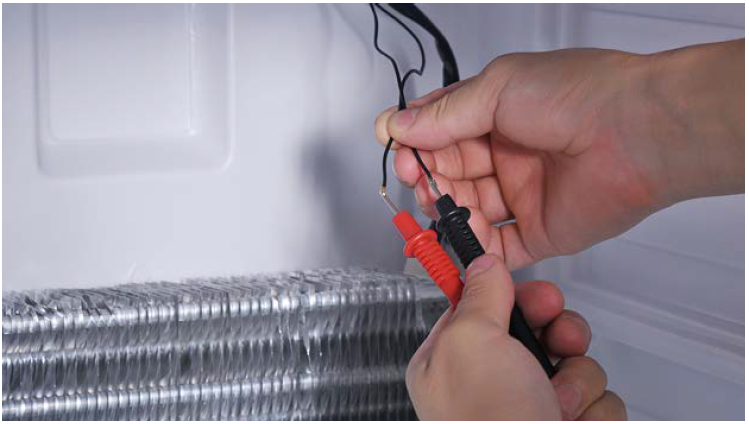

CHECK AND TEST 4

Step 1

Test resistance of sensor.

Step 2

Read the value.

Step 3

Measure the temperature of sensor.

CHECK AND TEST 5

Step 1

Connect the 2 ends in

PCB ends.

Step 2

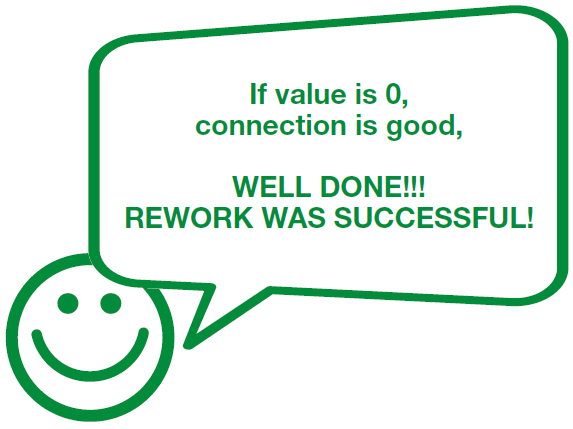

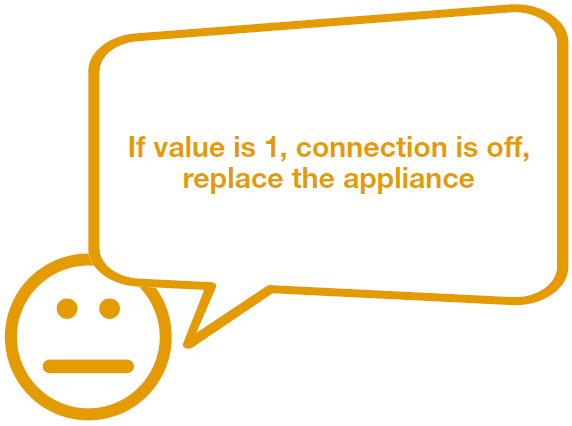

Test connection.

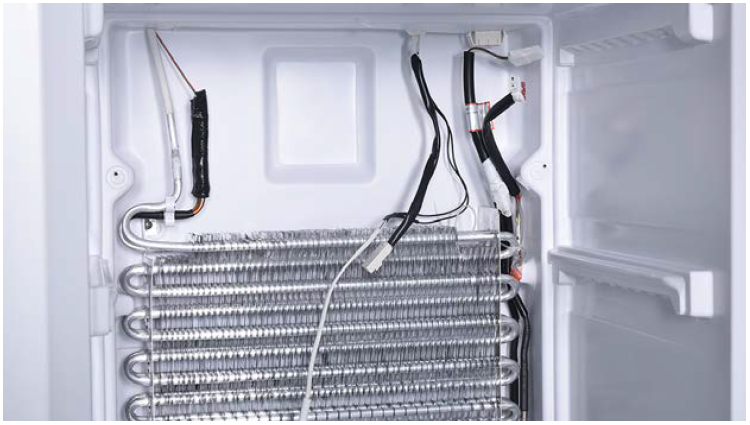

Tip 1

Before installing the airduct, please tie all wires

together.

Tip 2

fan well.

Tip 3

Insert left side first, then other side. Make sure

the cavity on the side is aligned with the ribs on

inner liner.

Tip 4

Check to see if there is a wide gap between air

duct and cabinet. If so, install air duct again.