CHECK AND TEST 1

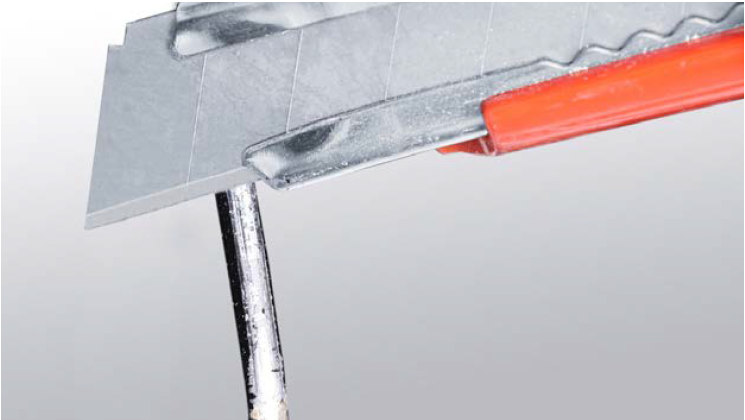

Step 1

Discharge refrigerant.

Cut off the charging tube with pliers.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

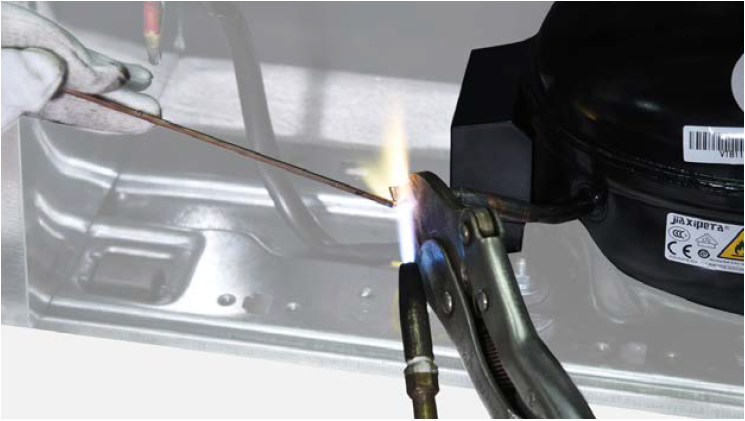

Melt brazing material with flame and pull

processing tube out with a pair of pliers.

Step 4

Re-braze a copper tube onto processing tube of

compressor. To get more details on

brazing requirements, please go to 10.4 Annex B1.

Step 5

Install quick connector onto re-brazed pipe.

Step 6

Use a pliers to cut the capillary off.

Step 7

Inject nitrogen (1.57Mpa) through quick connector into pipe.

Step 8

Check to see if gas is blowing out of capillary.

PROCEDURE 1

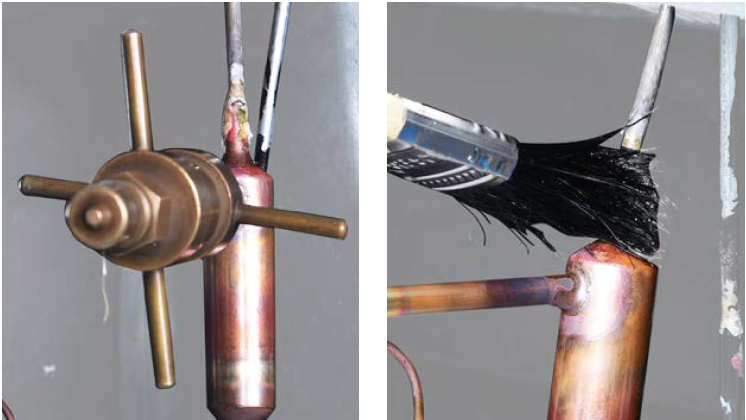

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Cut off the brazed joint of drying filter.

Step 3

Cut off capillary and remove the cut end by shaking.

Step 4

Braze on a new drying-filter.

Step 5

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 6

Add quick connector onto processing pipe of

drying-filter.

Step 7

Test for leaks on brazed joints of drying-filter and processing pipe on compressor.

Step 8

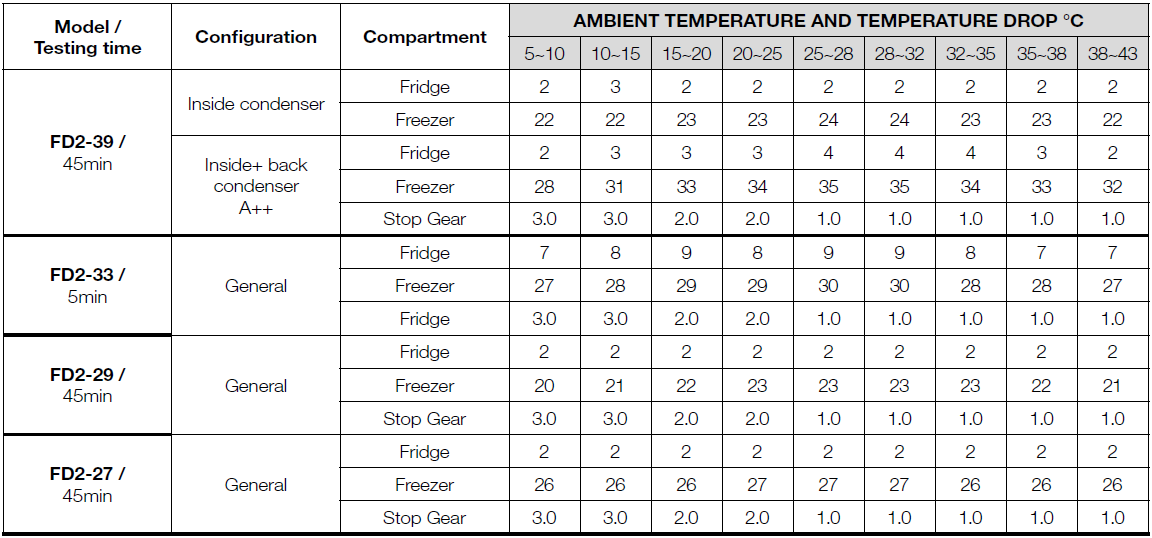

Vacuum and recharge. Click below link to

get more details for vacuuming and gascharging requirements, on 10.5 Annex B2.

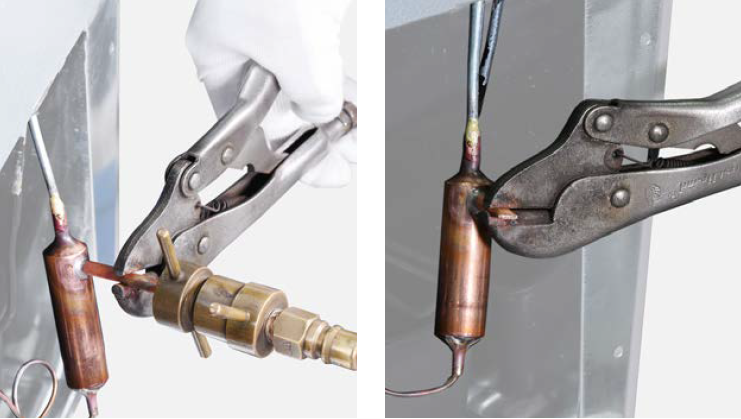

Step 9

Block processing pipe twice by locking pliers.

Step 10

Leave locked pliers attached to second

block and shake to cut off the remaining pipe.

Step 11

Braze the ends and remove the pliers.