CHECK AND TEST 1

Step 1

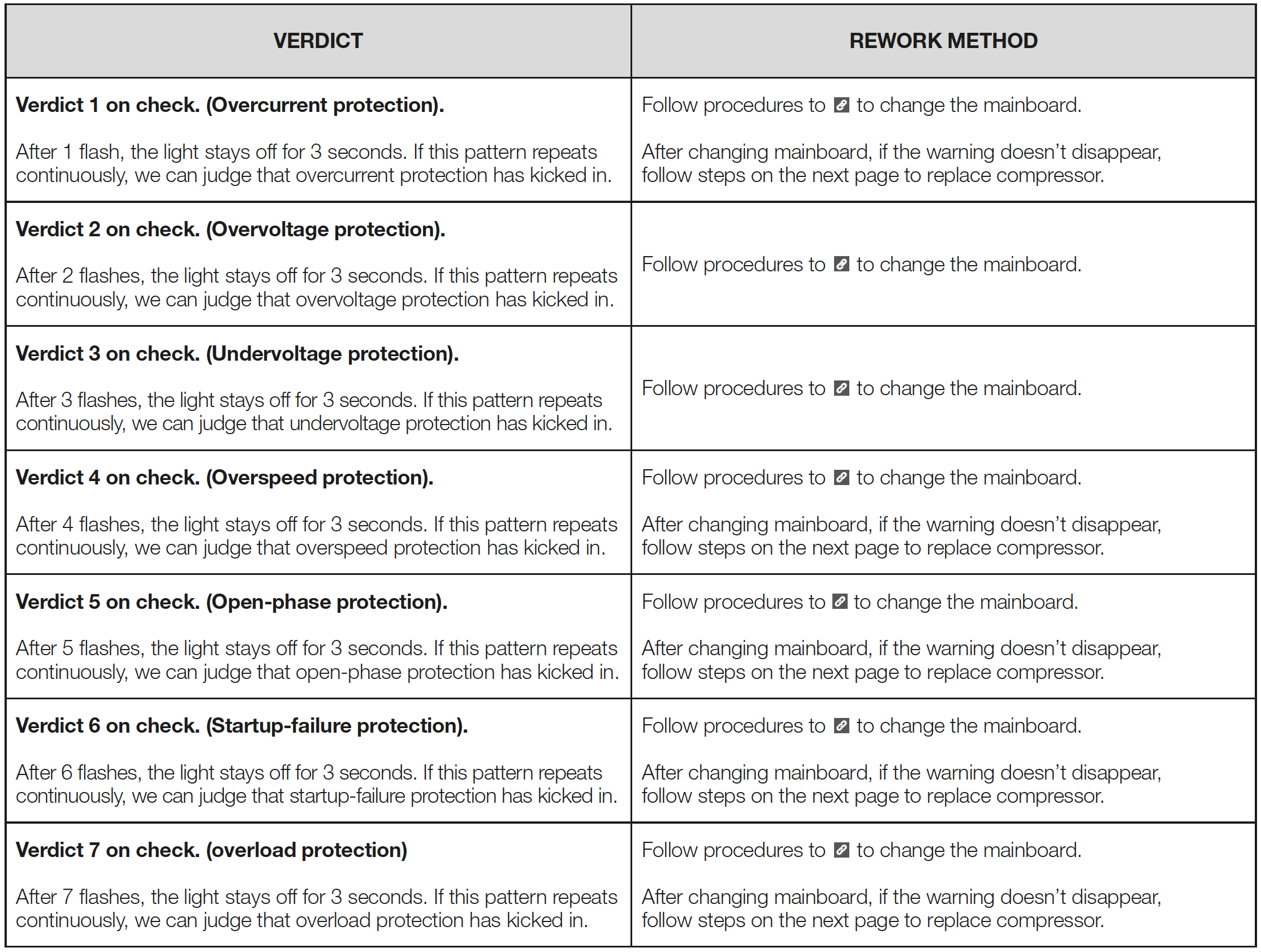

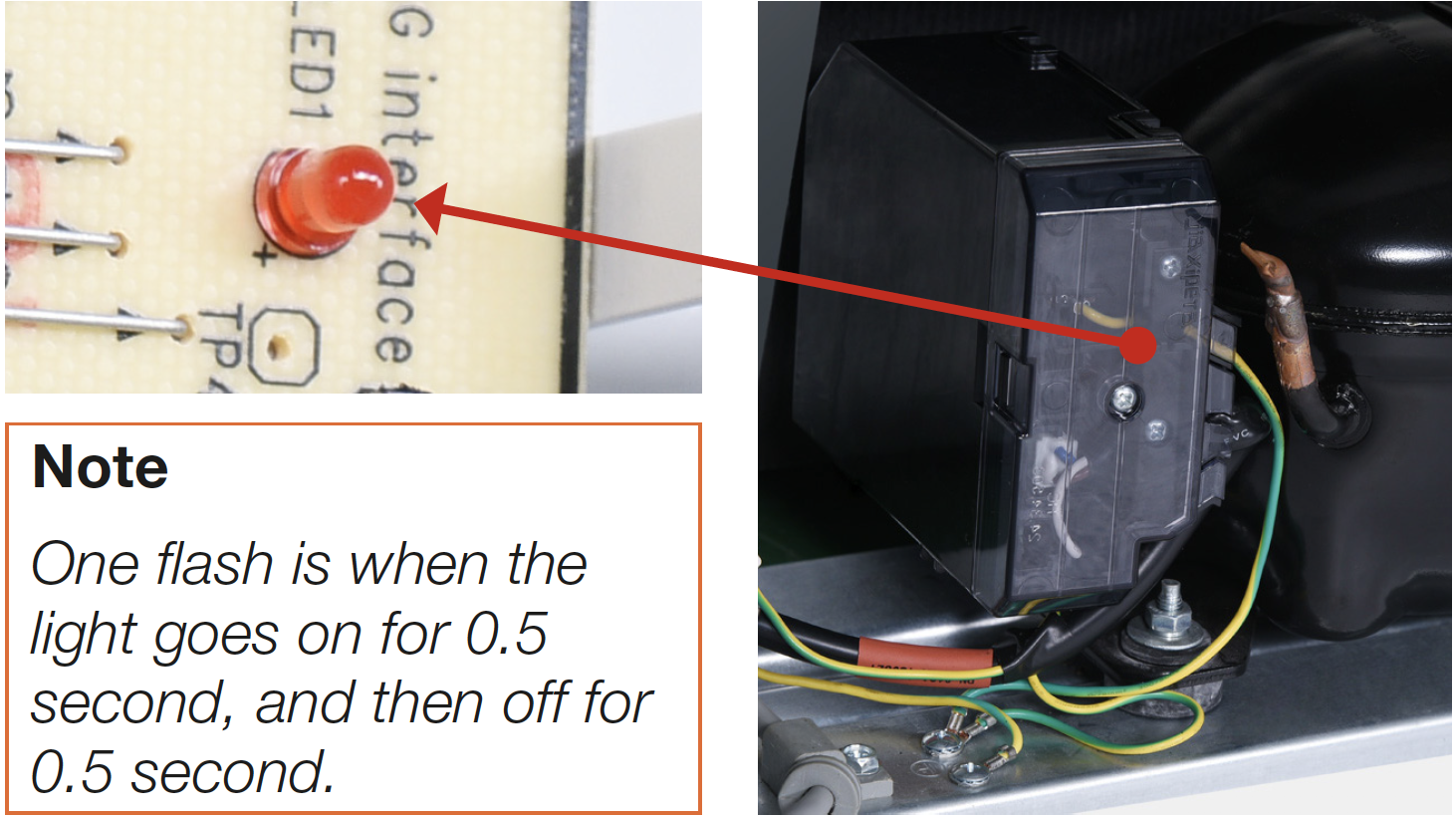

Watch the warning lightflashing on the inverter

box.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Pull up to removeinverter box.

Step 2

Disconnect terminals.

Step 3

Disconnect power cord.Step 4

Disconnect terminals.Reverse above steps to install a new inverter box.

DIAGNOSIS 2

PROCEDURE 2

Step 1

Discharge refrigerant.

Cut off the charging tube

with a pair of pliers.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

Cut off exhaust pipe and suction pipe

Step 4

Unscrew nut of compressor.

Step 5

Put on a new compressor and fix nuts onto compressor.

Step 6

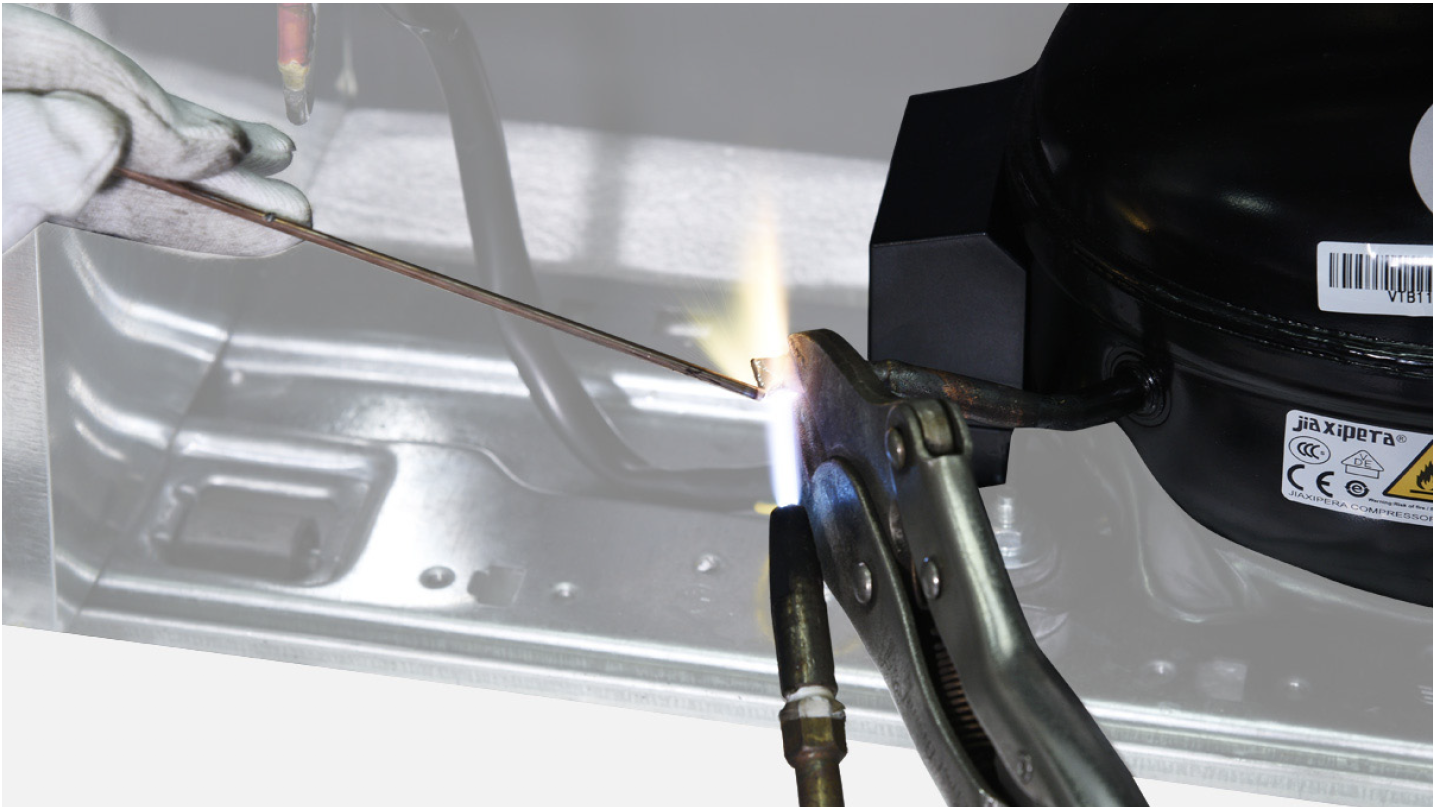

Braze the joints of suction and exhaust pipes.

Step 7

Re-braze a copper tube onto processing tube of compressor.

To get more details on

brazing requirements,

please go to Annex B1

PROCEDURE 3

Step 1

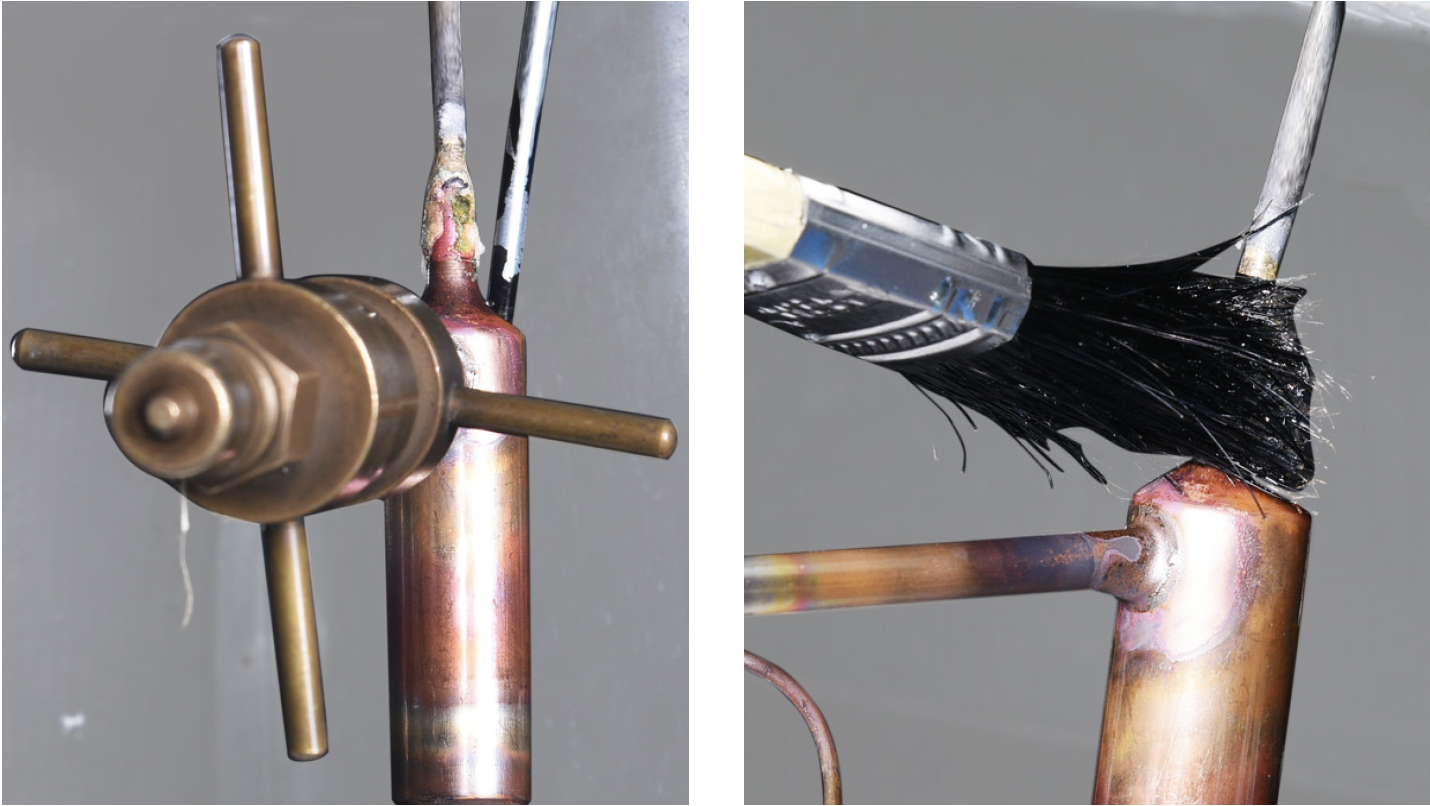

Clean away paint on brazed joint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and remove the cut end by shaking.

Step 4

Braze on a new drying-filter.

Step 5

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow left remaining refrigerant.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Do leakage test on brazed joints of drying- filter and compressor processing pipe.

Step 8

Vacuum and recharge.

Click below link to

get more details for

vacuuming and gas-

charging requirements,

on Annex B1

Step 9

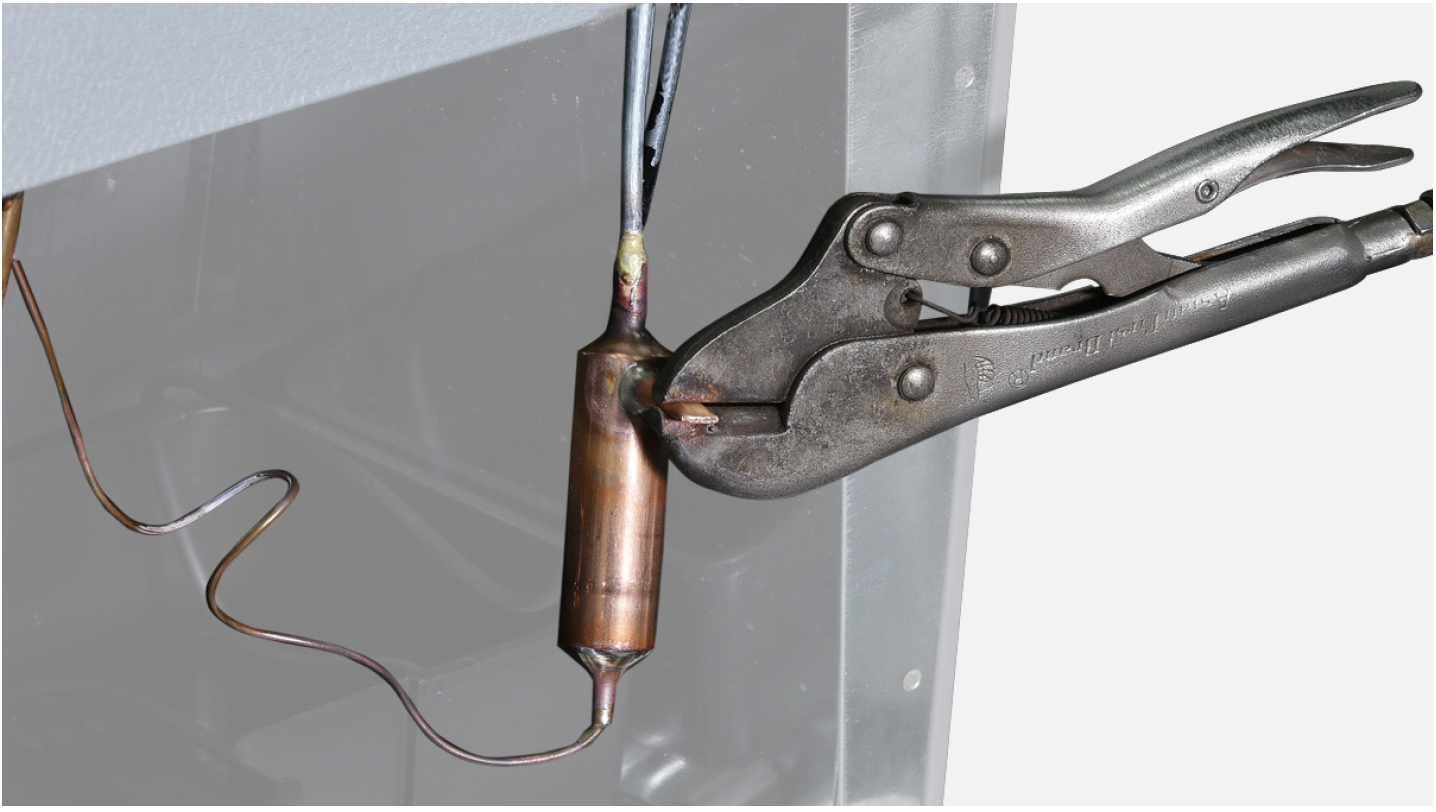

Block processing pipe twice with locking pliers.

Step 10

Leave locking pliers on the second block and shake to cut off the rest of pipe.

Step 11

Braze the ends and remove the pliers.

DIAGNOSIS 3