CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

In mainboard area, check if terminal is inserted to final position.

If not, reinserted it to final position.

Step 3

Turn power output of transformer to DC 12V.

Step 4

Supply power from terminal in PCB area (FAN & GND).

Step 5

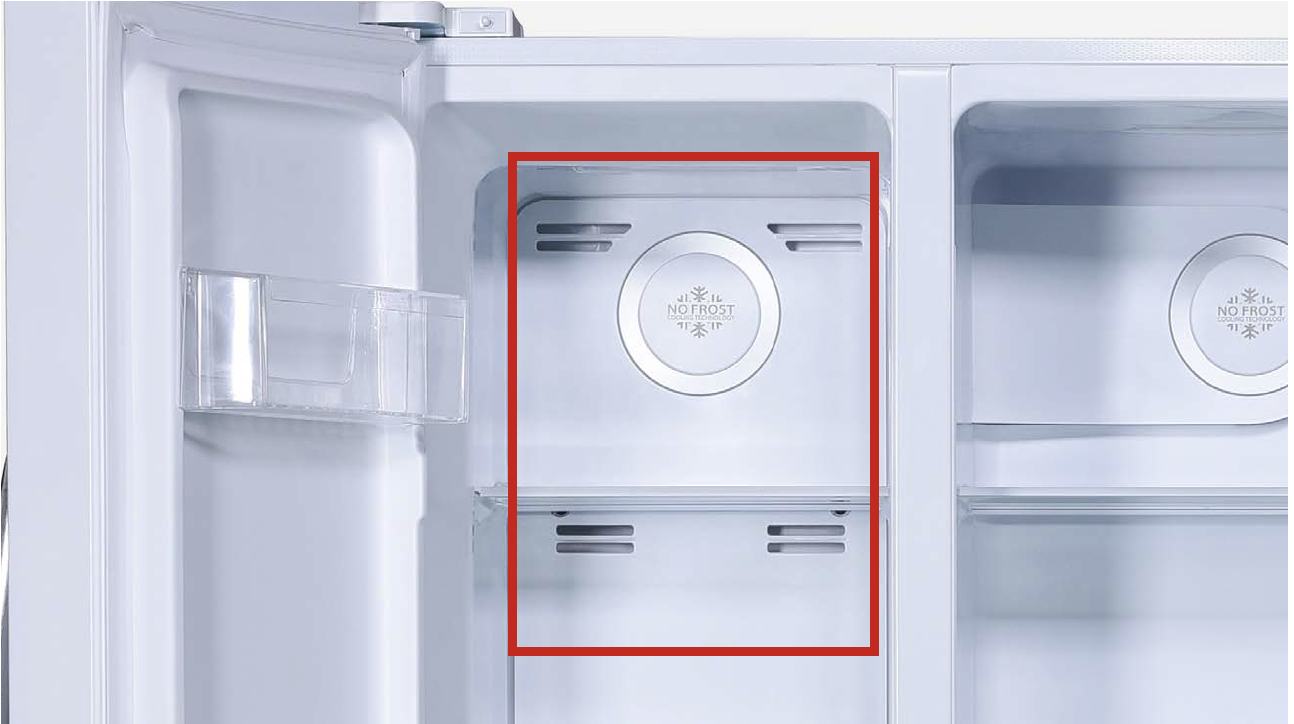

Put your hand near outlet of freezer air duct to feel if fan is blowing or not.

DIAGNOSIS 1

PROCEDURE 1

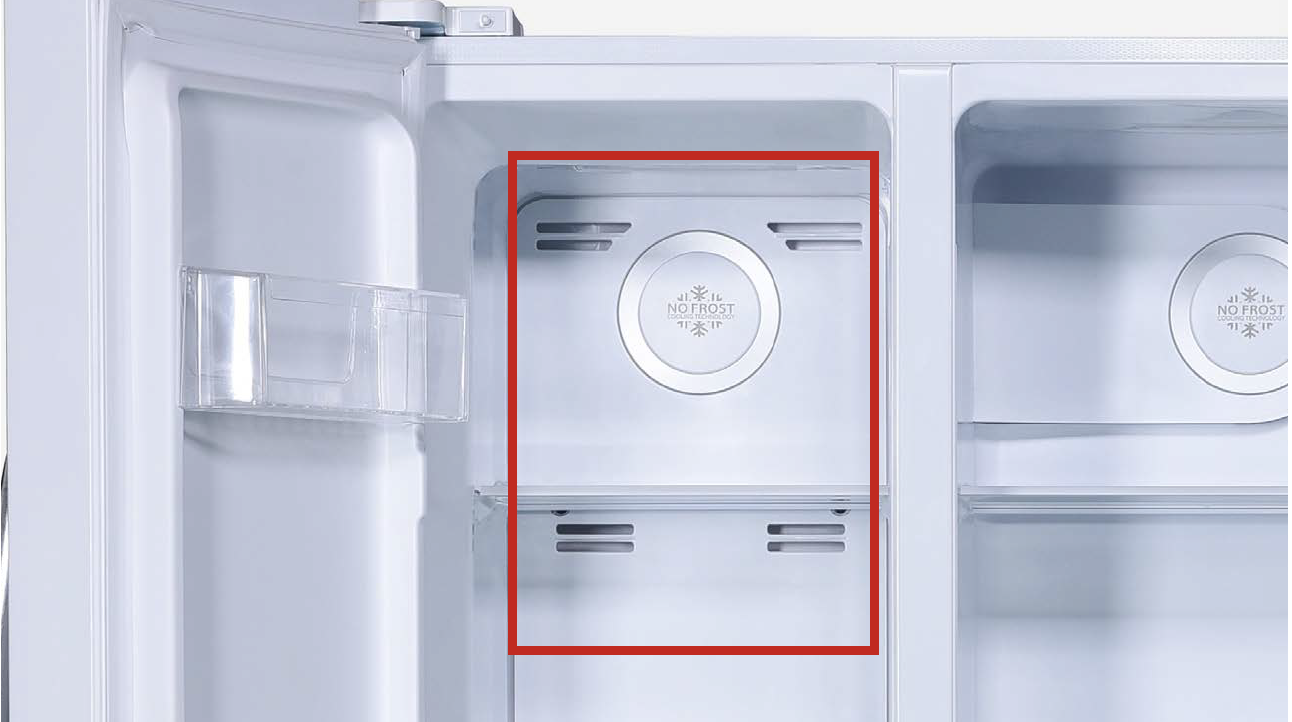

Step 1

Remove all freezer drawers.

Step 2

Remove all freezer shelves.

Step 3

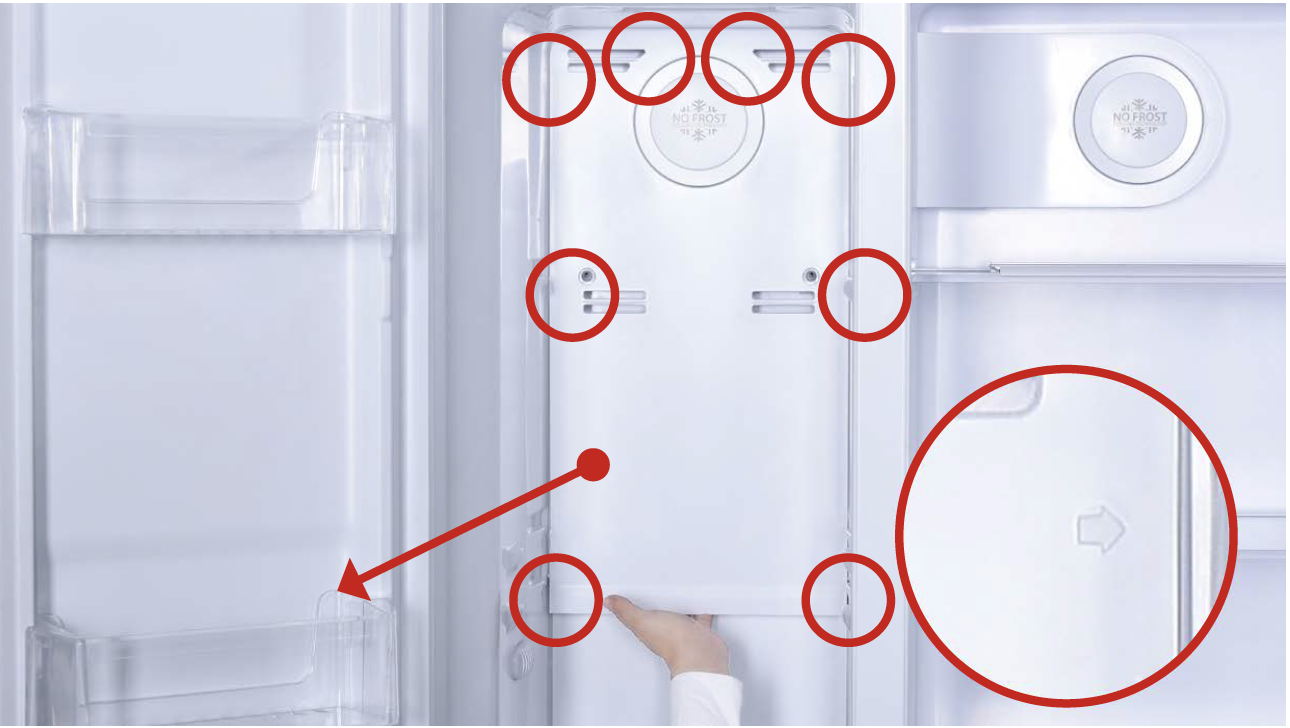

Remove screw covers (total of two) on upper freezer air duct with Slotted Screw Driver.

Step 4

Unscrew screws (total

of two) on upper freezer

air duct with Cross-head

screw driver.

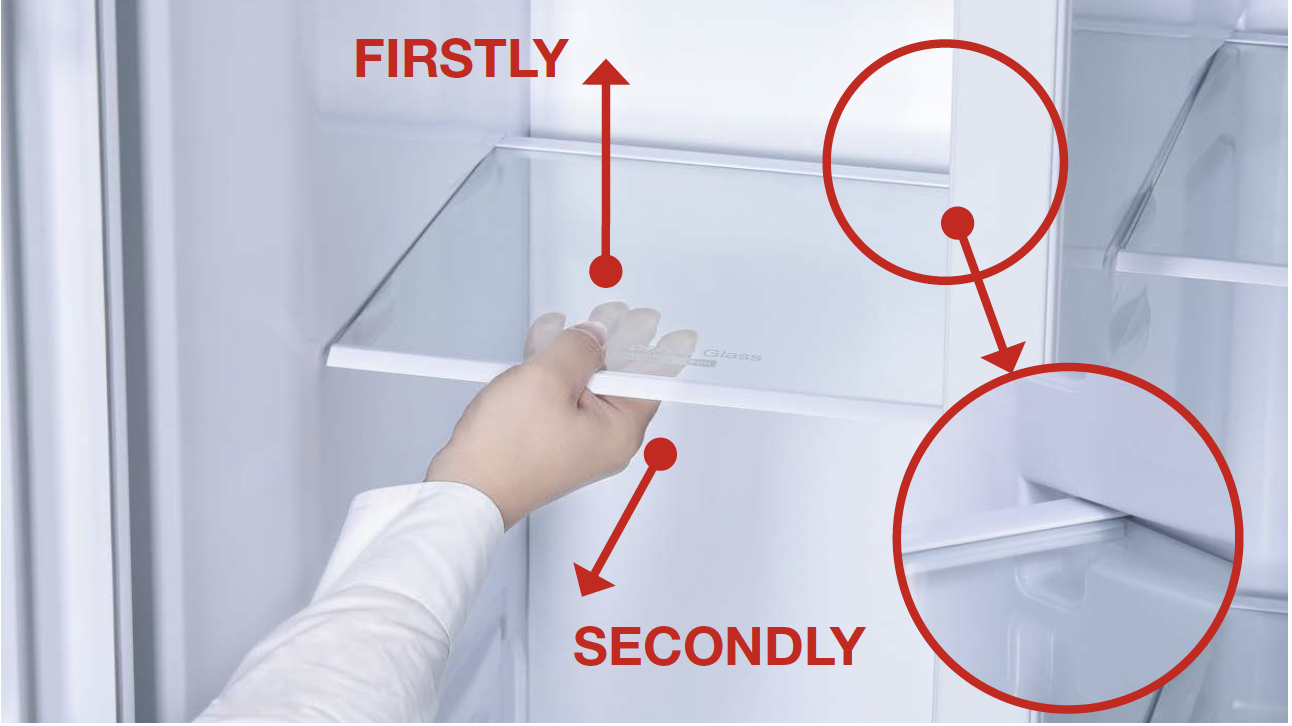

Step 5

Catch bottom of air duct upper freezer air duct and pull all buckles (total of 8) down.

Step 6

Take out upper freezer

air duct by tilting to one

side.

Pay attention to the

connectors when pulling

out the air duct.

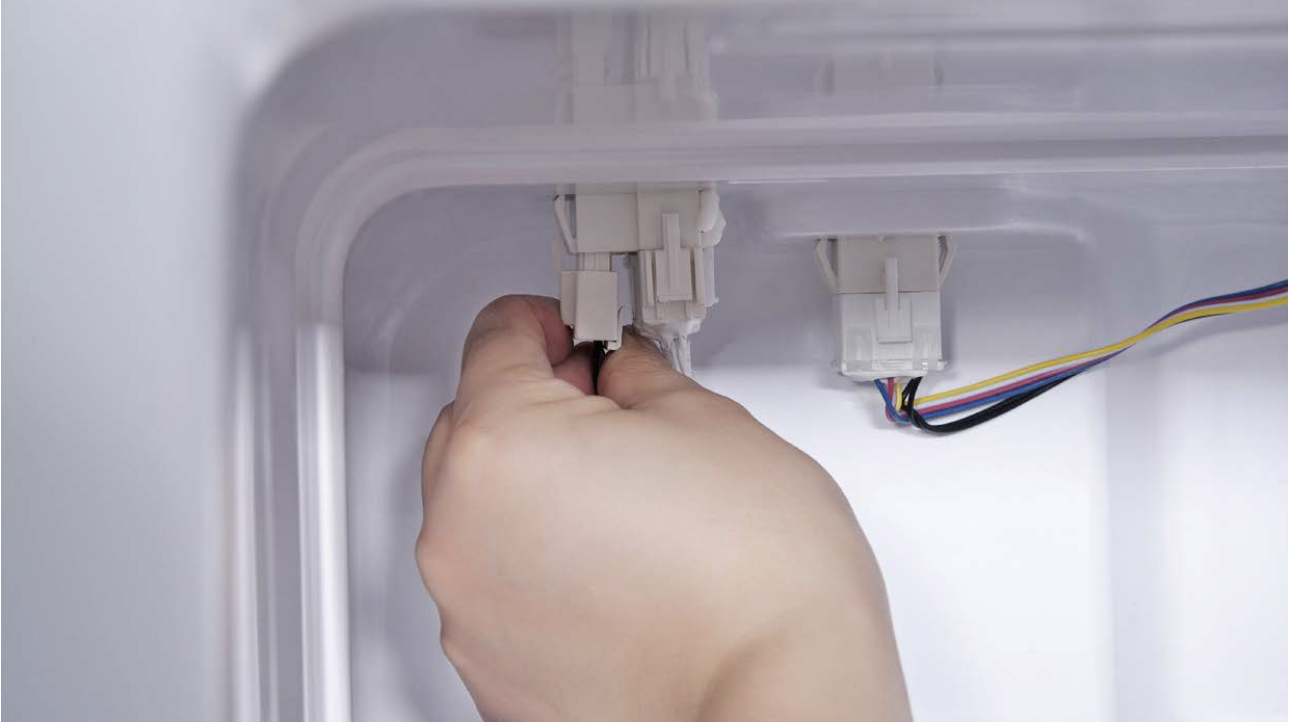

Step 7

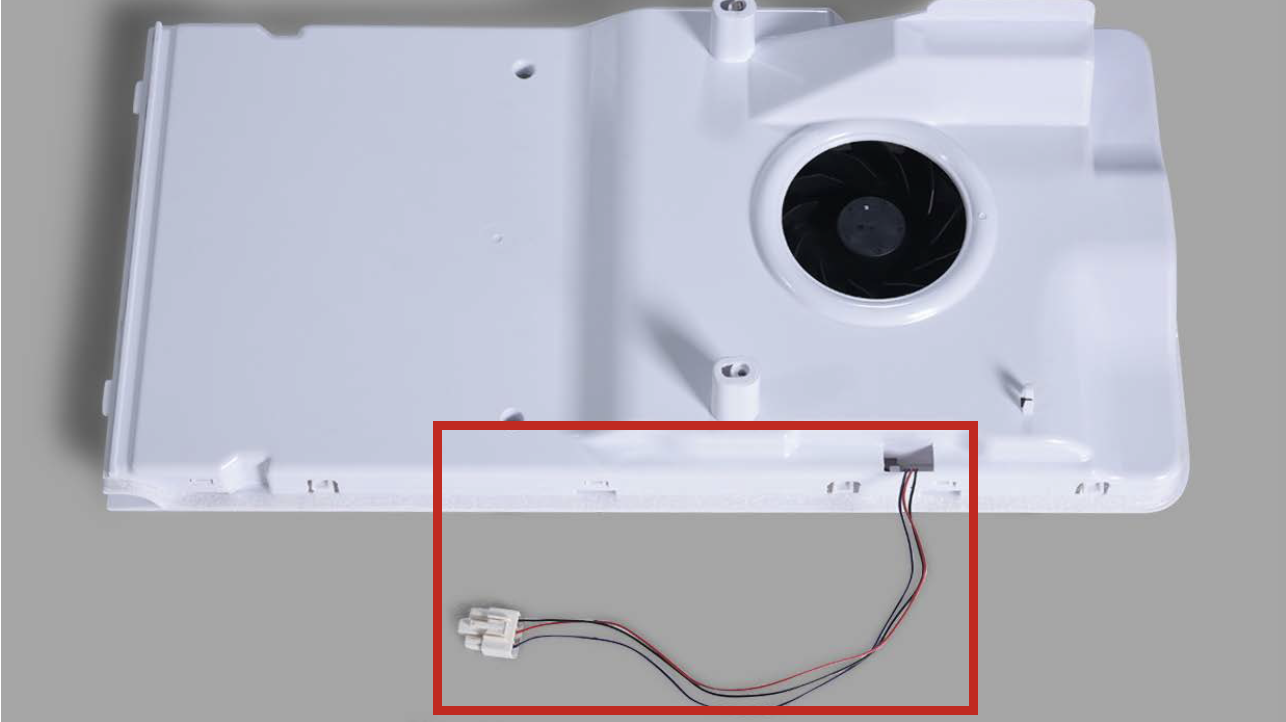

Disconnect the terminal for fan motor and move upper freezer air duct away.

CHECK AND TEST 2

Step 1

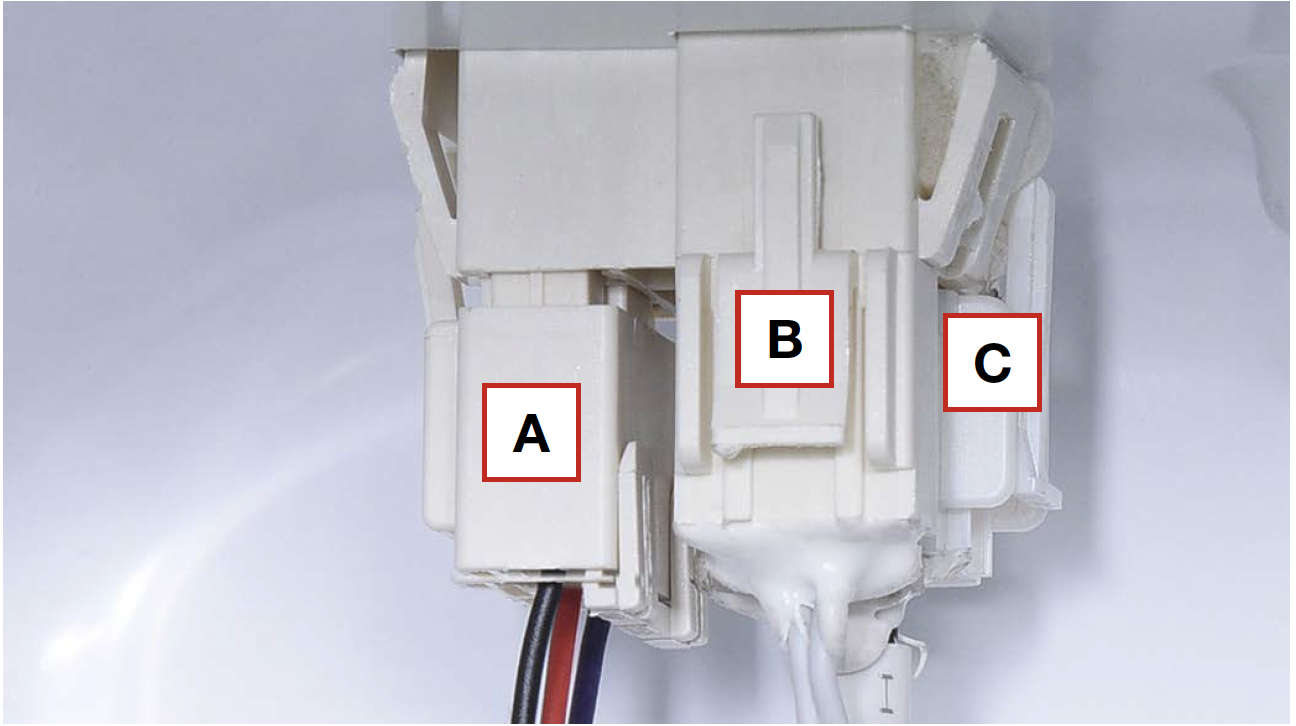

Check if terminal is

inserted to final position.

If not, reinsert it.

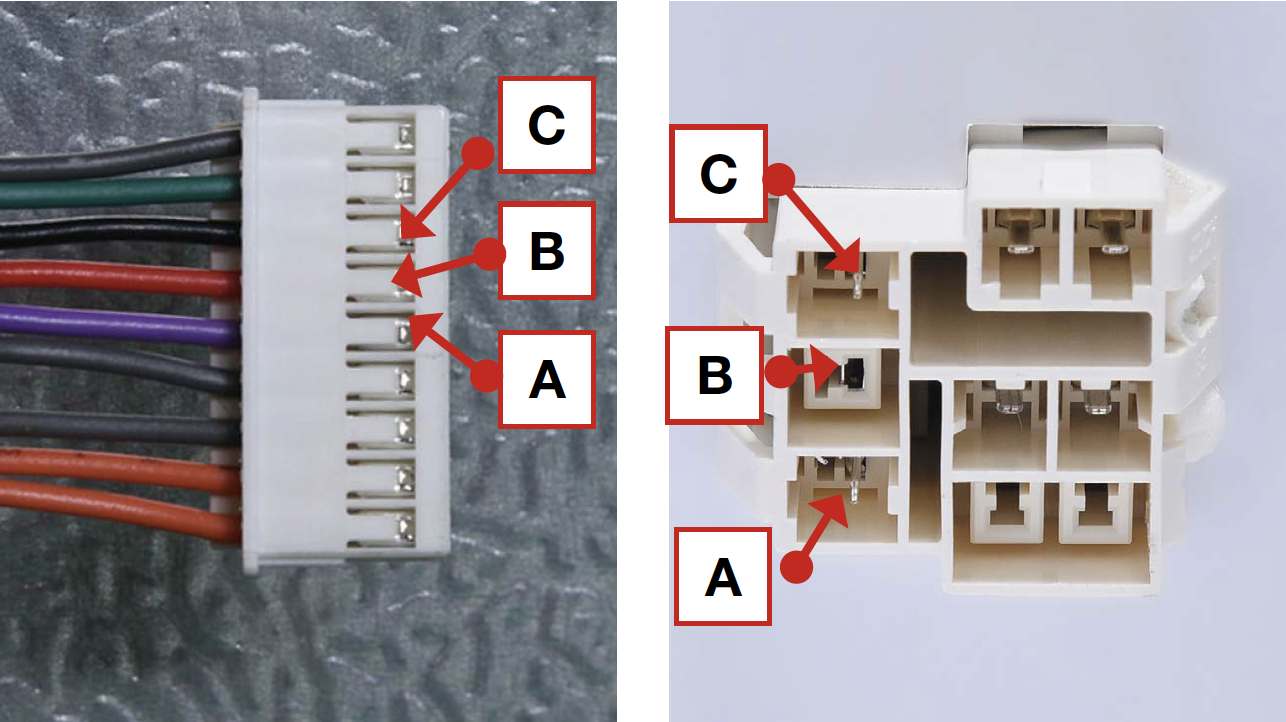

A is not correctly inserted; B & C is OK.

Step 2

Check if terminal is filled with foam or not.

If yes, use tweezers to clean and remove the foam.

Step 3

Check if wire order is correct or not.

Pictures on right side show correct wire order.

Step 4

Check if the wires are broken or not.

DIAGNOSIS 2

PROCEDURE 2

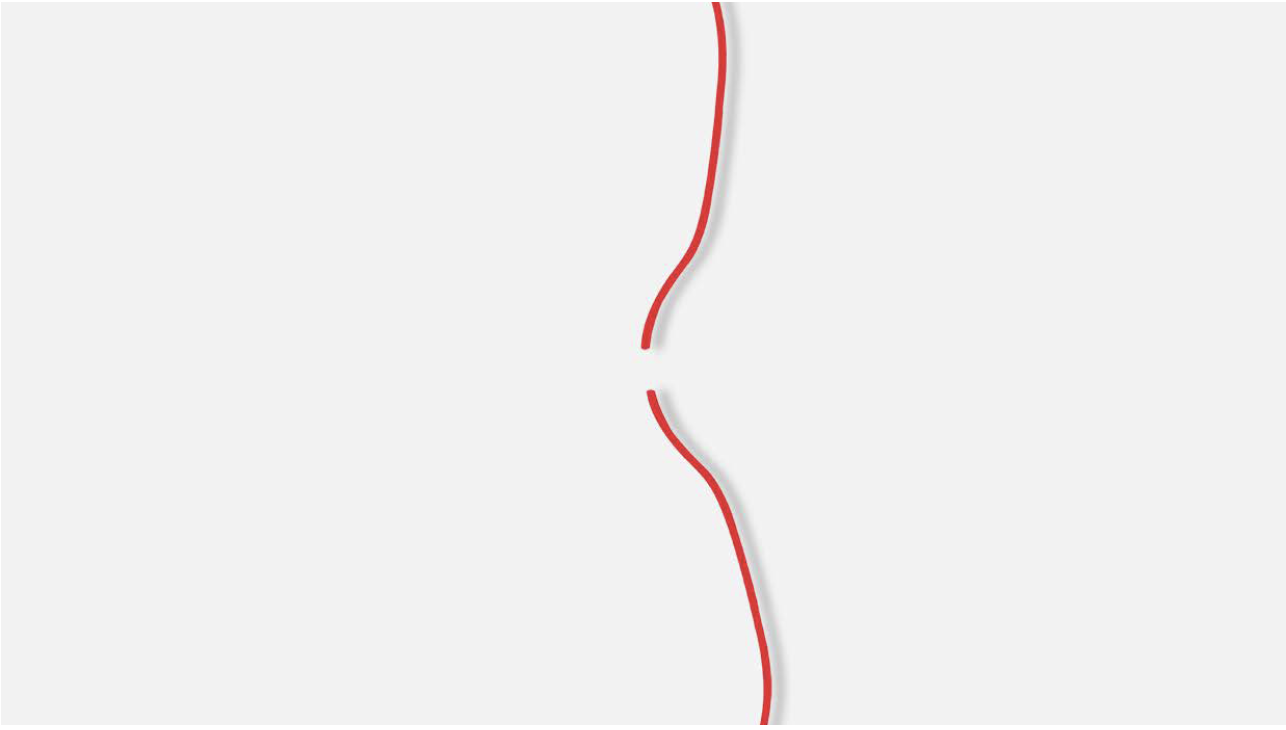

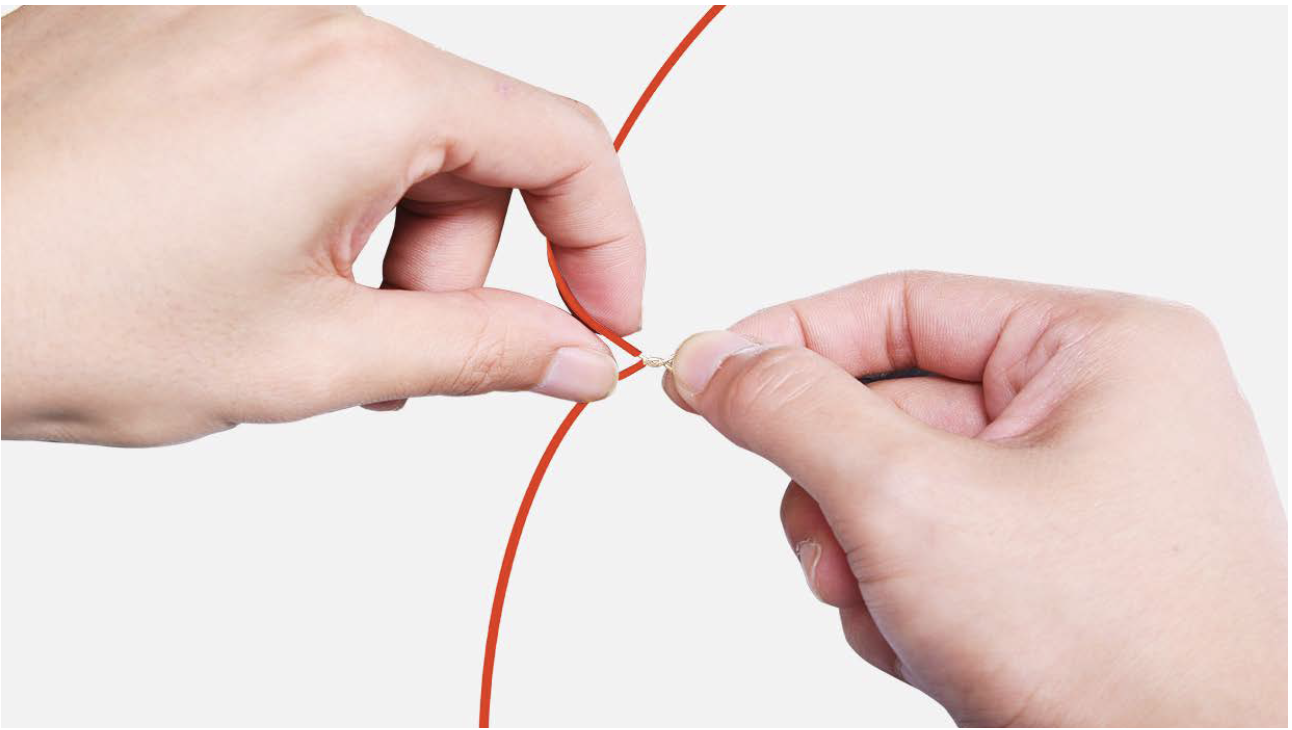

Step 1

Cut wire off from broken area.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper wire order and connect them.

Step 4

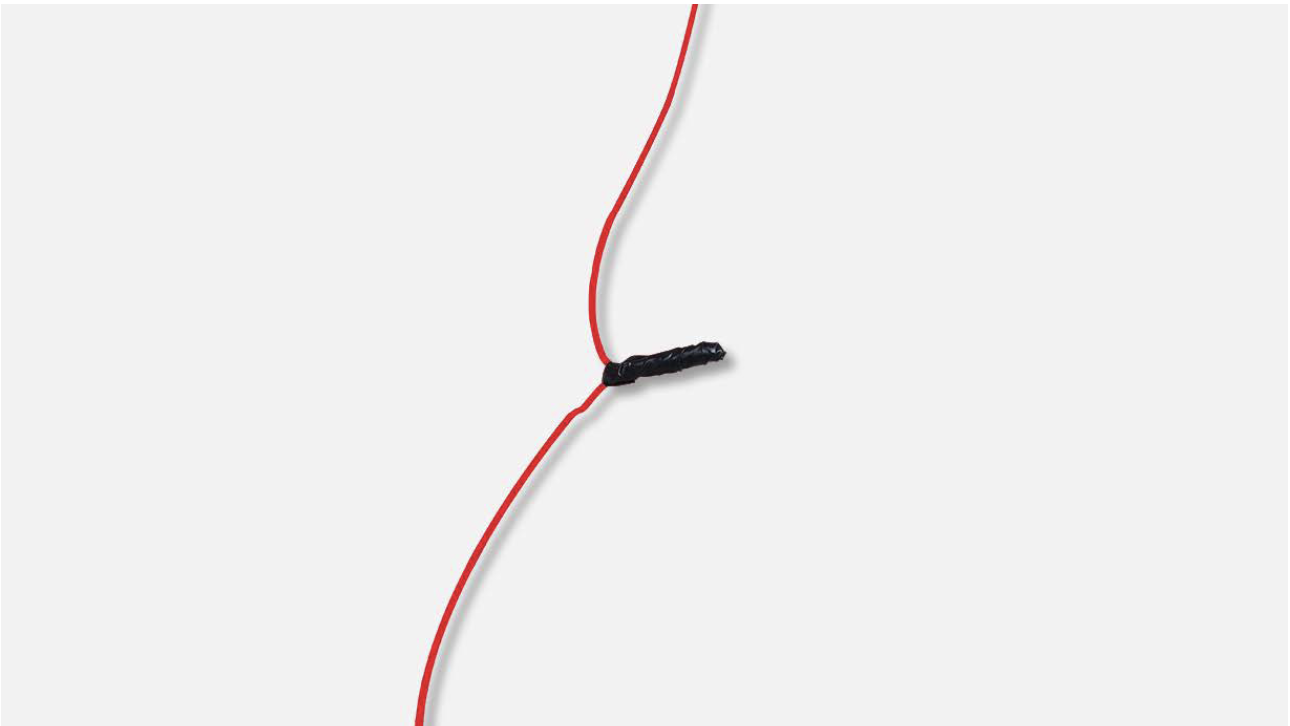

Tin soldering.

Step 5

Cover connection with electrical tape.

CHECK AND TEST 3

Step 1

Set output of transformer to DC 12V to test fan from the terminal behind the air duct.

Step 2

Use power source to test fan from terminal in the back of air duct.

DIAGNOSIS 3

Note

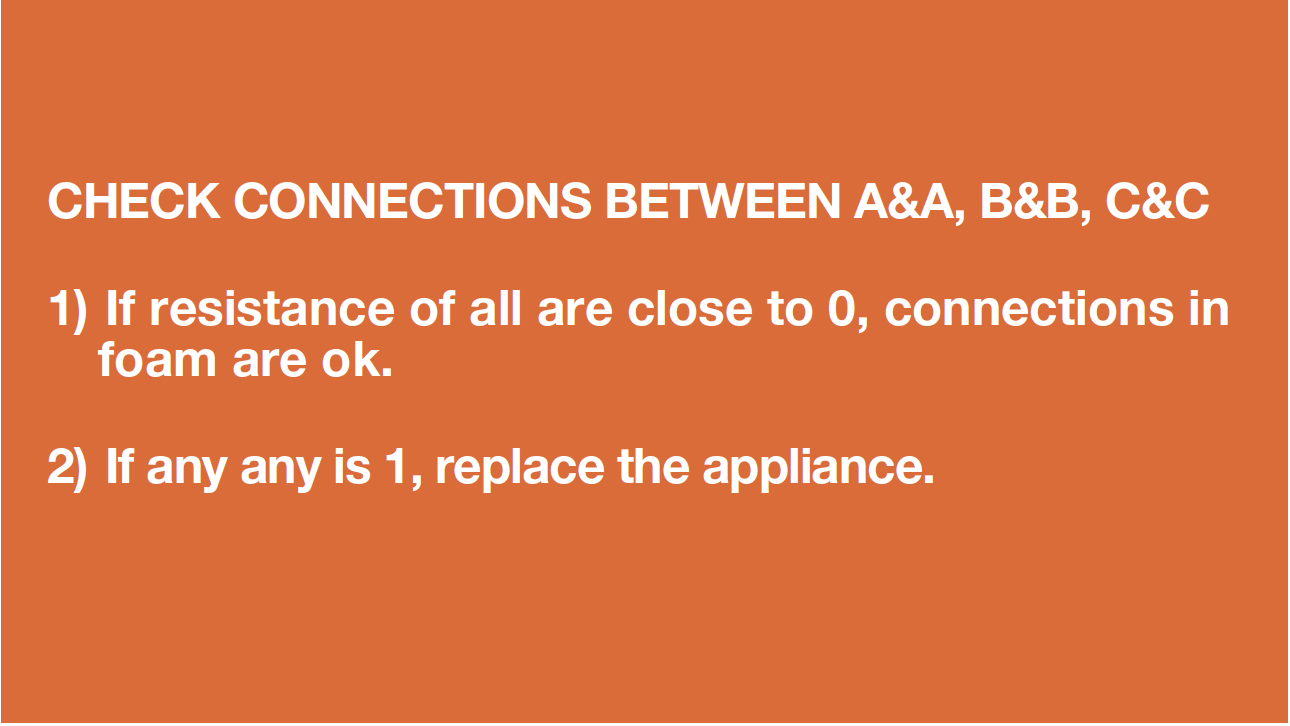

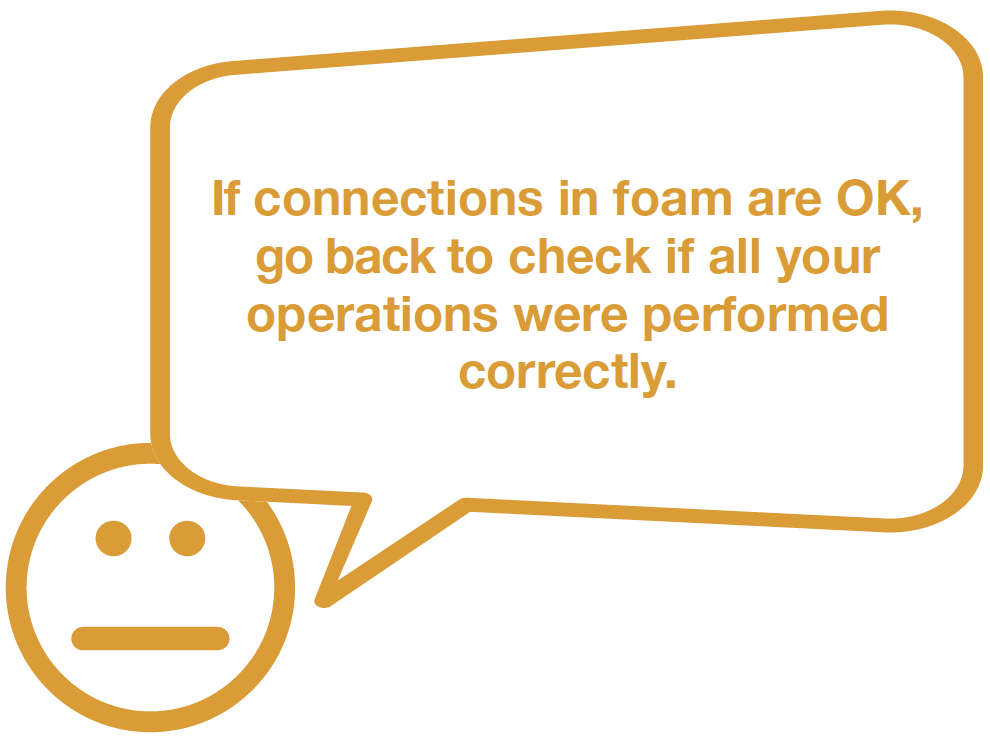

CHECK AND TEST 4

Step 1

Set multimeter to resistance gear.

Step 2

Put detector into one end of wires in PCB area.

Step 3

Put another detector into end of wires behind air duct.

DIAGNOSIS 4

CHECK AND TEST 5

Step 1

Reconnect terminal of fan motor.

Step 2

Turn power output of transformer to DC 12V.

Step 3

Supply power from terminal in PCB area (FAN & GND).

Step 4

Put your hand near outlet of freezer air duct to feel if fan is blowing or not.

DIAGNOSIS 6