CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

Check if terminal in PCB

area is pushed to final

position.

If not, reinsert it to final

position.

Step 3

Set multimeter to resistance gear.

Step 4

Test resistance of sensorfrom terminal in PCB

area.

Step 5

Take note of value.

Step 6

Measure the temperatureof freezer air duct, near the

defrost temp. sensor.

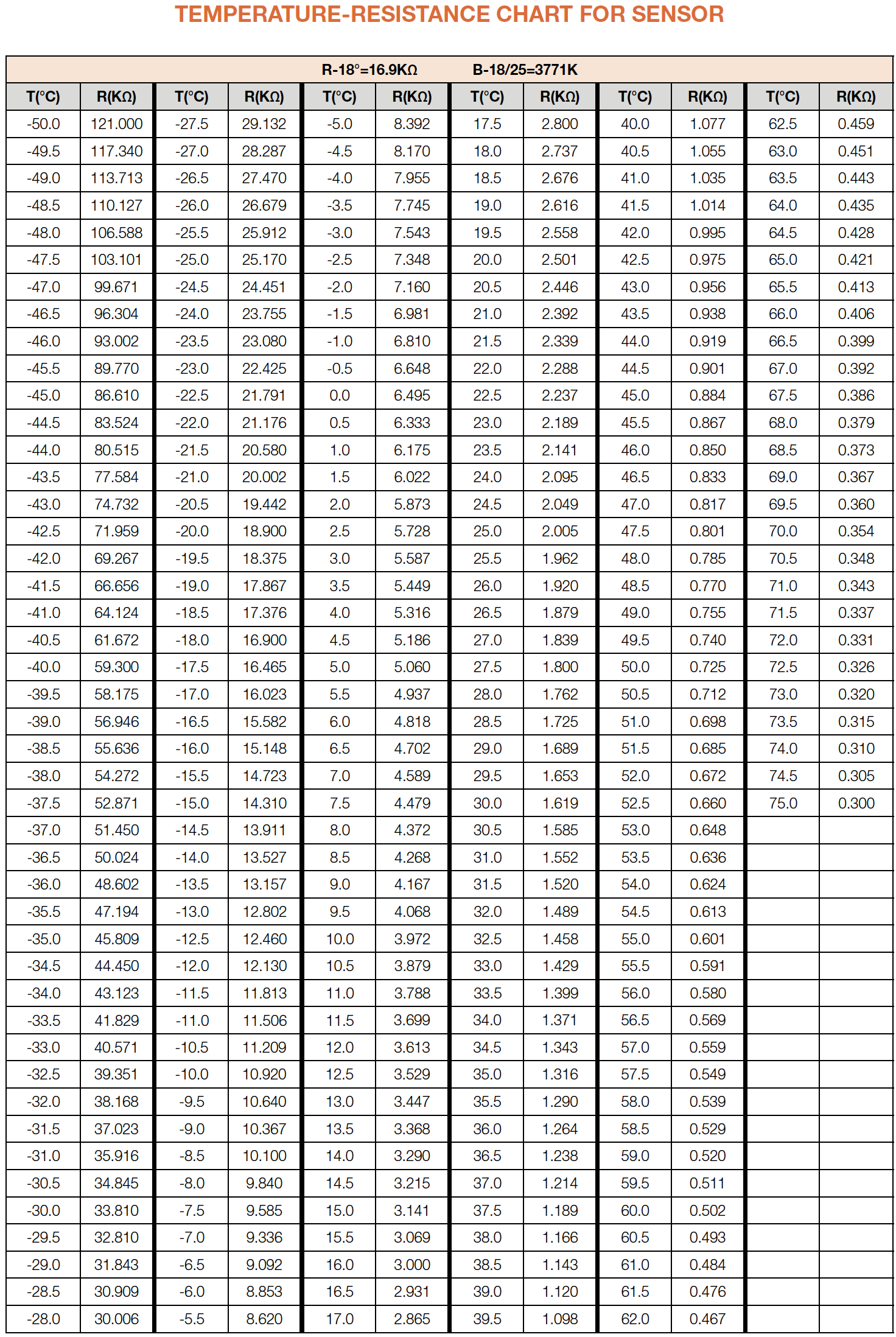

Use measured temperature

to find the standard

resistance value in

Temperature-Resistance

Chart of Sensor.

DIAGNOSIS 1

PROCEDURE 1

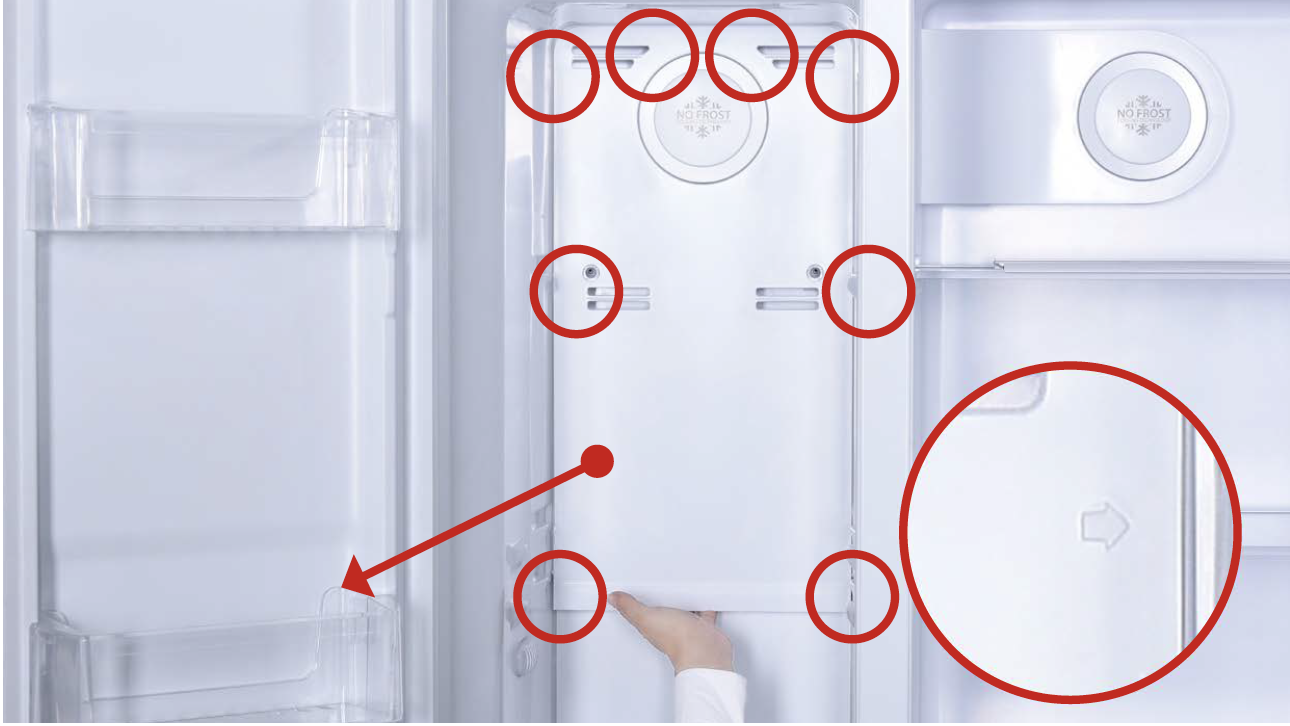

Step 1

Remove all freezerdrawers.

Step 2

Remove all freezer

shelves.

Step 3

Remove screw covers (total of two) on upperfreezer air duct with Slotted Screw Driver.

Step 4

Unscrew screws (totalof two) on upper freezer

air duct with Cross-head

screw driver.

Step 5

Catch bottom of air ductupper freezer air duct

and pull all buckles (total

of 8) down.

Step 6

Take out upper freezerair duct by tilting to one

side.

Pay attention to the

connectors when pulling

out the air duct.

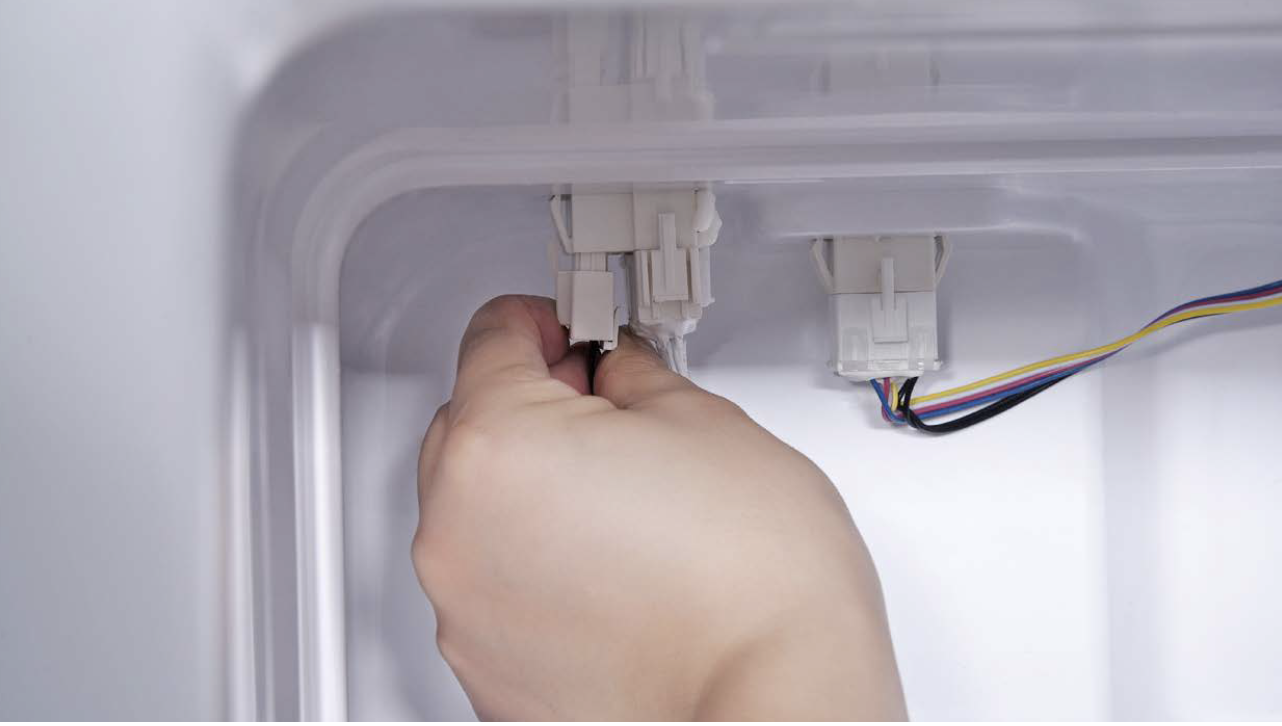

Step 7

Disconnect the terminalfor fan motor and move

upper freezer air duct

away.

Step 8

Remove the screw coveron bottom freezer air

duct with Slotted Screw

Driver.

Step 9

Unscrew the screw onbottom freezer air duct

with Cross-head screw

driver.

Step 10

Catch bottom of air ductbottom freezer air duct

and pull all buckles

(total of 10) down.

Step 11

Take out the lower airduct, tilting to one side.

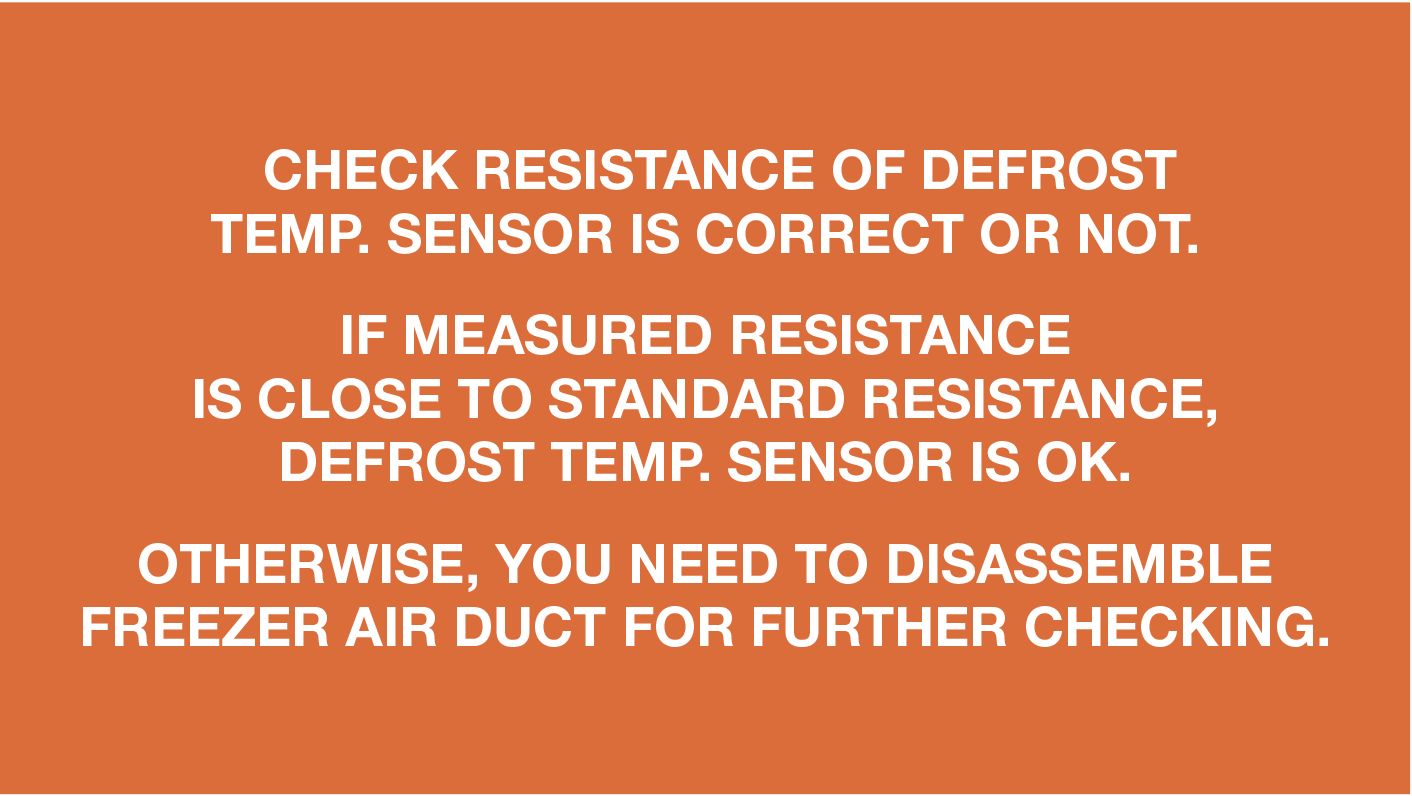

CHECK AND TEST 2

Step 1

Check if sensor attachedin correct position, as

shown in picture.

Step 2

Check if sensor attachedin correct position, as

shown in picture.

Step 3

Check if wire of defrostsensor is broken.

If yes, replace it with a

new one.

Step 4

Disconnect terminal ofdefrost temp. sensor (B).

Step 5

Check if the terminal isstuffed with foam.

Step 4

Measure resistance ofdefrost temp. sensor

from terminal in freezer,

and take note of it.

Step 7

Measure the temperatureof defrost temp. sensor.

Use measured

temperature to find the

standard resistance

value in Temperature-

Resistance Chart for

Sensor.

DIAGNOSIS 2

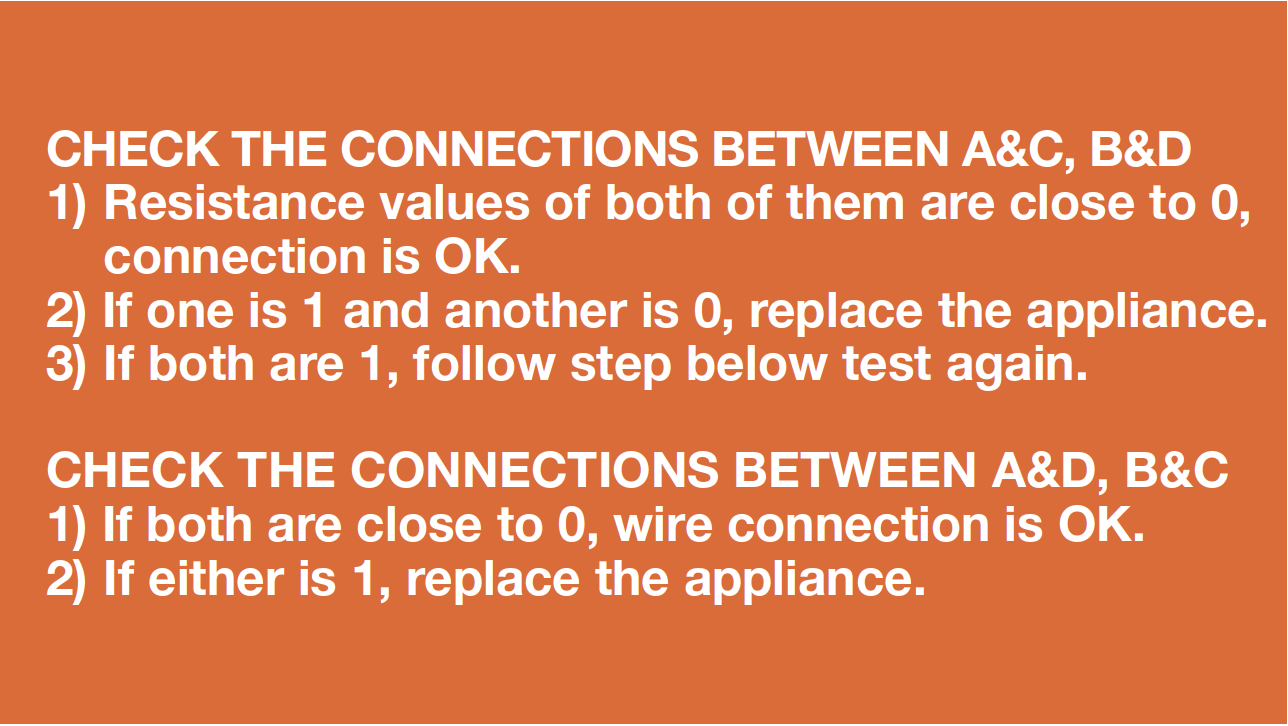

CHECK AND TEST 3

DIAGNOSIS 3

CASE 1:

METAL DOOR

PROCEDURE 2

Step 1

Push a 6mm suckeronto display and turn

the knob to strengthen

suction force.

Step 2

Attach strap to knobto facilitate pulling out

display board.

Tip 1

After connecting

terminal, please tape

wires in place to prevent

crushing by the cover.

Tip 2

After inserting displayn into cavity, press edge

until you hear a clicking sound, this means the

board is pushed properly into final position.

Please press all buttons on display

board to make sure display functions

properly.

CASE 2:

GLASS DOOR

PROCEDURE 2

Step 1

Lever off the cover ondoor cap.

Step 2

Remove the screws (intotal 2).

Step 3

Pull out the plastic;

Step 4

Disconnect the terminalfor display panel.

Step 5

Remove tape.

Step 6

testo testoPush display out by thecorner.

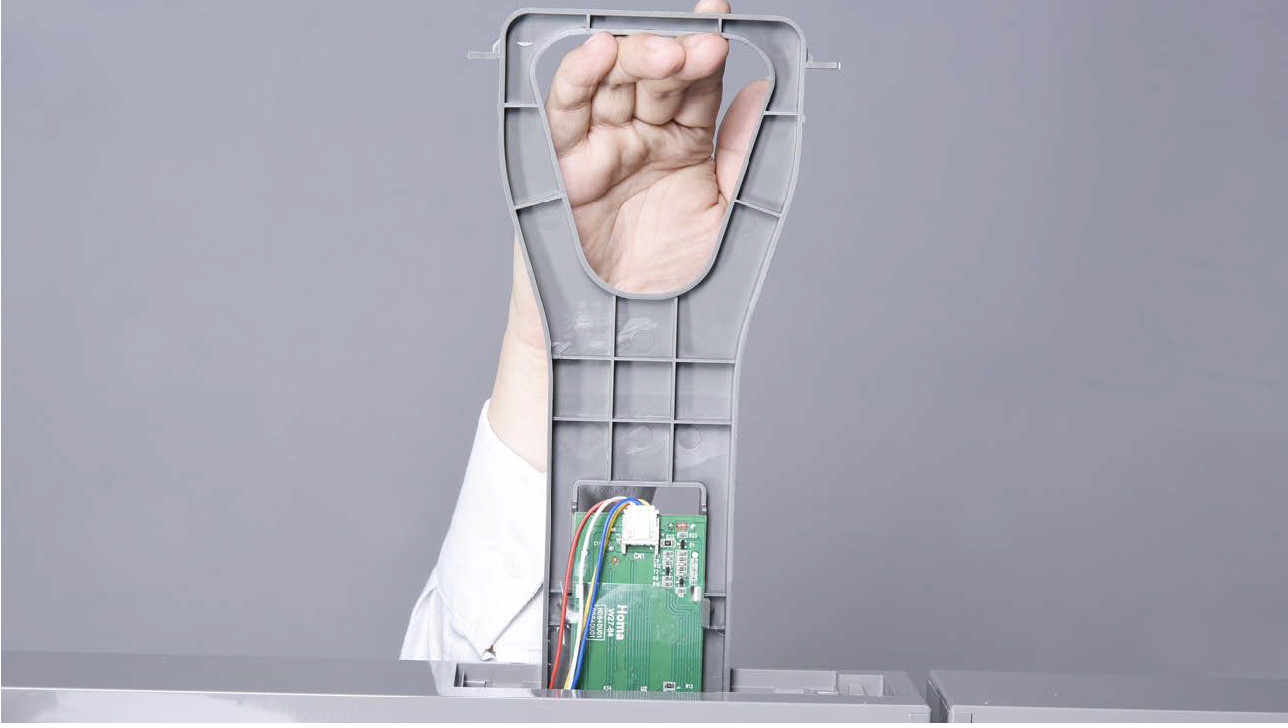

PROCEDURE 3

Tip 1

Please press all buttonson display board to verify

if it is working properly.

Make sure all words and

icons are clear.

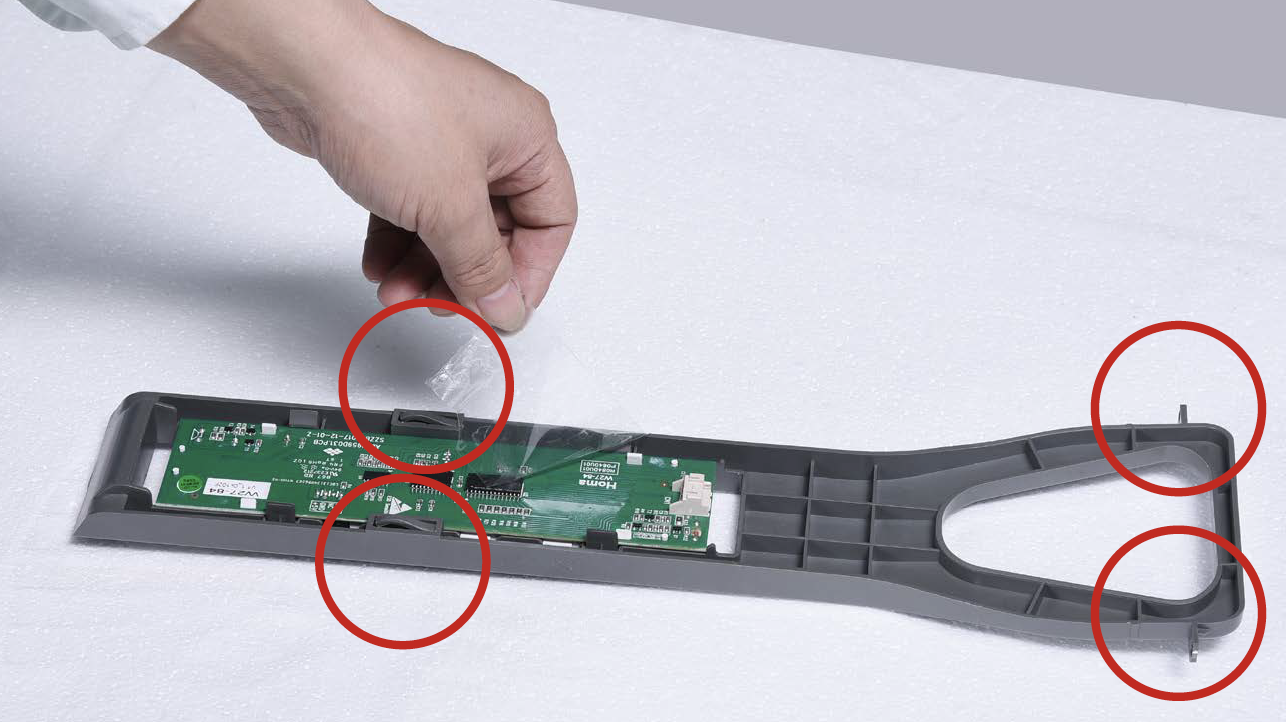

Tip 2

If not clear, disassembleand put tape on points

indicated by red circles.

CHECK AND TEST 4

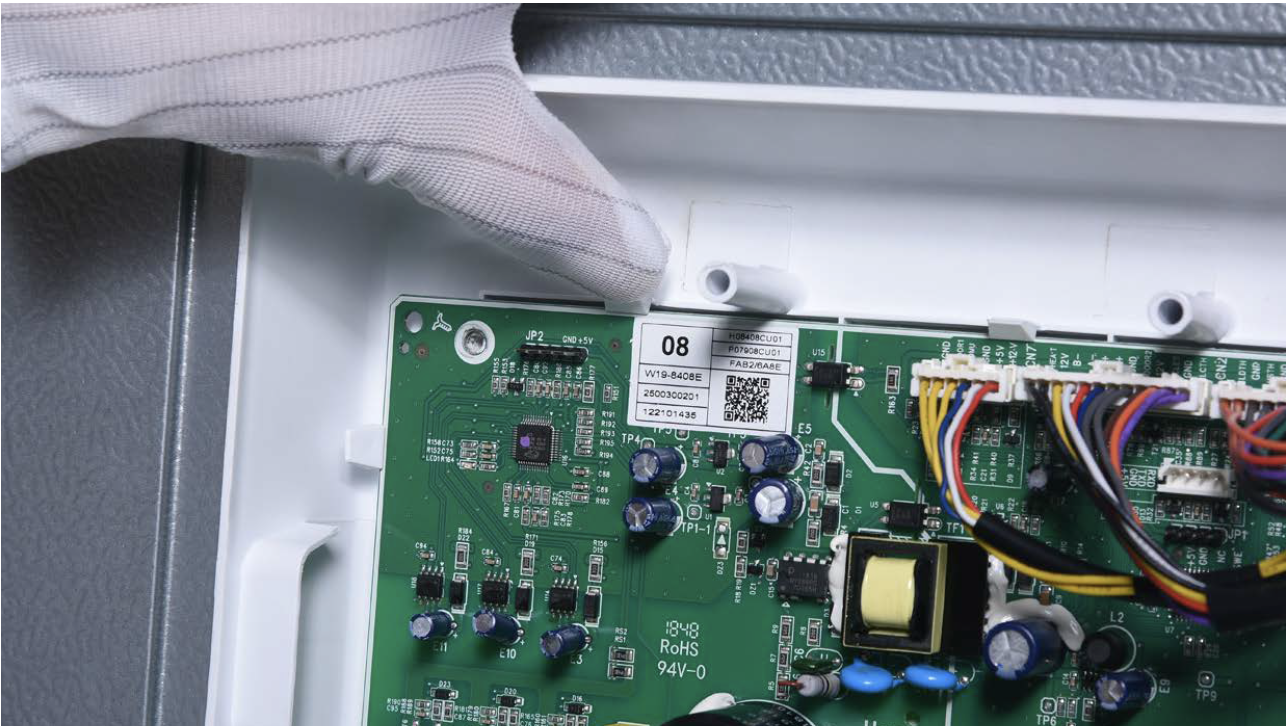

PROCEDURE 4

Step 1

Unscrew cover ofmainboard with a

Cross-head screwdriver.

Step 2

Disconnect terminals.

Step 3

Prize off earthing wires.

Step 4

Unscrew the mainboard.

Step 5

Prize off the buckle toremove mainboard.

PROCEDURE 5

CHECK AND TEST 5

Tip 1

When restoring the upper freezer air duct,fasten the wires to avoid crushing them with air

duct.

Tip 2

All buckles should be pushed into proper finalposition. If not, please repeat installation.