CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

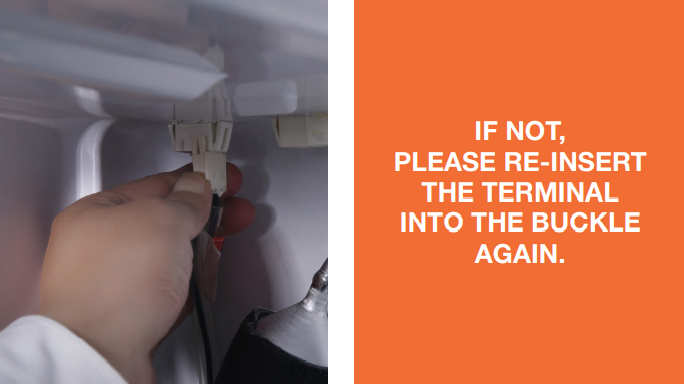

Step 2

Check if terminal in PCB area is pushed to final position. If not, reinsert it to final position.

Step 3

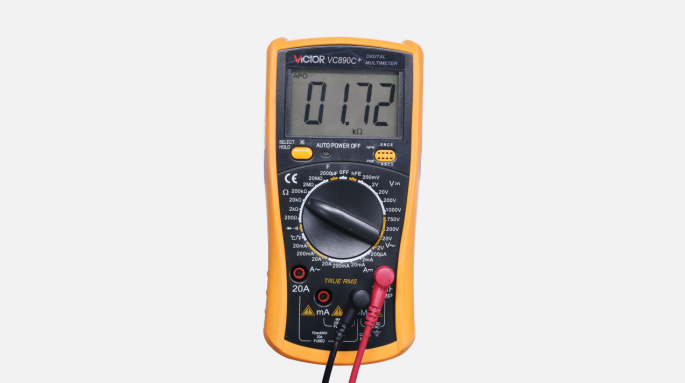

Set multimeter to

resistance gear.

Step 4

In PCB area, measure the resistance of defrost temp. sensor with a multimeter.

.

Step 5

Take note of the value.

Step 6

Measure the temperature of freezer air duct, near the defrost temp. sensor. Use measured temperature to find the standard resistance value in Temperature-Resistance Chart for Sensor .

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove all shelves.

Step 2

Remove upper drawers.

Step 3

Remove bottom drawer.

Step 4

Remove drawer cover.

Step 5

Remove glass shelves under drawers.

Step 6

Prize off the decorative panel and take if off.

Step 7

Unscrew the upper air duct.

Step 8

Pull outward and take off

the upper air duct.

Step 9

Unscrew the lower airduct.

Step 10

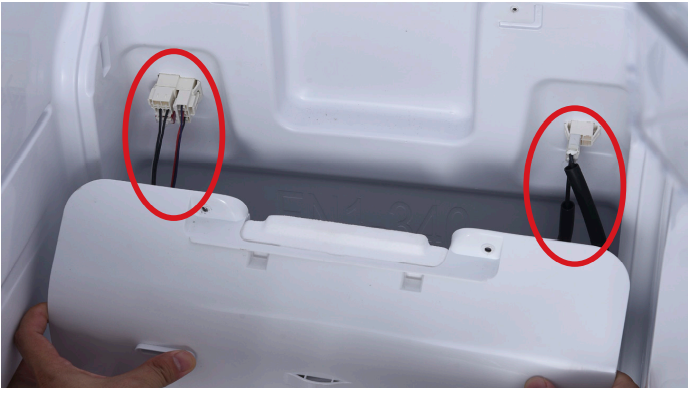

Disconnect the

connectors between

airduct and cabinet.

Step 11

Remove the lower air duct.

CHECK AND TEST 2

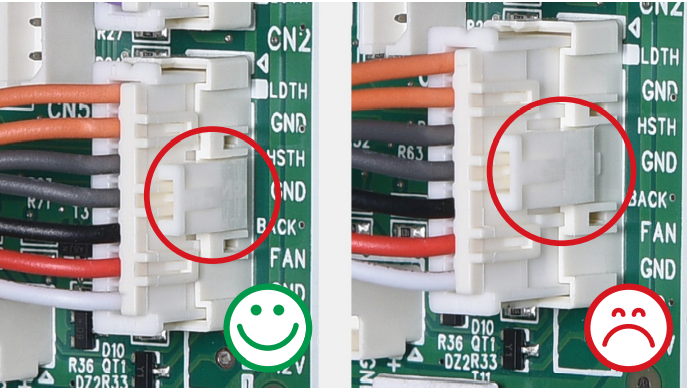

Step 1 Check if terminal is pushed properly into final position.

Step 2

Check if sensor is attached in proper position, as shown in picture. If not, correct it.

Step 3 Check if wire of defrost sensor is broken. If yes, replace it with a new one.

Step 4

Disconnect terminal of defrost temp. sensor.

Step 5

Check if the terminal is stuffed with foam.

Step 6

Measure resistance of defrost temp. sensor from terminal in freezer, and take note of it.

Step 7

Measure the temperature of defrost temp. sensor.

DIAGNOSIS 2

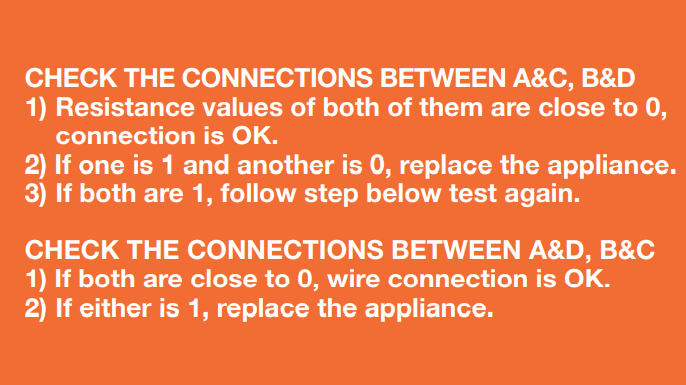

Step 2

Put detector into one end of wires in PCB area. Put another detector into end of wires behind air duct.

DIAGNOSIS 3

Tip 1

Make sure the sealing sponges are in good condition.

Tip 2

When reinstalling the air duct, fasten the wires to avoid crushing with air duct.

Tip 3

Check to see if there is a wide gap between air duct and cabinet. If there is, reinstall air duct.