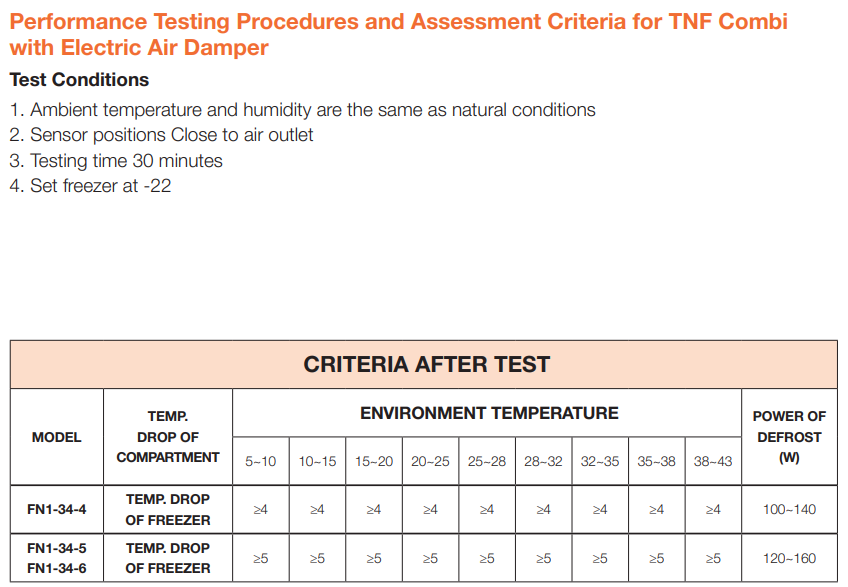

CHECK AND TEST 1

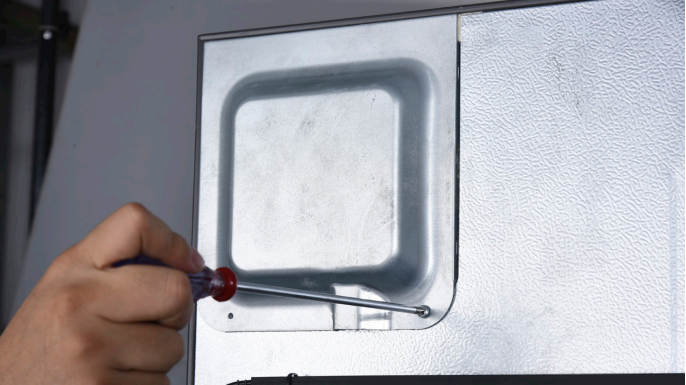

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

Check if terminal in PCB area is inserted to final position. If not, reinsert it to final position.

Step 3

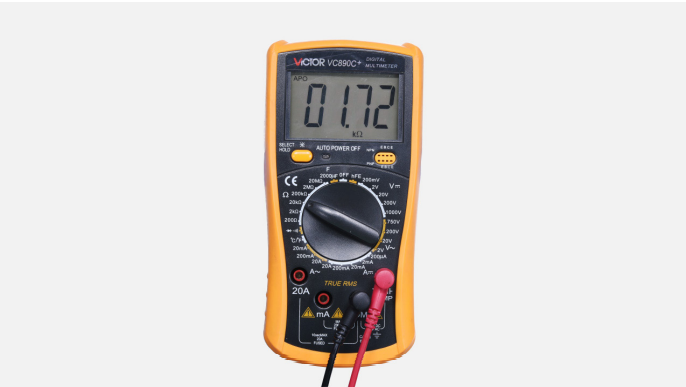

Set multimeter to resistance gear.

Step 4

In PCB area, measure the resistance of defrost temp. sensor with a multimeter.

Step 5

Take note of value. .

Step 6

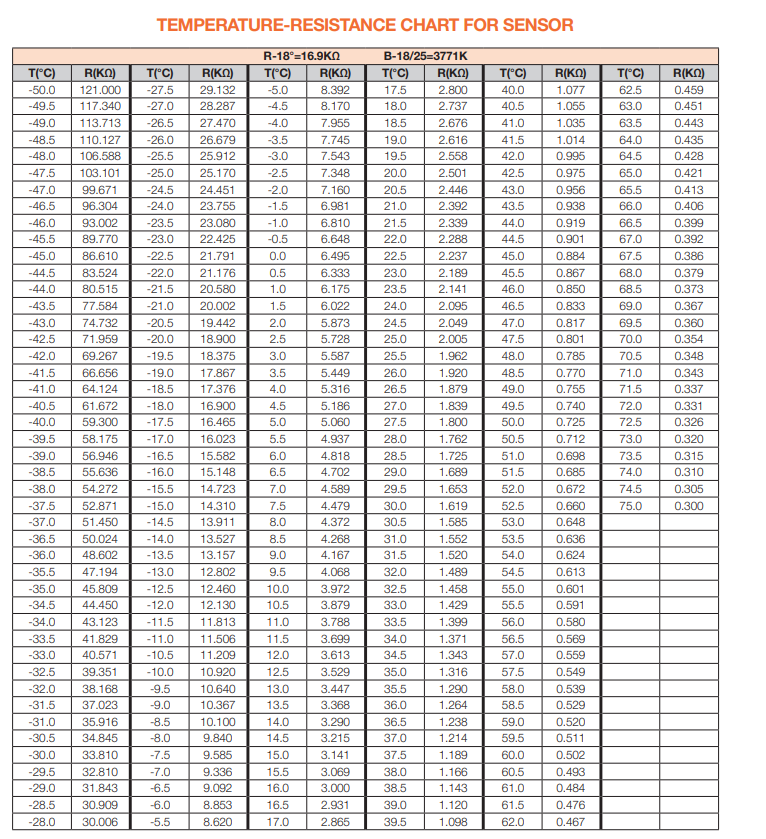

Measure temperature of freezer temp. sensor. Use the measured temperature to find the standard resistance value in Temperature-Resistance Chart for Sensor.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove all shelves.

Step 2

Remove upper drawer.

Step 3

Remove bottom drawer.

Step 4

Remove drawer cover.

Step 5

Remove glass shelves under drawers.

Step 6

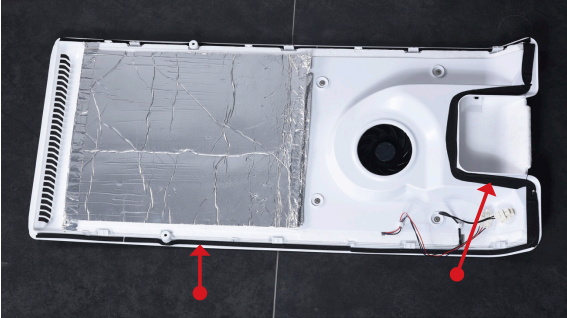

Prize off the decorative panel and take if off.

Step 7

Unscrew the upper air duct.

Step 8

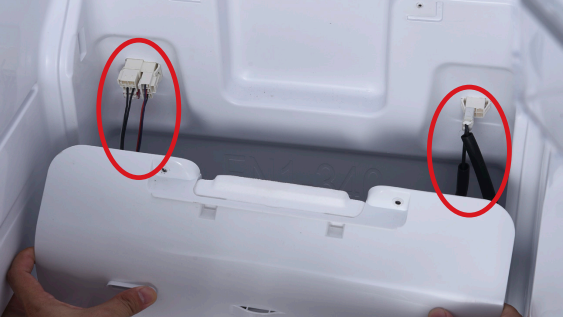

Disconnect the terminals. Pull outward and take off the upper air duct.

Step 9

Unscrew the lower airduct.

Step 10

Disconnect the connectors between airduct and cabinet.Step 11

Remove the lower air duct.

CHECK AND TEST 2

Step 1

Check if the terminal is

stuffed with foam.

Step 3

Measure resistance of freezer temp. sensor from terminal in freezer air duct cover.

Step 5

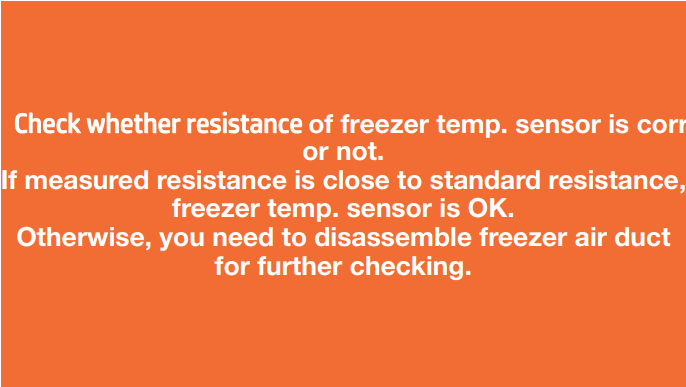

Measure temperature of freezer temp. sensor. Use the measured temperature to find the standard resistance value in TemperatureResistance Chart for Sensor.

DIAGNOSIS 2

CHECK AND TEST 3

Step 1

Set multimeter to resistance gear.

Step 2

Put detector into one end of wires in PCB area. Put another detector into end of wires behind air duct.

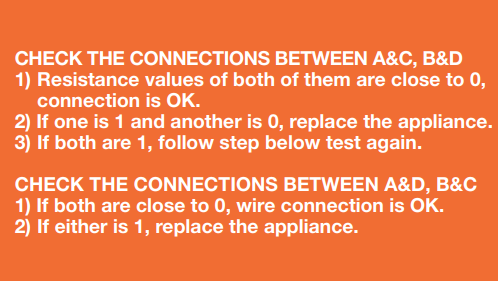

DIAGNOSIS 3

DIAGNOSIS 5