CHECK AND TEST 1

Step 1

Unscrew cover of mainboard with a Cross-head screwdriver.

Step 2

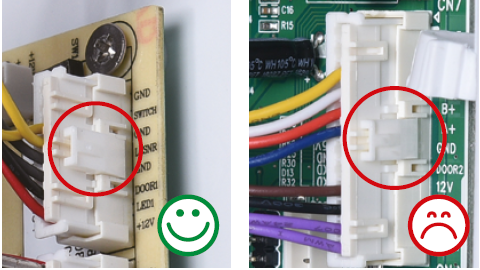

In mainboard area, check if terminal is pushed into proper final position. If not, reinsert it to final position.

Note: the photos shown are just for example, they are not actual images of the product.

Step 3

Set multimeter to resistance gear.

Step 4

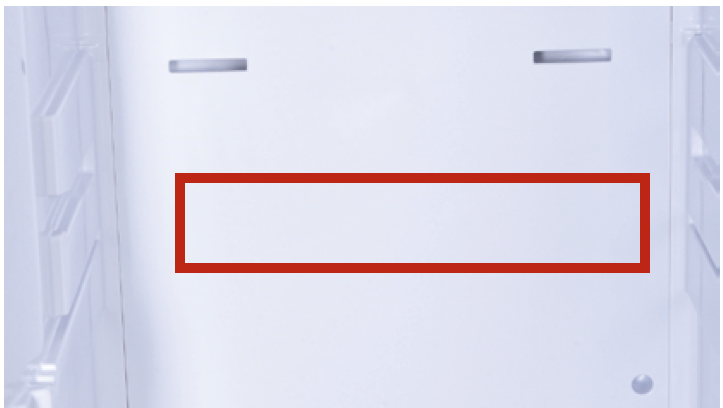

Measure resistance of fridge temp. sensor from terminal in PCB area.

Step 5

Take note of value.

Step 6

Measure the temperature of fridge temp. sensor. Use the measured temperature to find the standard resistance value in TemperatureResistance Chart for Sensor

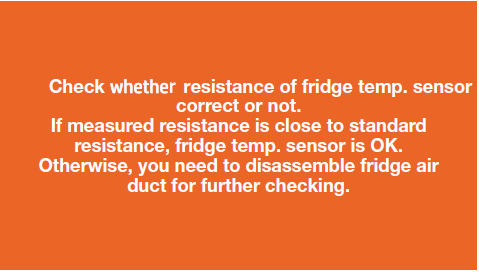

DIAGNOSIS 1

PROCEDURE 1

Step 1

Remove crispers.

Step 2

Remove shelves.

Step 3

Remove the upper air duct.

a. Prize up and remove the decorative cover.

b. Prize up the buckle on the air duct with slotted screwdriver, then remove the upper air duct

Step 4

Dismantle the air duct.a. Unscrew the screws (total four) with

Cross-head screw driver.

b. Catch the lower air duct and pull down

the air duct.

c. Pay attention to the connectors when

pulling out the air duct.

d. Disconnect the terminal for fan motor.

Disconnect the terminal for defrost sensor.

e. Move the air duct out of the fridge compartment.

CHECK AND TEST 2

Step 1

Check if terminal is inserted to final position.If not, please re-insert it to final position.

Step 2

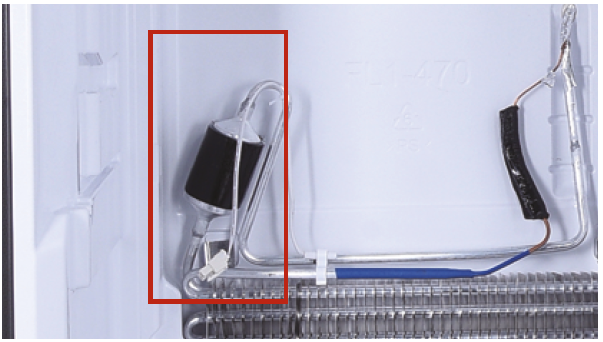

Check if sensor is attached in proper position, as shown in picture.If not, correct it.

Step 3

Check if wire of defrost sensor is broken.IF YES, REPLACE IT WITH A NEW ONE.

Step 4

Disconnect terminal of defrost temp. sensor.

Step 5

Check if the terminal is stuffed with foam.If so, use tweezers to smash it and remove.

Step 6

Measure resistance of defrost temp. sensor from terminal in fridge, and take note of it.

Step 7

Measure the temperature of defrost temp. sensor.

DIAGNOSIS 2

CHECK AND TEST 3

Step 1

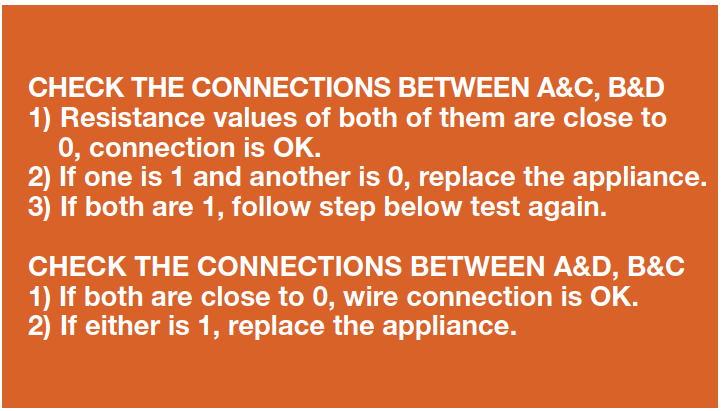

Set multimeter to resistance gear.

Step 2

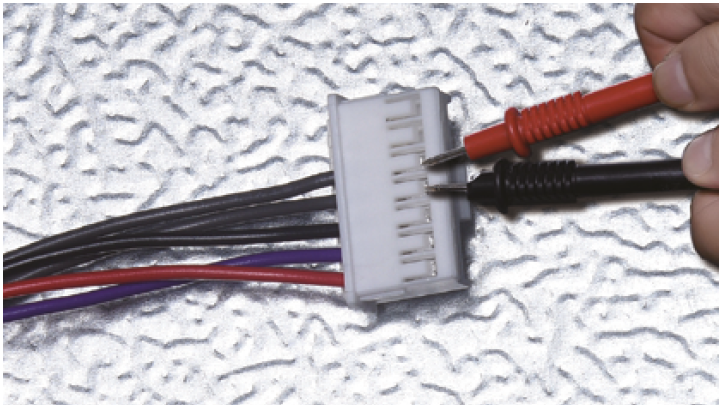

Put detector into one end of wires in PCB area.Put another detector into end of wires behind air duct.

DIAGNOSIS 3

Tip 1

Make sure the sealing sponges are in good

condition.

Tip 2

After pushing air duct into place, you should

hear clicking sounds at 8 buckle positions. If not, repeat again.

Tip 3

Check to see if there is a wide gap between air

duct and cabinet. If there is, reinstall air duct.