CHECK AND TEST 1

Step 1

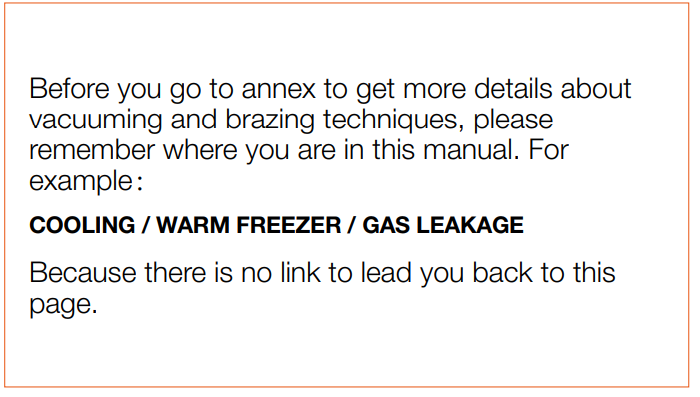

Discharge refrigerant: Use a pair of pliers to cut off the charging tube.

Step 2

Discharge all refrigerant toward the exhaust vent.

Step 3

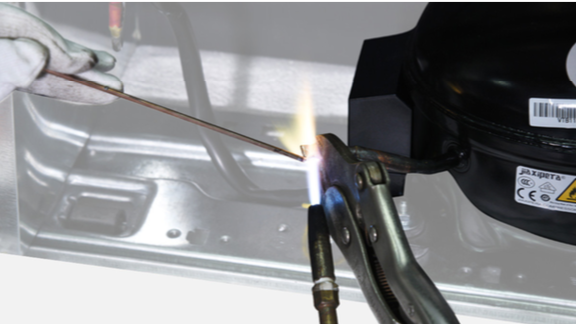

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 4

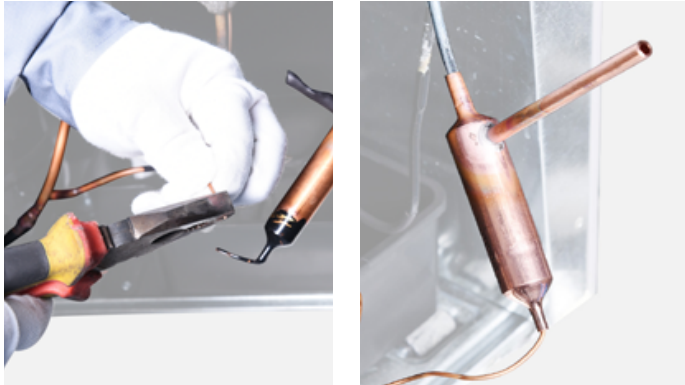

Re-braze a copper

tube onto compressor

processing tube.

Please get more details

of brazing requirements

on Annex b1

Note

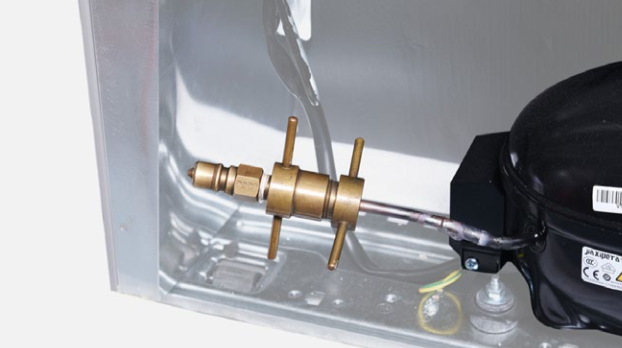

Step 5

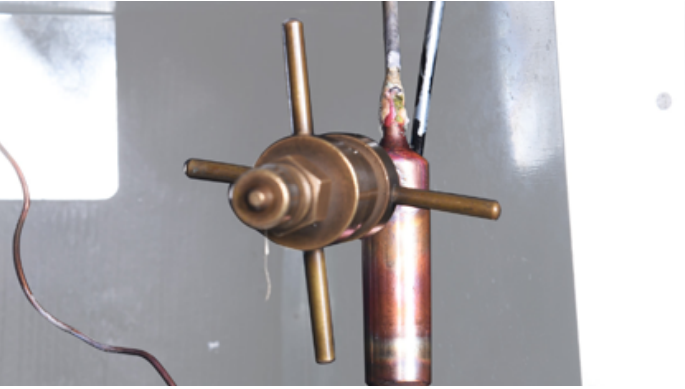

Install quick connector onto processing pipe.

Step 6

Cut off suction pipe and exhaust pipe.

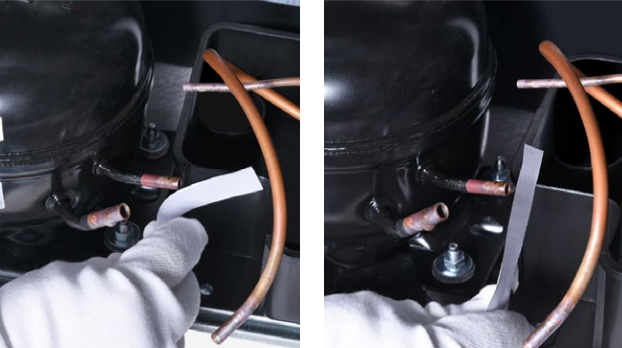

Step 7

Power up the compressor and feel the exhaust pressure from the exhaust pipe with a piece of paper.

Step 8

Feel the suction pressure of the suction pipe using a piece of paper.

DIAGNOSIS 1

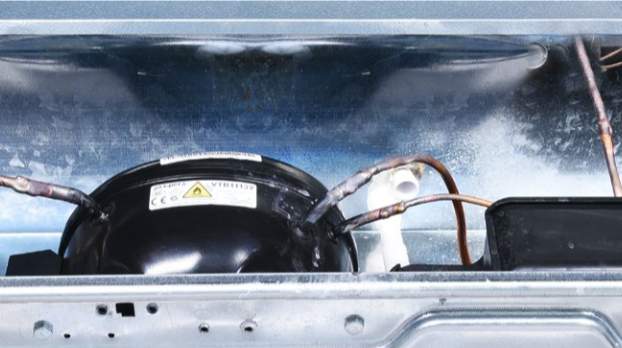

GENERAL PROCEDURES TO DISASSEMBLE THE COMPRESSOR

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover.

Step 3

Move out protector and starter.

Step 4

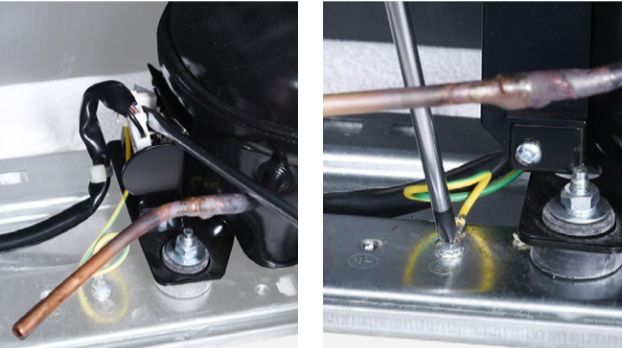

Unscrew earthing wire.

Step 5

Unscrew nut of compressor.

Step 6

Install a new compressor and tighten nuts onto compressor.

Step 7

Braze the joints of suction and exhaust pipes.

Step 8

Re-braze a copper

tube onto compressor

processing tube.

Please get more details

of brazing requirements

on Annex b1

Note

PROCEDURE 2

Step 1

Clean away paint on brazed joint of drying-filter.Step 2

Cut off drying-filter.

Step 3

Cut off capillary and shake to remove the cut end.Step 4

Braze on a new drying-filter.

Step 5

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 6

Add quick connector onto processing pipe of drying-filter.

Step 7

Perform leakage test on brazed joints of dryingfilter and compressor processing pipe.

Step 8

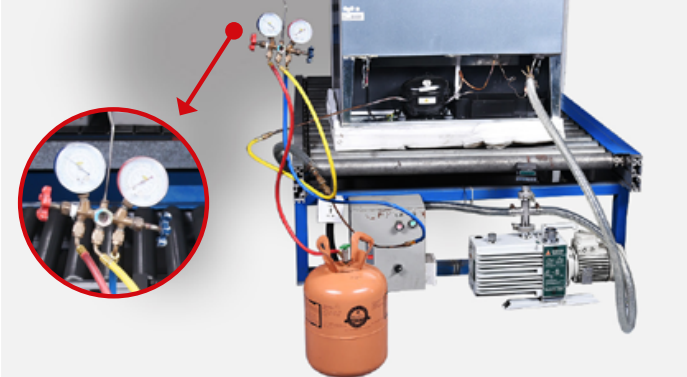

Vacuum and recharge.

Step 9

Block processing pipe twice by locking pliers.

Step 10

Leave locking pliers on the second block and cut off the rest pipe by shaking.

Step 11

Braze the ends and remove the pliers.

CHECK AND TEST 2