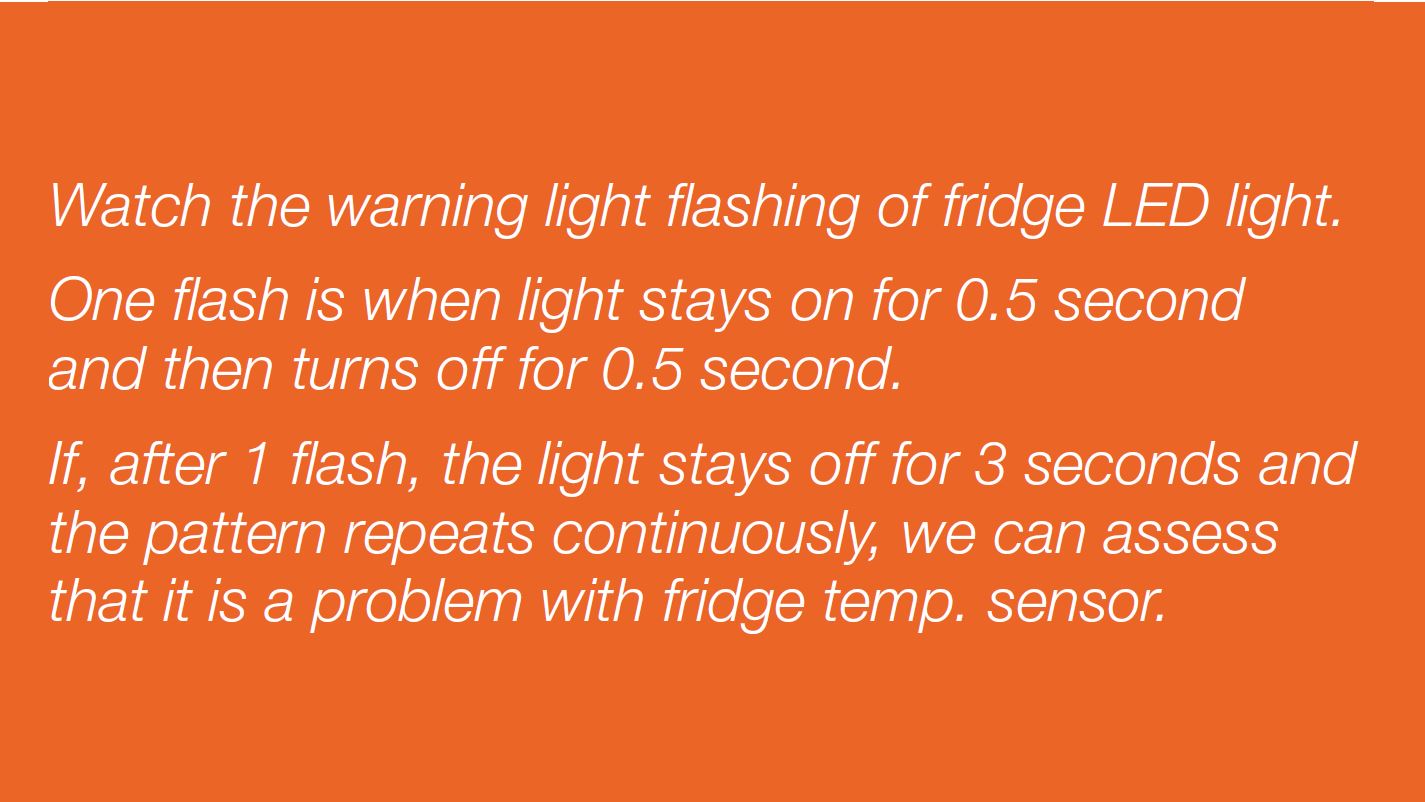

CHECK AND TEST 1

Step 1

Check the flashing

times of LED.

Note

DIAGNOSIS 1

CHECK AND TEST 2

Step 1

Unscrew cover of

mainboard with a

Cross-head screwdriver.

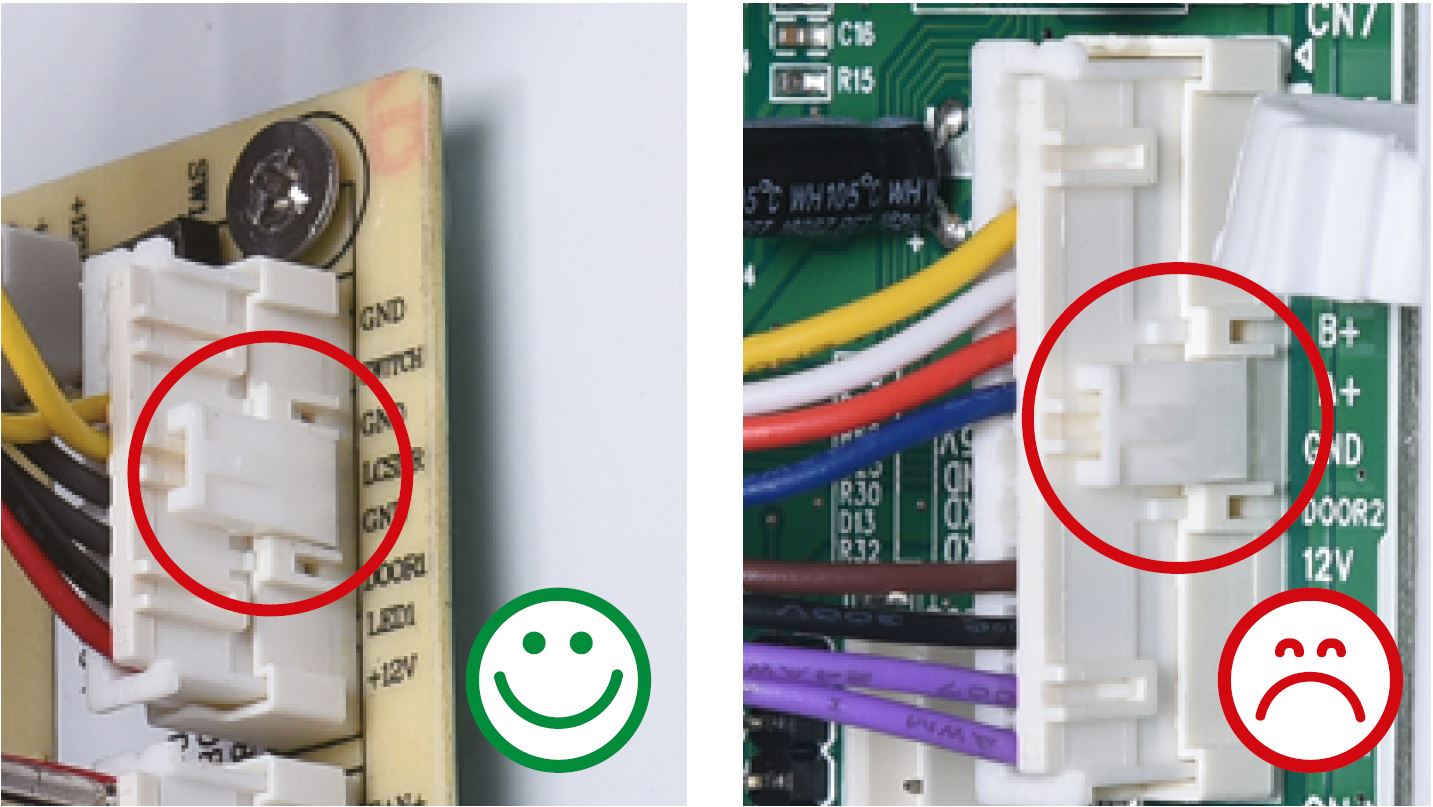

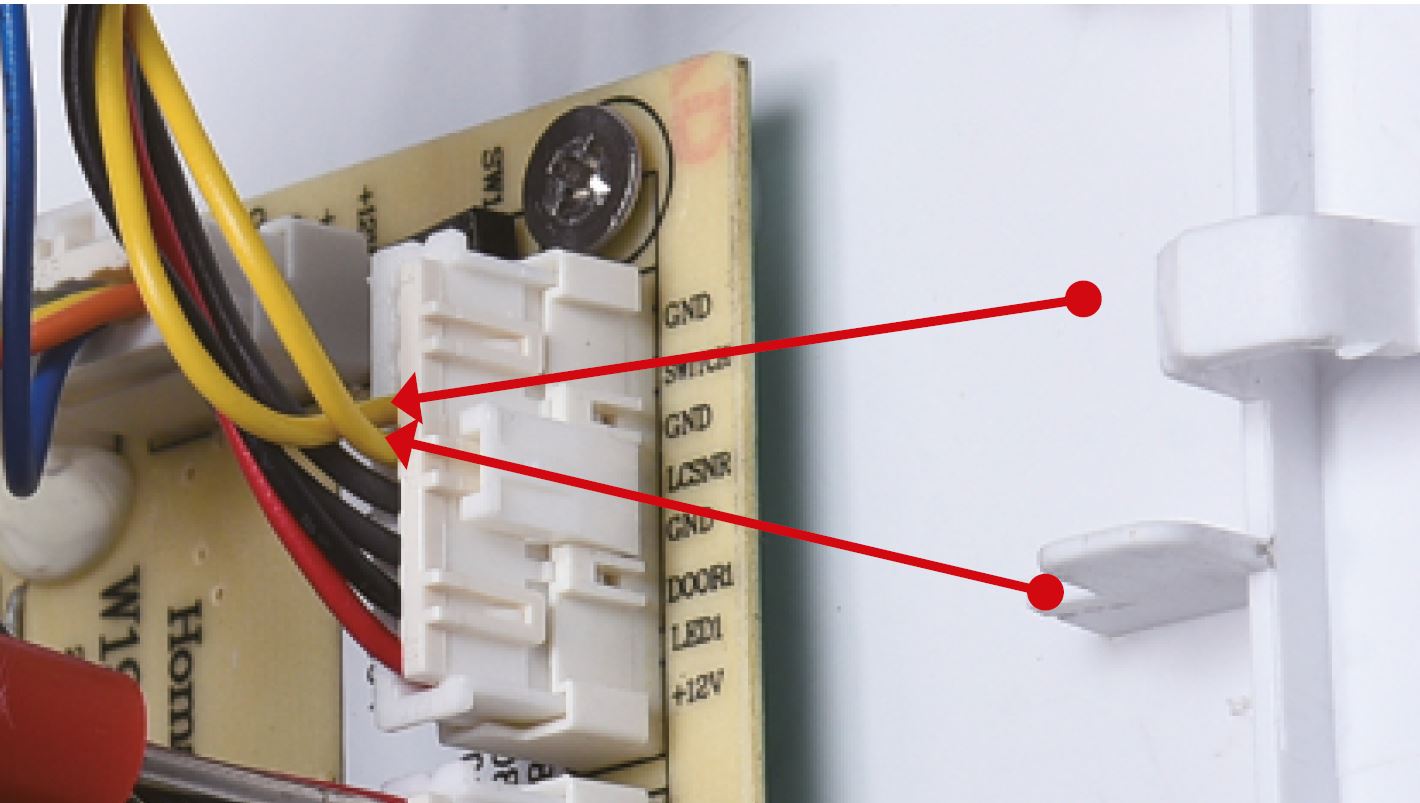

Step 2

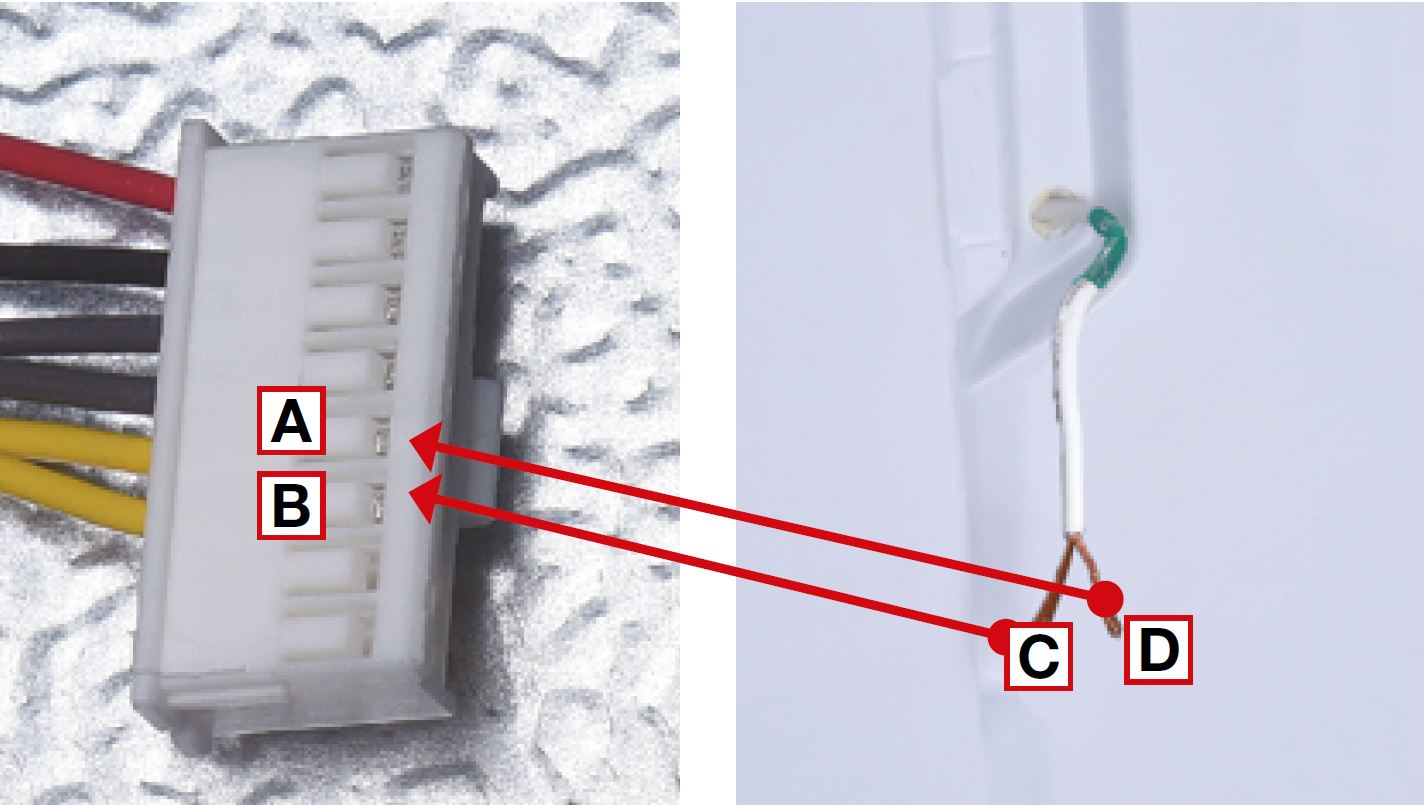

In mainboard area, check

if terminal is pushed into

proper final position.

Note: the photos shown

are just for example,

they are not actual

images of the product.

Step 3

Set multimeter to

resistance gear.

Step 4

Measure resistance of

fridge temp. sensor from

terminal in PCB area.

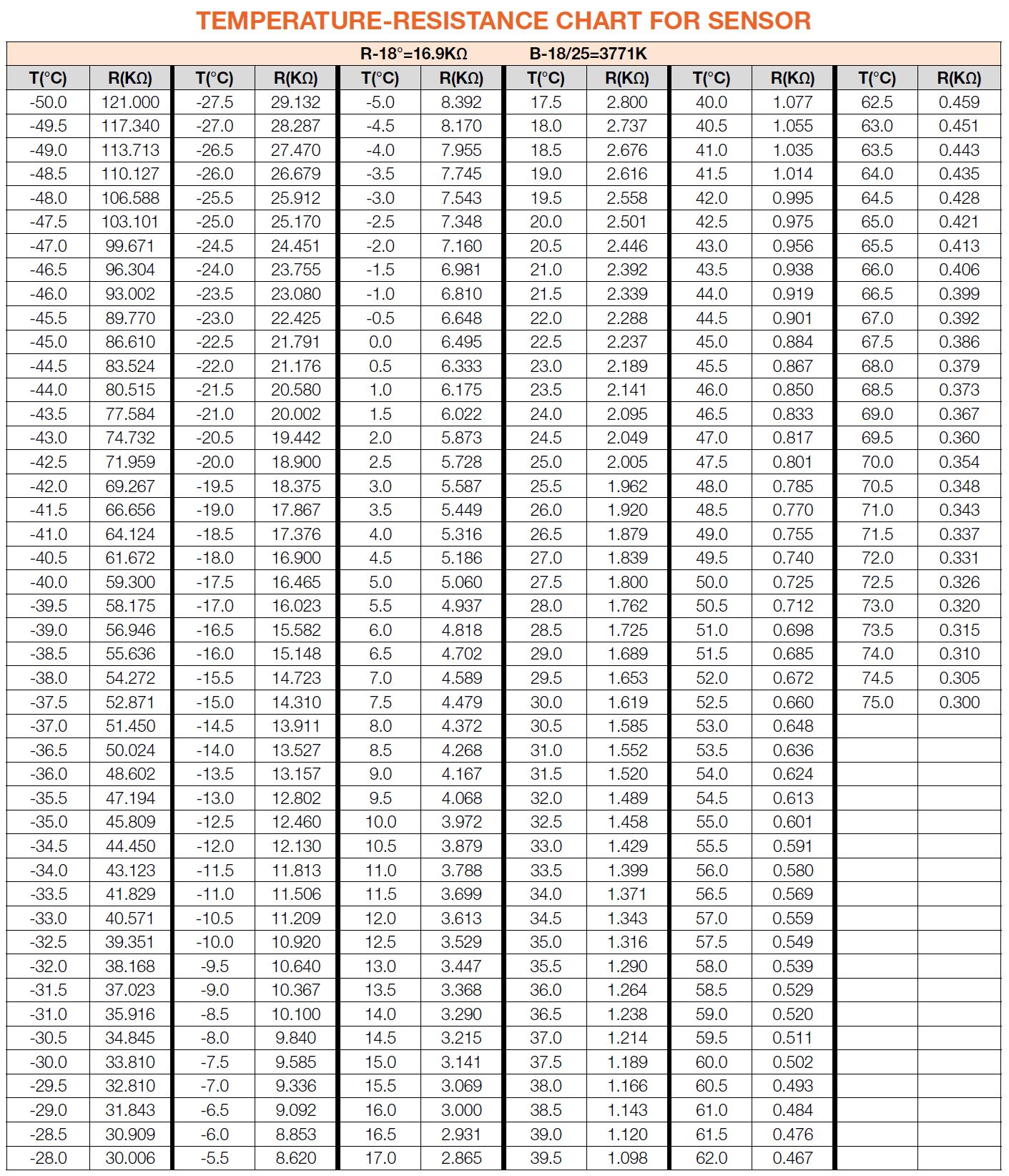

Step 5

Take note of value.

Step 6

Measure the temperature

of fridge temp. sensor.

Use the measured

temperature to find the

standard resistance

value in Temperature-

Resistance Chart for

Sensor.

DIAGNOSIS 2

PROCEDURE 1

Step 1

Remove crispers.

Step 2

Remove shelves.

Step 3

Remove the upper air

duct.

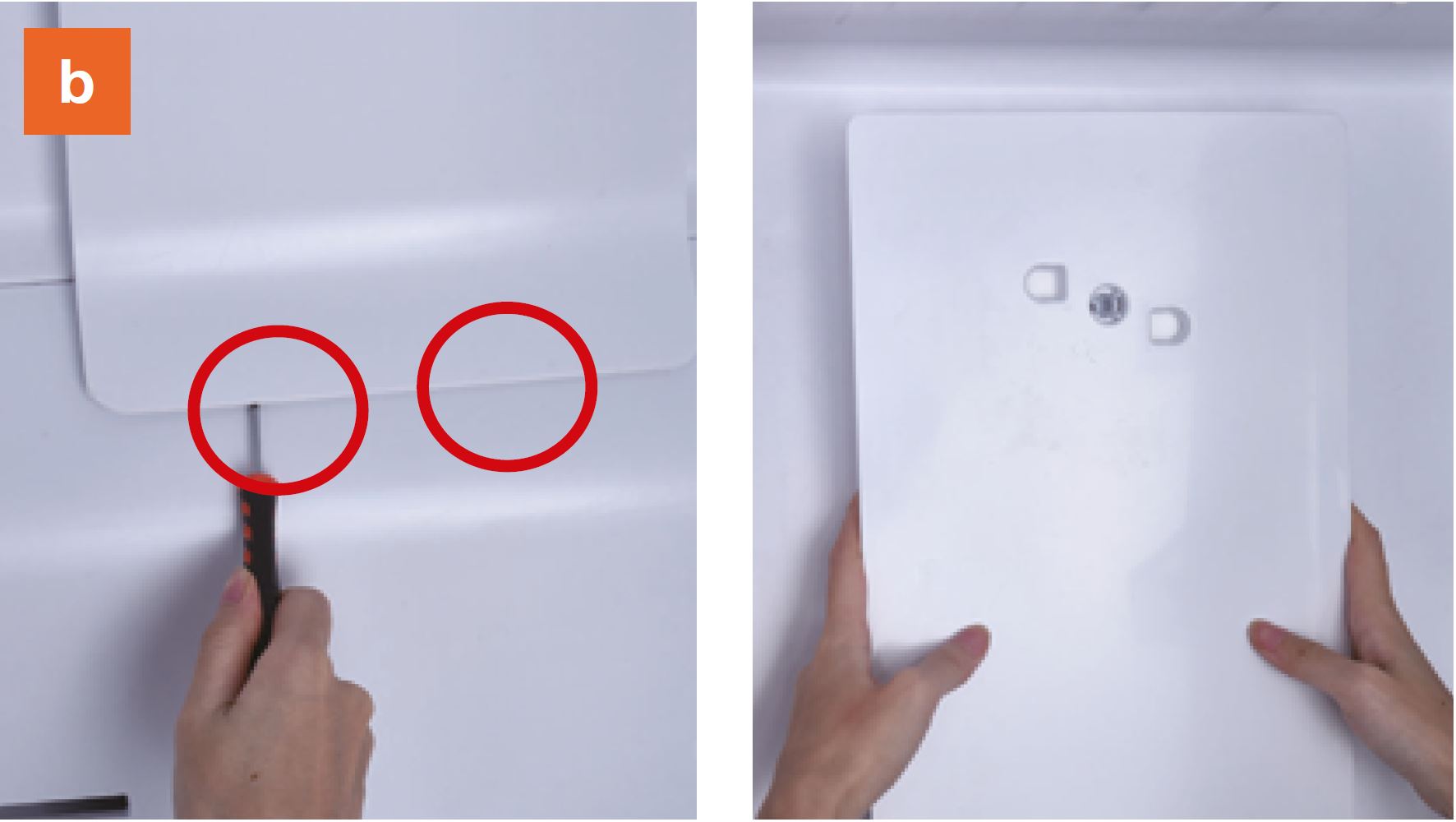

a. Prize up and remove

the decorative cover.

b. Prize up the buckle

on the air duct with slotted

screwdriver, then remove

the upper air duct.

CHECK AND TEST 3

Step 1

Check if wires of fridge

temp. sensor are

damaged or not.

if yes, reconnect it.

Step 2

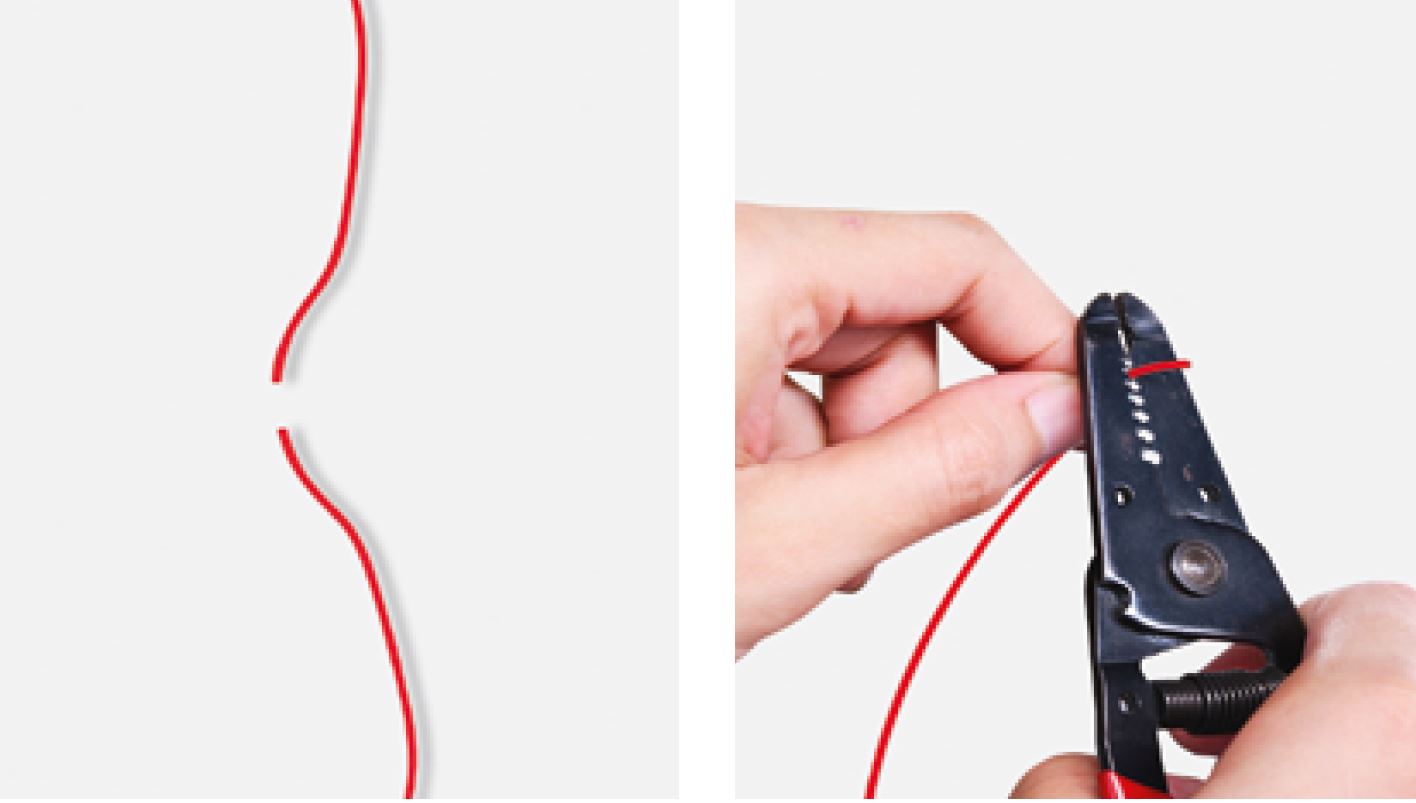

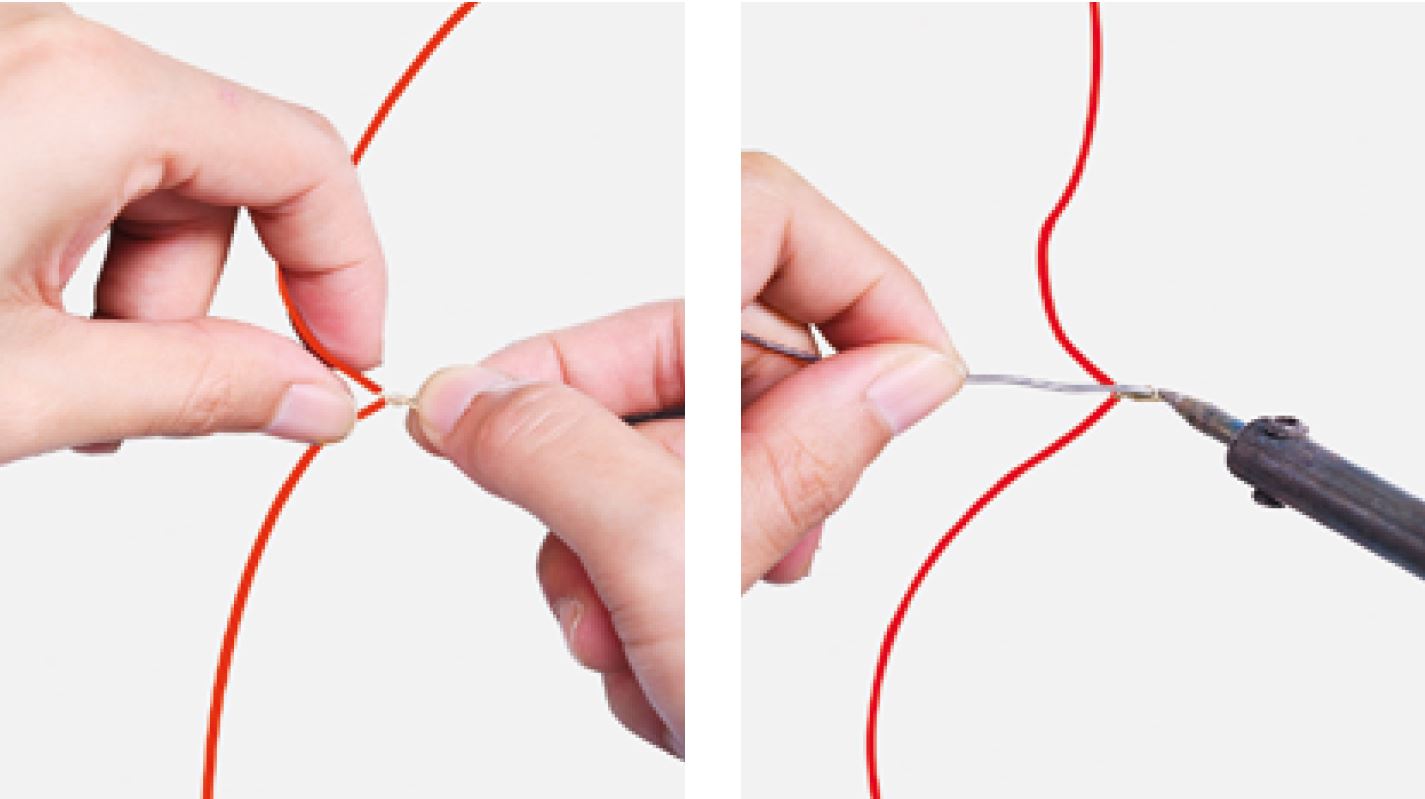

Cut off wires.Step 3

Measure the resistance of

fridge sensor from terminal

in fridge air duct cover and

record the value.

DIAGNOSIS 3

PROCEDURE 2

Step 1

Cut wire off.Step 2

Peel off the sleeves.

Step 3

Check to ensure proper

wire order and reconnect

them.

Step 4

Tin soldering.

Step 5

Cover connecting point

with electrical tape.

CHECK AND TEST 4

Step 1

Set multimeter to

resistance gear.

Step 2

Put one detector into

one end of wires in

PCB area, and another

detector into one end of

wires in fridge air duct

cover.

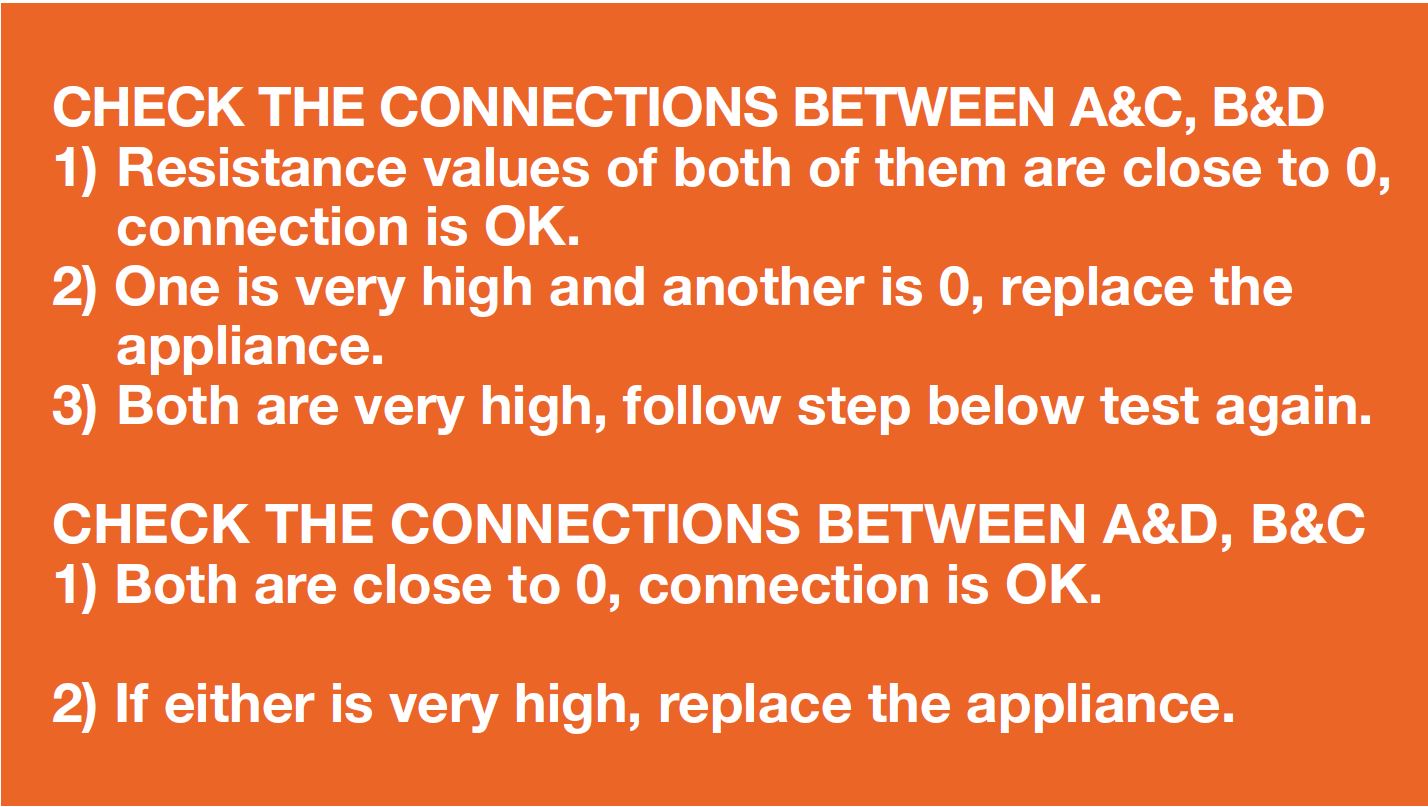

DIAGNOSIS 5

PROCEDURE 3

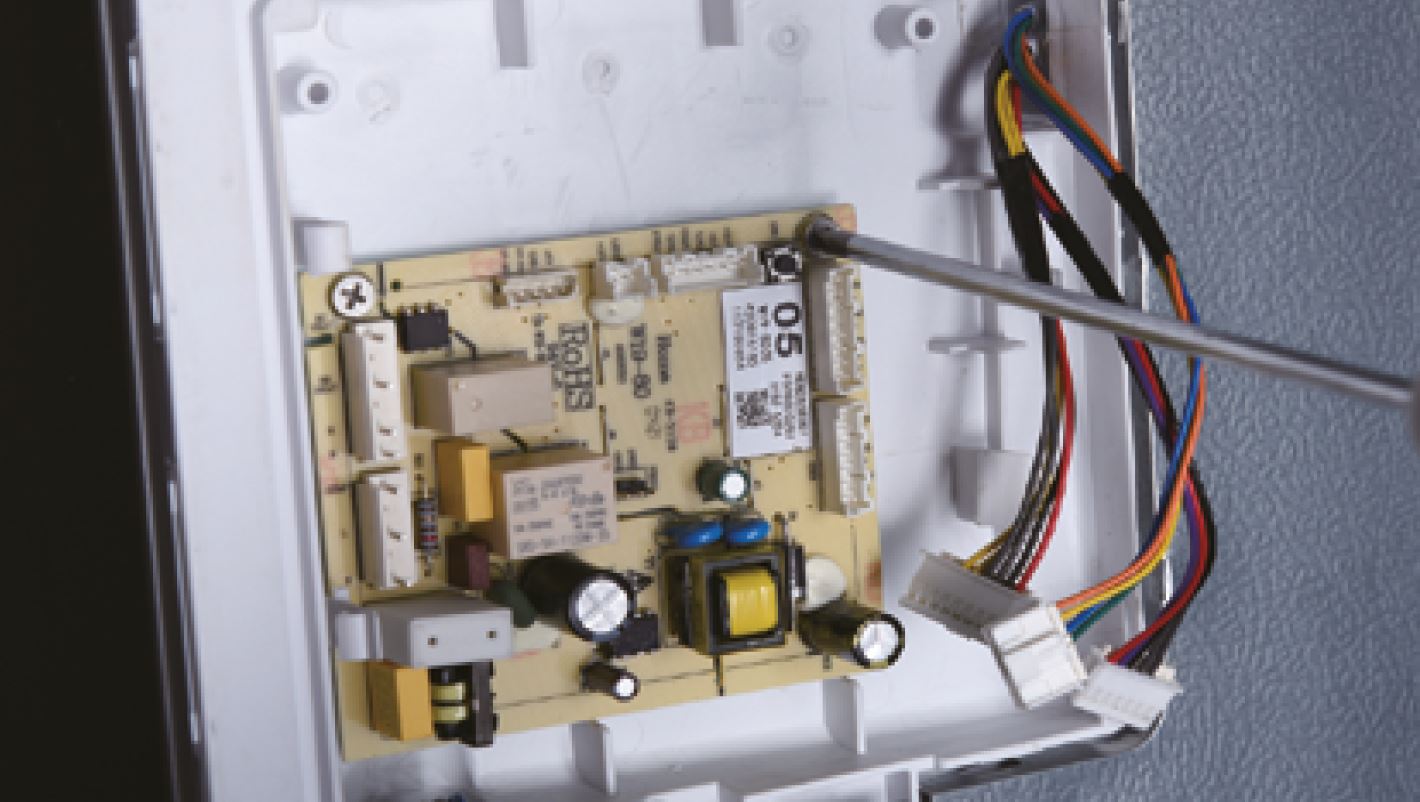

Step 1

Unscrew cover of

mainboard with a

Cross-head screwdriver.

Step 2

Disconnect terminals.

Step 3

Prize up the buckle and

disconnect the terminal.

Step 4

Unscrew the mainboard.

Step 5

Remove the mainboard.

Reverse steps above

to install a new

mainboard.

DIAGNOSIS 6