Step 2

Take note of measured value.

NOTE

Voltage between any two phases should be the same (100V~200V).

Step 3

Put hand onto compressor for a few minutes to feel if compressor is jammed or not.

DIAGNOSIS 1

CHECK AND TEST 2

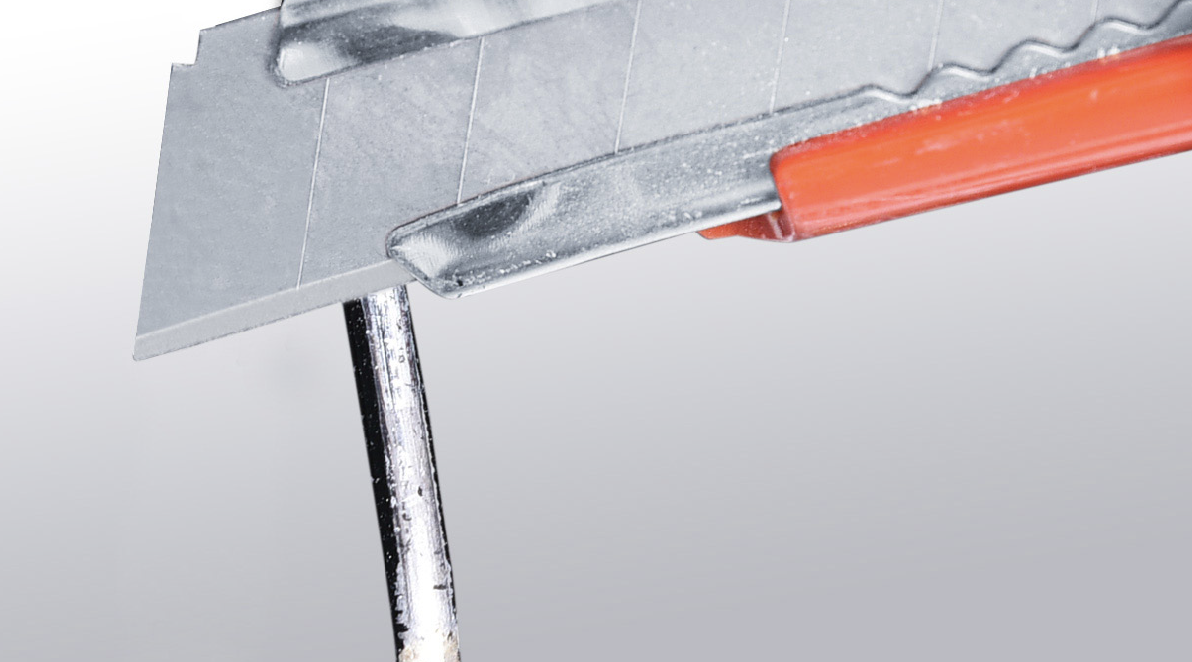

Step 1

Cut off capillary to discharge refrigerant.

Step 2

Cut off exhaust pipe and suction pipe.

Step 3

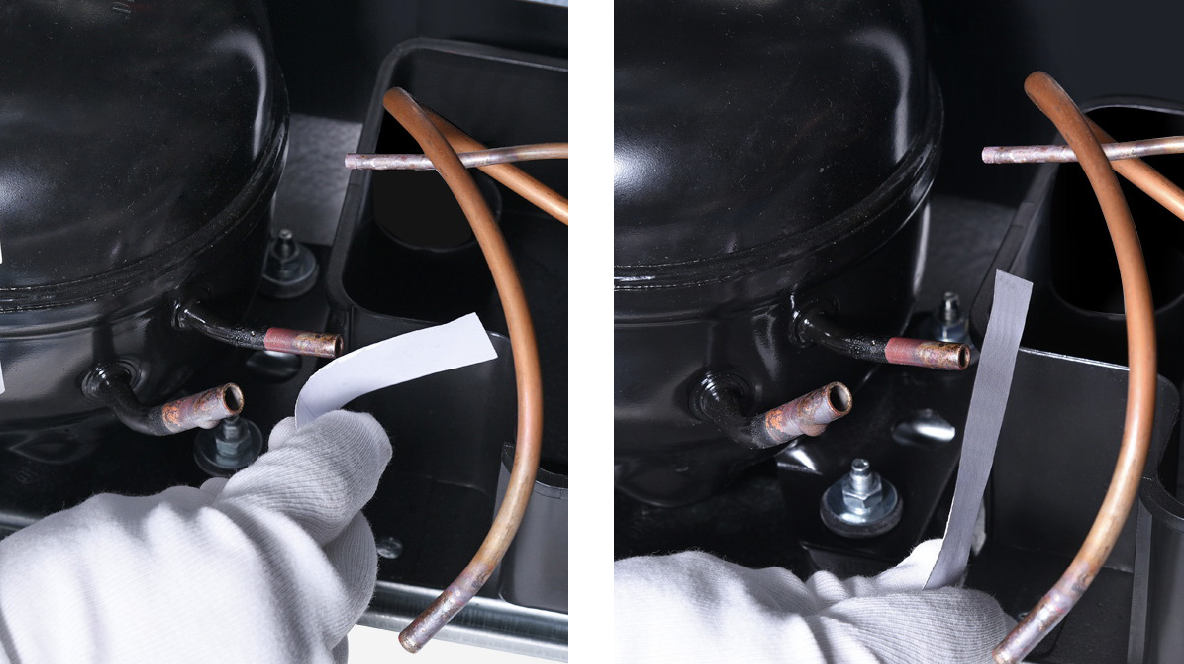

Power on the compressor and test exhaust pressure coming from exhaust pipe with a piece of paper.

DIAGNOSIS 2

PROCEDURE 1

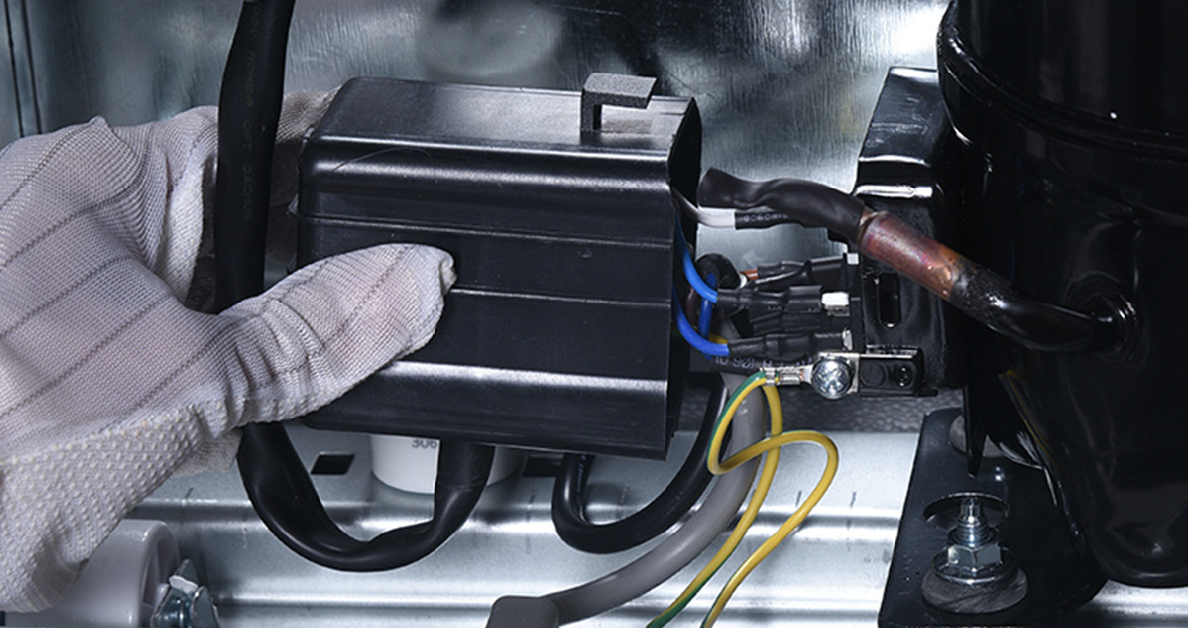

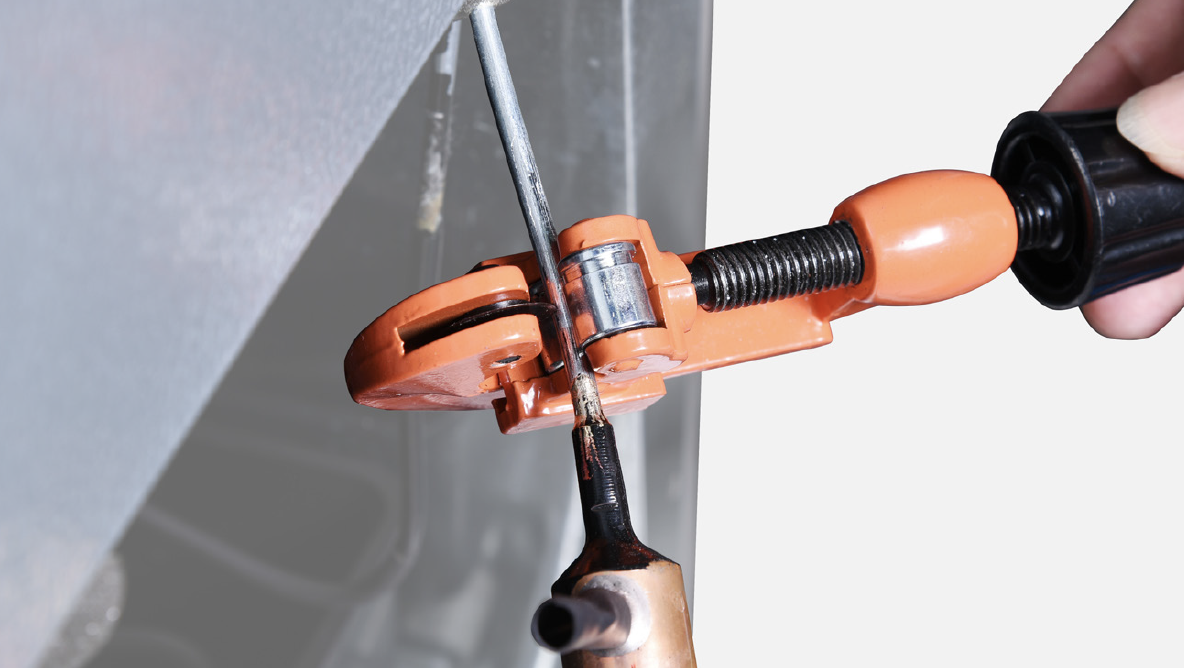

Step 1

Open the metal clasp.

Step 2

Remove terminal cover.

Step 3

Disconnect all terminals.

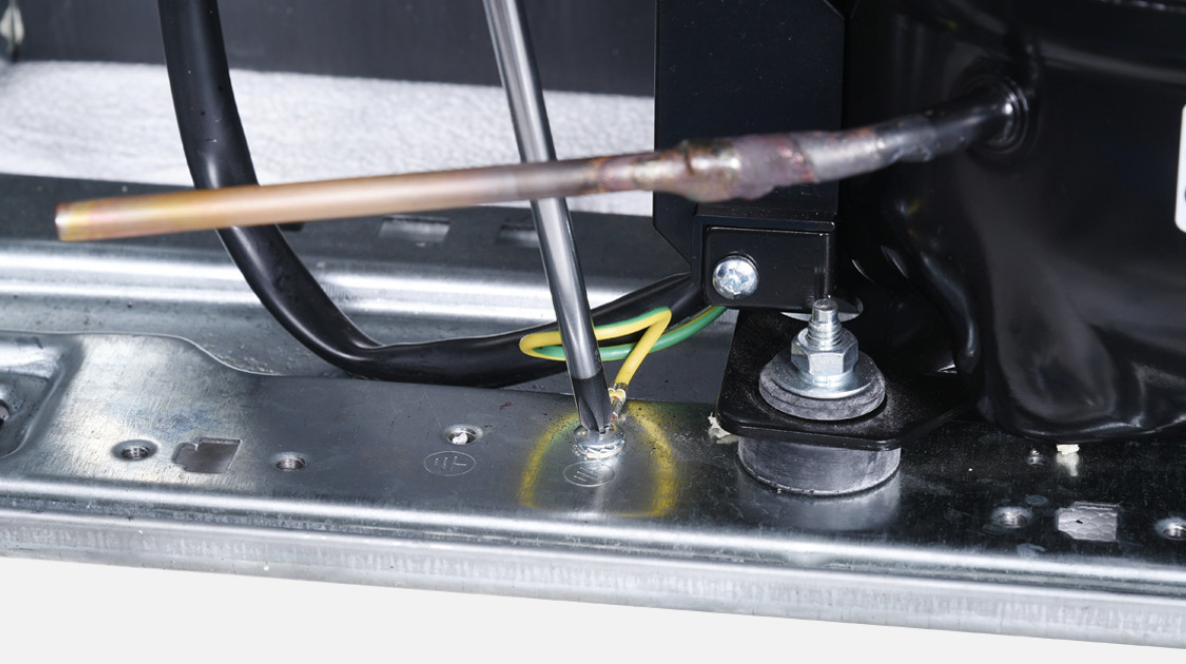

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut of compressor

Step 6

Install a new compressor on top.

Step 7

Braze the joints of suction and exhaust pipes.

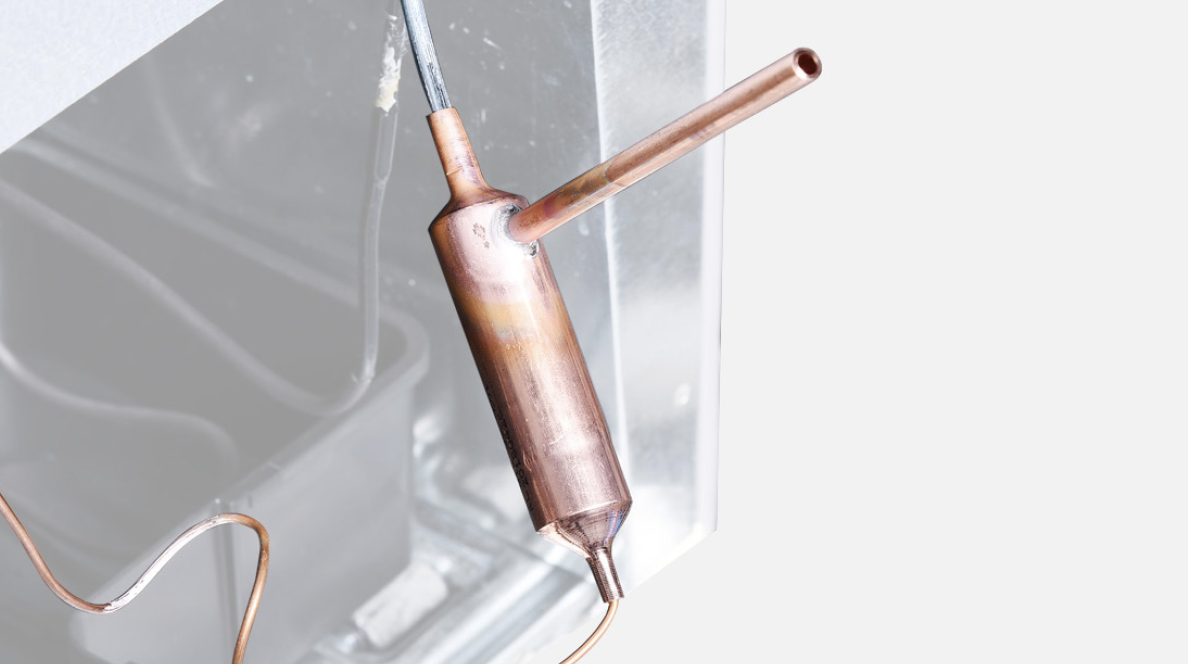

Step 8

Re-braze a copper tube onto processing tube of compressor.

Please find more details of brazing requirements, on Annex B1

NOTE

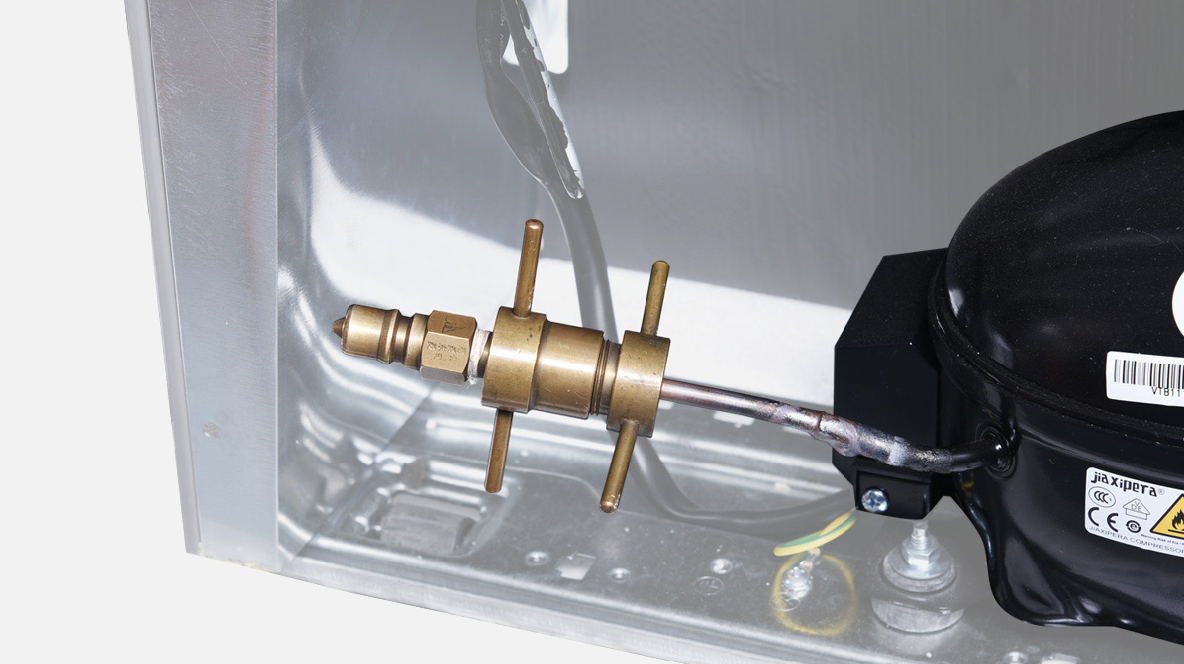

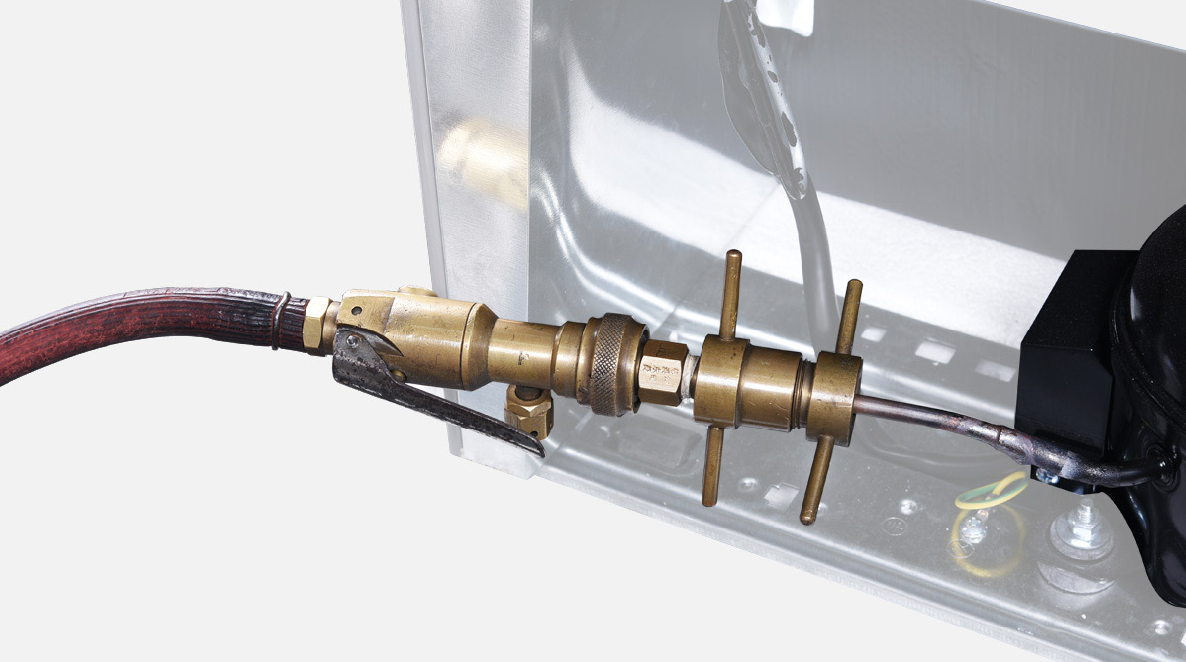

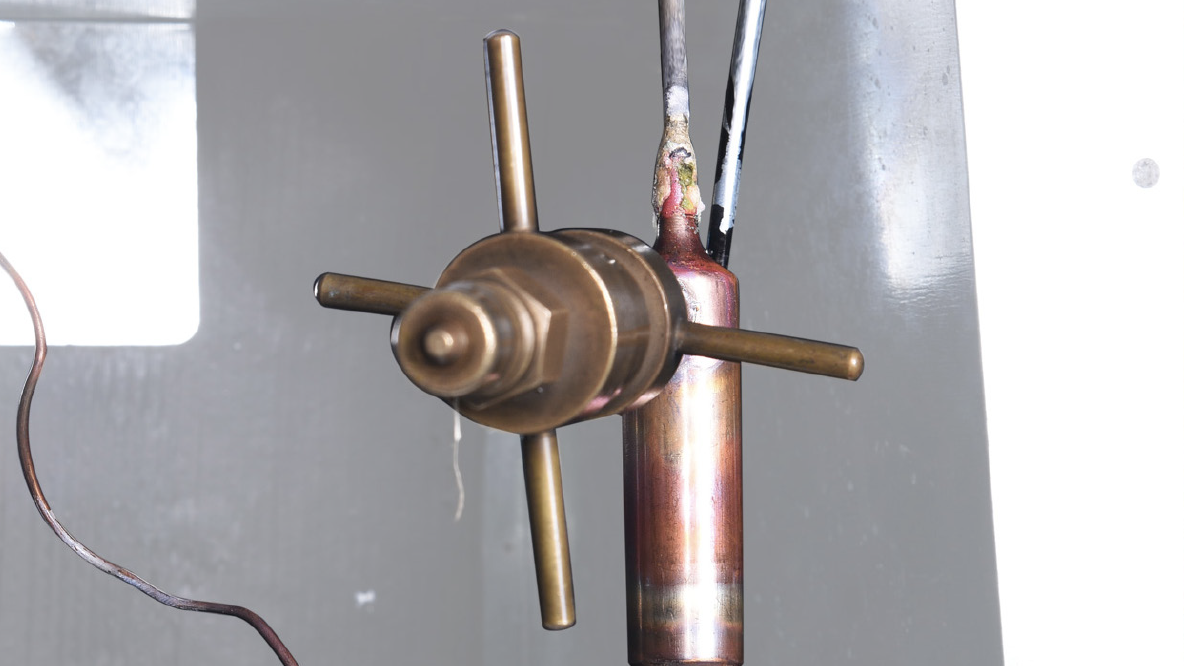

Step 9

Install quick connector onto re-brazed pipe.

Step 10

Clean paint off of brazed joint of drying filter.

Step 11

Cut off the brazed joint of drying filter.

Step 12

Cut off capillary and remove the cut end by shaking.

Step 13

Braze a new drying-filter.

Step 14

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 15

Add quick connector onto processing pipe of drying-filter.

Step 16

Test for leaks on brazed joints of drying-filter and processing pipe on compressor

Step 17

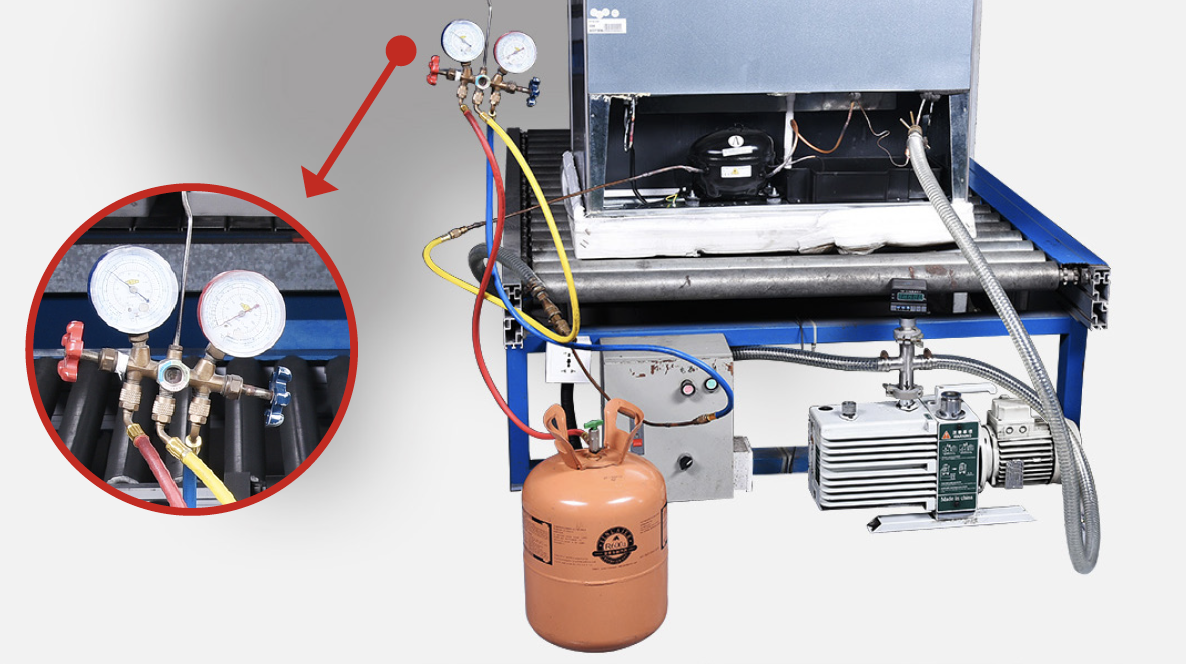

Vacuum and recharge.

Click below link to get more details for vacuuming and gas-charging requirements, on Annex B2

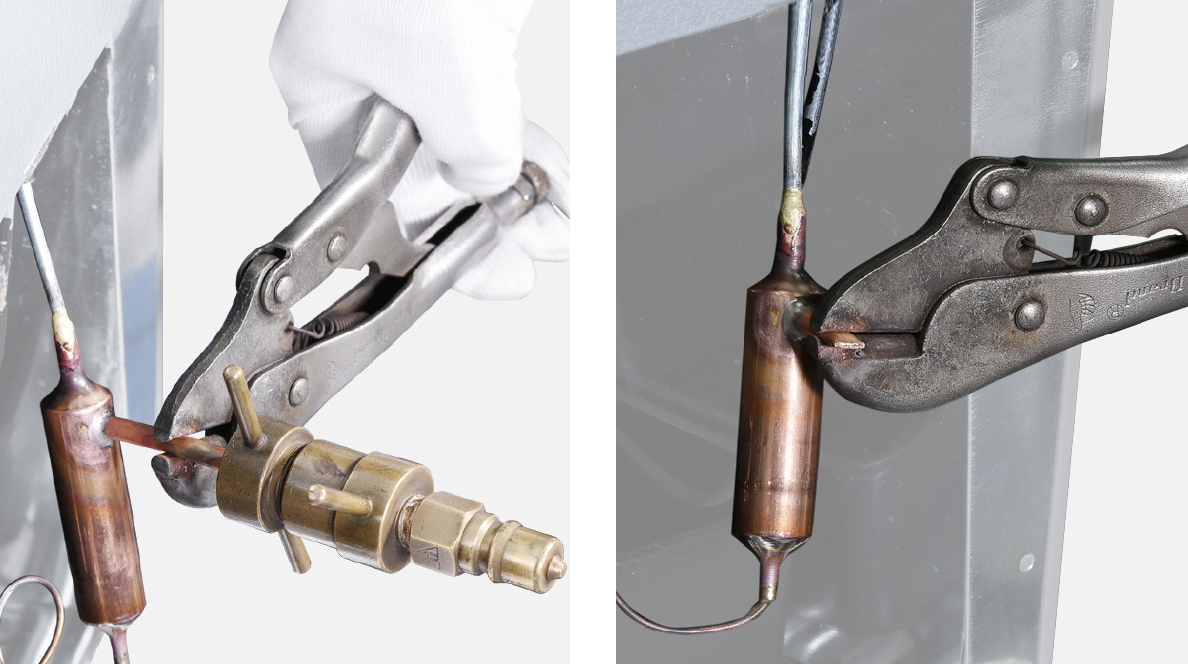

Step 18

Block processing pipe twice by locking pliers.

Step 19

Leave locked pliers attached to second block and shake to cut off the remaining pipe.

Step 20

Braze the ends and remove the pliers away.

Please find more details of brazing requirements, on Annex B1

NOTE

CHECK AND TEST 3

DIAGNOSIS 3