Step 2

Discharge all refrigerant toward the exhaust vent.

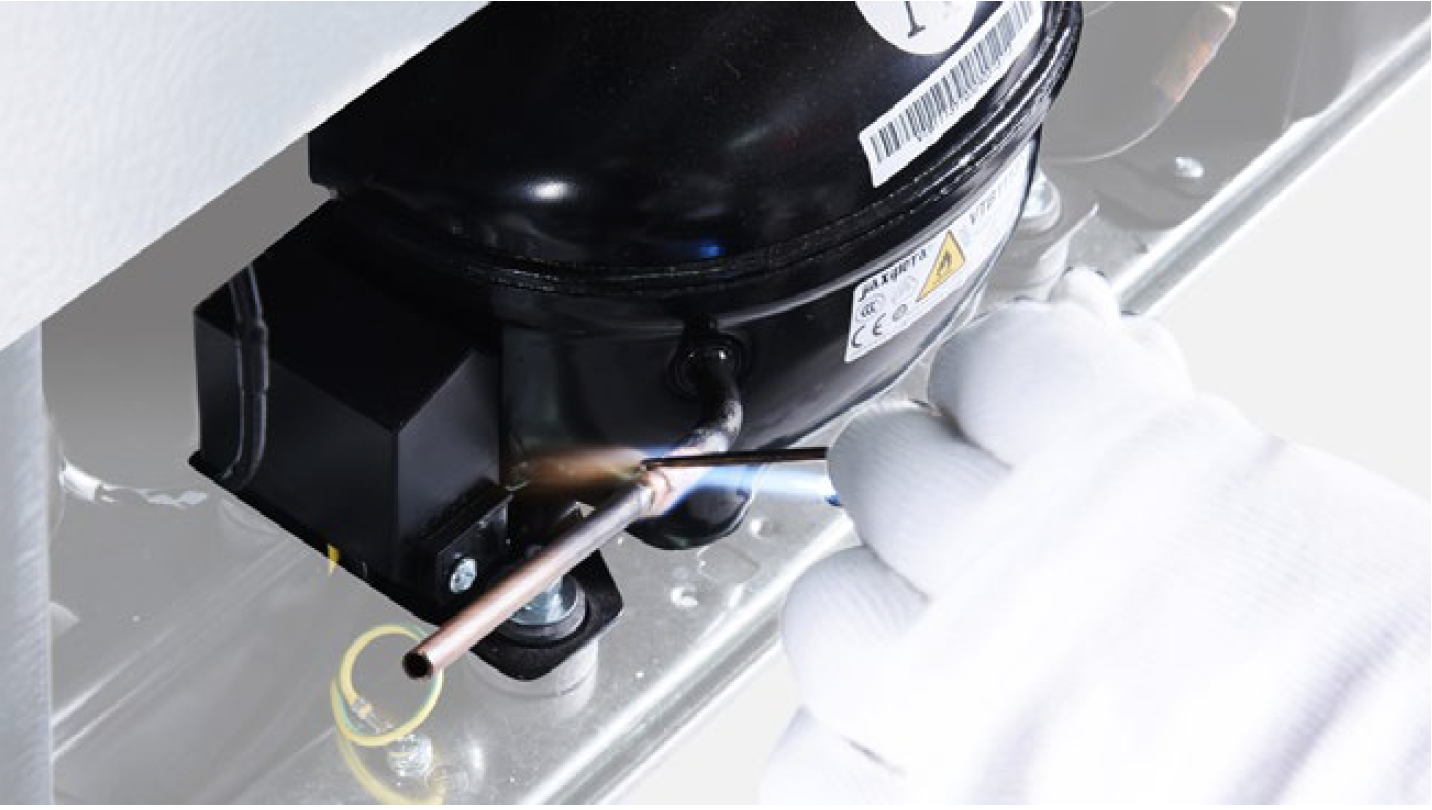

Step 3

Melt brazing material with flame and pull processing tube out with a pair of pliers.

Step 4

Re-braze a copper tube onto processing tube of compressor. To get more details on brazing requirements

NOTE

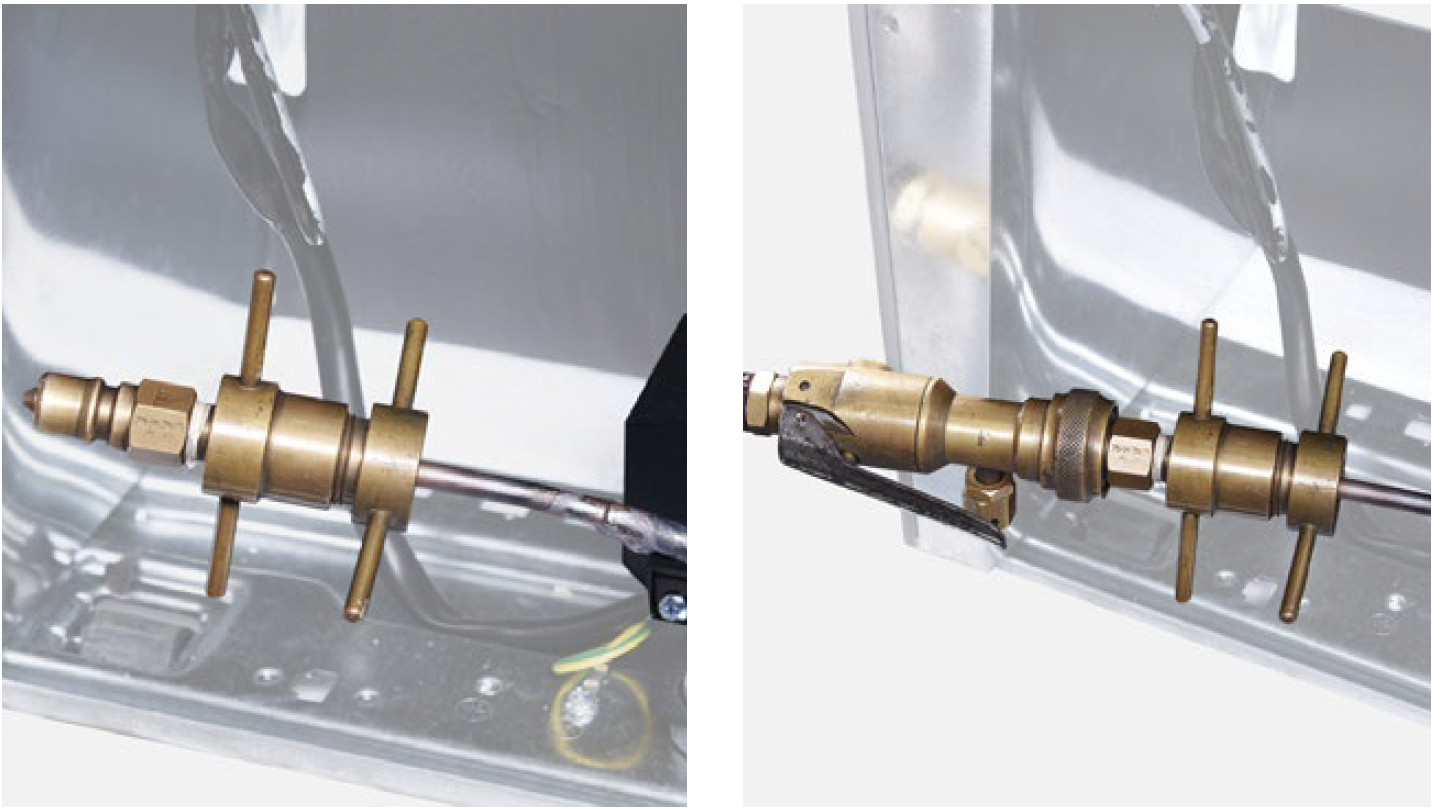

Step 5

Install quick connector onto re-brazed pipe.Step 6

Inject nitrogen gas with 1.57Mpa pressure through quick connector into pipe.

Step 7

Use pliers to cut the capillary off.

Step 8

Check to see if gas is blowing out of capillary.

Step 9

Block the end of filter to blow capillary for at least 3 min.

DIAGNOSIS 1

PROCEDURE 1

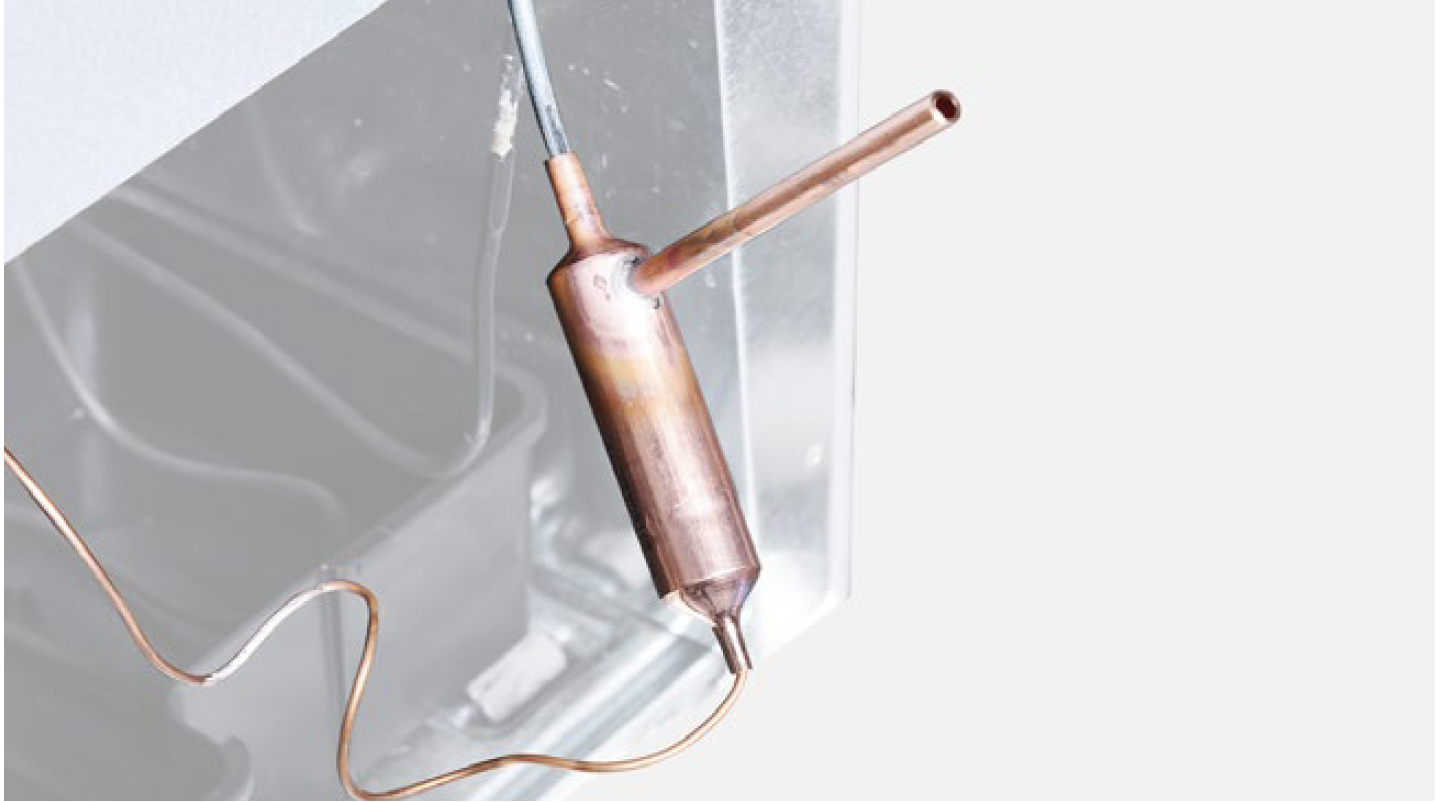

Step 1

Clean paint off of brazed joint of drying filter.

Step 2

Cut off the brazed joint of drying filter.

Step 3

Cut off capillary and remove the cut end by shaking.

Step 4

Braze on.

Step 5

Add quick connector onto processing pipe of drying-filter.

Step 6

Inject nitrogen (1.57Mpa)

through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 7

Perform leakage test on brazed joints of drying- filter and processing pipe on compressor.

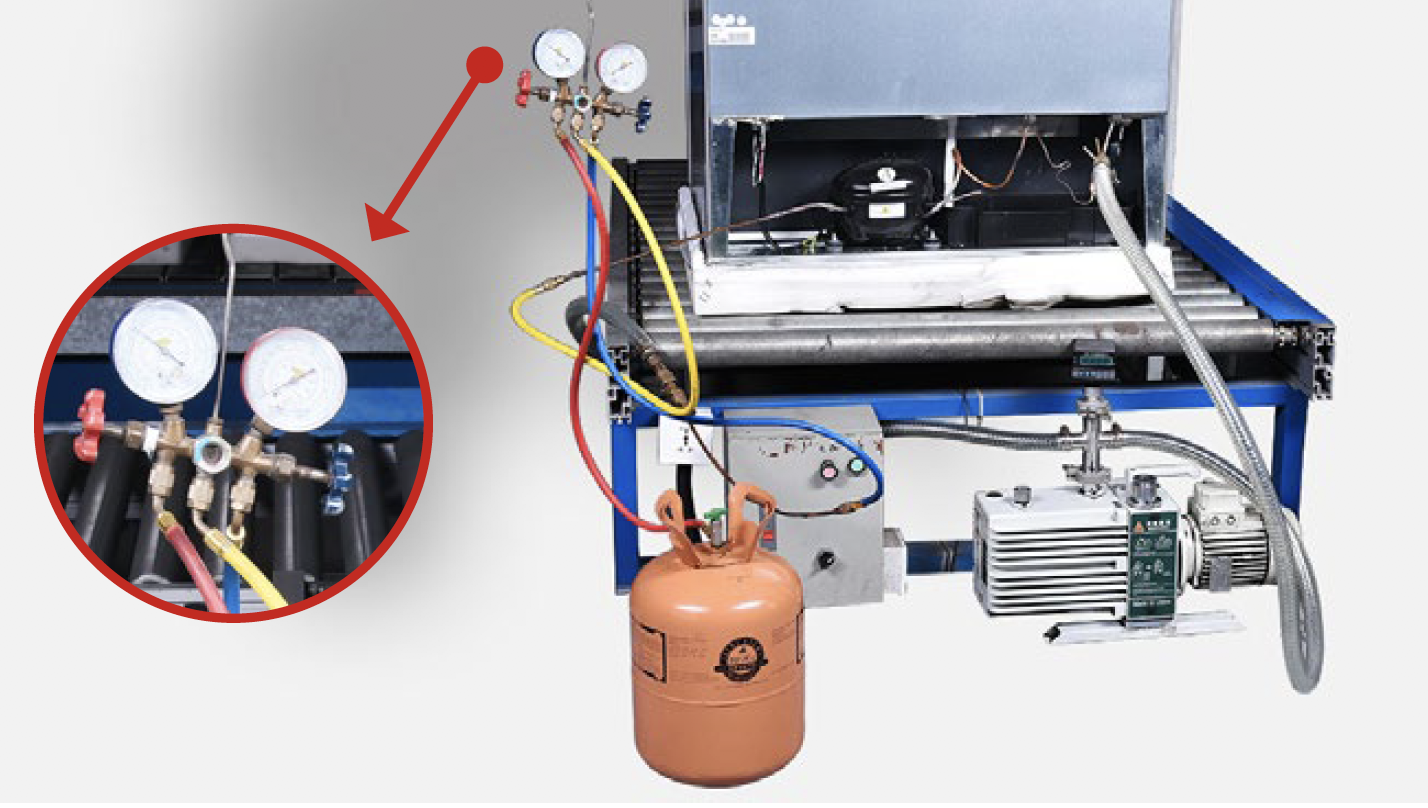

Step 8

Vacuum and recharge. Please get more details of vacuuming and gas- charging requirements

Step 9

Block processing pipe twice by locking pliers.

Step 10

Leave locking pliers on the second block and cut off the rest of the pipe by shaking.

Step 11

Braze.

DIAGNOSIS 2