Step 2

Discharge all refrigerant

toward the exhaust vent.

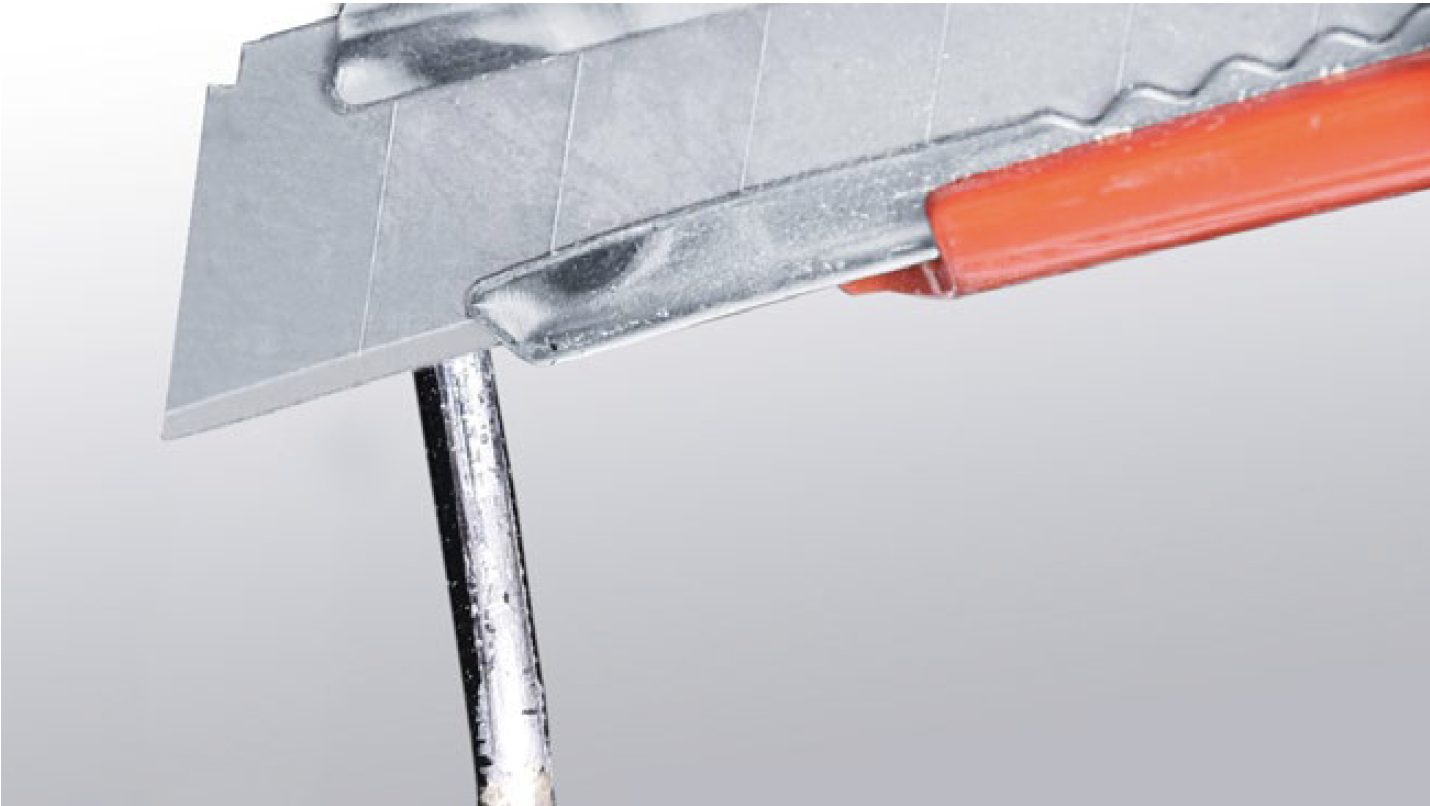

Step 3

Melt brazing material with flame and pull out processing tube using a pair of pliers.

Step 4

Re-braze a copper tube onto processing tube of compressor. To get more details on brazing requirements

NOTE

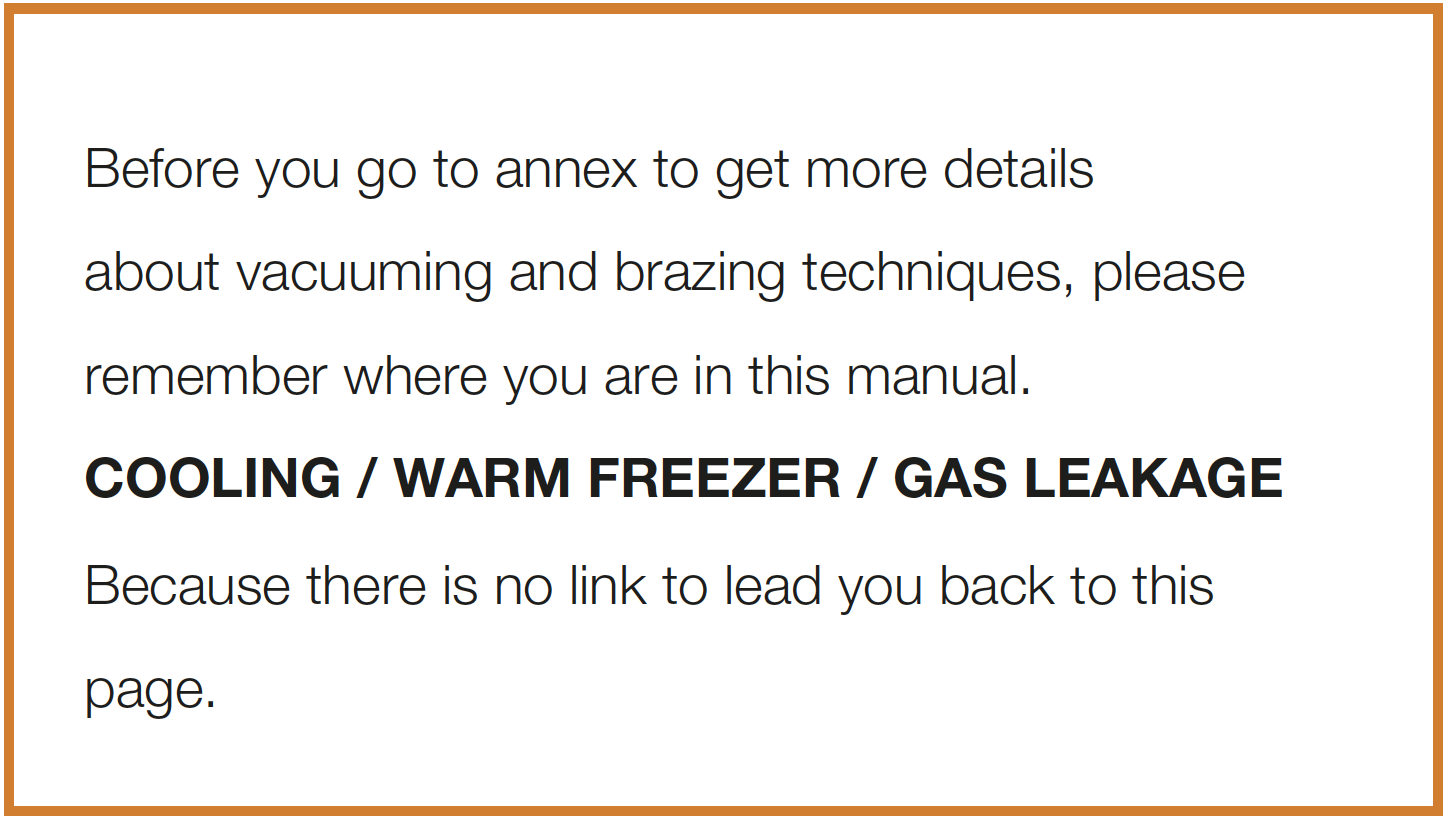

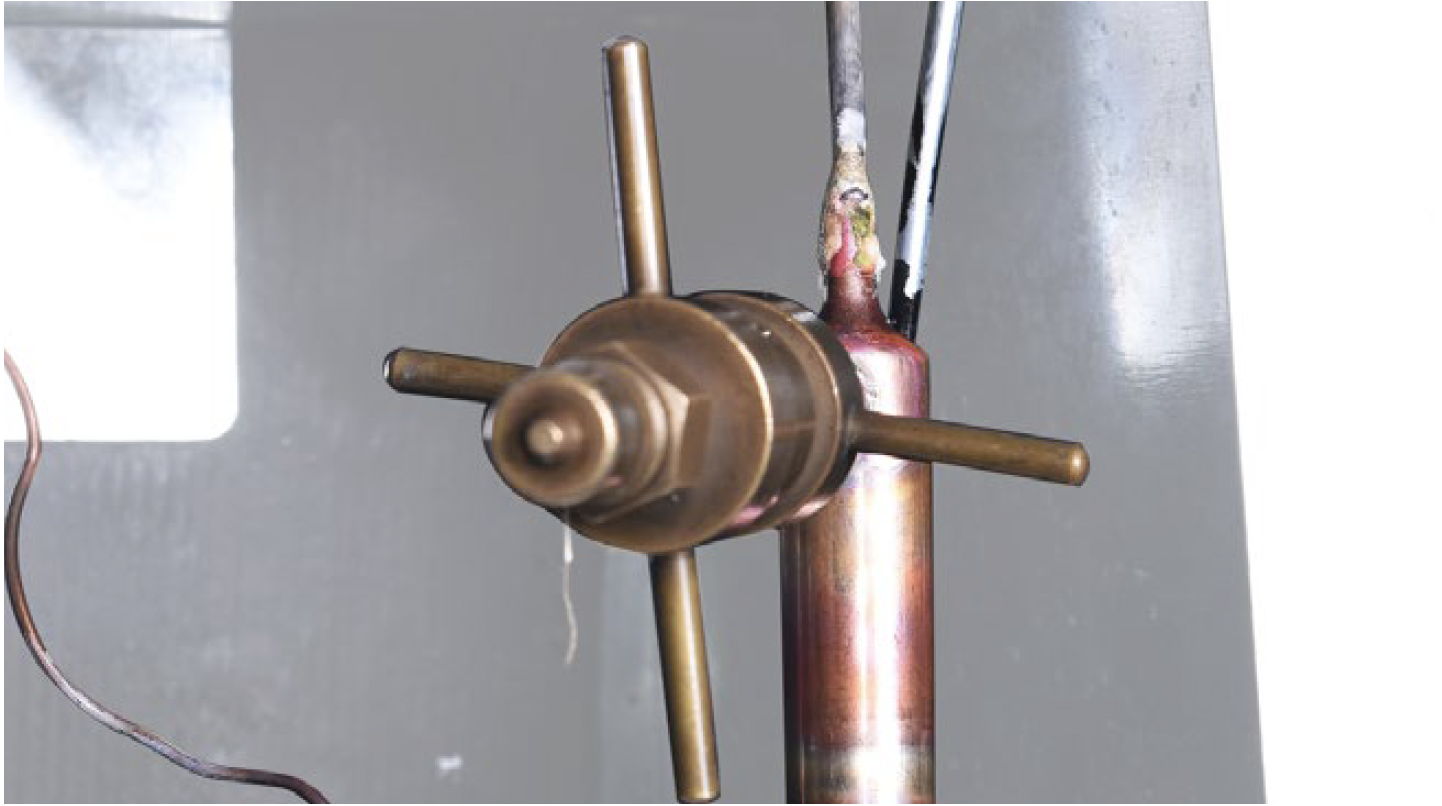

Step 5

Install quick connector onto re-brazed pipe.

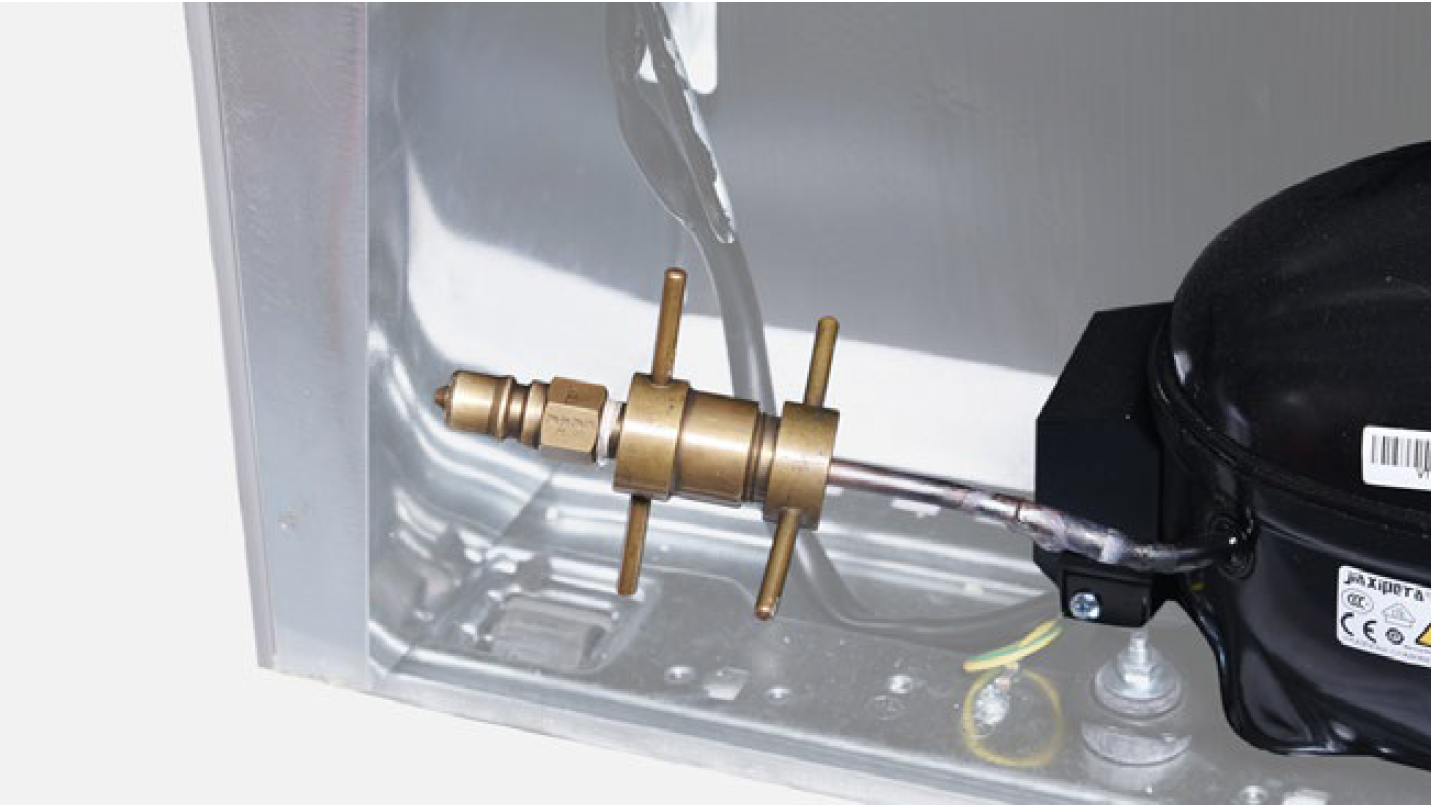

Step 6

Cut off exhaust pipe and suction pipe.

Step 7

Power up the compressor and feel the exhaust pressure from the exhaust pipe with a piece of paper.

Step 8

Feel the suction pressure of the suction pipe using a piece of paper.

DIAGNOSIS 1

PROCEDURE 1

Step 1

Unscrew terminal cover.

Step 2

Remove terminal cover.

Step 3

Remove protector and starter.

Step 4

Unscrew earthing wire.

Step 5

Unscrew nut for compressor.

Step 6

Install a new compressor and tighten nuts onto compressor.

Step 7

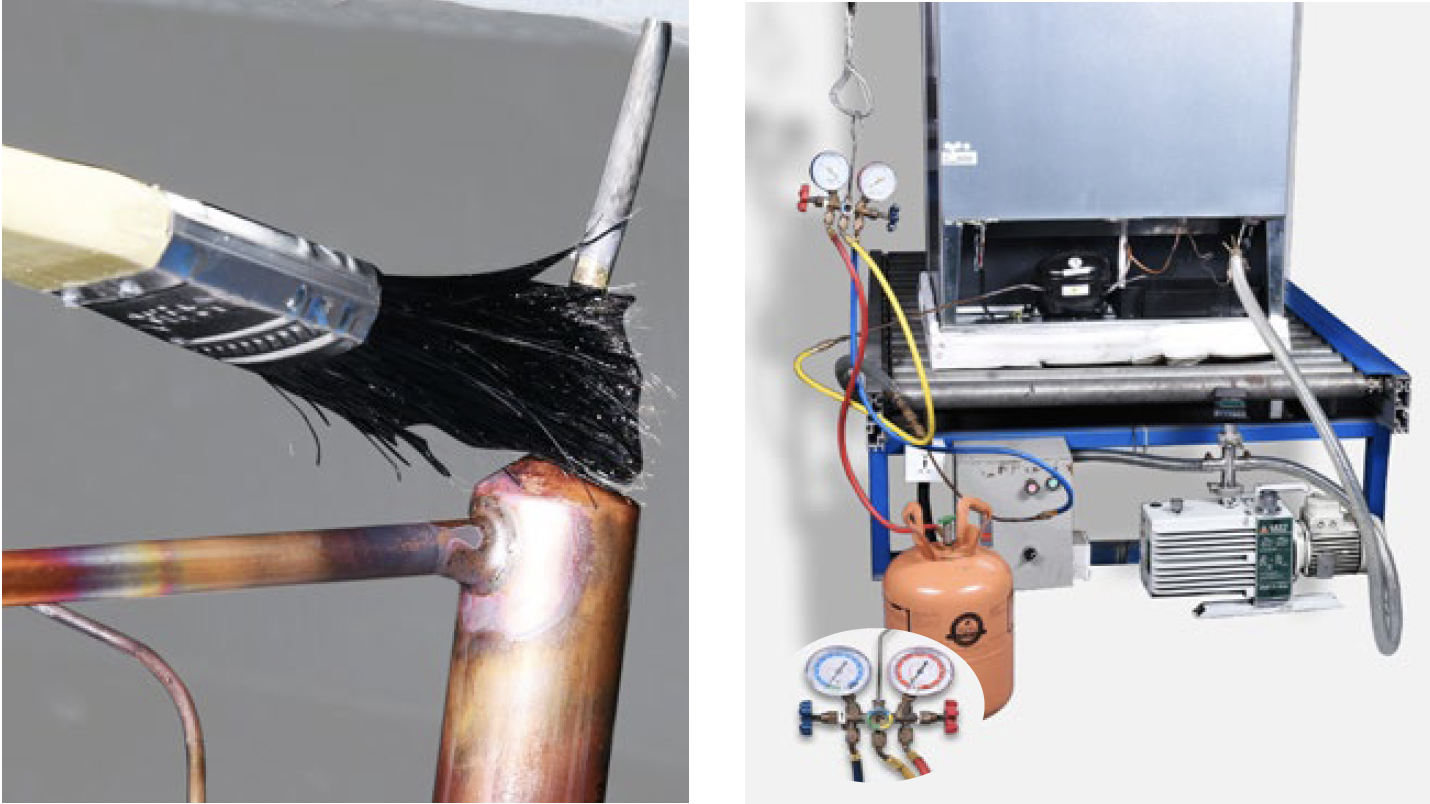

Braze.

PROCEDURE 2

Step 1

Clean paint off brazed joint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary and

shake to remove the cut

end.

Step 4

Braze.

Step 5

Add quick connector onto processing pipe of drying-filter.

Step 6

Inject nitrogen (1.57Mpa) through quick connector into pipe for at least 3 min to blow remaining refrigerant away.

Step 7

Perform leakage test on brazed joints of drying- filter and compressor processing pipe.

Step 8

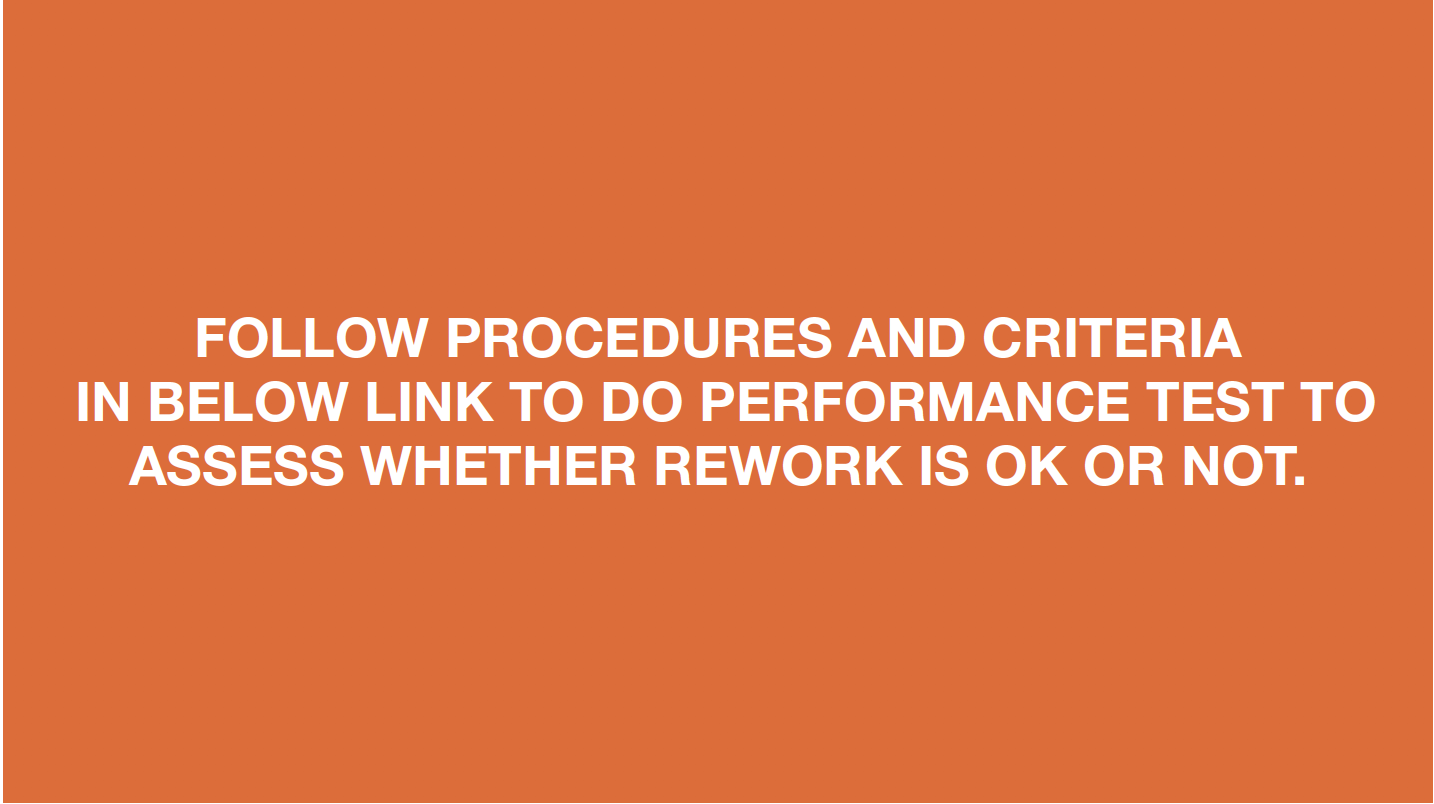

Vacuum and recharge. Please get more details of vacuuming and gas- charging requirements

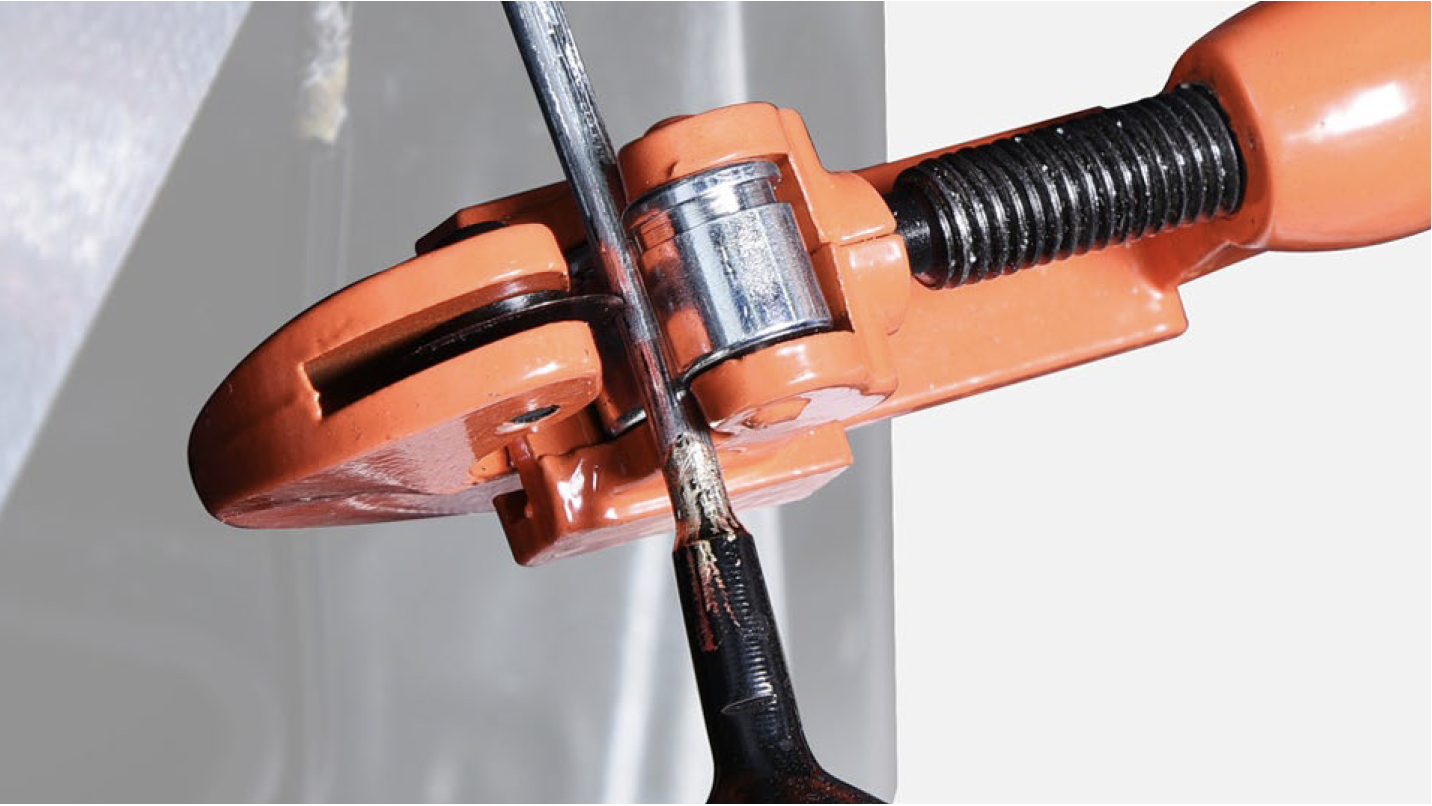

Step 9

Block processing pipe twice with locking pliers.

Step 10

Leave locking pliers on the second block and cut off the rest of the pipe by shaking.

Step 11

Braze.

DIAGNOSIS 2

ATTENTION