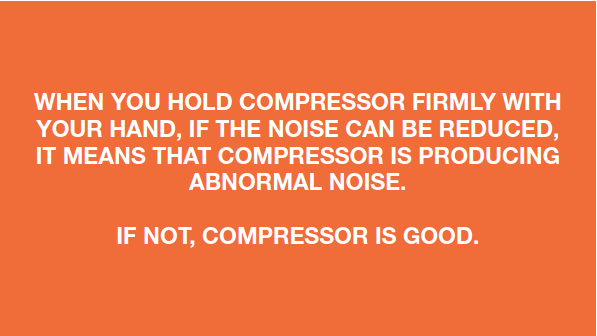

CHECK AND TEST 1

Step 1

By listening, it is evidentthat the compressor is

louder than normal.

DIAGNOSIS 1

PROCEDURE 1

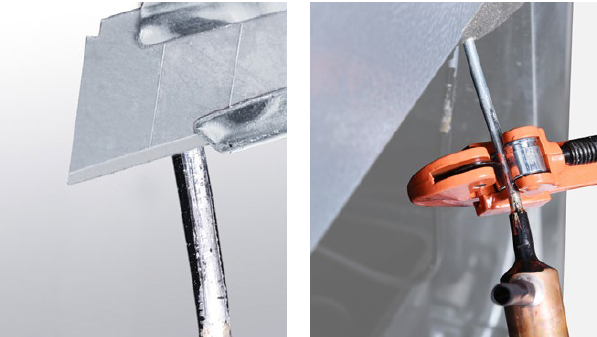

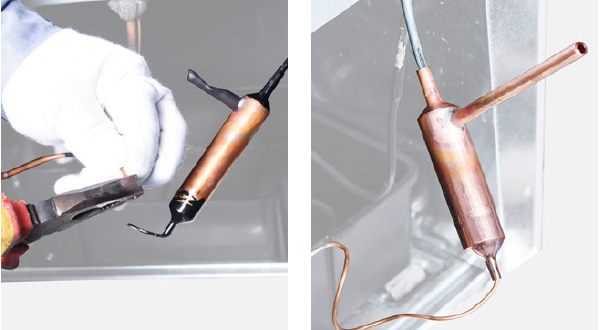

Step 1

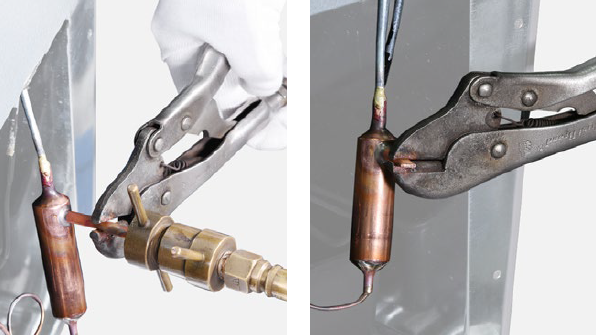

Discharge refrigerant.Cut charging tube off

with pliers.

Step 2

Discharge all refrigeranttoward the exhaust vent.

Step 3

Cut off suction pipe andexhaust pipe.

Step 4

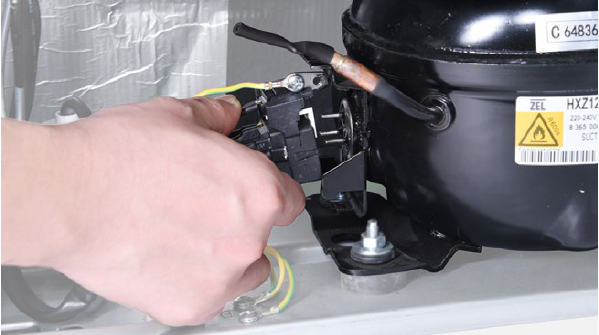

Unscrew terminal cover.

Step 5

Remove terminal cover.

Step 6

Remove protector andstarter.

Step 7

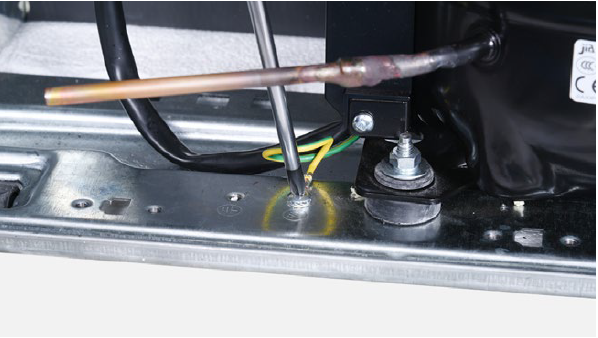

Unscrew earthing wire.

Step 8

Unscrew nut oncompressor.

Step 9

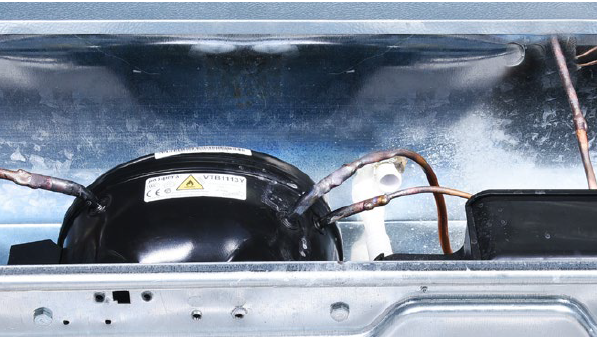

Install a new compressorand tighten the nuts onto

compressor.

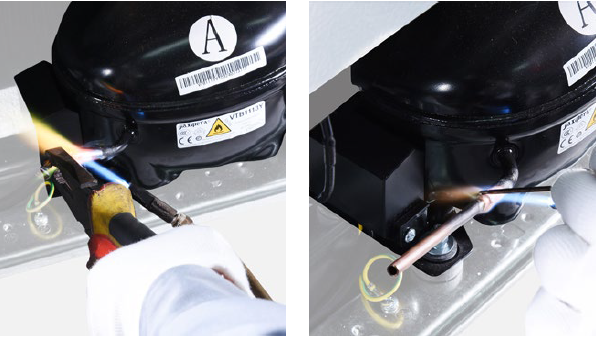

Step 10

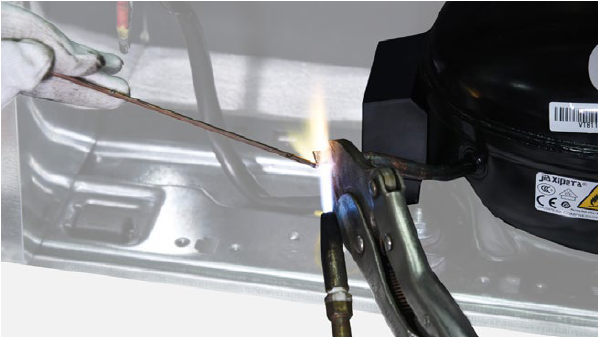

Braze the joints of suctionand exhaust pipes.

Step 11

Re-braze a copper tubeonto processing tube of

compressor.

To get more

details on brazing

requirements, please go

to Annex B1

Note

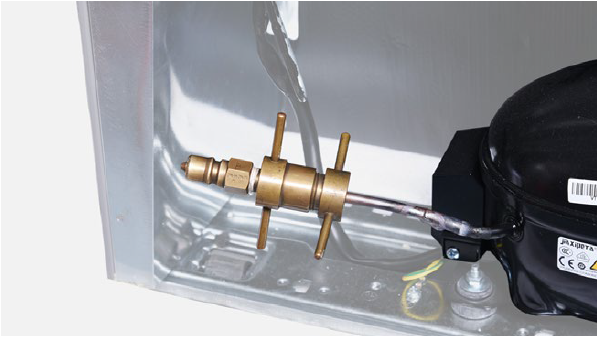

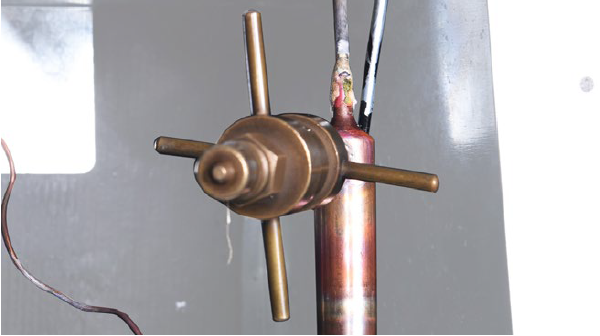

Step 12

Install quick connectoronto re-brazed pipe.

Step 13

Melt brazing materialwith flame and pull out

processing tube with

pliers.

Step 14

Re-braze a coppertube onto compressor

processing tube.

PROCEDURE 2

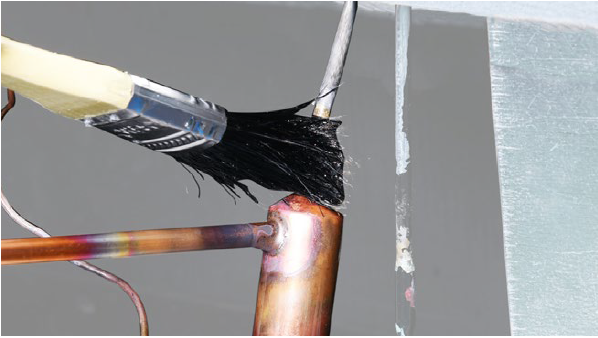

Step 1

Clean paint off brazedjoint of drying-filter.

Step 2

Cut off drying-filter.

Step 3

Cut off capillary andremove the cut end by

shaking.

Step 4

Braze on a newdrying-filter.

Step 5

Add quick connectoronto processing pipe of

drying-filter.

Step 6

Inject nitrogen (1.57Mpa)through quick connector

into pipe for at least

3 min to blow remaining

refrigerant away.

Step 7

Perform leakage test onbrazed joints of dryingfilter

and compressor

processing pipe.

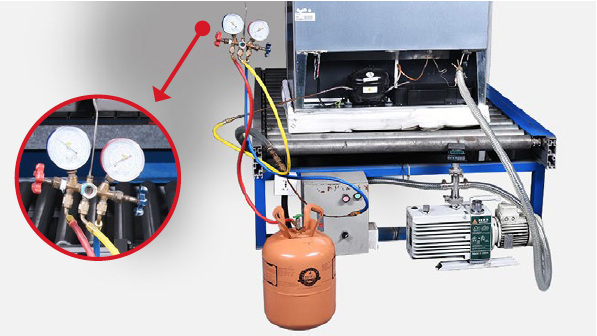

Step 8

Vacuum and recharge.Please get more details

of vacuuming and gascharging

requirements

on Annex B2

Step 9

Leave locked pliersattached to second

block and shake to cut

off the remaining pipe.

Step 10

Braze the ends andremove the pliers.

DIAGNOSIS 2