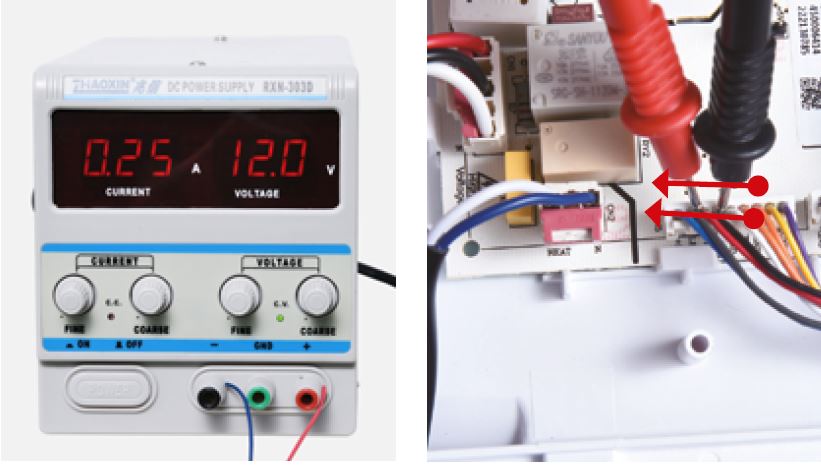

Step 2

Power off the appliance,

and turn the power

output of transformer to

DC 12V.

Step 3

Supply power from

terminal in PCB area.

Step 3

Open freezer door and press swithc,

then put your hand in freezer

compartment to feel if fan is

blowing or not.

Step 2

Remove basket.

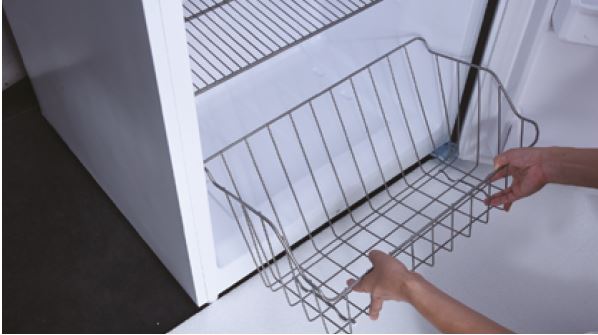

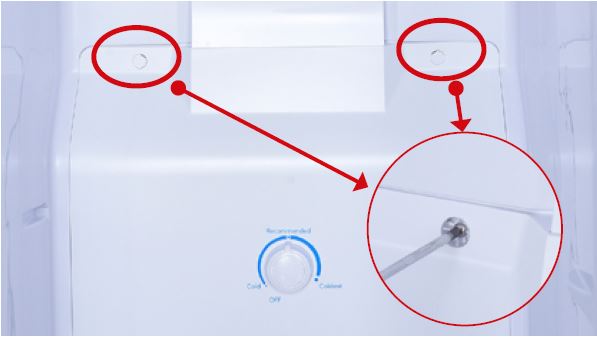

Step 3

Remove screw covers.

Step 4

Unscrew.

Step 5

Pull the buttom air duct

out.

Step 6

Disconnect the wires for

thermostat.

Step 7

Take bottom air duct away.

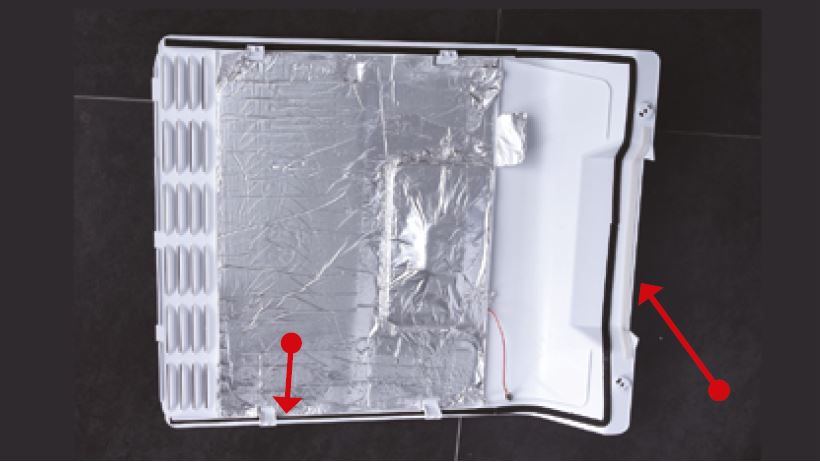

Step 8

Disconnect terminals.

Step 9

Remove the aluminium

tape.

Step 10

Unscrew.

Step 11

Pull the upper air duct

out and take it away.

CHECK AND TEST 2

Step 1

In duct area, check if

terminal is pushed into

final position.

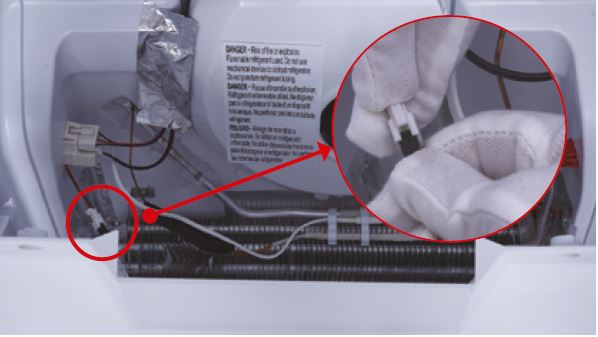

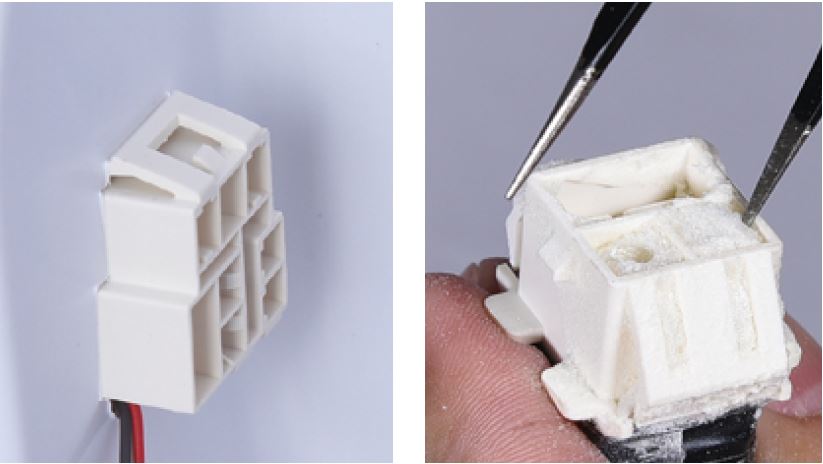

Step 2

Check if terminal is filled

with foam or not.

IF YES, please use

tweezers to clean and

remove the foam.

Then, reconnect the

terminals.

Step 3

Power off the appliance

and turn the power

output of transformer to

DC 12V.

Step 4

Supply power from

terminal in PCB area.

Step 5

Open fridge and freezer

doors on same side to

same degree to feel if fan

is blowing or not.

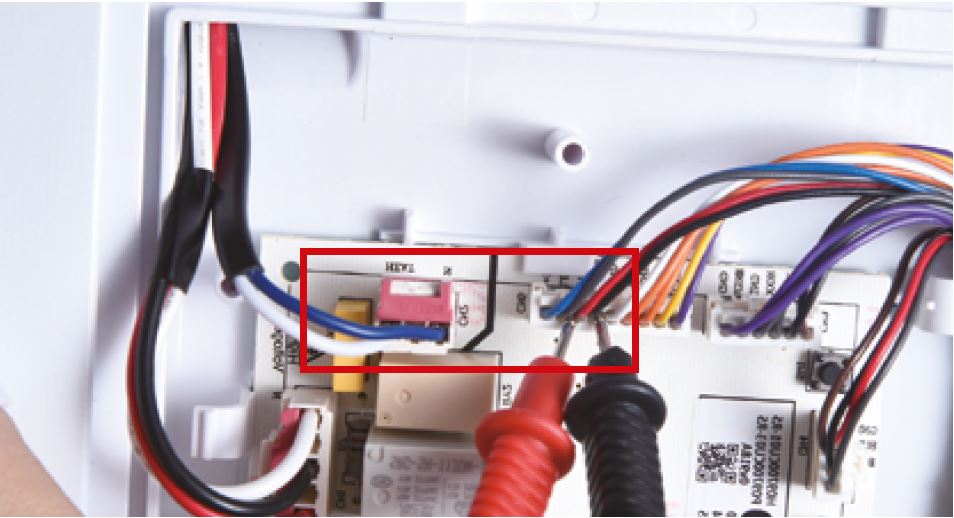

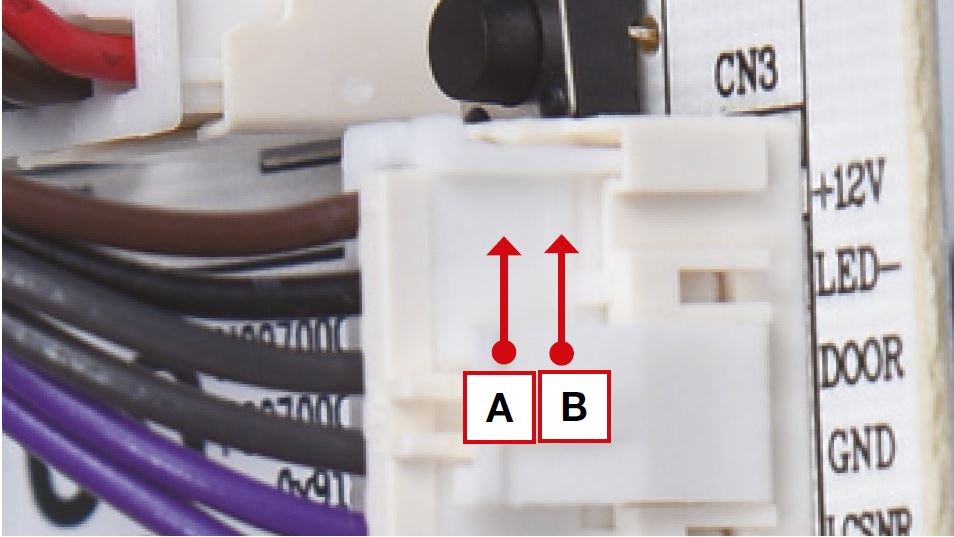

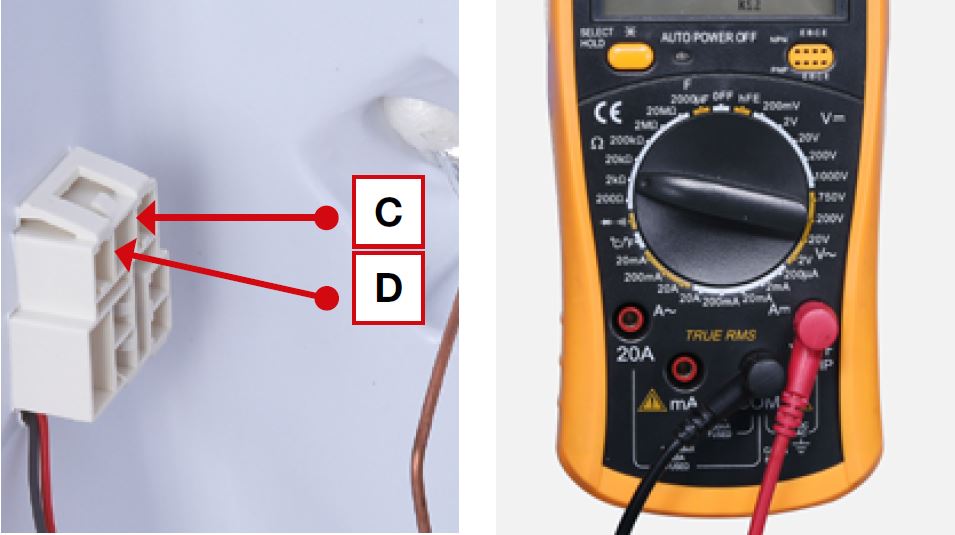

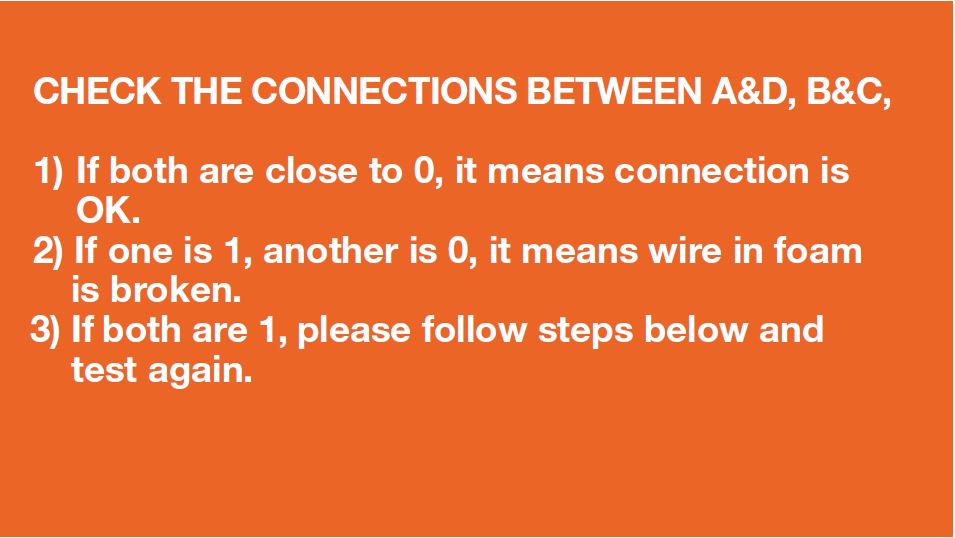

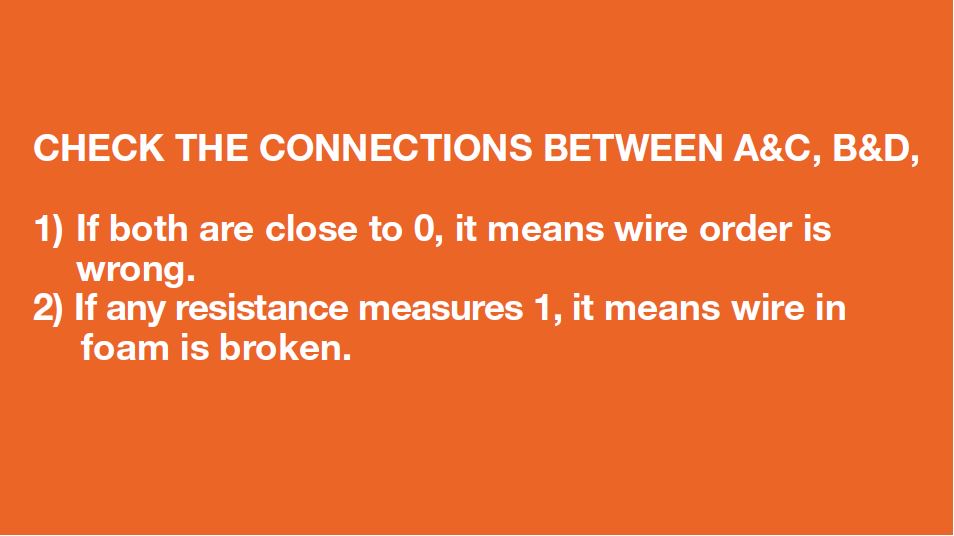

DIAGNOSIS 2

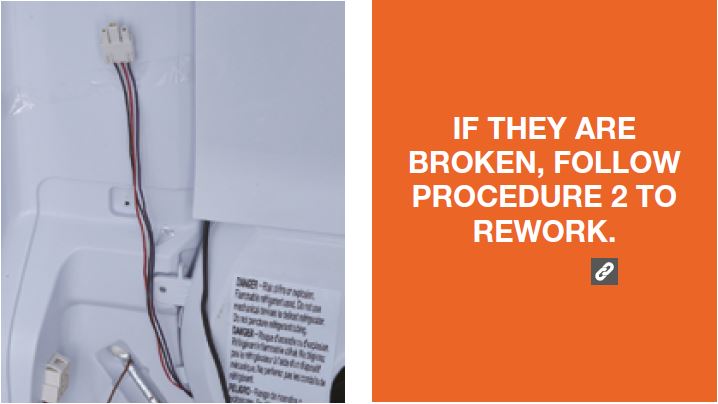

Step 2

Check to see if the wires

are in the correct order

and their connections in

the foam are correct:

1. Set multimeter to

resistance gear;

2. Put detector into one

end of wires in PCB

area;

3. Put another detector

into end of wires

behind air duct.

DIAGNOSIS 3

DIAGNOSIS 4

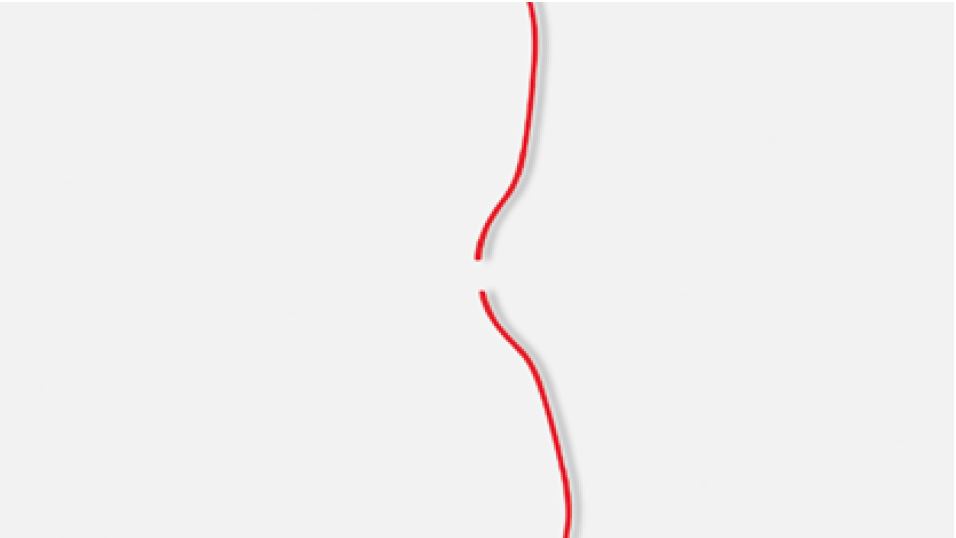

PROCEDURE 2

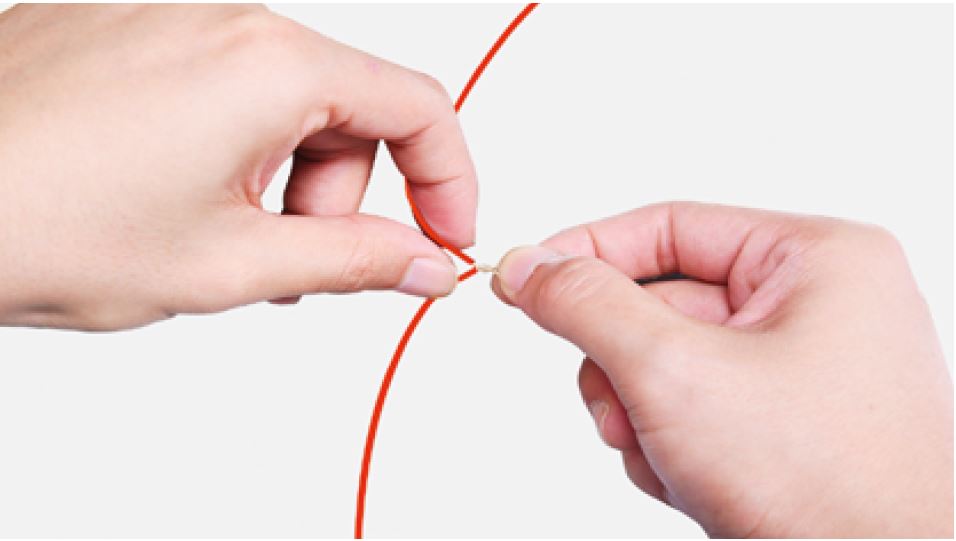

Step 1

Cut wire off from broken

area.

Step 2

Peel off the sleeves.

Step 3

Check to ensure proper

wire order and connect

them.

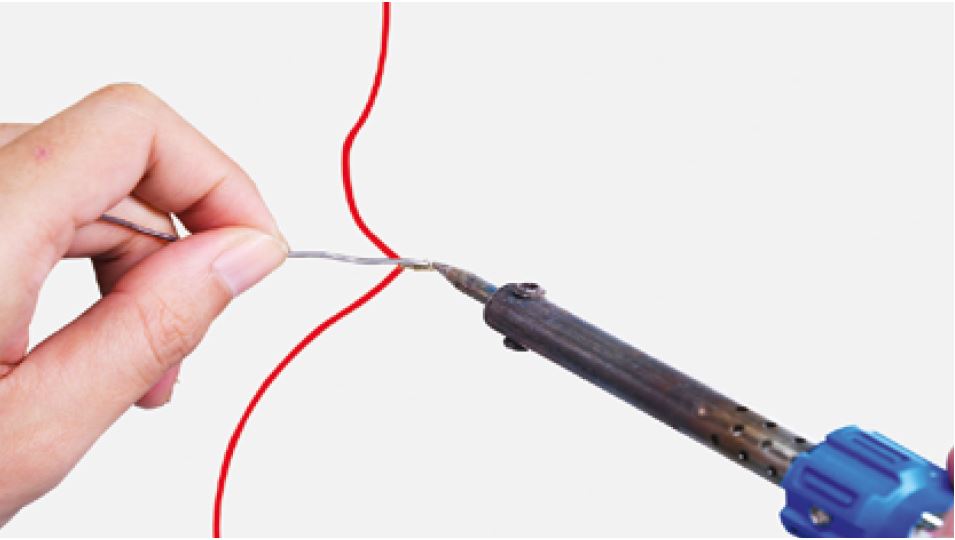

Step 4

Tin soldering.

Step 5

Cover connection with

electrical tape.

CHECK AND TEST 4

Step 1

Set output of transformer

to DC 12V to test fan

from the terminal behind

the air duct.

Step 2

Supply DC 12V to fan

from the terminal behind

the air duct and see if fan

is running.

DIAGNOSIS 5

Note

Tip 1

Make sure the sealing sponges are in good condition.

Tip 2

When reinstalling the air duct, fasten the wires to avoid crushing with air duct.

Tip 3

Check to see if there is

a wide gap between air

duct and cabinet. If there

is, reinstall air duct.

CHECK AND TEST 4

Step 1

Switch on the appliance,

open freezer door and

press swithc, then put

your hand in freezer

compartment to feel if

fan is blowing or not.

DIAGNOSIS 6