CHECK AND TEST 1

Step 1

Unscrew cover ofmainboard with a

cross-head screwdriver.

Step 2

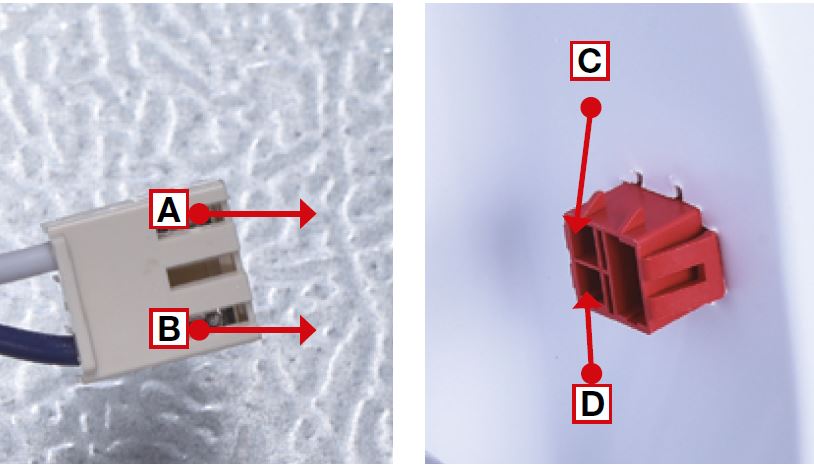

In PCB area, check if

terminal is inserted to

final position.

If not, reinsert it to final

position.

Step 3

Measure resistance of

heater from terminal in

PCB area.

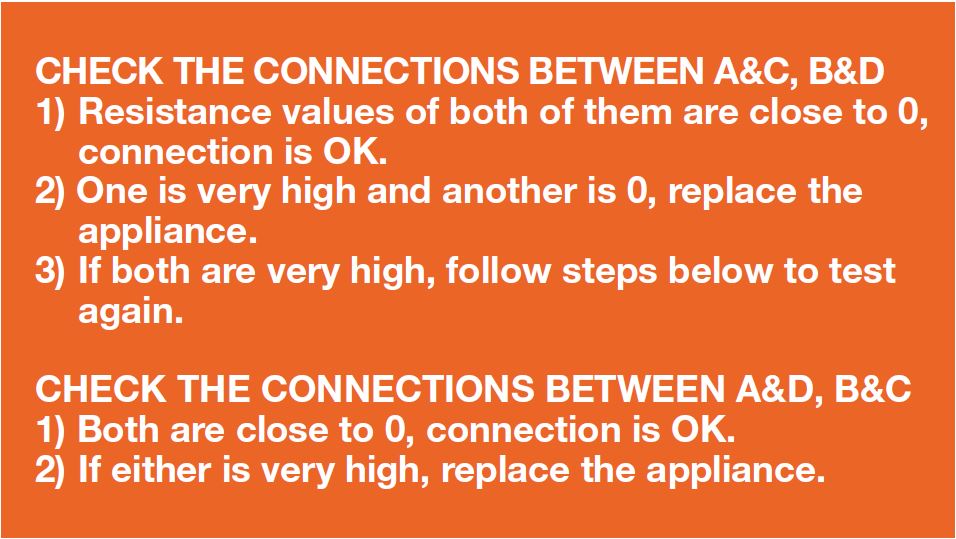

DIAGNOSIS 1

PROCEDURE 1

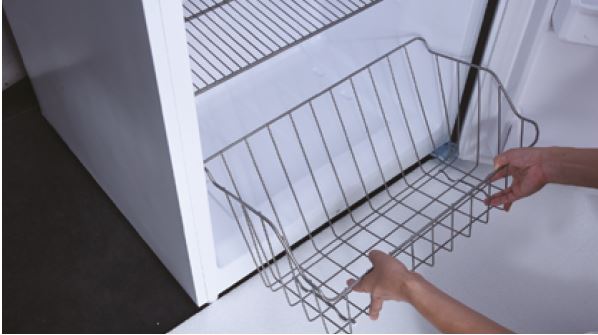

Step 1

Remove all shelves.

Step 2

Remove basket.

Step 3

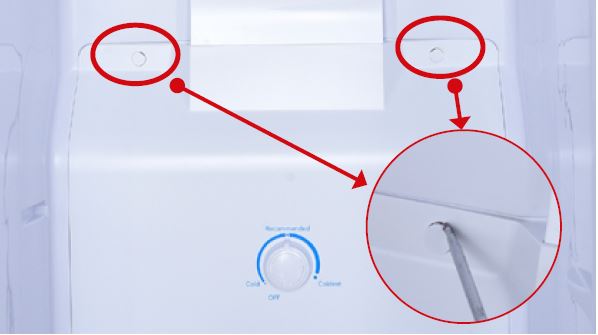

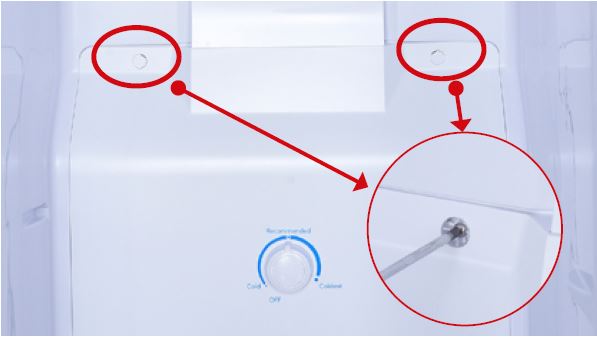

Remove screw covers.

Step 4

Unscrew.

Step 5

Pull the buttom air duct

out.

Step 6

Disconnect the wires for

thermostat.

Step 7

Take bottom air duct

away.

CHECK AND TEST 2

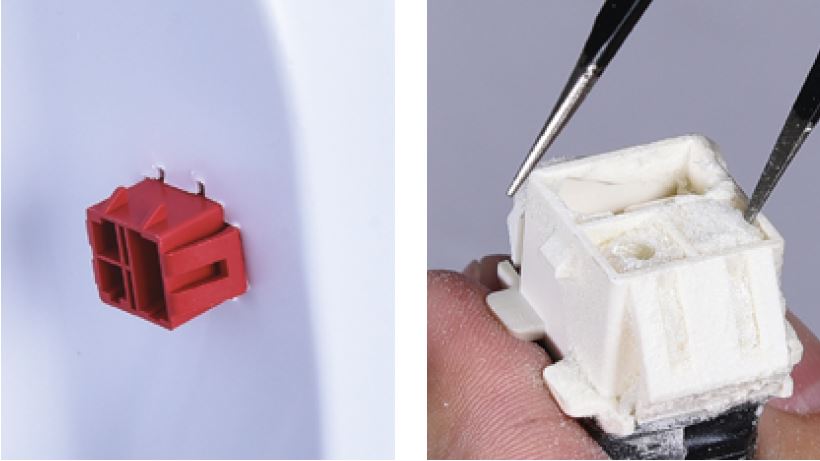

Step 1

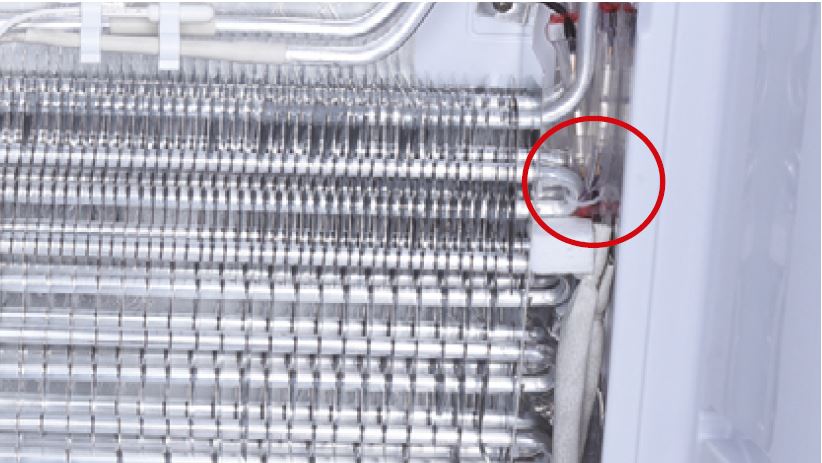

Check if the terminal

is inserted into final

position.

IF SO, RE-SINSERT

THEM.

Step 2

Check if wires of defrost

heater are broken.

If yes, follow procedures

on Page 162 to

replace the heater.

Step 3

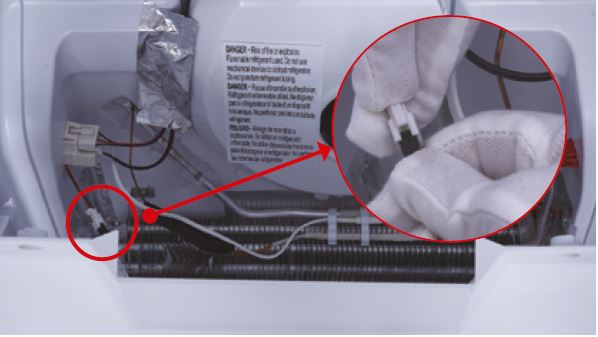

Disconnect the terminal.Step 4

Check if the terminal is

stuffed with foam.

IF SO, USE TWEEZERS

TO SMASH IT AND

REMOVE.

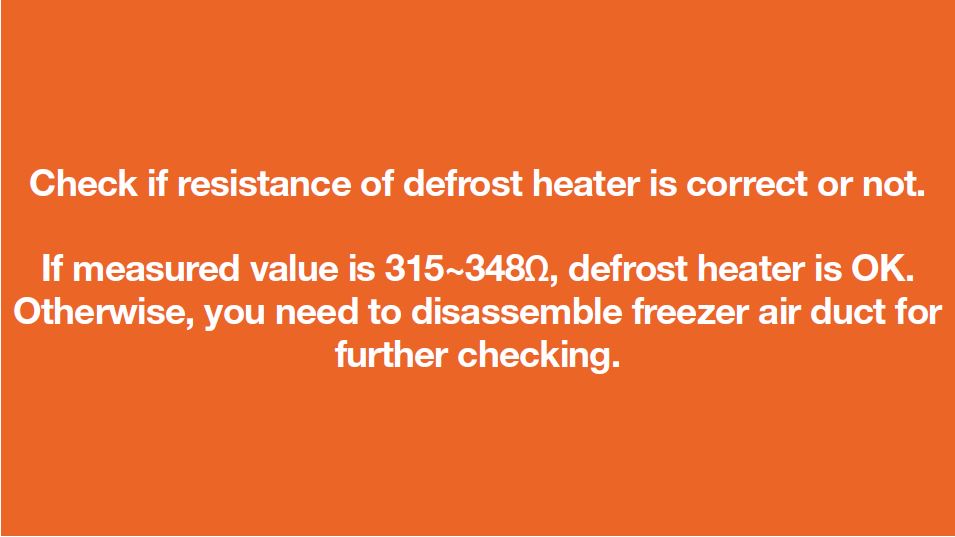

Step 5

Measure resistance of

heater from terminal in

freezer.

DIAGNOSIS 2

PROCEDURE 2

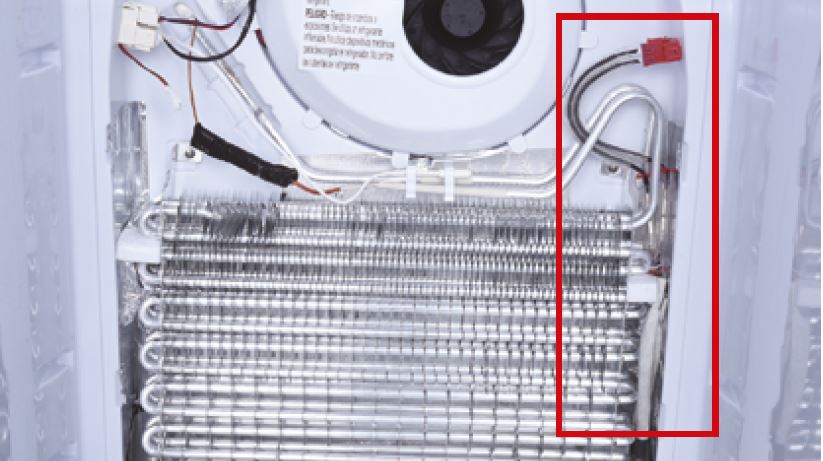

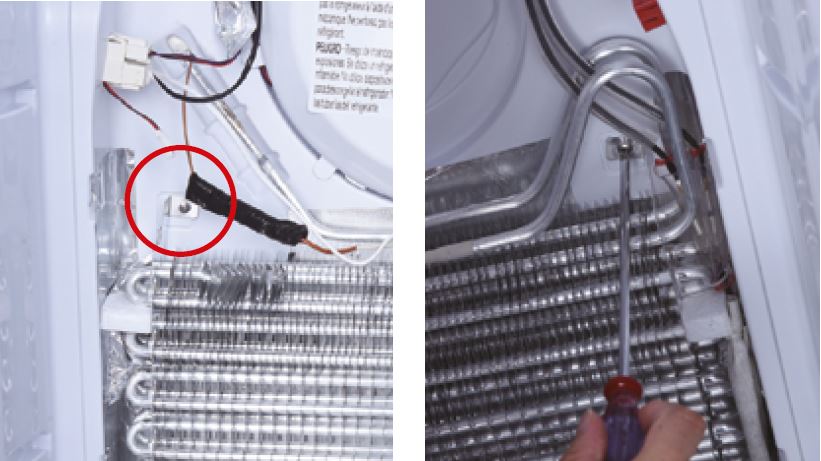

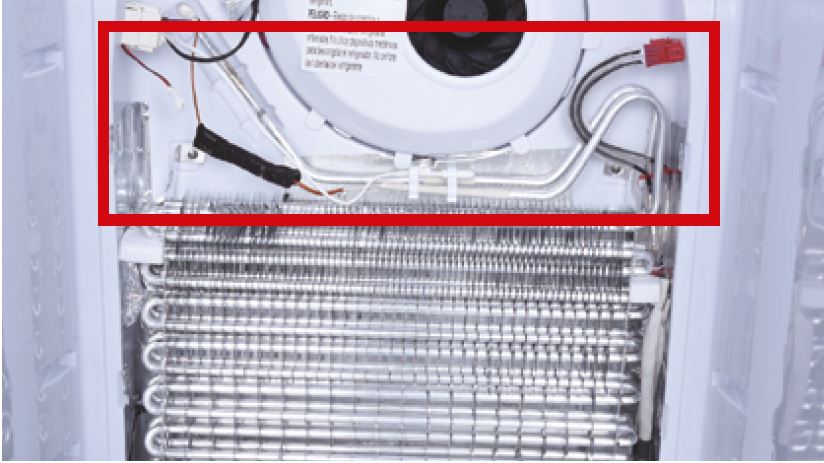

Step 1

Disconnect terminal of

heater.

Step 2

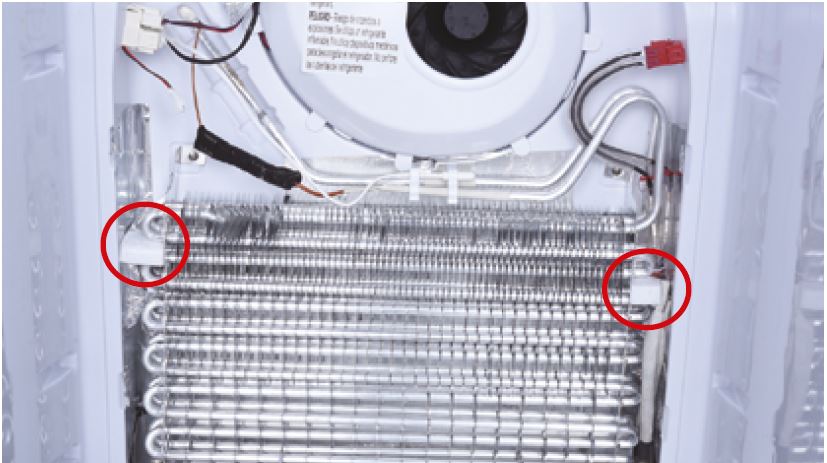

Unscrew the two screws

with 6mm cross-head

screwdriver.

Step 3

Cut off the fastening

strap.

Step 4

Take out the holding

foam.

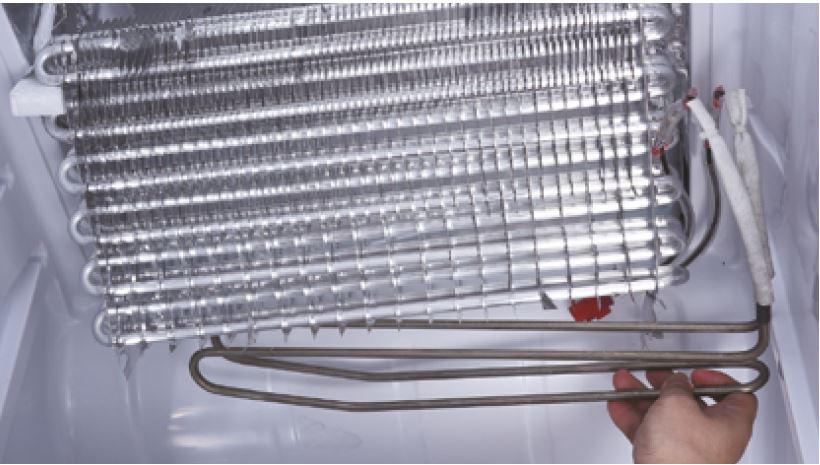

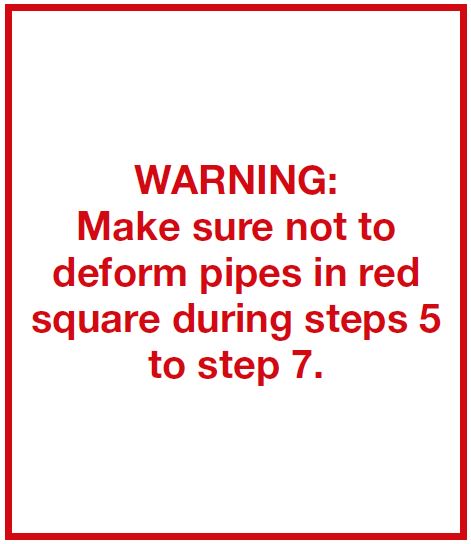

Step 5

Loosen heater fastening

clips.

Step 6

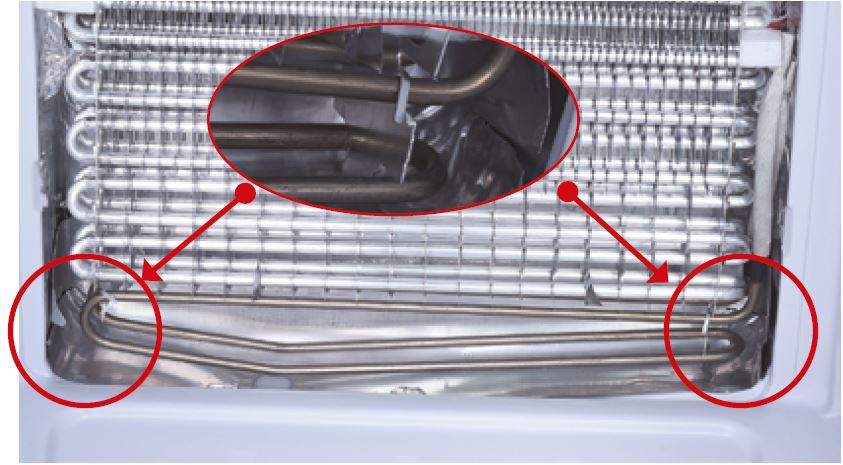

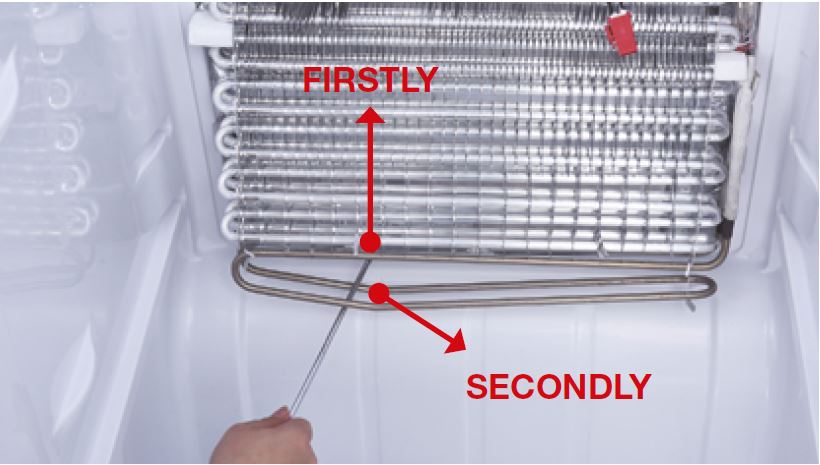

Lift evaporator with

heater up 20mm. Bottom

of evaporator must be

higher than the edge of

water trough.

Step 7

Remove the heater.

Reverse steps above to

reinstall the heater and

pay attention to the key

points below

Tip 1

Do not damage the

wires of the heater while

installing the new heater.

CHECK AND TEST 3

Step 1

Set multimeter to

resistance gear.

Step 2

Put detector into one

end of wires in PCB area.

Put another detector into

end of wires behind air

duct.

DIAGNOSIS 3

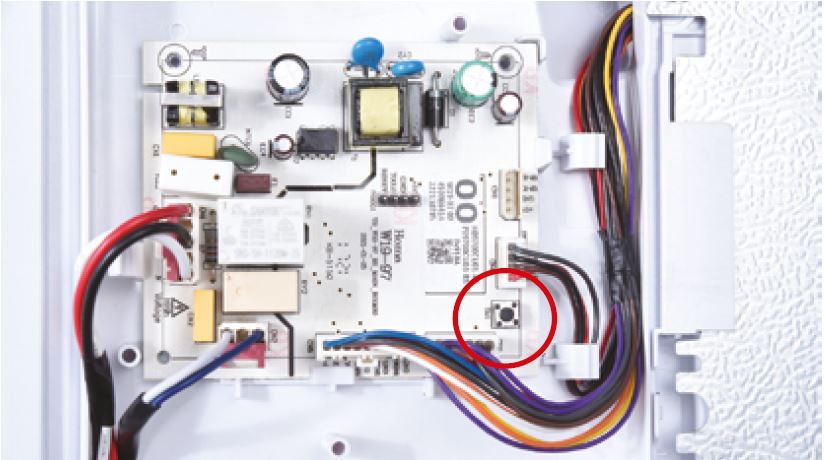

CHECK AND TEST 4

Step 1

Power on the appliance,

and press the button on

PCB to start manual defrost.

Step 2

Put your hand close to

defrost heater.

DIAGNOSIS 4

Tip 1

Make sure the sealing

sponges are in good

condition.

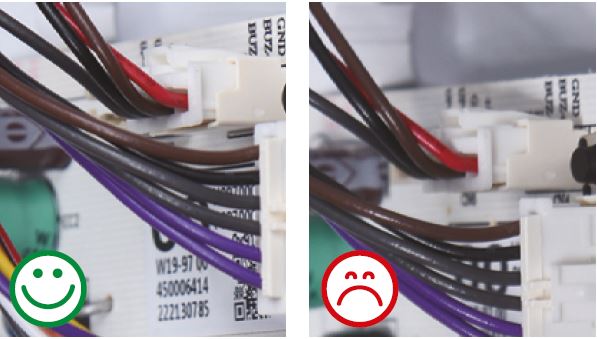

Tip 2

When reinstalling the air

duct, fasten the wires to

avoid crushing with air

duct.

Tip 3

Check to see if there is

a wide gap between air

duct and cabinet. If there

is, reinstall air duct.