CHECK AND TEST 1

Step 1

Unscrew cover ofmainboard with a

Cross-head screwdriver.

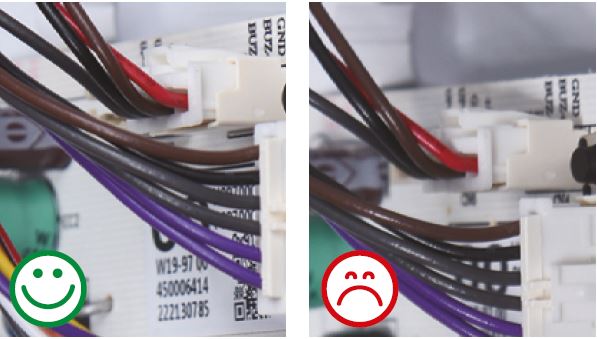

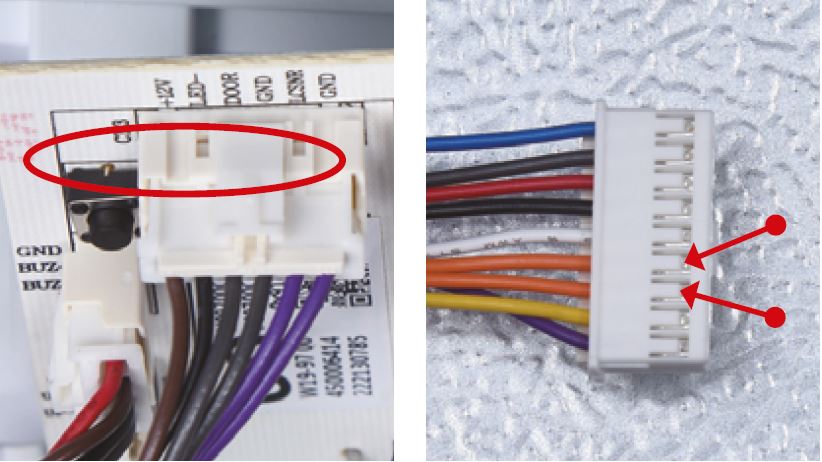

Step 2

Check if terminal in PCB

area is pushed to final

position.

If not, reinsert it to final

position.

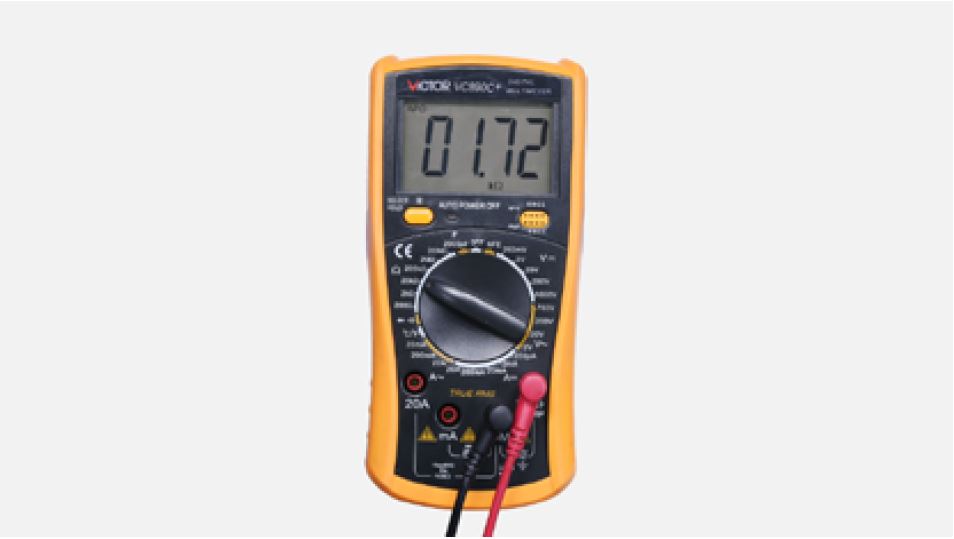

Step 3

Set multimeter to

resistance gear.

Step 4

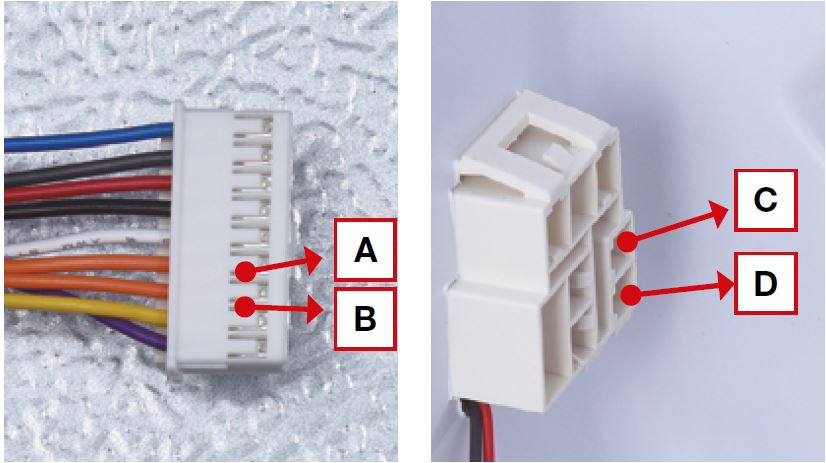

In PCB area, measure the

resistance of defrost temp.

sensor with a multimeter.

Step 5

Take note of value.

Step 6

Measure the temperature

of freezer air duct, near the

defrost temp. sensor.

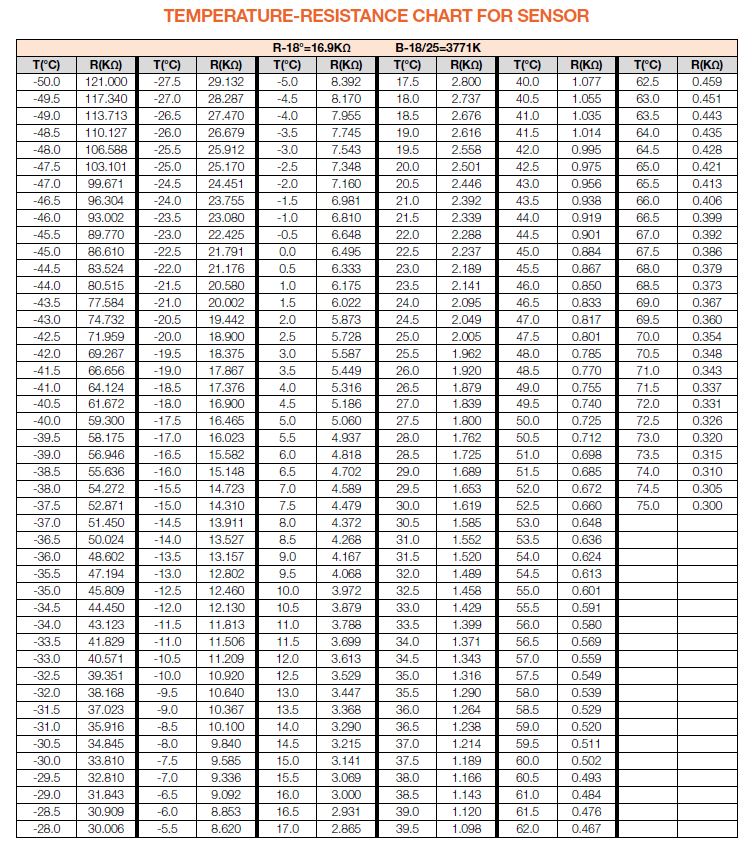

Use measured temperature

to find the standard

resistance value in

Temperature-Resistance

Chart for Sensor.

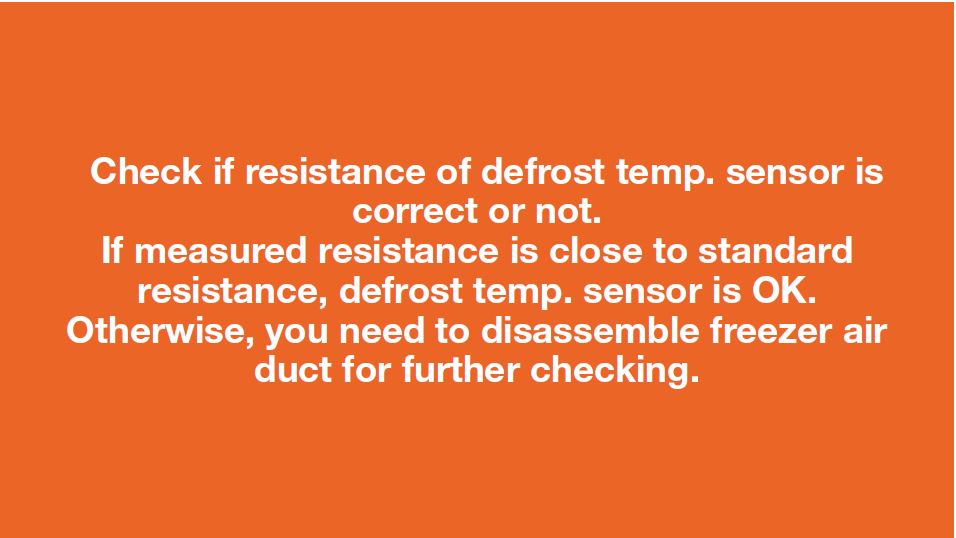

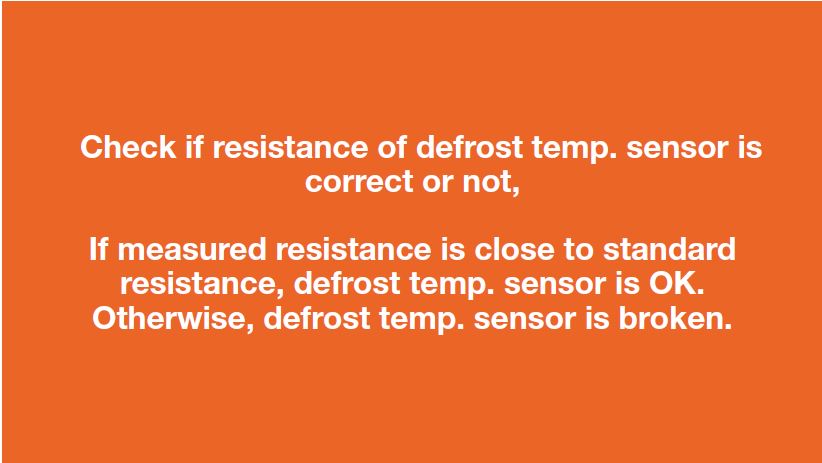

DIAGNOSIS 1

PROCEDURE 1

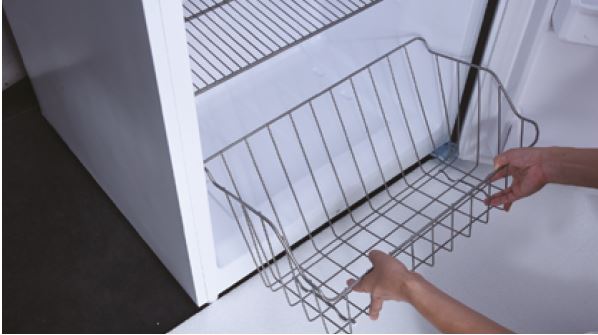

Step 1

Remove all shelves.

Step 2

Remove basket.

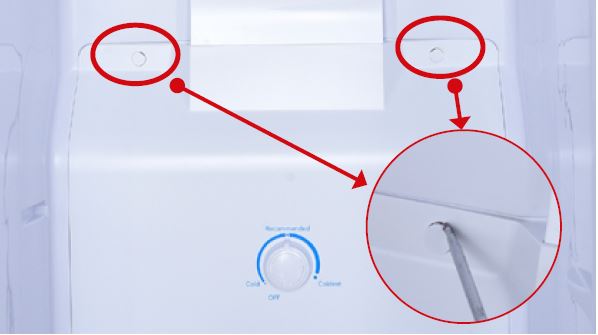

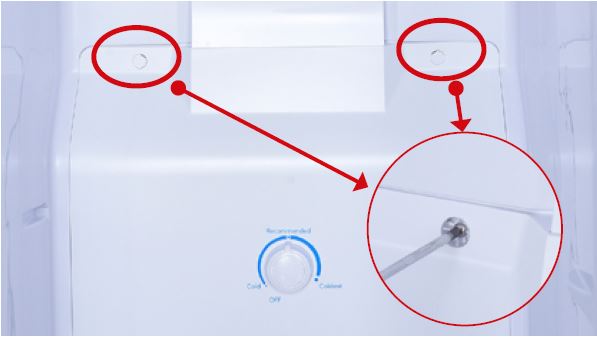

Step 3

Remove screw covers.

Step 4

Unscrew.

Step 5

Pull the buttom air duct

out.

Step 6

Disconnect the wires for

thermostat.

Step 7

Take bottom air duct

away.

CHECK AND TEST 2

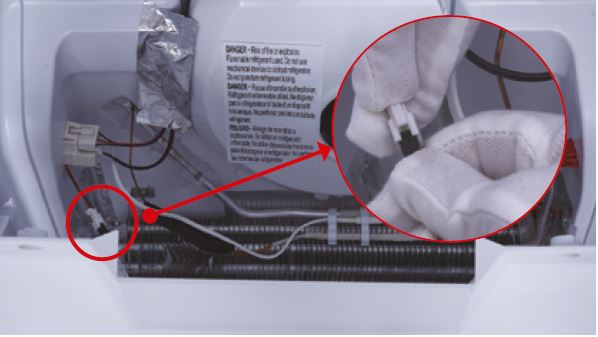

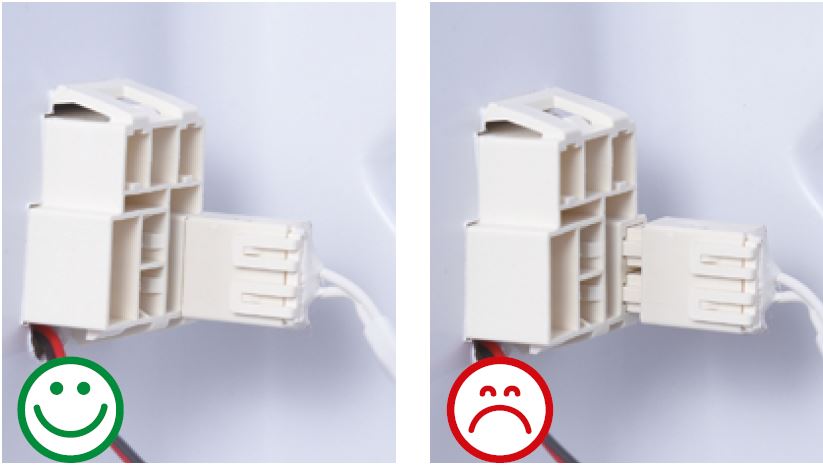

Check if the terminal

is inserted into final

position.

IF NOT, REINSERT

IT.

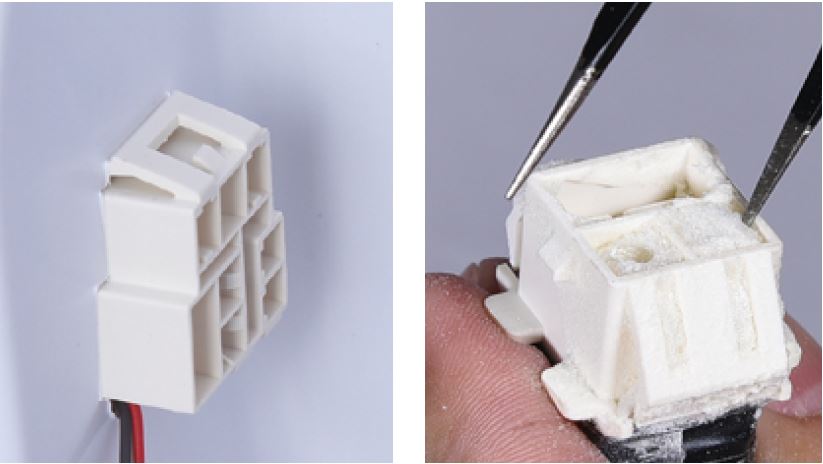

Step 2

Check if the terminal is

stuffed with foam.

IF SO, USE TWEEZERS

TO SMASH IT AND

REMOVE.

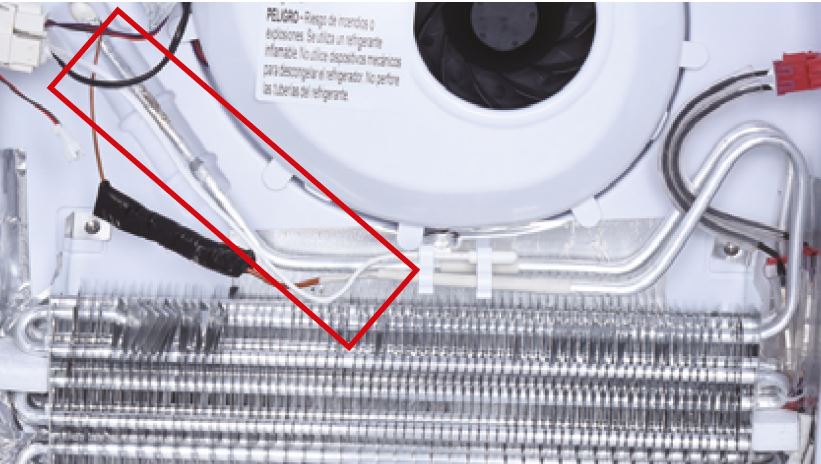

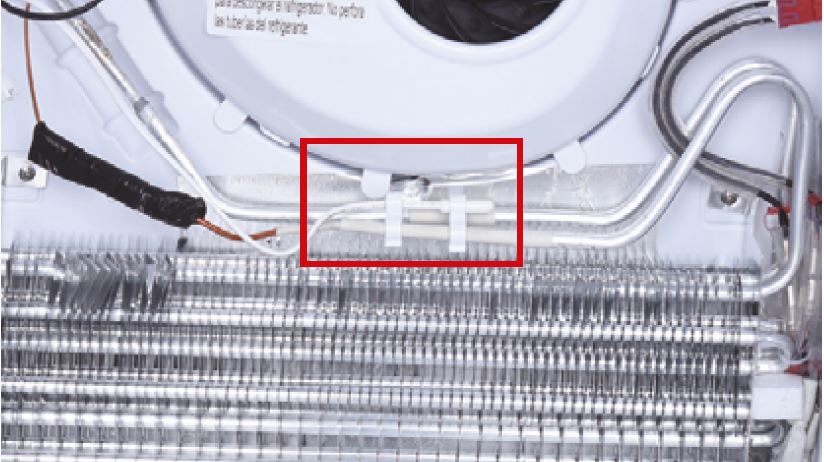

Step 3

Check if sensor is

attached in proper

position, as shown in

picture.

If not, correct it.

Step 4

Check if wire of defrost

sensor is broken.

If yes, replace it with a

new one.

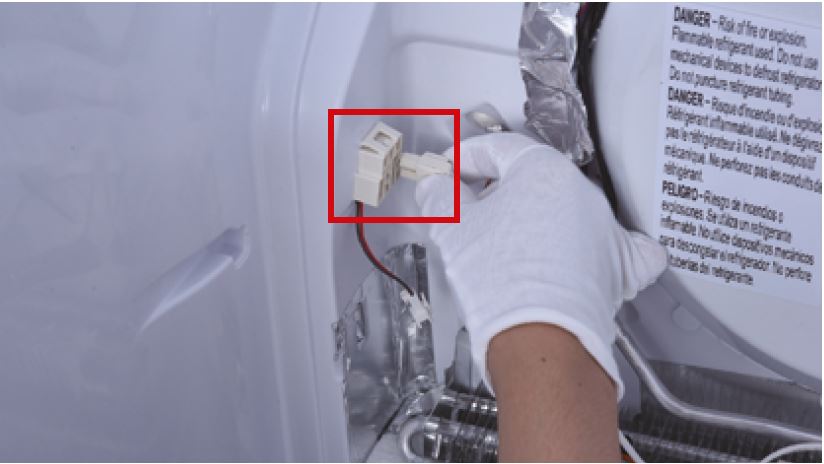

Step 5

Disconnect terminal of

defrost temp. sensor.

Step 6

Measure resistance ofdefrost temp. sensor

from terminal in freezer,

and take note of it.

Step 7

Measure the temperature

of defrost temp. sensor.

Use measured

temperature to find the

standard resistance

value in Temperature-

Resistance Chart for

Sensor.

DIAGNOSIS 2

CHECK AND TEST 3

Step 1

Set multimeter toresistance gear.

Step 2

Put detector into one

end of wires in PCB area.

Put another detector into

end of wires behind air

duct.

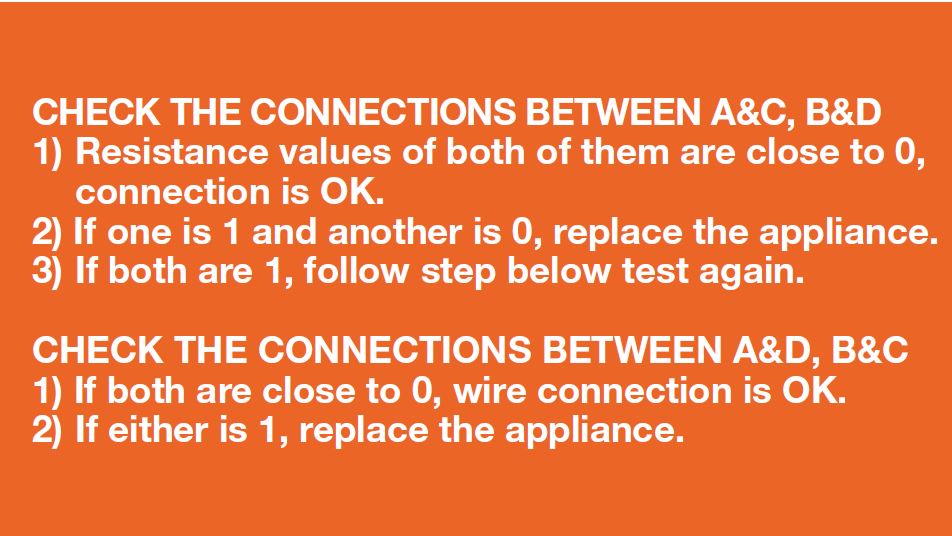

DIAGNOSIS